High-temperature-resistant easy-to-process thermoplastic transparent polyimide resin material with low thermal expansion coefficient and preparation method thereof

A technology of polyimide resin and low thermal expansion coefficient, which is applied in the field of thermoplastic transparent polyimide materials and its preparation, and can solve the problems of pure resin that does not have repeated processing, cannot be normally extruded and injected, and has low thermal expansion coefficient , to achieve excellent compatibility, lower processing temperature, and higher melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A high-temperature-resistant and easy-to-process thermoplastic transparent polyimide resin material with a low coefficient of thermal expansion has the following composition content:

[0056] (1) High temperature resistant thermoplastic transparent polyimide resin with a glass transition temperature greater than 240°C and a thermal expansion coefficient less than 45ppm / K: the content is 98%;

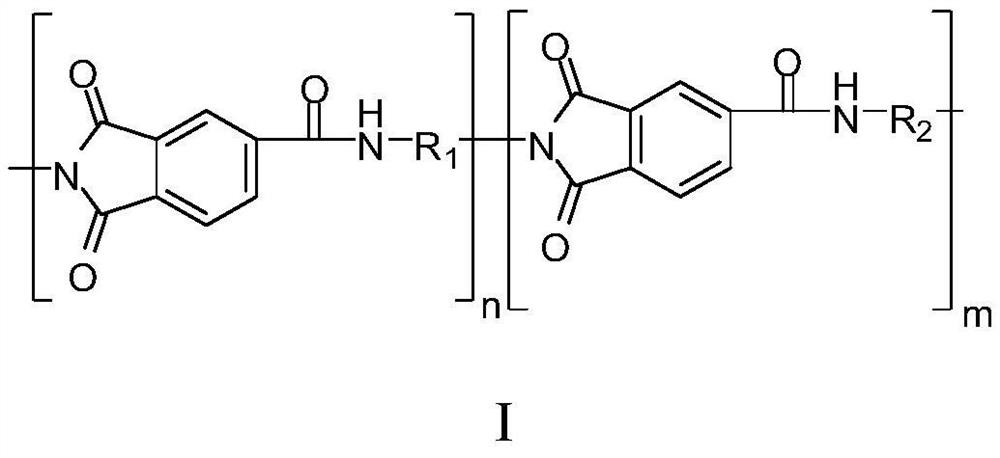

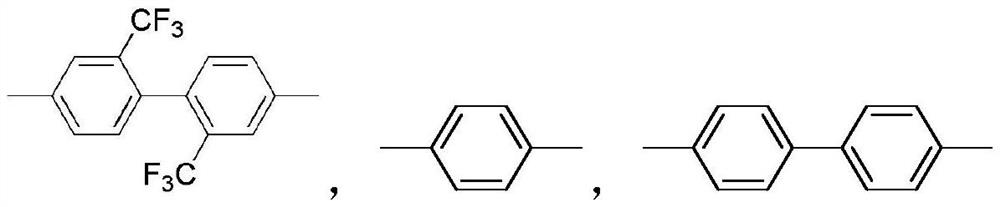

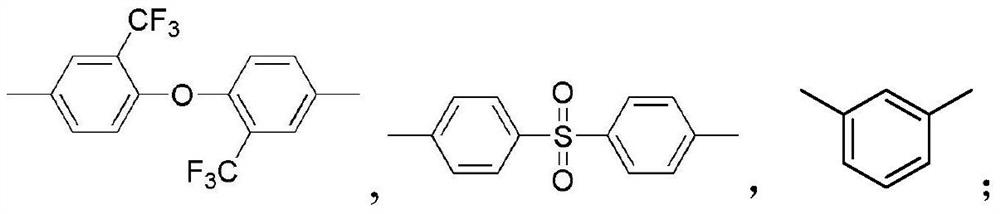

[0057] Its structural formula is as follows:

[0058]

[0059] It is prepared according to the preparation method disclosed in Example 1 of the patent CN 111057236 A (application number 201911214345.6).

[0060] Its inherent viscosity is 0.68dL / g, glass transition temperature is 295°C, and thermal expansion coefficient is 23ppm / K. .

[0061] (2) Antioxidant 1010: 0.5%;

[0062] (3) Lubricant PETS: 0.5%;

[0063] (4) Low molecular weight polyimide resin: 1%.

[0064] Its structural formula is as follows:

[0065]

[0066] Its inherent viscosity is: 0.21dL / g. The prepar...

Embodiment 2

[0074] A high-temperature-resistant and easy-to-process thermoplastic transparent polyimide resin material with a low coefficient of thermal expansion has the following composition content:

[0075] (1) High temperature resistant thermoplastic transparent polyimide resin with a glass transition temperature greater than 240°C and a thermal expansion coefficient less than 45ppm / K: the content is 99%;

[0076] Its structural formula is as follows:

[0077]

[0078] Its inherent viscosity is: 0.60dL / g.

[0079] (2) Antioxidant 1010: 0.3%;

[0080] (3) Lubricant PETS: 0.3%;

[0081] (4) Low molecular weight polyimide resin: 0.4%.

[0082] Its structural formula is as follows:

[0083]

[0084] The preparation method is the same as component (1), but the molecular weight is controlled, and the logarithmic viscosity is: 0.21dL / g.

[0085] The extrusion temperature of the WELLZOON brand C-type high-temperature desktop extruder is 330°C, and the extruded resin pellets are re...

Embodiment 3

[0087] A high-temperature-resistant and easy-to-process thermoplastic transparent polyimide resin material with a low coefficient of thermal expansion has the following composition content:

[0088] (1) High temperature resistant thermoplastic transparent polyimide resin with a glass transition temperature greater than 240°C and a thermal expansion coefficient less than 45ppm / K: the content is 95.5%;

[0089] Its structural formula is as follows:

[0090]

[0091] It is prepared according to the preparation method disclosed in Example 4 of the patent CN 111057236 A (application number 201911214345.6).

[0092] Its inherent viscosity is: 0.45dL / g.

[0093] (2) Antioxidant 168: 1.5%;

[0094] (3) Lubricant paraffin: 2.5%;

[0095] (4) Low molecular weight polyimide resin: 0.5%.

[0096] Its structural formula is as follows:

[0097]

[0098] The preparation method is the same as component (1), but the molecular weight is controlled, and the logarithmic viscosity is: 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Inherent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com