Hollow glass bead and polyurethane cooperated-modified unsaturated polyester composite material and preparation method thereof

A technology of hollow glass microspheres and polyester composite materials, applied in the field of hollow glass microspheres and polyurethane synergistically modified unsaturated polyester composite materials and its preparation, can solve the problem of low density, high toughness, hollow glass microspheres and unsaturated polyester Saturated resin has poor compatibility and other problems, and achieves the effect of good density and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

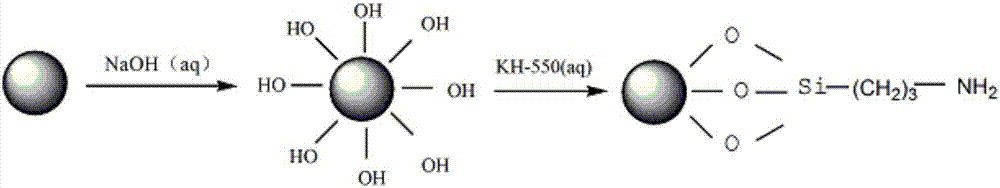

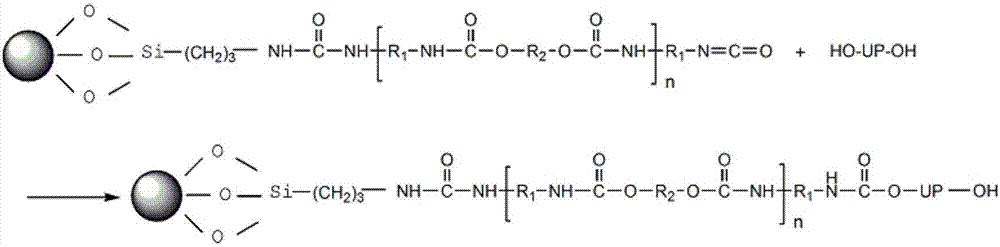

[0034] (1) Heat 5.4g of hollow glass microspheres in 0.3mol / L NaOH solution to 80°C while stirring for 1h, then wash with distilled water until neutral, filter and dry, and set aside;

[0035] (2) Heat the surface hydroxylated hollow glass microspheres obtained in step (1) to 80° C. in the prepared KH-550 solution, while stirring for 2 hours, then wash with absolute ethanol while suction filtration under reduced pressure, drying to obtain hollow glass microspheres with surface amination;

[0036] (3) Vacuum dehydrate 16.7g of polyethylene glycol 400 at 120°C for 3 hours, cool down to 70°C, add 4.5g of hollow glass microspheres obtained in step (2), stir mechanically for 30min, and then slowly add the mixture to 8.8g of TDI In -80, add 2 drops of dibutyltin dilaurate, control the temperature of the system at about 40-50 ° C, react for 1 h under nitrogen protection, and measure the content of -NCO with di-n-butylamine-toluene solution and Hcl-H2 O solution. Measure once every 3...

Embodiment example 2

[0039] (1) Heat 14.5g of hollow glass microspheres in 0.3mol / L NaOH solution to 80°C while stirring for 1h, then wash with distilled water until neutral, filter and dry, and set aside;

[0040] (2) Heat the surface hydroxylated hollow glass microspheres obtained in step (1) to 80° C. in the prepared KH-791 solution, while stirring for 2 hours, then wash with absolute ethanol while suction filtration under reduced pressure, drying to obtain hollow glass microspheres with surface amination;

[0041] (3) 27.4g of polypropylene glycol 400 was vacuum dehydrated at 120°C for 3h, cooled to 70°C and added with 9.8g of hollow glass microspheres obtained in step (2), mechanically stirred for 30min, and then the mixture was slowly added dropwise to 20.6g of Add 3 drops of stannous octoate solution to phenylmethane diisocyanate, control the temperature of the system at about 40-50°C, react for 1 hour under the protection of nitrogen, and measure the content of -NCO with di-n-butylamine-to...

Embodiment example 3

[0044] (1) Heat 26.0 g of hollow glass microspheres in 0.3 mol / L NaOH solution to 80 °C while stirring for 1 h, then wash with distilled water until neutral, filter and dry, and set aside;

[0045] (2) Heat the surface hydroxylated hollow glass microspheres obtained in step (1) to 80° C. in the prepared KH-550 solution, while stirring for 2 hours, then wash with absolute ethanol while suction filtration under reduced pressure, drying to obtain hollow glass microspheres with surface amination;

[0046] (3) 25.4g of polyethylene glycol 400 and 7.7g of polypropylene glycol 400 were vacuum dehydrated at 120°C for 3h, cooled to 75°C and added with 10.5g of hollow glass microspheres obtained in step (2), mechanically stirred for 30min, and then Slowly add the mixture to 8.7g TDI-80, add 3 drops of dibutyltin dilaurate, control the temperature of the system at about 40-50°C, react for 1h under the protection of nitrogen, and use di-n-butylamine-toluene solution and Hcl-H2 0 solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com