Welding structure multi-axial fatigue life evaluation method

A welding structure and fatigue life technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as stress states that are difficult to deal with, and achieve clear physical meaning and high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

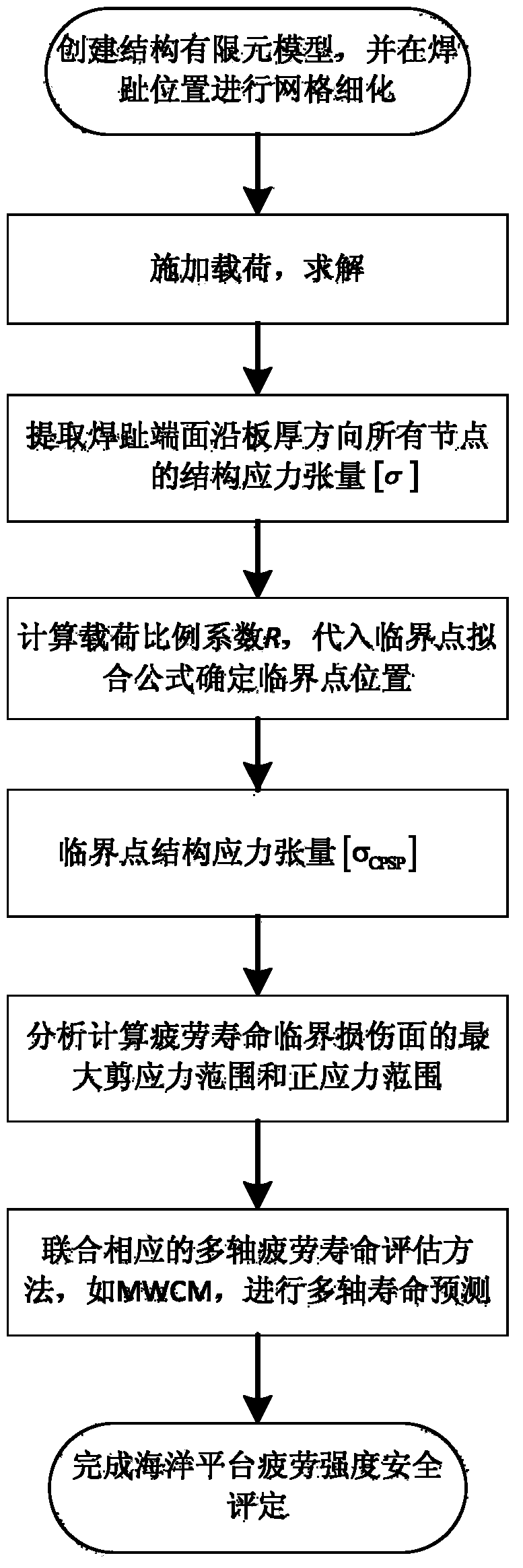

[0031] Such as figure 1 Shown: mainly includes the following steps: a method for evaluating the multiaxial fatigue life of welded structures has the following steps:

[0032] First, establish the finite element model of the welding structure to be measured, and perform local refinement at the weld toe position. In the embodiment of the present invention, the weld toe refinement grid size is 0.1t×0.1t, and the coarse grid size at other positions is 0.5t× 0.5t.

[0033] A variety of experimental loads are applied to the welded structure, and corresponding fatigue loads are applied to the established finite element model according to the test data: pure bending, pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com