Lithium-sulfur battery positive electrode material and cationic lithium-sulfur battery binding agent

A technology for lithium-sulfur batteries and cathode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems that limit the wide application of lithium-sulfur batteries, battery safety hazards, and low utilization of active materials, so as to suppress the shuttle effect and improve The effect of operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

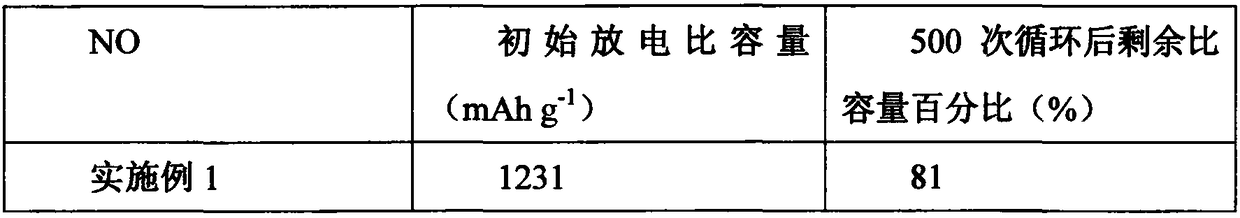

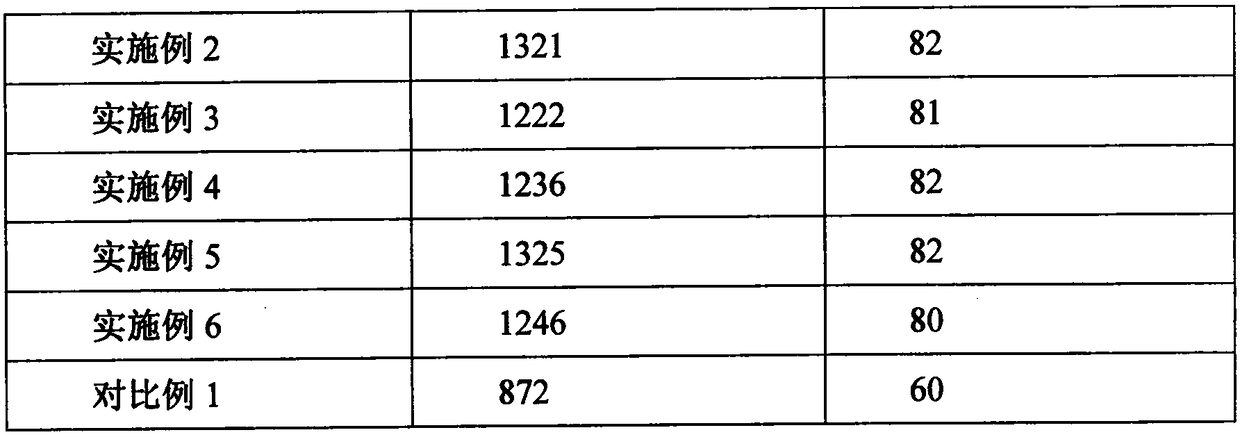

Examples

Embodiment 1

[0022] A lithium-sulfur battery cathode material, comprising a current collector metal aluminum foil and an electrode slurry coated on the surface of the current collector metal aluminum foil, the electrode slurry contains a carbon-sulfur compound and a lithium-sulfur battery binder, and the lithium The sulfur battery binder comprises a polymer obtained by polymerizing N,N-methylenebisacrylamide and aminoethylpiperazine. The preparation method of the lithium-sulfur battery cathode material is:

[0023] Step 1: Weigh 3g of N,N-methylenebisacrylamide into a 150mL round bottom flask equipped with a magnetic stirrer, add 30ml of DMF, mix well, seal the bottle mouth with a reverse stopper, and ventilate with argon After 20 minutes, under argon protection and magnetic stirring, 2 g of aminoethylpiperazine was added with a syringe. After the pinhole was sealed, the reaction bottle was placed in a constant temperature water bath at 30 ° C. After stirring for 8 hours, a light yellow vi...

Embodiment 2

[0028] A lithium-sulfur battery cathode material, comprising a current collector metal aluminum foil and an electrode slurry coated on the surface of the current collector metal aluminum foil, the electrode slurry contains a carbon-sulfur compound and a lithium-sulfur battery binder, and the lithium The sulfur battery binder comprises a polymer obtained by polymerizing N,N-methylenebisacrylamide and aminoethylpiperazine. The preparation method of the lithium-sulfur battery cathode material is:

[0029] Step 1: take 3.5g of N, N-methylenebisacrylamide in a 150mL round bottom flask equipped with a magnetic stirrer, add the mixture of 40ml deionized water and DMF (the volume ratio of water and DMF is respectively : 1 / 4), mix evenly, seal the bottle mouth with a reverse stopper, pass argon gas for 20 minutes, under the protection of argon gas and magnetic stirring, add 2.3g aminoethylpiperazine with a syringe, after the pinhole is sealed, the reaction Put the bottle in a constant...

Embodiment 3

[0034] A lithium-sulfur battery cathode material, comprising a current collector metal aluminum foil and an electrode slurry coated on the surface of the current collector metal aluminum foil, the electrode slurry contains a carbon-sulfur compound and a lithium-sulfur battery binder, and the lithium The sulfur battery binder comprises a polymer obtained by polymerizing N,N-methylenebisacrylamide and aminoethylpiperazine. The preparation method of the lithium-sulfur battery cathode material is:

[0035] Step 1: Weigh 4g of N,N-methylenebisacrylamide in a 150mL round bottom flask equipped with a magnetic stirrer, add a mixture of 40ml deionized water and DMF (the volume ratio of water and DMF is respectively: 2 / 3), mix evenly, seal the bottle mouth with a reverse stopper, pass argon gas for 20 minutes, under the protection of argon gas and magnetic stirring, add 3g aminoethylpiperazine with a syringe, after the pinhole is sealed, place the reaction bottle on the In a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com