Thermoplastic polyimide cable material for nuclear power aviation

A technology of polyimide and polyetherimide, which is applied in the field of thermoplastic polyimide cable materials for nuclear power and aviation, can solve the problems that the cable materials cannot be reached, and the fluidity of the soft melt at room temperature and low temperature needs to be improved. Achieve the effects of improving fluidity, good high temperature resistance, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

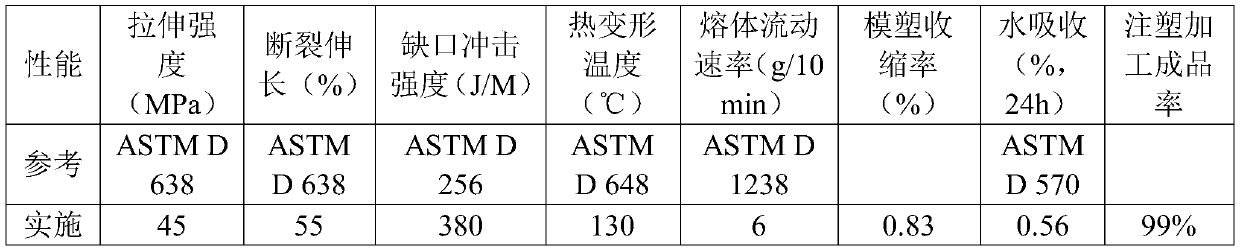

Examples

Embodiment 1

[0037] S1. Weigh 10 parts of polyimide (produced by Shanghai Resin, brand Ys-20: special product of Hangzhou Sumeng, brand SS100P=1:1), 14 parts of polyetherimide (Ultem1010), 50 parts by weight Parts of polyetherimide containing silicone (STM1700), 5 parts of polyethersulfone, 5 parts of fully aromatic polyimide liquid crystal polymer, 5 parts of polypropylene, 5 parts of polymethylphenyl silicone resin, 5 parts 1 part of talcum powder, 0.2 part of PETS, 0.3 part of anti-1010, 0.5 part of UV light stabilizer, mixed evenly to obtain a mixture.

[0038]S2. Add the mixed material to the main feed of the twin-screw extruder, melt it and extrude it out from the outlet of the die head, water-cool it and cut it into pellets to obtain thermoplastic polyimide cable material particles for nuclear power and aviation. Wherein, the melting extrusion temperature of the twin-screw extruder is 300-380° C., and the screw speed is 350 rpm / min.

[0039] The above-prepared cable material is pre...

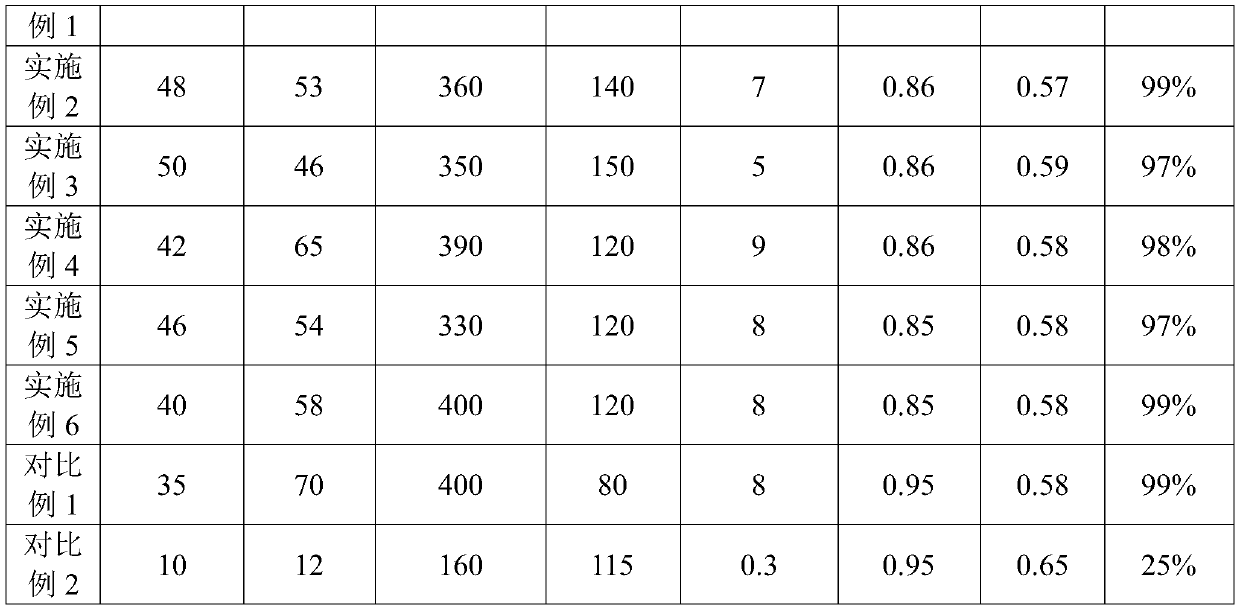

Embodiment 2

[0042] S1. Weigh 5 parts of polyimide (produced by Changchun Gaoqi Polyimide Material Co., Ltd., brand HI-P), 30 parts of polyetherimide (Torlon4000TF: 4203L=2:1), 30 parts Silicone-containing polyetherimide (STM1600), 5 parts of polyether ketone, 5 parts of fully aromatic polyester liquid crystal polymer, 25 parts of LLDPE (linear low density polyethylene), 5 parts of ethylene-propylene copolymer, 5 parts 1 part of polyphenylsilsesquioxane, 5 parts of talcum powder, 0.2 part of erucamide, 0.2 part of anti-1076, 0.6 part of anti-168, 10 parts of flame retardant, and mix evenly to obtain a mixture.

[0043] S2. Add the mixed material to the main feed of the twin-screw extruder, melt it and extrude it out from the outlet of the die head, water-cool it and cut it into pellets to obtain thermoplastic polyimide cable material particles for nuclear power and aviation. Wherein, the melting extrusion temperature of the twin-screw extruder is 300-380° C., and the screw speed is 250 rpm...

Embodiment 3

[0046] S1, take by weight 30 parts of polyimide (Aurum PL450C of Mitsui company), 5 parts of polyetherimide (ULtem1010), 30 parts of silicone-containing polyetherimide (STM1500:1700=5 : 1), 20 parts of polyetheretherketone copolymer, 10 parts of polyether ketone ketone, 5 parts of fully aromatic polyester liquid crystal polymer, 5 parts of low density polyethylene, 5 parts of phenyl MQ silicone resin, 11 parts of talc powder, 0.4 part of oleic acid amide, 0.4 part of anti-1010, 0.2 part of anti-P-EPQ, 4 parts of nucleating agent, and 1 part of carbon black, and mix them evenly to obtain a mixture.

[0047] S2. Add the mixed material to the main feed of the twin-screw extruder, melt it and extrude it out from the outlet of the die head, water-cool it and cut it into pellets to obtain thermoplastic polyimide cable material particles for nuclear power and aviation. Wherein, the melting extrusion temperature of the twin-screw extruder is 300-380° C., and the screw speed is 150 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com