Power battery device with phase-change material cooling system

A technology of power battery and phase change material, which is applied in secondary battery, secondary battery manufacturing, battery pack components and other directions, can solve the problem of reduced power performance, difficulty in giving full play to battery performance, and inability to ensure temperature consistency between batteries and other problems to achieve the effect of balanced temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

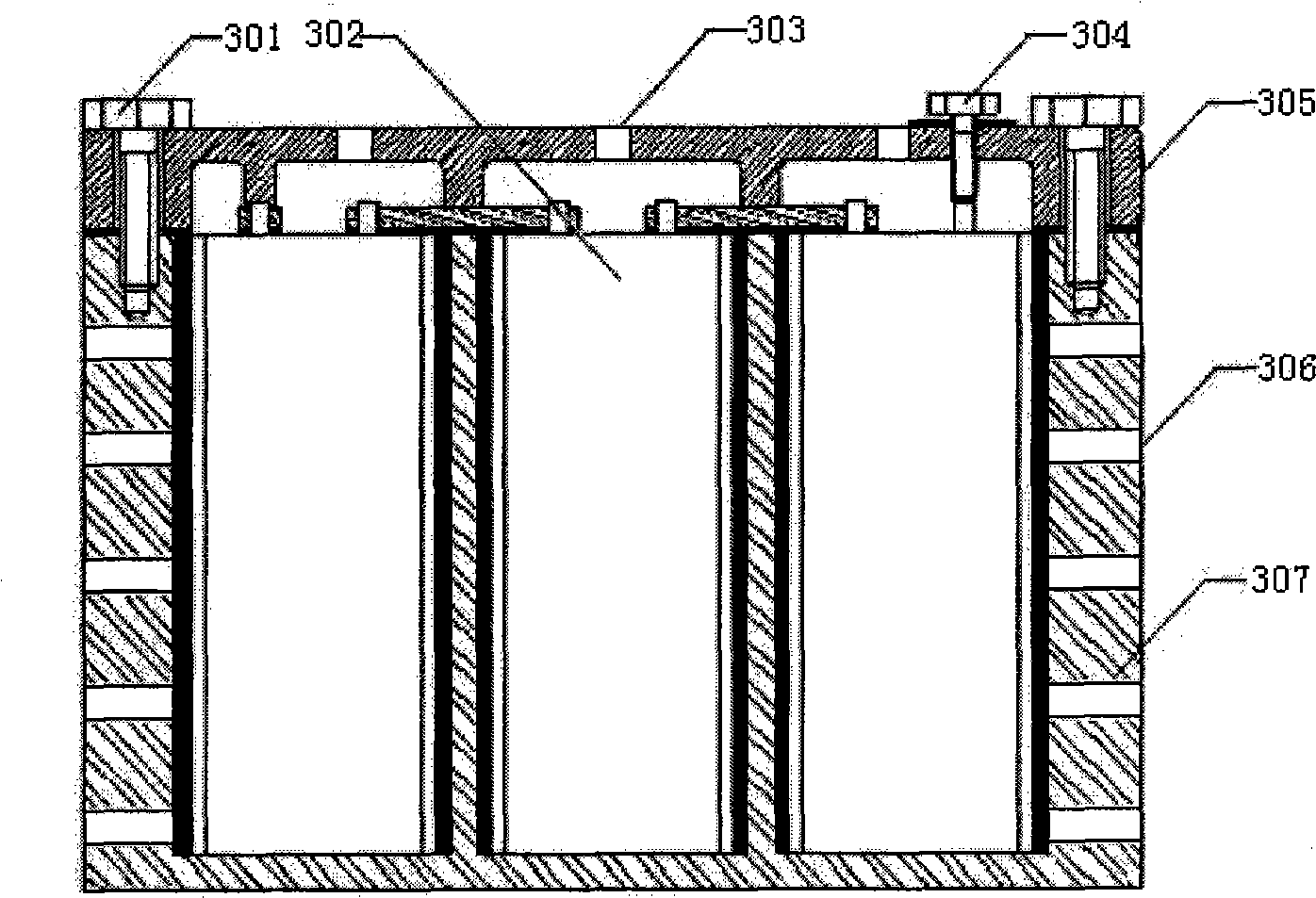

[0017] The invention adopts phase change material for cooling. The system design is different from the traditional air cooling system. It can make the power battery achieve the best cooling effect of the battery in the harsh thermal environment, and realize the temperature distribution between the battery cells. The balance of power equipment, so as to achieve the best operating conditions of the power equipment, ensure the stable performance of the battery stack, and play an important role in extending the battery life and improving the power performance of the power equipment.

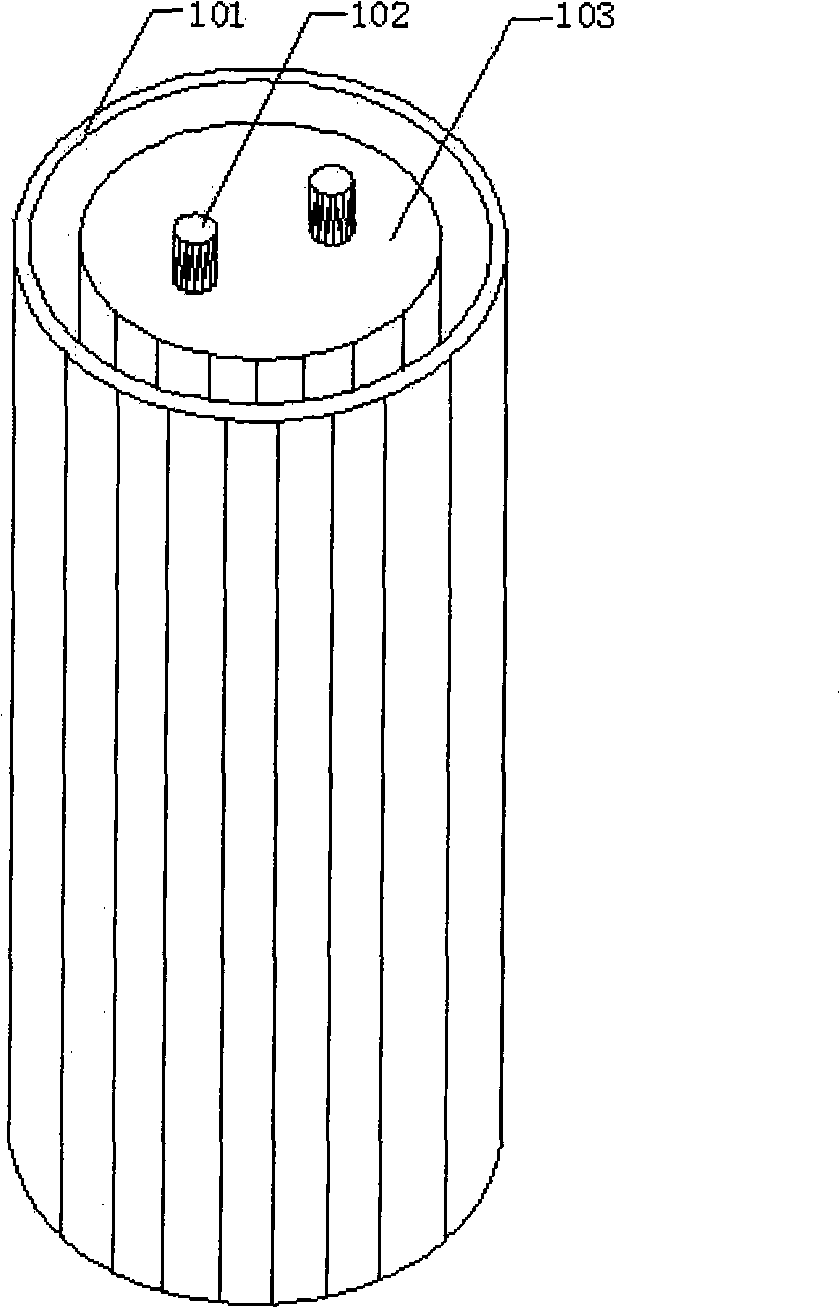

[0018] The structure of battery cell 302 is as attached figure 1 As shown, the battery 103 is used as the base body, and the outer casing 101 is tightly fitted and sealed with insulating rubber to prevent the phase change material from overflowing during the heat storage process. The battery 103 and the casing 101 are filled with the phase change material to generate the inside of the battery. The heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com