Nano-modified polypropylene soft packaging material

A polypropylene resin and modification technology, which is applied in the field of nano-modified polypropylene flexible packaging materials, can solve the problems of high surface resistance of PP films, excessive organic solvents, poor ink adhesion, etc., and achieve no food safety hazards and composite performance Improvement and surface resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] 1.1.1 Preparation of nano-silica (model NS-2):

[0078] Adding 120 grams of EVA emulsion with a solid content of 50% in a 500-milliliter four-necked bottle equipped with an electric stirrer, a thermometer, and a dropping funnel, the temperature of the system is controlled at 40° C. Add 30 grams of water glass (the Baume degree is 40 ° Be, the modulus is 3.5) dropwise from the dropping funnel within 30 minutes to the above-mentioned system, and mix for 1 hour. Add 10% (v%) sulfuric acid aqueous solution dropwise into the system from the dropping funnel until the system pH=4, and continue stirring for 1 hour. Pour the precipitate into 1 liter of distilled water, wash the precipitate, then let it stand still, pour off the supernatant; then add distilled water, stir for 10 minutes, let it stand, pour off the supernatant again, until it is washed without sulfate radicals ion. The slurry obtained is ground with a colloid mill, then spray-dried and pulverized to obtain EVA-m...

Embodiment 1~4

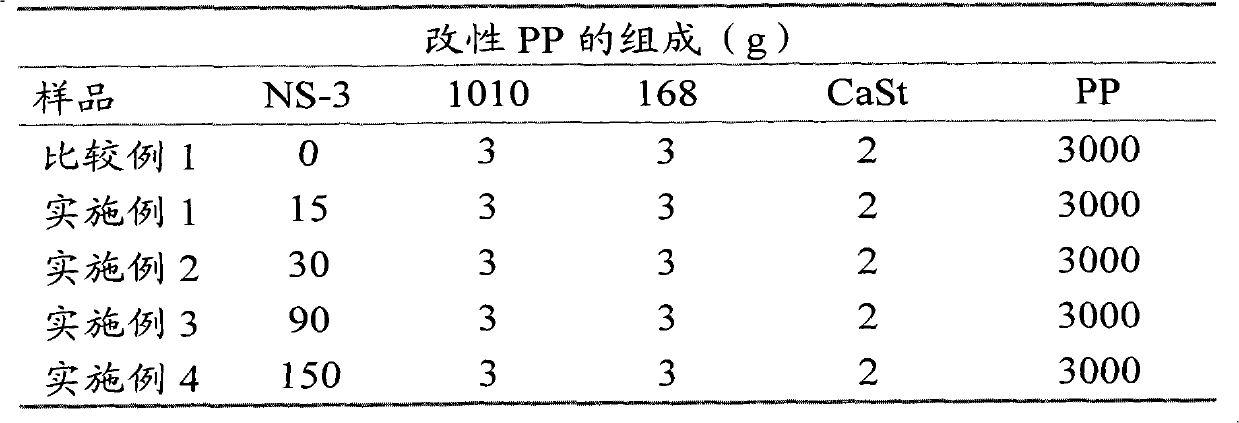

[0090] Examples 1-4: Preparation of modified PP resin samples

[0091] Blend polypropylene resin with NS-3 type nano-silica modifier, antioxidant 1010, antioxidant 168 and calcium stearate (referred to as CaSt) in proportion (see Table 1) in a high-speed mixer 5 minutes. Wherein Comparative Example 1 did not add nano-silica, and Examples 1-4 added NS-3 type nano-silica at 0.5 wt %, 1.0 wt %, 3.0 wt % and 5.0 wt %, respectively.

[0092] Table 1 Composition of modified and unmodified PP

[0093]

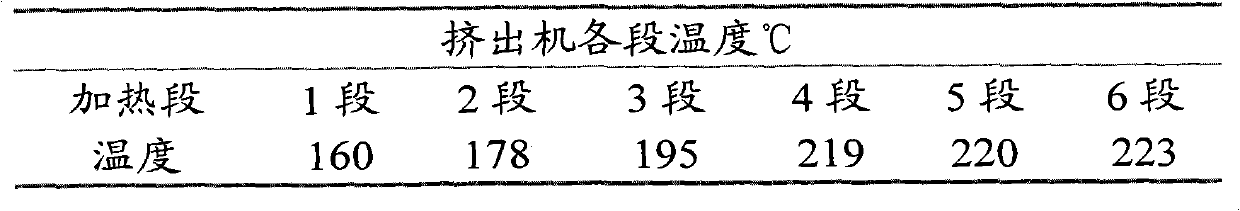

[0094] After mixing the above-mentioned raw materials, the nano-modified PP resin was obtained by melt co-extrusion on a twin-screw extruder, and the temperature control of the extruder was shown in Table 2.

[0095] Table 2 Melt extrusion temperature of modified and unmodified PP

[0096]

[0097] Using a plastic injection molding machine, the modified PP samples and the unmodified PP resin samples were injected to make samples; or a flat vulcanizer was used to make samples ...

Embodiment 1

[0116] Example 1 is the modified PP when the addition amount of NS-3 type nano-silica is 0.5wt%. Compared with the sample of Comparative Example 1, its toughness is greatly improved, and the tensile strength is similar. The elongation at break increased by nearly 4 times, the Young's modulus and fracture stress increased by 7% and 30%, respectively, and the tensile yield stress was almost unchanged; the melting temperature increased by nearly 3 °C, and the melting enthalpy (crystallinity) increased by 38%. %; the contact angle with water is reduced by 8°; due to the improvement of the polarity of the sample in Example 1, its ink adhesion is increased by 55%, and the peel strength with the pressure-sensitive tape is increased by 14%; the dynamic friction coefficient is reduced by 15%, and the static friction coefficient The change is not obvious; the toluene residue is reduced by 91%; the surface resistance is reduced by 36%. It shows that when the nano-silica modified PP, when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com