Preparation method of bisphenol F with high ortho-position isomer content

A technology of isomers and high ortho positions, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of easy crystallization of resins, slow curing speed of bisphenol F epoxy resins, and vicinal problems in bisphenol F. low content of isomers, etc., to achieve the effect of simple and easy process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

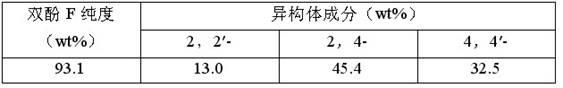

[0018] Add 540g of molten phenol in a 1000ml three-necked flask, and protect it with nitrogen. Start stirring, and adjust the pH value to 2 with phosphoric acid with a mass concentration of 65%, and heat up to 70°C, and drop 20g of formaldehyde solution with a mass concentration of 37.2% within 1h, and react at 70°C for 1.5h; Then add 100g of phosphoric acid solution with a mass concentration of 65% to the reaction solution, and maintain the temperature at 60°C, add 6g of formaldehyde solution with a mass concentration of 37.2% dropwise within 30min, and keep it at 60°C for about 2h, and end reaction. Then the reaction solution is placed in a separatory funnel, allowed to stand for layers, and the phosphoric acid phase of the lower layer is separated; then neutralize the organic phase with 5% sodium hydroxide solution, so that the pH of the organic phase is 5; Phenol, until the temperature is 190°C, the bisphenol F product is obtained. (The concentrations of the above-mentio...

Embodiment 2

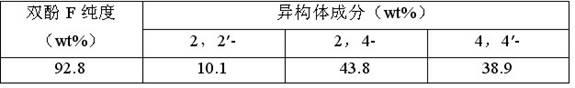

[0022] Add 552g of molten phenol in a 1000ml three-necked flask, and protect it with nitrogen. Start stirring, and adjust the pH value to about 2 with 65% phosphoric acid, and heat up to 70°C, and drop 20g of formaldehyde solution with a mass percentage of 37.2% within 1h, and react at 70°C for 1.5h; Add 100g of phosphoric acid solution with a concentration of 65% to the reaction solution, and maintain the temperature at 60°C, add 6g of formaldehyde solution with a concentration of 37.2% dropwise within 30min, and maintain the reaction at 62°C for 2h to end the reaction. Then the reaction solution was placed in a separatory funnel, allowed to stand for layers, and the phosphoric acid phase in the lower layer was separated; then neutralized the organic phase with 5% sodium hydroxide solution, so that the pH of the organic phase was 6; Phenol, until the temperature is 190°C, the bisphenol F product is obtained. (The concentrations of the above-mentioned solutions are all in mas...

Embodiment 3

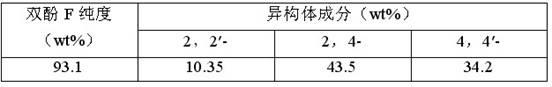

[0026] Add 564g of molten phenol in a 1000ml three-necked flask, and protect it with nitrogen. Start stirring, and adjust the pH value to 2 with phosphoric acid with a mass concentration of 65%, and heat up to 70°C, and drop 30g of formaldehyde solution with a mass concentration of 37.2% within 1h, and react at 70°C for 1.5h; Then add 100g of phosphoric acid solution with a mass concentration of 65% to the reaction solution, and maintain the temperature at 61°C, add 22g of a formaldehyde solution with a mass concentration of 37.2% dropwise within 30min, and keep it at 61°C for 2h to end the reaction . Then the reaction solution is placed in a separatory funnel, allowed to stand for layers, and the phosphoric acid phase of the lower layer is separated; then neutralize the organic phase with 5% sodium hydroxide solution, so that the pH of the organic phase is 5; Phenol, until the temperature is 190°C, the bisphenol F product is obtained.

[0027] The composition analysis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com