Polyvinyl alcohol capable of being subjected to melting processing modification, and preparation method thereof

A technology of polyvinyl alcohol and melt processing, which is applied in the field of modified polyvinyl alcohol and its preparation, can solve the problems of reduced regularity of molecular chains of modified polyvinyl alcohol, reduced crystallization ability, and small melt index, etc., and achieves good mechanical properties , Improve fluidity, increase the effect of melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 200g of vinyl acetate and 40g of vinyl decanoate into 160g of methanol solution in which 0.24g of azobisisobutyronitrile is dissolved, stir and mix evenly, then react in a water bath at 65°C for 5h, raise the temperature to 75°C, Add 50g of methanol once to blow off, the number and time of adding methanol are determined according to the actual situation, and blow off for 3h to end the reaction.

[0039] Take 200g of the above solution, and add 550g of methanol to make the concentration of modified vinyl acetate reach 10%, then add 0.09g of sodium hydroxide to react at 45°C, break up after gelation, and react for a total of 45min. The product is washed with methanol and filtered. The thermoplastic processability modified polyvinyl alcohol can be obtained by vacuum drying at 60°C.

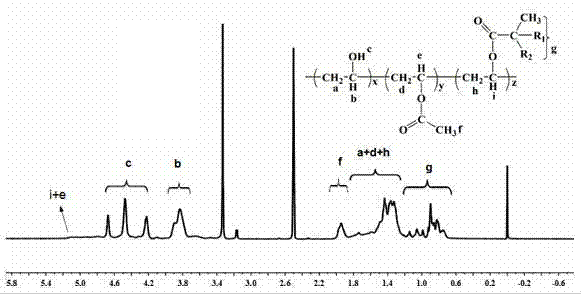

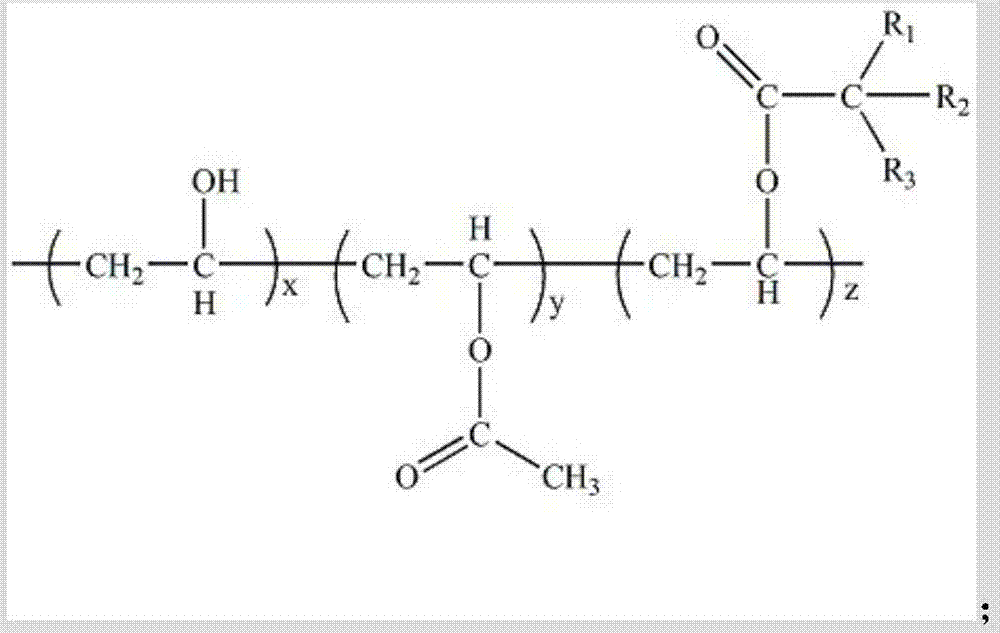

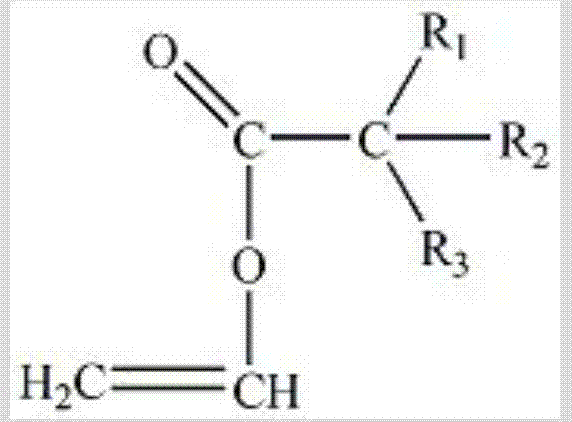

[0040] The proton nuclear magnetic resonance spectrum figure of the modified polyvinyl alcohol prepared in embodiment 1 is shown in figure 1 , it can be proved by this figure that long-ch...

Embodiment 2

[0044]Add 200g of vinyl acetate and 32g of vinyl nonanoate into 160g of methanol solution in which 0.24g of azobisisobutyronitrile is dissolved, stir and mix evenly, then react in a water bath at 45°C for 5h, raise the temperature to 75°C, and Add 50g of methanol once to blow off, the number and time of adding methanol are determined according to the actual situation, and blow off for 4h to end the reaction.

[0045] Take 200g of the above solution, and add 510g of methanol to make the concentration of modified vinyl acetate reach 12%, then add 0.09g of sodium hydroxide to react at 45°C, break up the gel, react for a total of 52min, wash and filter the product with methanol, and The thermoplastic processability modified polyvinyl alcohol can be obtained by vacuum drying at 60°C.

[0046] The melting point of the modified polyvinyl alcohol is 187°C, the decomposition temperature is 266°C, the degree of polymerization is 710, the degree of alcoholysis is 88%, and the melt index ...

Embodiment 3

[0049] Add 200g of vinyl acetate and 22g of vinyl decanoate into 117g of an ethanol solution in which 0.13g of azobisisoheptanonitrile is dissolved, stir and mix evenly, then react in a water bath at 65°C for 5h, raise the temperature to 75°C, and Add 50g of ethanol once to blow off, the number and time of adding methanol are determined according to the actual situation, and blow off for 3h to end the reaction.

[0050] Take 200g of the above solution, and add 532g of ethanol to make the concentration of modified vinyl acetate reach 10%, then add 0.10g of potassium hydroxide to react at 45°C, break up the gel, react for a total of 56min, wash and filter the product with ethanol, and The thermoplastic processability modified polyvinyl alcohol can be obtained by vacuum drying at 60°C.

[0051] The melting point of the modified polyvinyl alcohol is 192°C, the decomposition temperature is 290°C, the degree of polymerization is 960, the degree of alcoholysis is 91%, and the melt in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com