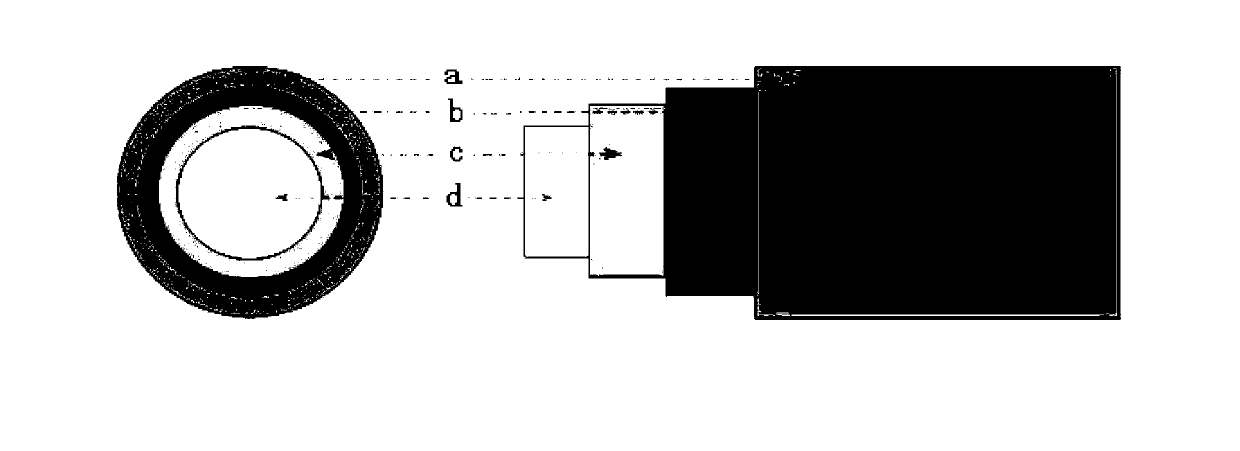

Double-layer composite polymer group wear-resisting bearing and preparation method thereof

A kind of anti-friction bearing, composite technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of rubber noise, poor dimensional stability, volume expansion, etc., to improve heat resistance and working temperature, and broaden the damping Temperature range, effect of improving thermoplastic processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

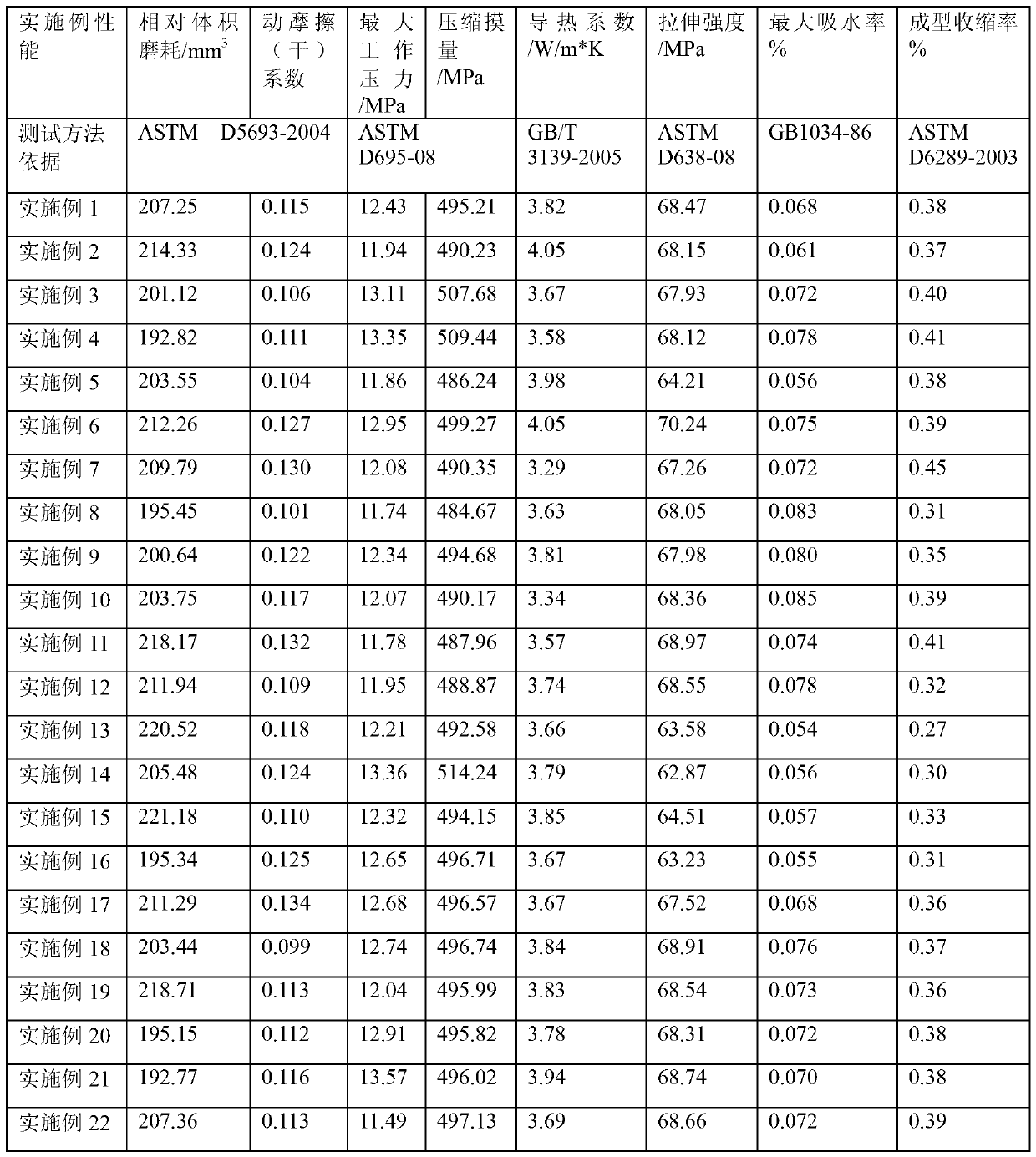

Examples

Embodiment 1

[0029] (1) Surface treatment of functional fillers: use a plasma activation instrument (plasma cleaning experimental equipment EPT-02, produced by Suzhou Opus Plasma Technology Co., Ltd.; the same below.) to activate aramid fibers and flake-shaped thermally conductive graphite by irradiation powder to clean the surface and activate its surface sites at the same time; dry-treat chopped thermally conductive carbon fibers, flaky thermally conductive graphite powder and nano thermally conductive carbon powder with acetone-dispersed silane coupling agent for 1 hour;

[0030] (2) Preparation of bearing inner layer material: Add 65g of toluene diisocyanate to 35g of polyethylene adipate under nitrogen protection, and react at 70°C for 2 hours to obtain a polyurethane prepolymer; add 55g of polyurethane prepolymer Polymer, 5g aramid fiber, 20g flake thermal graphite powder, 2g butanediol, 2g dibutyltin dilaurate, 10g methyl methacrylate, 10g styrene, 2g dibenzoyl peroxide and 10g dimet...

Embodiment 2

[0035] (1) Surface treatment of functional fillers: use a plasma activator to irradiate and activate aramid fiber and scaly thermally conductive graphite powder to clean the surface and activate its surface sites; dry-treat chopped thermally conductive carbon fiber with acetone-dispersed silane coupling agent , flaky thermal graphite powder and nano thermal conductive carbon powder for 1.5 hours;

[0036] (2) Preparation of bearing inner layer material: Add 60g of toluene diisocyanate to 40g of polyethylene adipate under nitrogen protection, and react at 70°C for 2 hours to obtain a polyurethane prepolymer; add 55g of polyurethane prepolymer Polymer, 5g aramid fiber, 20g flake thermal graphite powder, 2g butanediol, 2g dibutyltin dilaurate, 10g methyl methacrylate, 10g styrene, 2g dibenzoyl peroxide and 10g dimethyl Mix the aniline evenly, seal it and place it in a constant temperature box at 25°C for 24 hours, then cure it at 100°C for 6 hours, and keep it under reduced press...

Embodiment 3

[0041] (1) Surface treatment of functional fillers: use a plasma activator to irradiate and activate aramid fiber and scaly thermally conductive graphite powder to clean the surface and activate its surface sites; dry-treat chopped thermally conductive carbon fiber with acetone-dispersed silane coupling agent , flaky heat-conducting graphite powder and nano-scale heat-conducting carbon powder for 2 hours;

[0042] (2) Preparation of bearing inner layer material: Add 55g of toluene diisocyanate to 45g of polyethylene adipate under nitrogen protection, and react at 70°C for 2 hours to obtain a polyurethane prepolymer; add 55g of polyurethane prepolymer Polymer, 5g aramid fiber, 20g flake thermal graphite powder, 2g butanediol, 2g dibutyltin dilaurate, 10g methyl methacrylate, 10g styrene, 2g dibenzoyl peroxide and 10g dimethyl Mix the aniline evenly, seal it and place it in a constant temperature box at 25°C for 24 hours, then cure it at 100°C for 6 hours, and keep it under redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer layer thickness | aaaaa | aaaaa |

| Tube inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com