Method for cleanly preparing bioplastic food packaging film at low cost

A technology of food packaging film and bioplastics, applied in flat products, applications, coatings, etc., can solve the problems of incomplete cellulose treatment, food safety impact, short production process, etc., to improve thermoplastic processing performance and production cost The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

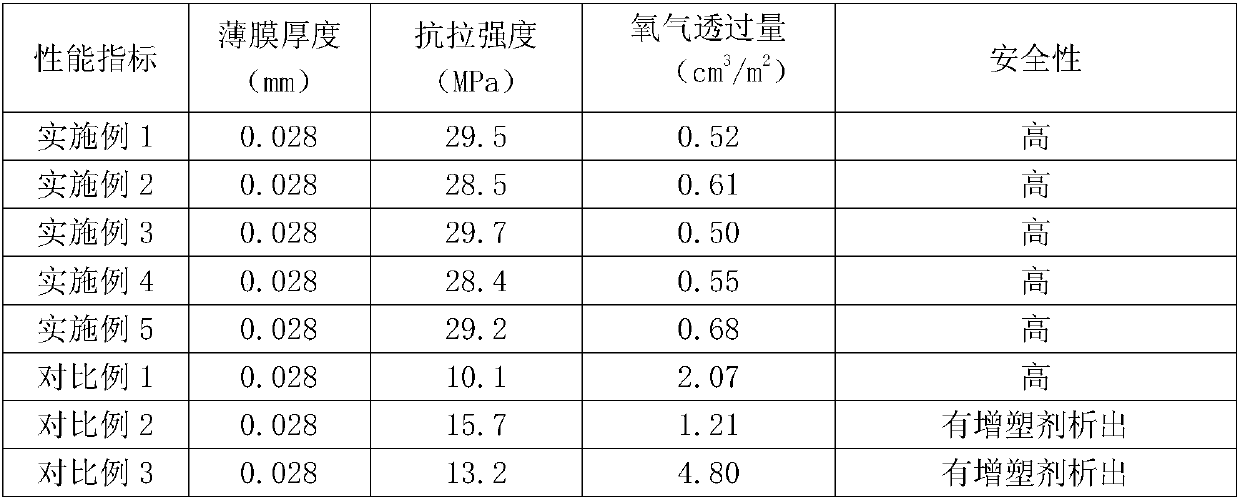

Examples

Embodiment 1

[0027] A low-cost clean method for preparing a bioplastic food packaging film, the specific process of preparing the food packaging film is as follows:

[0028] (1) Put hydroxypropyl methylcellulose in a quartz pot, put it into a vacuum chamber, and carry out magnetic stirring. At the same time, connect the vacuum chamber to the extreme ultraviolet generator so that the direction of the exit of the extreme ultraviolet light is aligned with the cellulose. During the stirring process, the cellulose undergoes hydrogen bond destruction under the bombardment of extreme ultraviolet high-energy radiation, and the treatment time of extreme ultraviolet light is 4 to 6 minutes to obtain modified cellulose;

[0029] (2) Mix the modified cellulose obtained in step (1) with polylactic acid, gallic acid, and glycerin in a mass ratio of 20:40:1:2, heat in a mixer at 100°C, and stir at a speed of 60r / min , the mixing time was 15min, and then added to an extrusion calender to obtain a prototyp...

Embodiment 2

[0033] A low-cost clean method for preparing a bioplastic food packaging film, the specific process of preparing the food packaging film is as follows:

[0034](1) Put hydroxyethyl cellulose in a quartz pot, put it into a vacuum chamber, and carry out magnetic stirring. At the same time, connect the vacuum chamber to the extreme ultraviolet generator so that the direction of the extreme ultraviolet light exit is aligned with the cellulose. During the magnetic stirring process, In the process, the cellulose undergoes hydrogen bond destruction under the bombardment of extreme ultraviolet high-energy radiation, and the treatment time of extreme ultraviolet light is 5 minutes to obtain modified cellulose;

[0035] (2) Mix the modified cellulose obtained in step (1) with polylactic acid, gallic acid, and glycerin in a mass ratio of 30:30:2:2, heat in a mixer at 120°C, and stir at a speed of 80r / min , the mixing time is 20min, and then added to the prototype film of the extrusion ca...

Embodiment 3

[0039] A low-cost clean method for preparing a bioplastic food packaging film, the specific process of preparing the food packaging film is as follows:

[0040] (1) Put carboxymethyl cellulose in a quartz pot, put it into a vacuum chamber, and carry out magnetic stirring. At the same time, connect the vacuum chamber to the extreme ultraviolet generator so that the direction of the extreme ultraviolet light exit is aligned with the cellulose. During the magnetic stirring process, Among them, the cellulose undergoes hydrogen bond destruction under the bombardment of extreme ultraviolet high-energy radiation, and the treatment time of extreme ultraviolet light is 6 minutes to obtain modified cellulose;

[0041] (2) Mix the modified cellulose obtained in step (1) with polylactic acid, gallic acid, and glycerin in a mass ratio of 50:40:3:5, heat in a mixer at 100°C, and stir at a speed of 60r / min , the mixing time is 15min, and then added to the prototype film of the extrusion cale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com