Graphene and epoxy resin composite foam material and preparation method thereof

A technology of olefinic epoxy resin and composite foam, which is applied in the field of single-component foamed graphene epoxy resin composite foam material and its preparation, can solve the problems of complex process and unfavorable on-site foaming, and achieve simplified foaming process, Contributes to environmental protection and improves dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The N-aminoethylpiperazine adopted in the following examples comes from Sigma-Aldrich; Epoxy resin is purchased from Taiwan Nanya, epoxy value 0.51eq / 100g; Foam stabilizer ethylene oxide-propylene oxide triblock copolymer From Sigma-Aldrich, average molecular weight 2800; graphene from Changzhou Jiangnan Graphene Research Institute, brand GN-1.

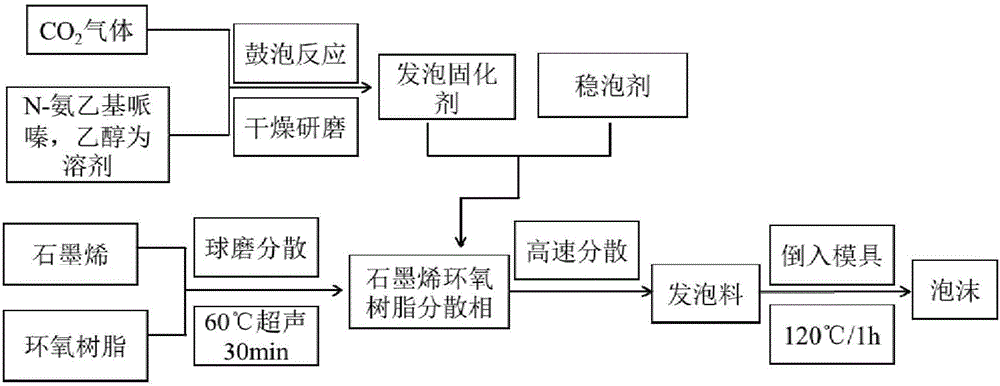

[0028] A kind of preparation method of one-component graphene epoxy resin composite foam material, the technological process of its preparation step is as follows figure 1 Shown, the concrete steps of preparation method are as follows:

[0029] (1) Synthesis of curing-foaming agent: in parts by mass, after mixing 100 parts of dehydrated alcohol and 25 parts of N-aminoethylpiperazine, add CO 2 After bubbling for 11 hours, filter and dry to obtain a light yellow solid solidification-foaming agent.

[0030] (2) In parts by mass, epoxy resin, graphene, curing-foaming agent, and foam stabilizer are weighed, and the specific formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com