Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Change crystal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy boron-containing carbide ultrahigh temperature ceramic powder and preparation method thereof

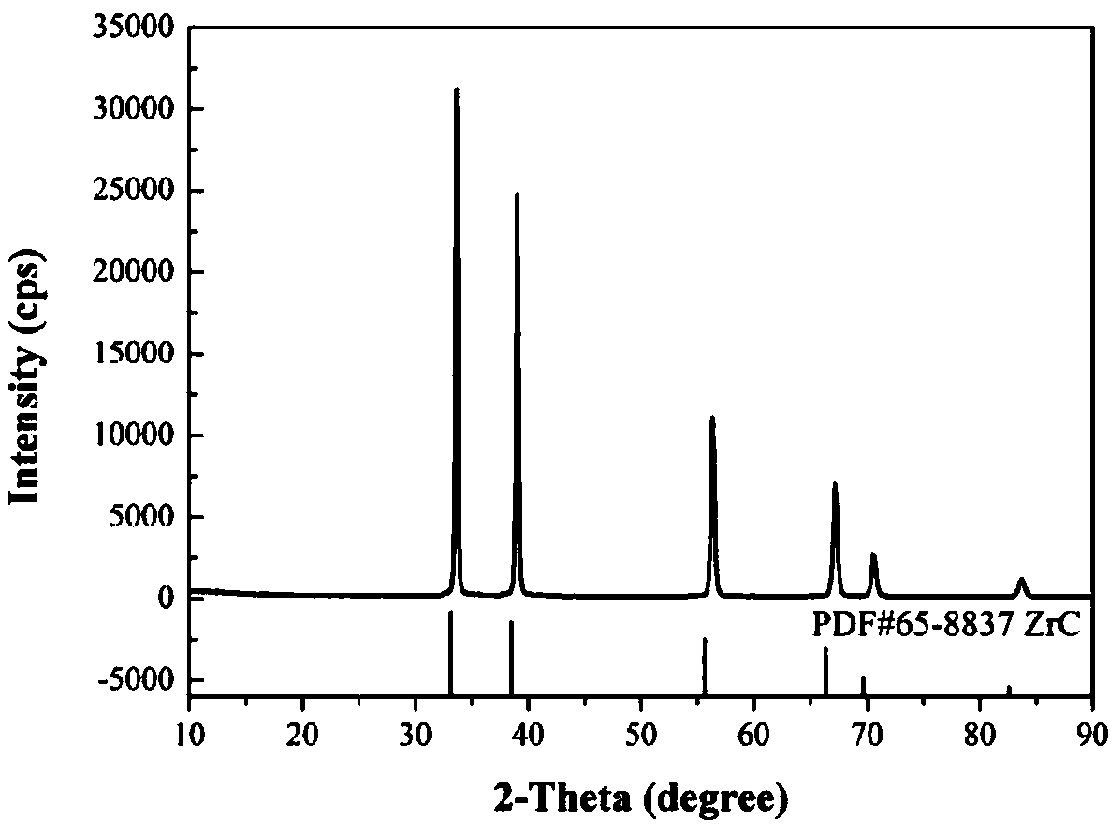

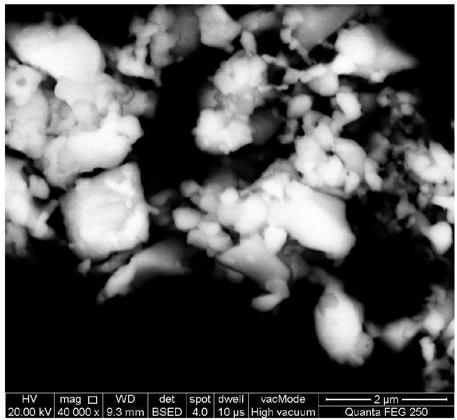

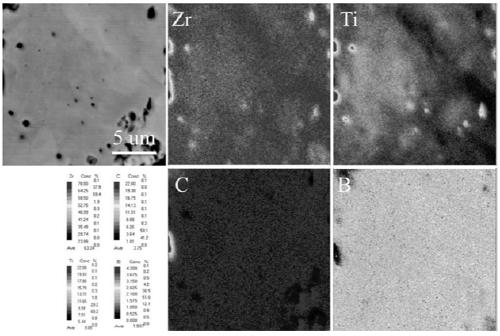

The invention belongs to the technical field of carbide ceramics, and concretely relates to a high-entropy boron-containing carbide ultrahigh temperature ceramic powder and a preparation method thereof. The molecular formula of the ceramic powder is XCyBz, wherein X is at least two of Zr, Ti, Hf, V, Nb, Ta, Cr, Mo and W, y is equal to or more than 0.6 and less 1.0, z is more than 0 and equal to orless than 0.4, and y + z = 1. The ceramic powder has a single phase face-centered cubic structure. The preparation method comprises the following steps: carrying out ball-milling mixing on at least two metal powders and C powder, carrying out pressureless plasma sintering and crushing to obtain carbide powder, mixing the carbide powder with B2O3 powder and a carbon source, and then performing high temperature sintering and crushing to obtain the ceramic powder. The ceramic powder is a single-phase solid solution, has the face-centered cubic structure, and contains the boron element, so the ceramic powder integrates the high temperature resistance of carbides and the oxidation resistance of borides, and can be used to prepare an ablation and oxidation resistant high-entropy boron-containing carbide ultrahigh temperature ceramic block or composite material.

Owner:CENT SOUTH UNIV

Multifunctional filter material for circulating water treatment and preparation method thereof

InactiveCN101857311AReduce scaleEfficient removalScale removal and water softeningBiological water/sewage treatmentSodium bicarbonateSludge

The invention discloses a multifunctional filter material for circulating water treatment, which is prepared from 1 to 10 weight percent of nano tourmaline powder, 55 to 80 weight percent of coarse tourmaline powder, 1 to 15 weight percent of kieselguhr, 1 to 15 weight percent of sepiolite powder, 1 to 15 weight percent of scallop powder, 1 to 10 weight percent of sodium bicarbonate and 0.5 to 1 weight percent of silver-carried zeolite powder. A preparation method comprises the following steps of: stirring and mixing raw materials uniformly, injecting the uniformly mixed powder into a turntable machine, and rotating the powder for 15 to 30 minutes with controlled humidity of 15 to 50 percent and rotational speed of 20 to 200 revolutions per minute by using attapulgite of 0.1 to 1 millimeter as a core; and finally sintering the powder for 4 to 8 hours at the temperature of between 400 and 600 DEG C in a muffle furnace to form a ceramic filter material with the diameter of 1 to 10 millimeters. The filter material can effectively remove Ca2+ and Mg2+ from the water and achieve the effects of inhibiting scales, preventing corrosion and removing biological sludge.

Owner:厦门柏斯顿智能科技有限公司

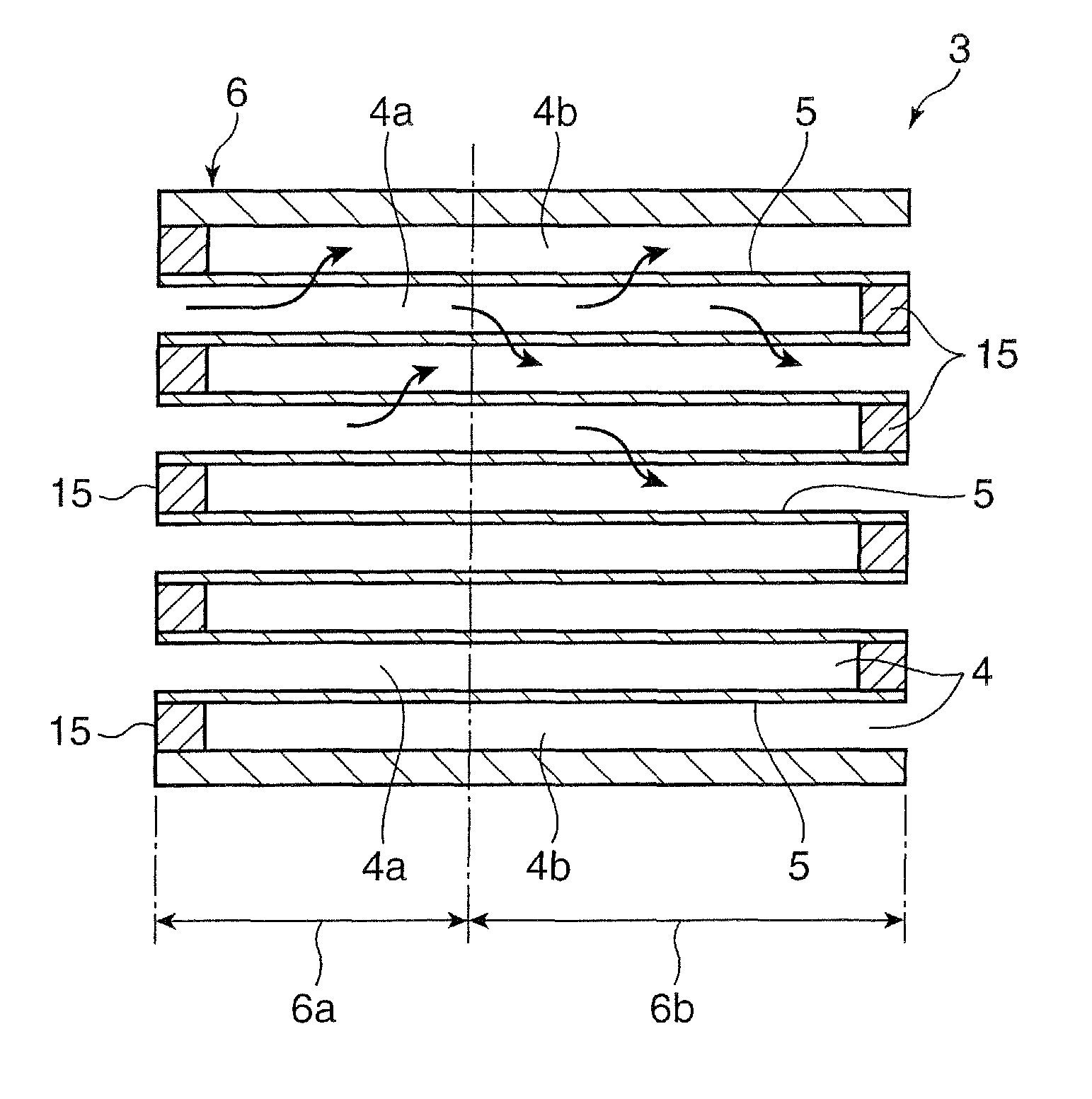

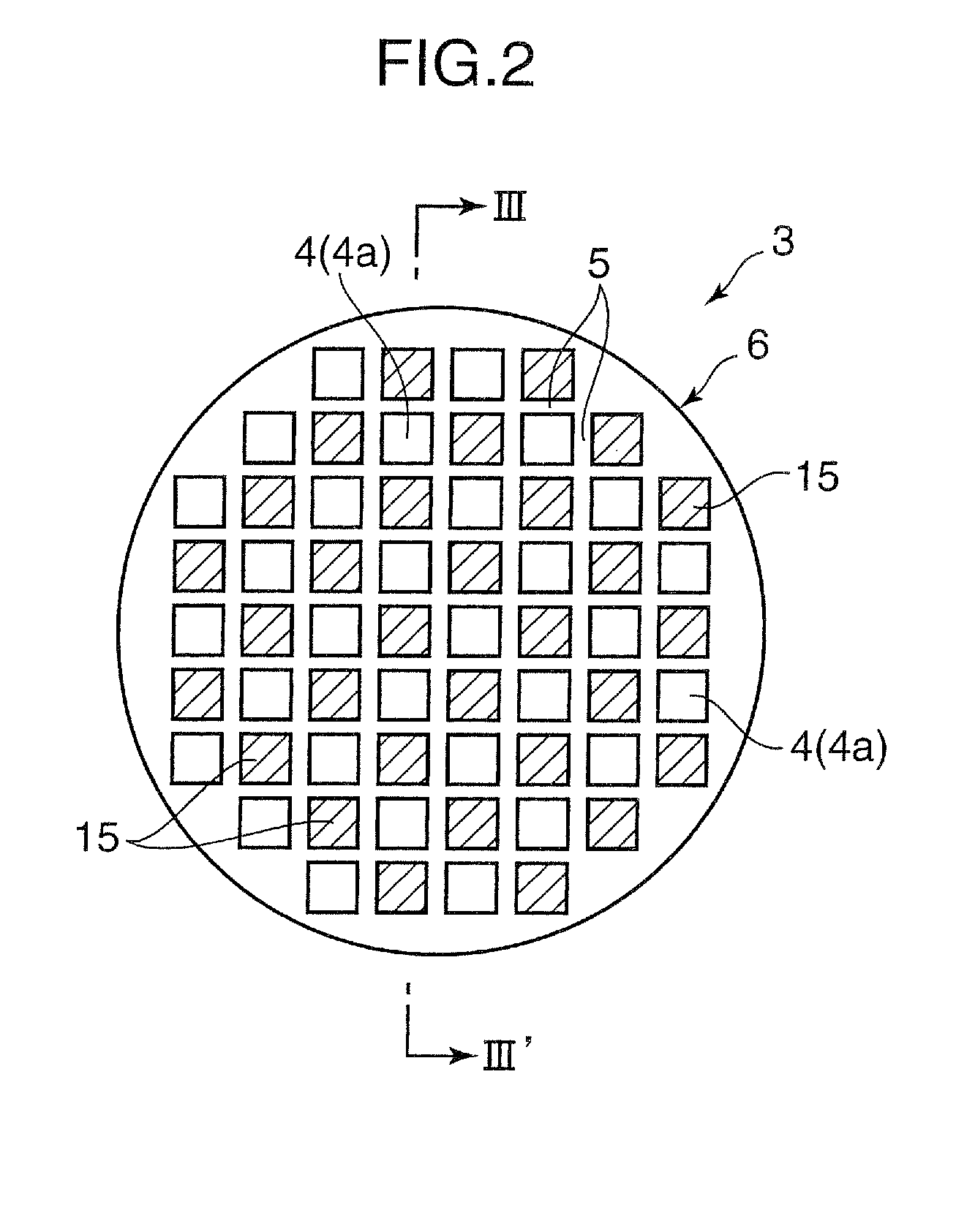

Particulate filter

Disclosed is a particulate filter, which is adapted to be disposed in an exhaust passage of an engine to trap particulate matter contained in exhaust gas discharged from the engine. The particulate filter comprises a filter body having a porous partition wall which defines a plurality of exhaust gas channels allowing the exhaust gas to pass therethrough, and a catalyst layer formed on a surface of the porous partition wall. The catalyst layer includes a Zr-based composite oxide which contains zirconium (Zr), and a rare-earth metal except cerium, wherein a content ratio of an oxide of the non-cerium rare-earth metal to a total amount of ZrO2 and the oxide of the non-cerium rare-earth metal in the Zr-based composite oxide is set in the range of greater than 33 mol % to less than 40 mol %. The particulate filter of the present invention can achieve a higher PM burning rate to burn PM within a shorter period of time. In addition, the higher PM burning rate makes it possible to provide enhanced fuel economy performance in an engine designed to perform a post-injection control.

Owner:MAZDA MOTOR CORP

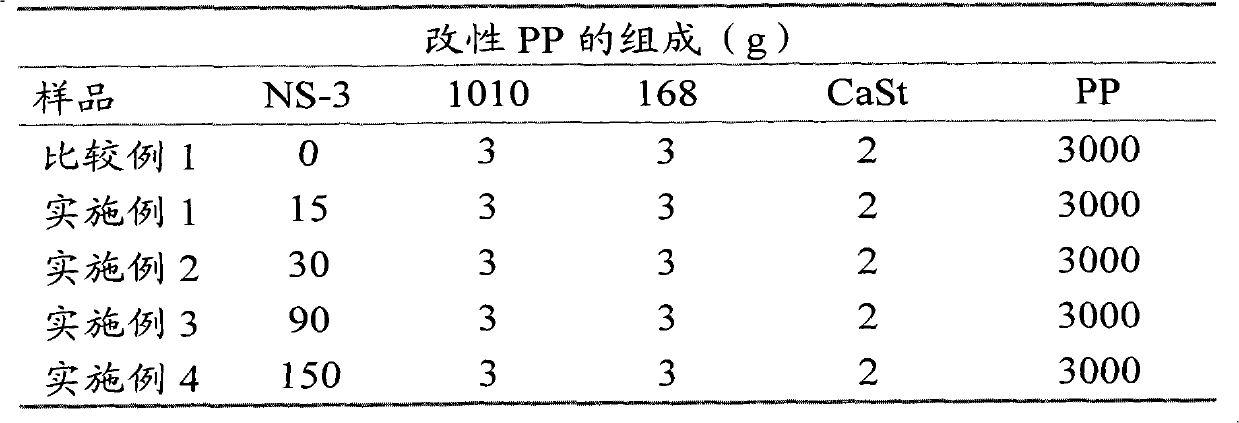

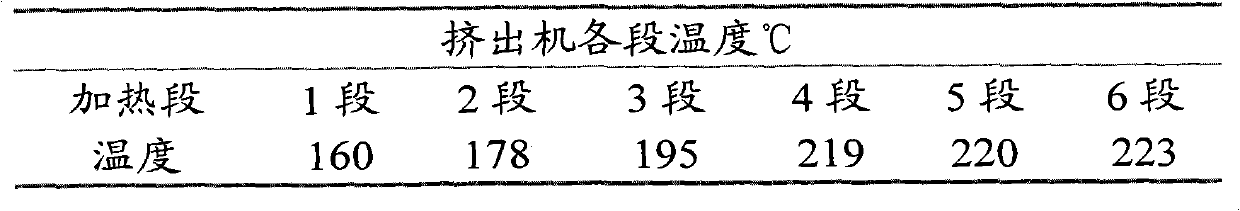

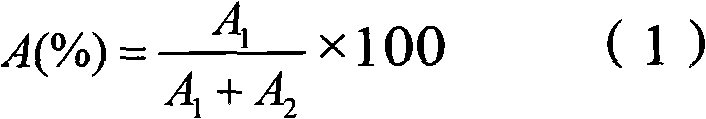

Nano-modified polypropylene soft packaging material

ActiveCN102020796AImprove mechanical propertiesImprove printing effectProcedure AgentsPolymer science

The invention provides a packaging polyolefin processing agent composition which is a mixture of nano silicon dioxide and ethylene-vinyl acetate copolymer, wherein the mass of the nano silicon dioxide accounts for 10-40% of the total mass of the processing agent composition, and the mass of the ethylene-vinyl acetate copolymer accounts for 60-90% of the total mass of the processing agent composition. The invention also provides packaging polyolefin modified by the processing agent composition. The modification of the nano silicon dioxide has greater influences on the mechanical property, the crystallization property, the polarity, the printing property, the composite property, the residue of organic solvent, and other indexes of the polypropylene. A result shows that after the polypropylene soft packaging material is subjected to nano modification, the toughness of the polypropylene soft packaging material is greatly enhanced; meanwhile, the polarity, the printing ink adhesive force and the peel strength of the material are improved; the adsorption of the modified polypropylene on toluene is greatly reduced. After nano modification, the using performance of the polypropylene used as the soft packaging material can be greatly improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Preparation method for element-doping manganese bioxide electrode material for super capacitor

InactiveCN101409152AEvenly distributedHigh specific capacitanceHybrid capacitor electrodesElectrolytic capacitorsCapacitanceHigh energy

The invention relates to a preparation method of an element doped manganese dioxide electrode material for a supercapacitor; the preparation method is characterized in that the high-energy ball milling method is adopted to mix any one of Al, Ti, Ni and Fe with manganese atoms in manganese dioxide according to the ratio of 0.05: 0.95 and then the mixture is placed in a high-energy ball milling tank, a ball milling medium is selected from agate balls with the different diameters, ratio of grinding media to material is 20:1, ethanol is added for preventing the agglomeration, the ball milling speed is 250 turns / minute, the ball milling time is controlled to be 15 hours; products are taken out after the ball milling tank is cooled to the room temperature, the drying at the constant temperature of 80 DEG C is carried out in a drying box for 48 hours; the powder after the drying is ground in an agate mortar to obtain the element doped manganese dioxide supercapacitor electrode material prepared by ball milling. The preparation method has low cost and simple preparation technology, the obtained element doped manganese dioxide electrode material has uniform distribution, high specific capacitance and good cycle stability; the preparation method can be applied in occasions which need power supply with neutral electrolyte, high stability and high power density.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Environment-friendly high-performance waterproof flame-retardant plastering mortar and preparation method thereof

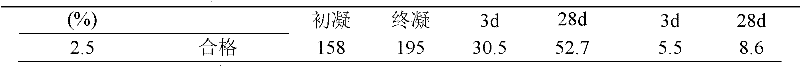

The invention relates to environment-friendly high-performance waterproof flame-retardant plastering mortar, which is prepared by mixing the following components of: P.O42.5R cement, modified phosphogypsum, redispersible latex powder, limestone powder, ceramic microspheres, modified expandable graphite, a water-retaining agent, a toughening agent and a water repellent in a mass ratio of (1-2):(0.4-0.9):(0.1-0.4):(0.1-0.5):(0.5-1):(0.25-1.5):(0.005-0.04):(0.005-0.01):(0.005-0.03). The environment-friendly high-performance waterproof flame-retardant plastering mortar has a great significance for high-efficiency flame retardance, heat insulation, water prevention, permeation resistance, composite heat preservation, energy conservation, the recycling of the phosphogypsum and the reduction in the pollution of solid wastes to environment, and has the advantages of low cost and high strength.

Owner:WUHAN UNIV OF TECH

Metal surface nanometer powder permeating method based on laser induction shock waves

The invention relates to a metal surface nanometer powder permeating method based on laser induction shock waves. The method comprises the following steps that base materials are pretreated; a machining surface is covered with an absorbing layer; a base metal surface is covered with the absorbing layer; a restraining layer is exerted on the base metal surface; pre-impact life-extension treatment is carried out on the base metal surface on which the restraining layer is exerted; impact life extension is carried out on the base metal surface subjected to the impact life extension treatment; and base metal materials are subjected to aftertreatment. In the process of covering the machining surface with the absorbing layer, in a clean room, a thin plate is taken, and an opening with the needed size and shape is shorn out in the middle; the thin plate is attached to the surface of the absorbing layer, and the middle of the thin plate is evenly coated with nanometer particles; and the rest is removed thoroughly, and a particle coating layer with the thickness equal to that of the thin plate is formed on the surface of the absorbing layer. According to the metal surface nanometer powder permeating method, a crystal structure, orientation distribution and metal surface elementary components on the base metal surface are obviously changed, the hardness, the fatigue life, the abrasion resistance and the corrosion resistance of the metal surface are effectively improved, operation is simple, and cost is low.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Composite metamorphic agent and composite metamorphic method of regenerative cast aluminum alloy

The invention discloses a composite metamorphic agent and a composite metamorphic method of a regenerative cast aluminum alloy, and relates to the technical field of metamorphism of cast aluminum alloys. The composite metamorphic agent is used for composite metamorphism of the regenerative cast aluminum alloy, and comprises a Mn agent, an Al-B intermediate alloy, and an Al-Sr intermediate alloy, wherein the Mn agent is an Al-Mn intermediate alloy or a Mn additive, and the appending proportion of the Mn agent is 30%-60% of the Fe content in the regenerative cast aluminum alloy; the additive amount of a B agent in the Al-B intermediate alloy is 0.01-0.05% of the melt mass of the regenerative cast aluminum alloy, and the additive amount of Sr in the Al-Sr intermediate alloy is 0.01-0.05% of the melt mass. According to the composite metamorphic agent, the purpose of synchronously refining three phases of alpha-Al, eutectic silicon, and an iron-rich phase can be achieved, thus the elongation of the alloy can be increased, and the composite metamorphic agent is especially suitable for composite metamorphism of a regenerative aluminum-silicon alloy with the high iron content.

Owner:GUANGDONG INST OF NEW MATERIALS

Method for enabling metal surface to penetrate nano powder by laser-induced impact

InactiveCN104947035ALow costSimple operation processSolid state diffusion coatingNanoparticleHardness

The invention belongs to the technical field of metal material surface treatment, and particularly relates to a method for enabling a metal surface to penetrate nano powder by laser-induced impact. The method comprises the following steps: coating on the surface of an absorption layer to form a nano particle coating layer, and covering the nano particle coating layer on a working end surface of a target material; applying a restraint layer on the absorption layer; enabling a to-be-treated substrate metal surface to face towards a laser beam, firstly carrying out pre-penetration treatment and then carrying out penetration treatment on the to-be-treated substrate metal surface; and enabling the substrate metal surface obtained by cleaning to penetrate into nano particles, thereby improving the hardness of the substrate metal surface. The method is simple in operation process, and is a metal surface treatment technology which is low in cost, efficient and green. According to the method, element components of the metal substrate surface are improved, the elements of the metal surface are re-distributed, and lattice distortion, dislocation and grain refinement are caused, so that the strength and the hardness of the metal surface are improved, and thus, the abrasion-resistance of a metal component is improved and a fatigue life of the metal component is prolonged.

Owner:SHENYANG LIGONG UNIV

Gas sensor element

InactiveUS7045047B2Improve conductivityLow activation temperatureWeather/light/corrosion resistanceVolume/mass flow measurementDc currentEngineering

A gas sensor element which may be employed in measuring the concentration of gas such O2, NOx, or CO. The gas sensor element consists of an electrochemical cell made up of a solid electrolyte body formed by a partially stabilized zirconia and a pair of electrodes disposed on the solid electrolyte body. The electrochemical cell is subjected to an aging treatment in which the dc current is applied to the electrodes at a given voltage to enhance the activation of the electrochemical cell.

Owner:DENSO CORP

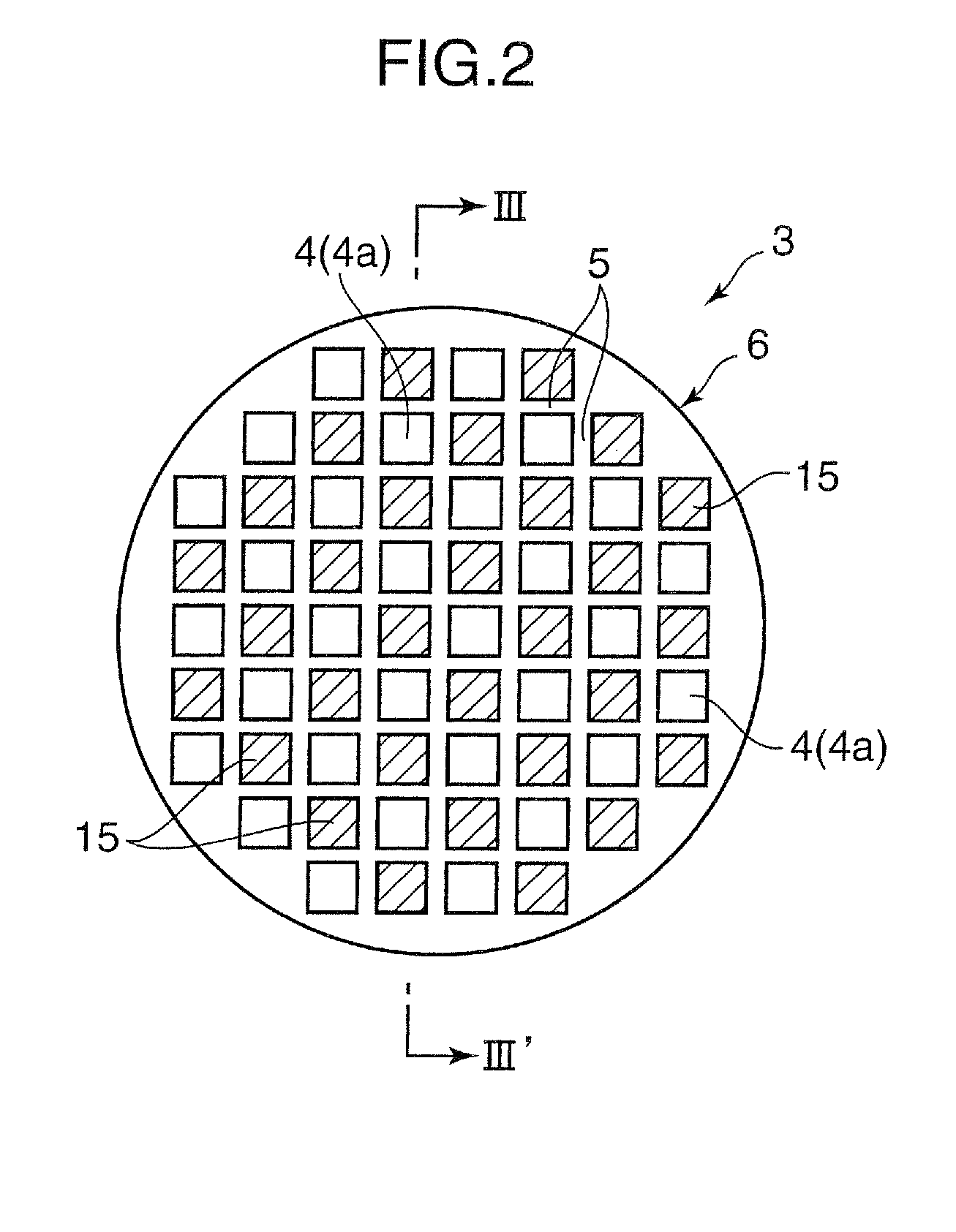

Method of producing n-type group-13 nitride semiconductor, method of forming current confinement layer, method of producing surface emitting laser, method of changing resistance of nitride semiconductor and method of producing semiconductor laser

InactiveUS20080220550A1Improve the immunityChange crystal structureSemiconductor/solid-state device manufacturingNanoopticsPhysical chemistryMaterials science

The object of the present invention is to provide a method of producing an n-type group-13 nitride semiconductor which enables resistance of the n-type group-13 nitride semiconductor to be changed, as well as, a method of producing a laser using the above method to produce a current confinement structure. There is provided a method of producing an n-type group-13 nitride semiconductor, including: preparing an n-type group-13 nitride semiconductor; and irradiating the n-type group-13 nitride semiconductor with light having a wavelength of 350 nm or more to 370 nm or less so as not to change a crystal structure of the n-type group-13 nitride semiconductor before and after the light irradiation, thereby increasing resistance of the n-type group-13 nitride semiconductor.

Owner:CANON KK

Particulate filter

Disclosed is a particulate filter, which is adapted to be disposed in an exhaust passage of an engine to trap particulate matter contained in exhaust gas discharged from the engine. The particulate filter comprises a filter body having a porous partition wall which defines a plurality of exhaust gas channels allowing the exhaust gas to pass therethrough, and a catalyst layer formed on a surface of the porous partition wall. The catalyst layer includes a Zr-based composite oxide which contains zirconium (Zr), and a rare-earth metal except cerium, wherein a content ratio of an oxide of the non-cerium rare-earth metal to a total amount of ZrO2 and the oxide of the non-cerium rare-earth metal in the Zr-based composite oxide is set in the range of greater than 33 mol % to less than 40 mol %. The particulate filter of the present invention can achieve a higher PM burning rate to burn PM within a shorter period of time. In addition, the higher PM burning rate makes it possible to provide enhanced fuel economy performance in an engine designed to perform a post-injection control.

Owner:MAZDA MOTOR CORP

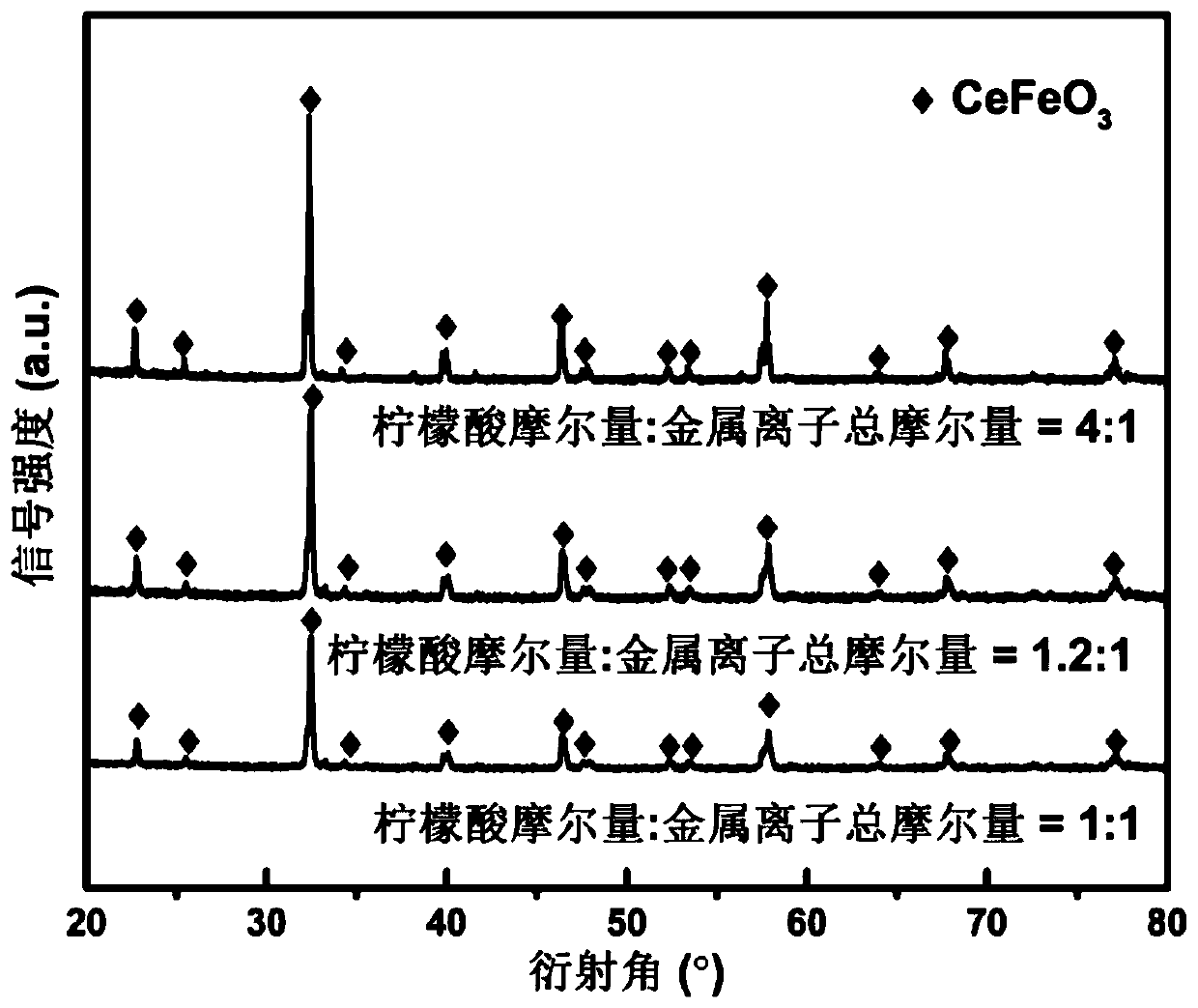

Perovskite type composite metal oxide oxygen carrier as well as preparation method and application thereof

ActiveCN110876938AEasy to prepareLow costHydrogenHeterogenous catalyst chemical elementsLanthanum nitrateCarbon dioxide

The invention belongs to the technical field of oxygen carriers, and discloses a perovskite type composite metal oxide oxygen carrier and a preparation method and application thereof. The perovskite type composite metal oxide oxygen carrier is of a perovskite structure, the general formula of the oxygen carrier is La<1-x>Ce<x>FeO<3>, and x is greater than 0 and less than or equal to 1. A sol-gel method is adopted in the preparation method, and the preparation method comprises the following steps: firstly, taking lanthanum nitrate, cerium nitrate and ferric nitrate as precursors, and preparinga solution from the precursors and a complexing agent; then evaporating to remove water, and converting an obtained transparent sol into a viscous gel; and aging and roasting to obtain the composite metal oxide oxygen carrier with a perovskite structure. When the perovskite type composite metal oxide oxygen carrier is chemical-looping methane reforming reaction, methane can be partially oxidized with high activity and high selectivity to prepare synthesis gas; meanwhile, the oxygen carrier is reduced to be in a low valence state, the reduced oxygen carrier can react with carbon dioxide or water vapor to be oxidized to be in a high valence state, lattice oxygen is obtained again, cyclic regeneration of the oxygen carrier is achieved, and meanwhile carbon dioxide is converted into carbon monoxide or the water vapor is converted into hydrogen gas.

Owner:TIANJIN UNIV +1

Steel pipe installing and expanding equipment with high-temperature heating and remodeling functions

InactiveCN104588520AThere will be no phenomenon of being stuck in the steel pipeFast expansionShaping toolsCouplingArchitectural engineering

The invention discloses steel pipe installing and expanding equipment with high-temperature heating and remodeling functions. The equipment comprises a base. The base is provided with a baffle, a transition rail, a rotating clamping device, a guide rail and a telescopic cylinder in sequence from left to right. A sliding block is movably connected to the guide rail. One end of the sliding block is connected with the output end of the telescopic cylinder. A number one motor is fixedly connected to the sliding block. An output shaft of the number one motor is connected with an expansion die through a coupler. A steel pipe is fixedly connected to the rotating clamping device and a clamping plate. The number one motor and the telescopic cylinder are matched to enable the expansion die to rotate while advancing, and the expansion speed of the steel pipe is increased; similarly, the phenomenon that the expansion die gets stuck in the steel pipe is avoided, the steel pipe rotates reversely under driving of a number two motor, and a spray gun is matched, so that the part, to be expanded, of the steel pipe is heated, the crystal structure in the part, to be expanded, of the steel pipe is changed, expanding is easier, and burst of the steel pipe is avoided.

Owner:杜玉华

Method for synthesizing SAPO-35 molecular sieve by using bi-template

ActiveCN101417811ALarge specific surface areaReduce intensityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesAlkaneCrystallinity

The invention discloses a method for synthesizing an SAPO-35 molecular sieve by a two-mode agent, which is characterized in that the method comprises the steps of mixing aluminum source, phosphorus source, silicon source and an organic template to glue at the temperature of room temperature to 100 DEG C and preparing into the reaction mixture with the molar ratio components of a1R1+a2R2: Al2O3: bP2O5: cSiO2: dH2O, wherein R1 and R2 are the organic templates, the value of a1 is 0.5-1.8, the value of a2 is 0.1-1.0, the value of b is 0.5-1.5, the value of c is 0.05-2.5, and the value of d is 10-150; the reaction mixture undergoes hydrothermal crystallization for 0.5-500 hours at the temperature of 150-250 DEG C and the crystallization product is recovered. The R1 is hexamethylene imine, and the R2 is any of cyclohexane, piperidine, tropine, diethylamine and triethylamine. The method provided by the invention can synthesize the high-crystallinity SAPO-35 molecular sieve in a relatively wide silica content range. The SAPO-35 molecular sieve synthesized by the method of the invention is applicable to the hydrocarbon conversion technology. Applied to the olefin preparation reaction by methanol dehydration, the molecular sieve has very low alkane selectivity and high product yield of ethylene and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biological straw feed preparation method

InactiveCN105614053AChange crystal structurePromote digestionAnimal feeding stuffAcetic acidDistilled water

The invention relates to a biological straw feed preparation method. The biological straw feed preparation method includes the following steps that 1, crushing is performed: a straw material is smashed by using a smashing machine; 2, pretreatment is performed: the smashed straw material obtained in the step 2 is pretreated, wherein the adopted temperature is 90-130 DEG C, a treating agent is dilute sulfuric acid, peracetic acid, a sodium hydroxide solution or quick lime, and the solid-liquid ratio is 1:10; 3, enzymolysis is performed: the straw material treated in the step 2 is cleaned with distilled water, is dried and then is put into a table for enzymolysis, wherein used enzyme is cellulase and xylanase, the temperature is 30-60 DEG C, the PH is 4-7, the enzyme adding amount is 200-350 u / g, the solid-liquid ratio is 1:10-1:7, and the rotating speed of the table is 100-160 rpm; 4, a biological straw feed is obtained through drying. The biological straw feed can replace or partly replace the corn in a traditional basic diet and plays a positive promoting role on feed digestion.

Owner:TIANJIN ZHONGLIAN FEED CO LTD

High-wear-resistance regenerative aluminum alloy and preparation method and application thereof

The invention provides high-wear-resistance regenerative aluminum alloy and a preparation method and application thereof, and relates to the technical field of aluminum alloy. The high-wear-resistanceregenerative aluminum alloy mainly comprises the following components: 7.0-12.0% of Si, 1.2-5.0% of Fe, 0.5-1.5% of Mn, 0.1-0.4% of Mg, 0.03-0.06% of B, 0.05-0.30% of RE, 0.01-0.06% of Sr, 0-0.15% ofimpurity elements and the balance of Al. The preparation method of the high-wear-resistance regenerative aluminum alloy comprises the following steps: melting waste aluminum materials; adjusting components of molten aluminum according to the requirements for the components; then adding intermediate alloy such as Al-B, Al-Sr and Al-RE according to the ratio; and refining and standing, and then pouring into ingots or tundish. By a composite modification technology, regenerated aluminum which contains an iron-rich phase with high volume fraction is prepared, and the wear resistance of the alloyis greatly improved. The high-wear-resistance regenerative aluminum alloy has the advantages of simple process, low cost and the like.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

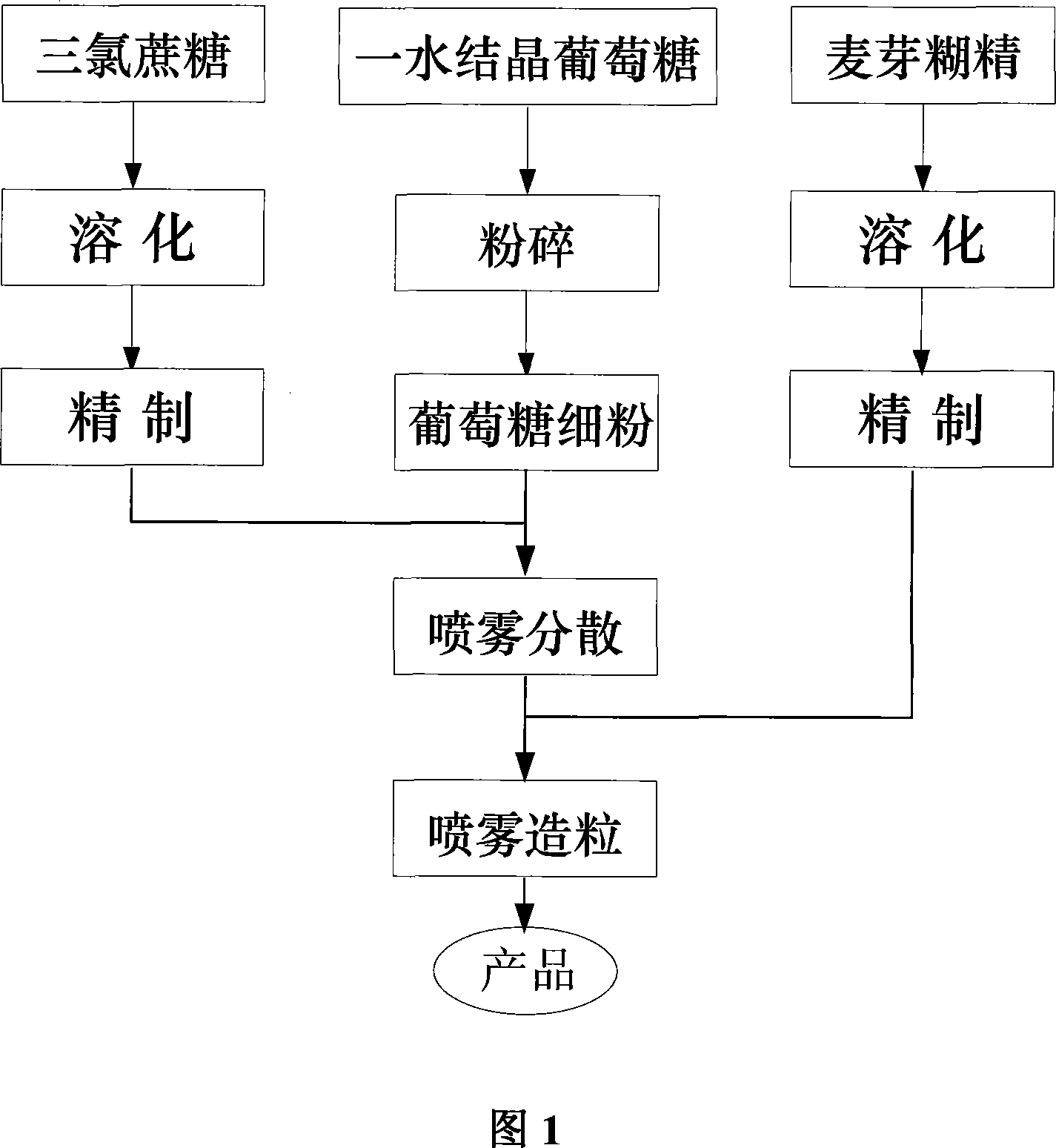

Sucrose succedaneum and preparation method thereof

InactiveCN101181050AHighlight substantive featuresSignificant progressFood preparationSucroseAdditive ingredient

The invention provides a cane sugar substitute and the preparation method of the substitute, of which the elements are: 90 percent to 97 percent of glucose, 2 percent to 8 percent of maltodextrin and 0.5 percent to 3 percent of sucralose. The technique is that: the maltodextrin and the sucralose are added into a vessel to mix with deionized water, then the temperature is raised to 50 DEG C to 65 DEG C for dissolution and the mixture is stirred, then active carbon is added and the mixture is kept warm for 40 minutes to 50 minutes and filtered when still being warm, and the filtrate respectively is converged to a reserve tank which is provided with jacket heating; the glucose is crushed and sent to a spraying fluidized-bed with the temperature of the bed layer being 30 DEG C to 85 DEG C, and the well prepared sucralose solution is firstly pumped in and continuously sprayed for decentralization, then the well prepared maltodextrin solution is pumped in and continuously sprayed for granulating, and the cane sugar substitute with good decorated surface is prepared. The proposal takes glucose and sucralose as main raw materials to make the sweetness of the product be 2 times to 12 times of the sweetness of ordinary cane sugar by making sweetness decoration and packing on the surface. The preparation process of the invention is easy and simple, thereby being applicable for scale production.

Owner:DALIAN SANTAI BIOLOGICAL TECH

High-CTI flame-retardant polycarbonate alloy material, preparation method and applications thereof

The invention discloses a high-CTI flame-retardant polycarbonate alloy material, a preparation method and applications thereof. The high-CTI flame-retardant polycarbonate alloy material is prepared from the following raw materials in percentage by weight: 55-95% of polycarbonate, 1-40% of syndiotactic polystyrene, 0.01-5% of a nucleating agent, 1-10% of a toughening agent and 0.05-2% of a flame retardant, wherein the nucleating agent is one or a plurality of materials selected from nano CaCO3, nano titanium dioxide, nano clay, kaolin, mica powder, carbon nanotubes, organic silicon rubber, talcum powder and magnesium-aluminum hydrotalcite. The nucleating agent system can achieve a synergistic effect, promote syndiotactic polystyrene crystallization and change of a crystal form structure, further endow the polycarbonate alloy material with a high CTI value, and maintains the flame retardant property and the mechanical property of the polycarbonate alloy material. The high-CTI flame-retardant polycarbonate alloy material is applicable to the fields of household appliances, wall switches and charging piles.

Owner:WANHUA CHEM GRP CO LTD +1

Preparation method of naphthalimide-based metal organic framework film, and application of naphthalimide-based metal organic framework film in hydrazine hydrate detection

ActiveCN110643049AChange crystal structureEasy to identifyMaterial analysis by observing effect on chemical indicatorHydration reactionMetal-organic framework

The invention belongs to the field of porous material synthesis and application, and particularly relates to a preparation method of a naphthalimide-based metal organic framework film, and an application of the naphthalimide-based metal organic framework film in hydrazine hydrate detection. The naphthalimide-based metal organic framework film is prepared from a ligand containing a naphthalimido group, zinc nitrate hexahydrate, N,N-dimethylformamide, water, ethanol and an FTO glass coated with nanometer zinc oxide in a disposable scintillation bottle by a hydrothermal technology. The prepared film has a good recognition effect on hydrazine hydrate steam. The method has the advantages of novelty, uniqueness, simple experimental steps are simple, avoiding of a complex post-treatment process,and obtaining of the required film through a one-step reaction, and the prepared film provides a good application prospect for the material in the fields of ion recognition and the like.

Owner:FUZHOU UNIV

Method for preparing phosphinic acid modified aluminum hydroxide flame retardant agents

InactiveCN102329525AImprove flame retardant performanceGood compatibilityPigment treatment with non-polymer organic compoundsEpoxyOrganic solvent

The invention discloses a method for preparing phosphinic acid modified aluminum hydroxide flame retardant agents, which is characterized by comprising the following steps that: the aluminum hydroxide is taken, the organic solvent glacial acetic acid is taken according to the proportion being 10 to 15 times of the mass of the aluminum hydroxide, and the organic phosphinic acid is taken according to the mol ratio of the aluminum hydroxide to the organic phosphinic acid of 1 / 1.0 to 2.0; the aluminum hydroxide is dispersed in the organic solvent glacial acetic acid, the organic phosphinic acid is added into the aluminum hydroxide dispersing liquid during stirring, the reaction is carried out for 24 to 36h at the room temperature to 80 DEG C after the nitrogen gas is introduced for 10 to 30 minutes, and reacted materials are obtained; and the reacted materials are filtered while being hot, solid materials are washed and dried, and the phosphinic acid modified aluminum hydroxide flame retardant agents are prepared. When the method is adopted, the prepared phosphinic acid modified aluminum hydroxide flame retardant agents have better heat stability and hydrophobicity and are used in epoxy resin composite materials, the mechanical performance and the like of the composite materials are obviously improved, and the flame retardant performance is good.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Iron-rich phase modifier as well as preparation method and modification method thereof

The invention relates to the technical field of iron-rich phase modification. An iron-rich phase modifier comprises the following components by mass: 4.5-7.0% of Si, 2.5-5.0% of Fe, 0.7-1.4% of Mn, 0.03-0.1% of B, 0-0.15% of impurity elements and the balance of Al, wherein a preparation method of the iron-rich phase modifier comprises the following steps: placing Al, Al-Si, Al-Fe and Al-Mn in a melting furnace at a proportion for melting, then adding an Al-B intermediate alloy, and pouring the melt to form round ingots after degassing, impurity removal, heat preservation and standing, and slagging; the ingots are thermally extruded and processed to prepare an alloy rod after turning, sectioning and homogenizing treatment; and a modification method comprises the following steps: melting aniron-containing aluminum alloy, then adding the modifier, stirring, and then refining, standing, slagging and pouring to form ingots or performing production. According to the invention, a modification process is simplified, the impurity elements are reduced, and the dosage of the modifier is reduced.

Owner:GUANGDONG INST OF NEW MATERIALS

A kind of high wear-resistant secondary aluminum alloy and its preparation method and application

The invention provides high-wear-resistance regenerative aluminum alloy and a preparation method and application thereof, and relates to the technical field of aluminum alloy. The high-wear-resistanceregenerative aluminum alloy mainly comprises the following components: 7.0-12.0% of Si, 1.2-5.0% of Fe, 0.5-1.5% of Mn, 0.1-0.4% of Mg, 0.03-0.06% of B, 0.05-0.30% of RE, 0.01-0.06% of Sr, 0-0.15% ofimpurity elements and the balance of Al. The preparation method of the high-wear-resistance regenerative aluminum alloy comprises the following steps: melting waste aluminum materials; adjusting components of molten aluminum according to the requirements for the components; then adding intermediate alloy such as Al-B, Al-Sr and Al-RE according to the ratio; and refining and standing, and then pouring into ingots or tundish. By a composite modification technology, regenerated aluminum which contains an iron-rich phase with high volume fraction is prepared, and the wear resistance of the alloyis greatly improved. The high-wear-resistance regenerative aluminum alloy has the advantages of simple process, low cost and the like.

Owner:GUANGDONG INST OF NEW MATERIALS

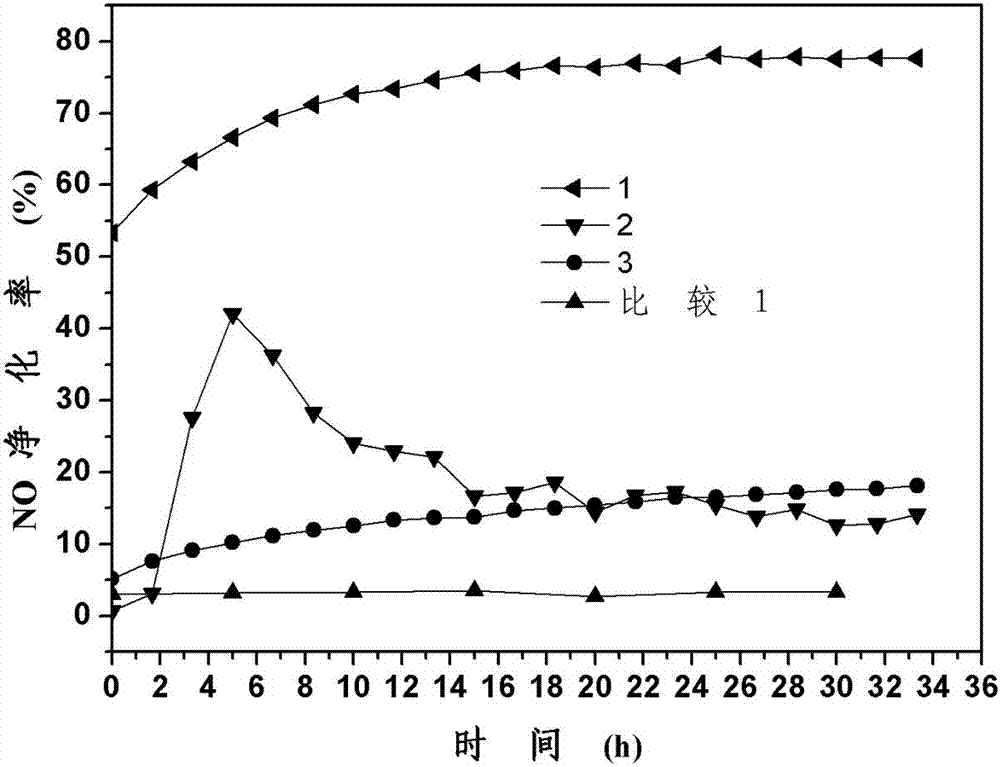

A kind of monolithic chromium oxide catalyst for alkali treatment and its preparation method and application

InactiveCN103657632BHigh activityImprove stabilityDispersed particle separationCatalyst activation/preparationPtru catalystCatalytic oxidation

The invention relates to an alkali liquor treated integral chrome oxide catalyst, a preparation method and an application. According to the catalyst, an active ingredient chrome is soaked to an inert carrier cordierite honeycomb ceramic with a soaking method, the specific surface area of the integral catalyst is increased with an alkali liquor treatment method after drying and roasting, the chemical state of the active ingredient is changed, the active site is increased, and NO catalytic oxidation reactivity and the long-time stability under normal pressure and temperature are improved. According to the catalyst, the preparation method and the application, the process is simple, raw materials are easy to obtain, and engineering application is realized.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of temperature-resistant iron oxide yellow

The invention discloses a preparation method of temperature-resistant iron oxide yellow. The preparation method comprises the following steps: 1. adding iron oxide yellow, zinc oxide, aluminum hydroxide and basic carbonate into a mixing machine according to the mass ratio of 70:(20-40):(1.5-3.5):(0.5-2.0), mixing for 0.5-2 hours, uniformly pulverizing the mixture in a jet mill, and mixing in the mixing machine for 0.5-2 hours until all the substances are mixed thoroughly and uniformly; and 2. calcining the mixture obtained in the step 1 at 700-1000 DEG C for 2-6 hours, and mixing in the mixing machine for 10-20 minutes, thereby obtaining the temperature-resistant zinc iron yellow product. The temperature-resistant zinc iron yellow produced by the method has the advantages of high staining power and bright color. Other metal ions are doped to change the original crystal structure of common ferrite yellow, so that the temperature resistance can reach 250-280 DEG C.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Method for producing lithium ion battery negative electrode material by asphalt secondary coating process

ActiveCN109473678AHigh specific capacityImprove the first charge and discharge efficiencyCell electrodesMetallurgyMicrometer

The invention proposes a method for producing a lithium ion battery negative electrode material by an asphalt secondary coating process. By the method, the problem that the electrochemical performanceof the lithium ion battery negative electrode material in the prior art is solved. The method comprises the following sequential steps of S1, mixing needle coke after being smashed and asphalt powderwith grain size being 20-40 micrometers for 20-30 minutes by a mixing machine to obtain a mixture A; S2, performing surface modification and fusion on the mixture A to obtain a primary asphalt coating material, allowing the primary asphalt coating material to enter a furnace for high-temperature graphitization at 800 DEG C under protection of high-pure N2, and cooling to a room temperature to obtain a material B; S3, smashing and classifying the material B, and mixing the material and asphalt powder with grain size being 2-5 micrometers again for 30-40 minutes by the mixing machine to obtaina material C; and S4, fusing the material C to obtain a secondary asphalt coating material, sending the secondary asphalt coating material to another one furnace for high-temperature carbonization at3,000 DEG C under protection of high-pure N2, and removing tar contained in the material C, thereby obtaining the lithium ion battery negative electrode material.

Owner:WEIFANG HUICHENG NEW MATERIAL TECH

Monolithic chromium oxide catalyst as well as preparation method and application thereof

InactiveCN103990448AEfficient oxidationHigh activityDispersed particle separationCatalyst activation/preparationCatalytic oxidationCordierite

The invention discloses a preparation method for a monolithic chromium oxide catalyst. The preparation method comprises the following steps: preparing a monolithic catalyst provided with a chromium oxide coating by adopting an impregnation method: weighing a chrome precursor and dissolving the chrome precursor in deionized water, stirring the solution at normal temperature, pouring the chrome precursor on a cordierite honeycomb ceramic carrier after the chrome precursor is dissolved uniformly, after the cordierite honeycomb ceramic carrier is impregnated repeatedly, drying at 100 DEG C, and roasting for 4 hours at 300 DEG C to obtain the monolithic catalyst provided with the chromium oxide coating; preparing the monolithic chromium oxide catalyst by an alkaline liquid processing method: soaking the monolithic catalyst provided with the chromium oxide coating prepared by the step (1) in an alkaline liquid in an excessive impregnating way, wherein the PH of the alkaline liquid is 8 to 10, soaking the monolithic catalyst provided with the chromium oxide coating, roasting the monolithic catalyst provided with the chromium oxide coating for 2 to 6 hours after being dried for 12 hours, thereby obtaining the alkaline liquid surface processed monolithic chromium oxide catalyst. The catalytic oxidation of a NO reaction at normal temperature is realized; NO can be eliminated at the normal temperature; the engineering application is realized. The catalyst disclosed by the invention has a good application prospect because raw materials are easily available and the process is simple.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Liquid crystal display device and manufacturing method thereof

InactiveCN107065344AChange crystal structureReduce manufacturing costPrinted circuit aspectsSolid-state devicesLiquid-crystal displayEngineering

Owner:SAMSUNG DISPLAY CO LTD

PLGA (Poly Lactic-co-Glycolic Acid)-gelatin composite microspheres carrying genistein and preparation method thereof

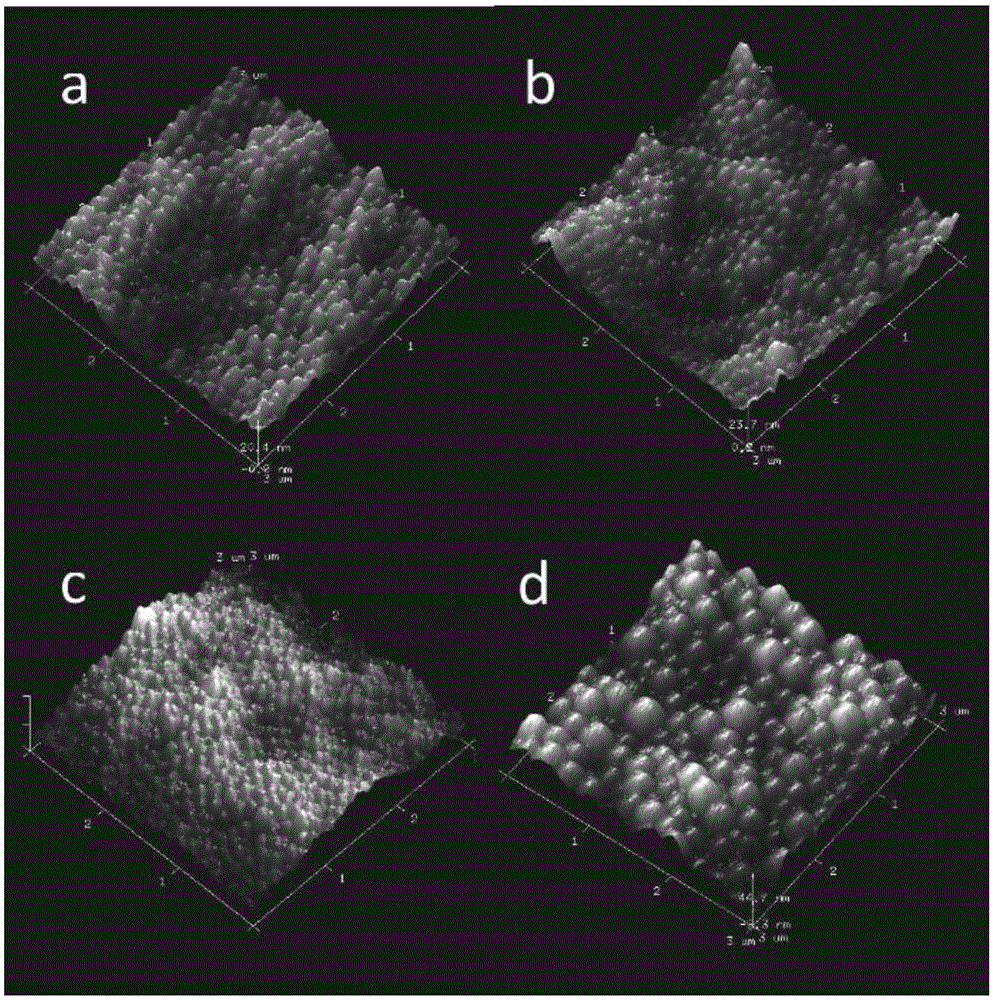

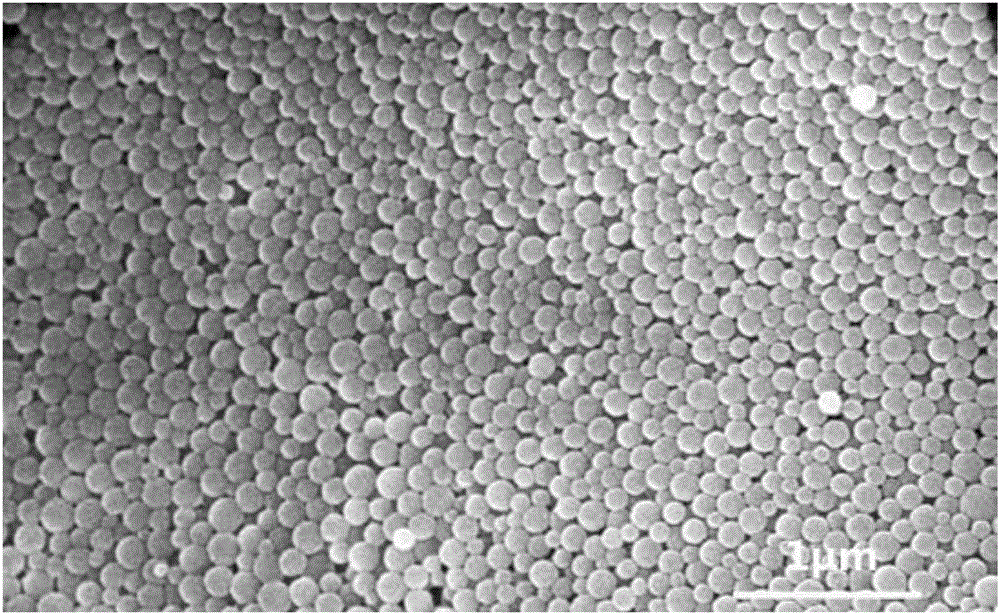

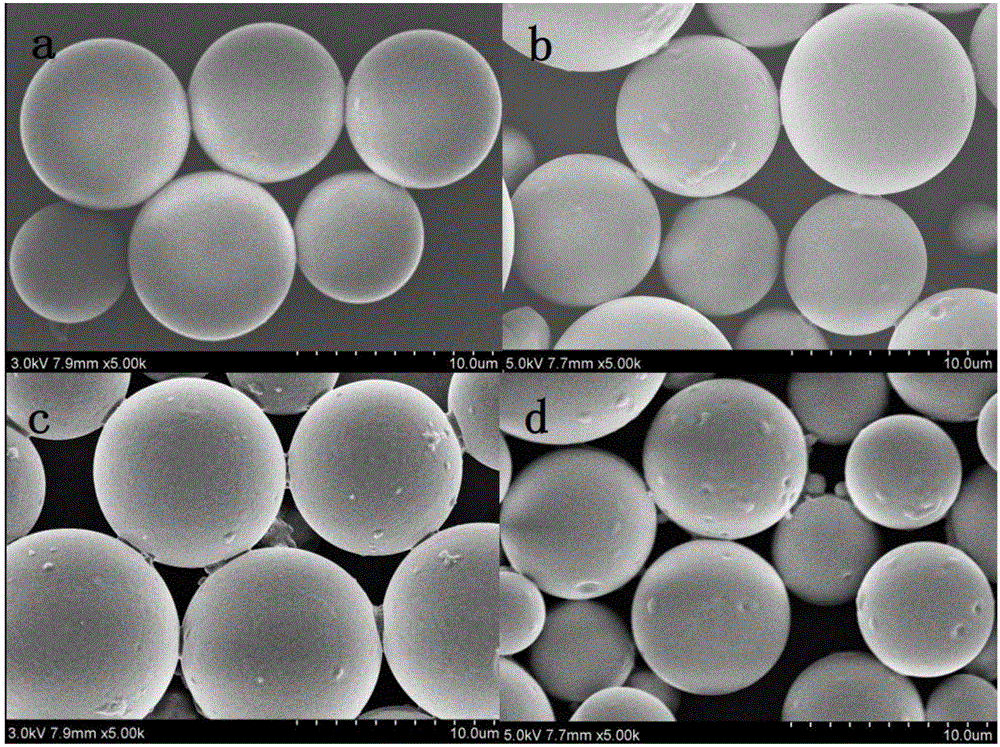

InactiveCN106727361ACombined orderlyGood emulsificationOrganic active ingredientsSkeletal disorderControlled releaseMicrosphere

The invention discloses PLGA (Poly Lactic-co-Glycolic Acid)-gelatin composite microspheres carrying genistein and having a controlled-release effect and a preparation method thereof, and belongs to the technical field of biomedical materials. The method comprises the following steps: preparing gelatin nanoparticles by a two-step desolvation method; adsorbing the genistein in the gelatin nanoparticles; entrapping the gelatin nanoparticles adsorbing drugs in PLGA microspheres by an improved S / O / W method to prepare the PLGA-gelatin composite microspheres carrying the genistein, which have the advantages of high drug loading capacity, capability of overcoming burst release of drugs and uniform particle sizes and are applied in the field of drug delivery. The obtained PLGA-gelatin composite microspheres carrying the genistein are white or faint yellow in appearance, and are 3 to 8mu m in particle sizes, the particles are dispersed, and adhesion is prevented; the highest drug loading amount of the genistein is about 12.1 percent by weight. The gelatin nanoparticles prepared in a preparing process are 60 to 300 nanometers in particle sizes, drugs are released hardly within 24 hours, and the release rate of the genistein is about 80 percent within 20 days along with the degradation of the composite microspheres.

Owner:JILIN UNIV

Industrial pure lead with liquid oxidation resistance and application thereof

InactiveCN101633988AImprove antioxidant capacityReduce surface oxidationAntioxidant capacitySurface oxidation

The invention relates to an industrial pure lead product, in particular to industrial pure lead with liquid oxidation resistance and application thereof. A main method is to add certain antioxidative microelements (selected from one or a compound of Zn, Ag, Cu, Al, Ge and Sn) in the common industrial pure lead so as to improve the antioxidant capacity of the surface of liquid lead at atmosphere pressure. The industrial pure lead product with the liquid oxidation resistance can be widely applied to preparing alloys taking Pb as a main raw material, such as Sn-Pb solder, grids of lead-acid accumulators, lead base Babbitt and the like, can reduce the surface oxidation and slag forming quantity of the alloys in industrial smelting, and achieves the aim of reducing lead loss caused by oxidation in the alloy smelting process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com