Anacardol glycidyl ether modified mixed amine hardener and preparation method thereof

A technology of glycidyl ether and cardanol, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve problems such as poor performance, unfriendly environment, and high requirements for construction environment, and reduce toxicity and volatility, improve paint film disease, reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

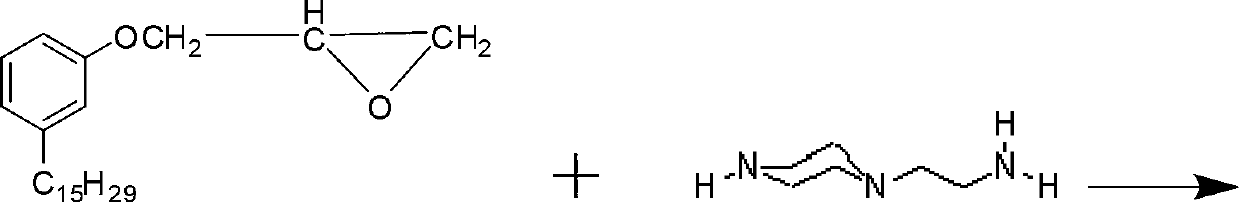

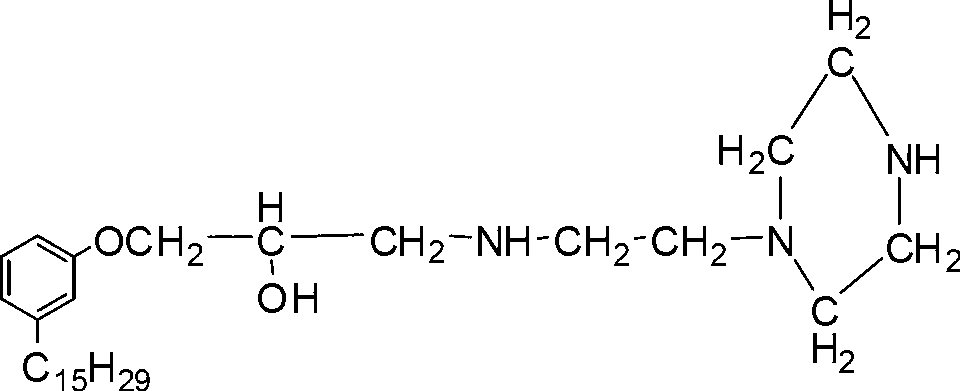

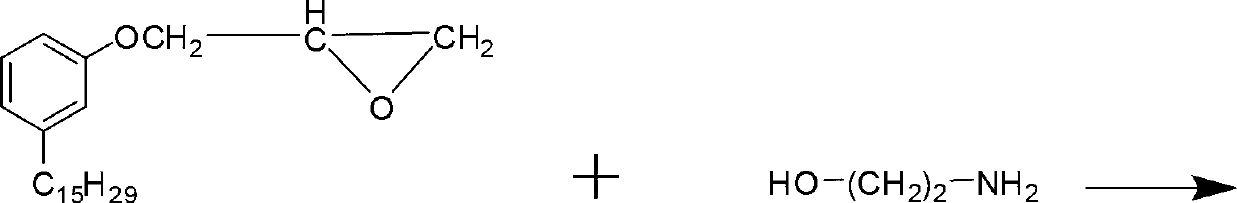

Method used

Image

Examples

Embodiment 1

[0030] Add 28 parts of mixed amines into the reaction kettle, and slowly add 72 parts of cardanol glycidyl ether dropwise at 60°C under stirring conditions of 600 to 800 rpm, and complete the dropwise addition within 2 hours. Stir and disperse for 3- After 4 hours, the final product was obtained.

[0031] Further, the mixed amine is composed of N-aminoethylpiperazine, 2-aminoethanol, polyethylenepolyamine and triethylenetetramine, and the N-aminoethylpiperazine, 2-aminoethanol, poly The weight ratio of ethylene polyamine to triethylenetetramine is 10-12:33-36:30-33:19-21.

[0032] The listening plate is polished with sandpaper, cleaned with xylene solvent, degreased and degreased, and dried.

Embodiment 2

[0034] The cardanol glycidyl ether modified mixed amine curing agent of the present invention is synthesized from cardanol glycidyl ether and mixed amine components, and the weight ratio of the cardanol glycidyl ether to the mixed amine is 60:40, so Described mixed amine is made up of N-aminoethylpiperazine, 2-aminoethanol, polyethylenepolyamine and triethylenetetramine, and described N-aminoethylpiperazine, 2-aminoethanol, polyethylenepolyamine and The weight ratio of triethylenetetramine is 10-12:33-36:30-33:19-21. Add mixed amines into the reaction kettle, and slowly add cardanol glycidyl ether dropwise at 50°C under stirring conditions of 600-800 rpm, and complete the dropwise addition within 1 hour. Stir and disperse for 3-4 hours to obtain the final product.

[0035] Further, the weight ratio of N-aminoethylpiperazine, 2-aminoethanol, polyethylene polyamine and triethylenetetramine is 11.2:34.6:31.8:20.

Embodiment 3

[0037] The cardanol glycidyl ether modified mixed amine curing agent of the present invention is synthesized from cardanol glycidyl ether and mixed amine components, and the weight ratio of the cardanol glycidyl ether to the mixed amine is 80:20, so Described mixed amine is made up of N-aminoethylpiperazine, 2-aminoethanol, polyethylenepolyamine and triethylenetetramine, and described N-aminoethylpiperazine, 2-aminoethanol, polyethylenepolyamine and The weight ratio of triethylenetetramine is 10-12:33-36:30-33:19-21. Add mixed amines into the reaction kettle, and slowly add cardanol glycidyl ether dropwise under the stirring condition of 70°C and 600-800 rpm, and complete the dropwise addition within 3 hours, stir and disperse for 3-4 hours to obtain the final product.

[0038] Further, the weight ratio of N-aminoethylpiperazine, 2-aminoethanol, polyethylene polyamine and triethylenetetramine is 11.2:34.6:31.8:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com