Insulation cable material and preparation method thereof

A technology of insulating cables and raw materials, which is applied in the field of insulating cable materials and their preparation, can solve the problems of mechanical properties, thermal stability and flame retardancy not meeting the expected requirements, unfavorable popularization and use, and insufficient mechanical strength, etc., and achieve excellent thermal stability. Stability and flame retardant properties, conducive to large-scale industrial production, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An insulating cable material, which is prepared from the following raw materials in parts by weight:

[0023] 30 parts of polyvinyl chloride, 20 parts of polypropylene resin, 16 parts of bisphenol F epoxy resin, 12 parts of γ-aminopropyltriethoxysilane, 10 parts of phthalic anhydride, 5 parts of modified kaolin, modified 5 parts of diatomaceous earth, 3 parts of dimethylaminoethoxyethanol, 2 parts of polyglycolic acid, 1 part of triallyl isocyanurate, 1 part of aluminum hydroxide, 1 part of antimony trioxide, titanium carbide 1 serving.

[0024] Among them, the preparation method of the modified kaolin is: soak the kaolin with 10% (V / V) hydrochloric acid for 10 minutes first, subject to the fact that the kaolin has not passed through, centrifuge at 500 rpm for 3 minutes, collect the precipitate, dry it, and grind it into a particle size of 300 The purpose powder is obtained; the preparation method of the modified diatomite is: first soak the diatomite with 10% (V / V) hy...

Embodiment 2

[0031] An insulating cable material, which is prepared from the following raw materials in parts by weight:

[0032] 40 parts of polyvinyl chloride, 30 parts of polypropylene resin, 20 parts of bisphenol F epoxy resin, 15 parts of γ-aminopropyltriethoxysilane, 12 parts of phthalic anhydride, 6 parts of modified kaolin, modified 6 parts of diatomaceous earth, 4 parts of dimethylaminoethoxyethanol, 3 parts of polyglycolic acid, 2 parts of triallyl isocyanurate, 2 parts of aluminum hydroxide, 2 parts of antimony trioxide, titanium carbide 2 servings.

[0033] Among them, the preparation method of the modified kaolin is: soak the kaolin with 10% (V / V) hydrochloric acid for 10 minutes first, subject to the fact that the kaolin has not passed through, centrifuge at 500 rpm for 3 minutes, collect the precipitate, dry it, and grind it into a particle size of 300 The purpose powder is obtained; the preparation method of the modified diatomite is: first soak the diatomite with 10% (V / V...

Embodiment 3

[0040] The performance test of the insulating cable material prepared by the present invention:

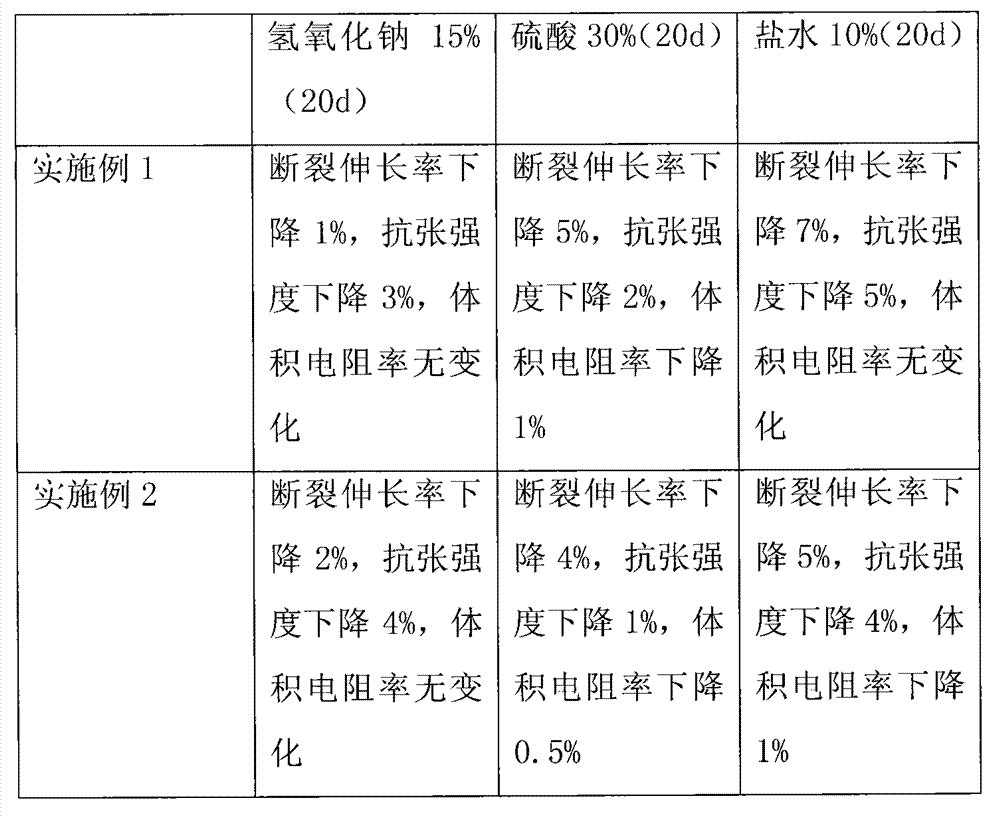

[0041] Performance tests are carried out for the insulating cable materials prepared in Examples 1 and 2 of the present invention; the test results of the gained materials are shown in Table 1-2:

[0042] Table 1

[0043]

[0044] Table 2

[0045]

[0046] table 3

[0047]

[0048]Conclusion: the insulating cable material prepared by the present invention not only possesses better insulation performance (volume resistance), but also has better mechanical properties, excellent thermal stability and flame retardancy; the insulating cable material prepared by the present invention also has better Excellent corrosion resistance; the cost of raw materials used in the invention is low, the preparation method is simple and feasible, and it is beneficial to large-scale industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com