Silicone rubber based thermal failure protection material and preparation method and application thereof

A protective material, silicone rubber technology, applied in the field of silicone rubber-based thermal failure protection materials and its preparation, to achieve the effects of prolonging the vulcanization induction period, preventing combustion, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

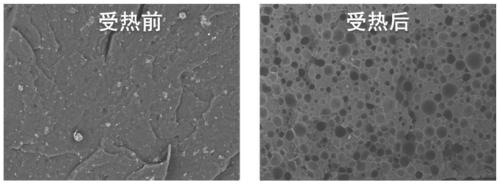

Image

Examples

Embodiment 1

[0057] (1) Add N-aminoethylpiperazine to the vacuum kneader, and pass high-purity carbon dioxide gas into the vacuum kneader at a rate of 93mL / min for mechanical mixing, set the mixing time to 2h, the mixing temperature to 30°C, and the rotor speed to 40rpm , to obtain passivated N-aminoethylpiperazine in white powder;

[0058] (2) Add epoxidized methyl vinyl silicone rubber with an epoxy group mole fraction of 3.5% into a vacuum kneader, perform high-temperature mastication under vacuum conditions, set the mastication time to 26 minutes, and the mastication temperature to 155°C, the rotor speed is 135rpm, the silicone rubber masticated rubber is prepared, and it is parked at room temperature for 24h, and it is ready for use;

[0059] (3) 100 parts of silicone rubber masticated by the above step (2), 42 parts of methyl silicone oil, 10 parts of ammonium polyphosphate, 24 parts of precipitated white carbon black, 5 parts of hydroxyl silicone oil, 23 parts of lead-based glass P...

Embodiment 2

[0069] (1) Add N-aminoethylpiperazine into the vacuum kneader, and pass high-purity carbon dioxide gas into the vacuum kneader at a rate of 76mL / min for mechanical mixing, set the mixing time to 3.2h, the mixing temperature to 33°C, and the rotor speed to 55rpm, passivated N-aminoethylpiperazine in the form of white powder;

[0070] (2) Add 100 parts of epoxidized methyl vinyl phenyl silicone rubber with a mole fraction of 2.1% into a vacuum kneader, and carry out high-temperature mastication under vacuum conditions. The mastication time is 26 minutes, and the mastication temperature is 162°C. The rotor speed is 95rpm, and the silicone rubber is plasticized, and it is parked at room temperature for 24h, and it is ready for use;

[0071] (3) 100 parts of silicone rubber masticated by the above step (3), 43 parts of vinyl silicone oil, 18 parts of magnesium hydroxide, 2 parts of fumed silica, 5 parts of dimethyldimethoxysilane , 34 parts of hydroxyl glass powder, 7.5 parts of b...

PUM

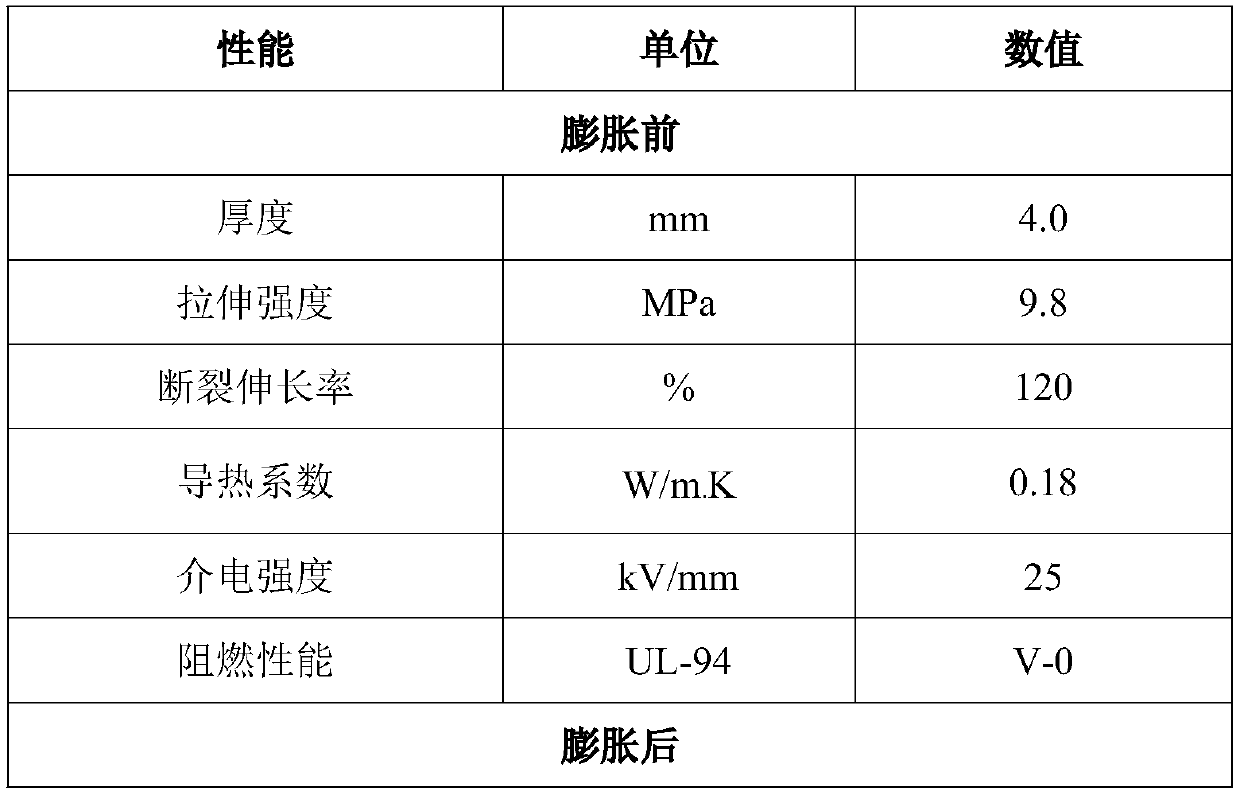

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com