Wear-resistant self-lubricating thermoplastic polyimide composite material and preparation method thereof

A polyimide and composite material technology, applied in the field of polymer composite materials, can solve the problems of poor thermoplastic processing performance, difficult processing of thermoplastic processing equipment, etc., to improve melt viscosity, improve thermoplastic processability, and expand application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

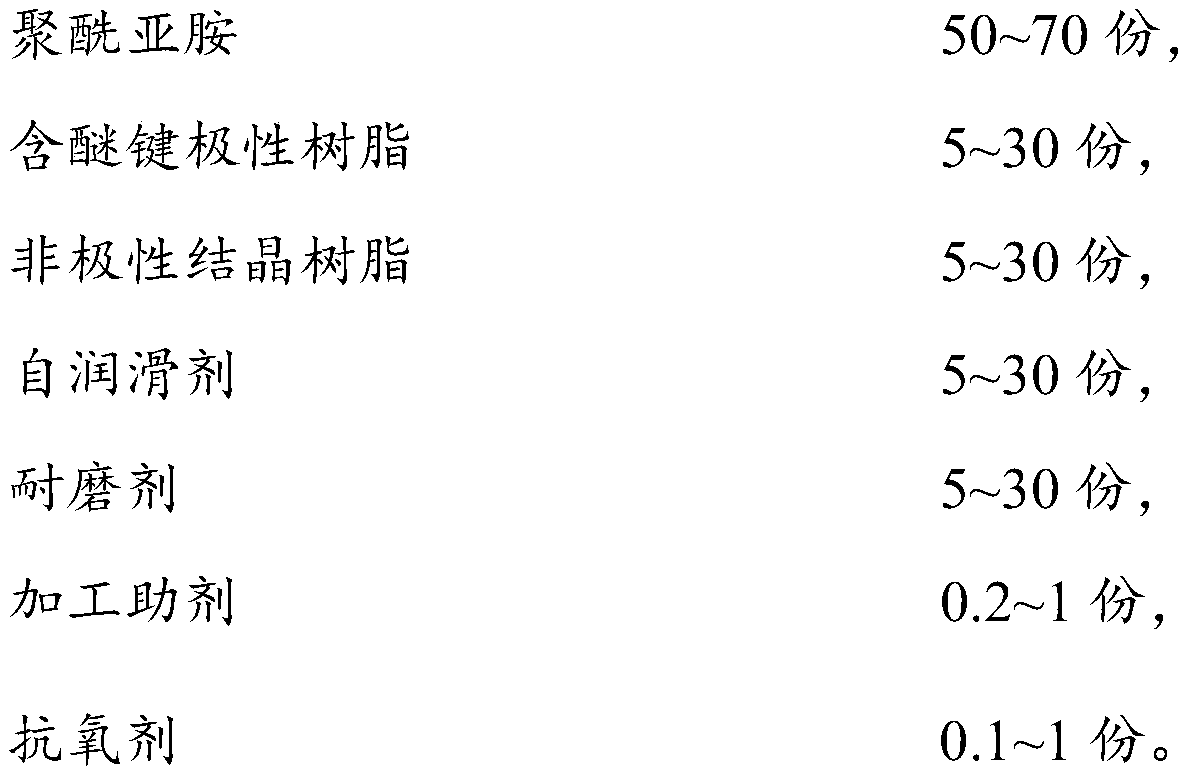

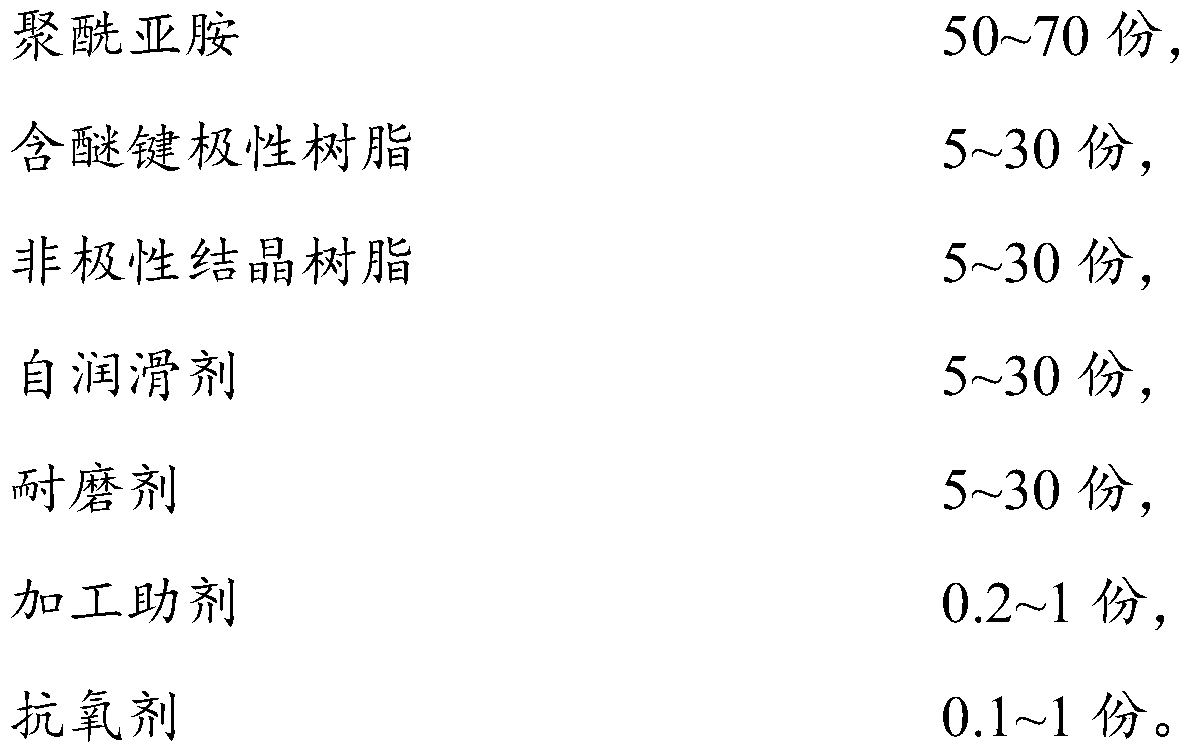

Method used

Image

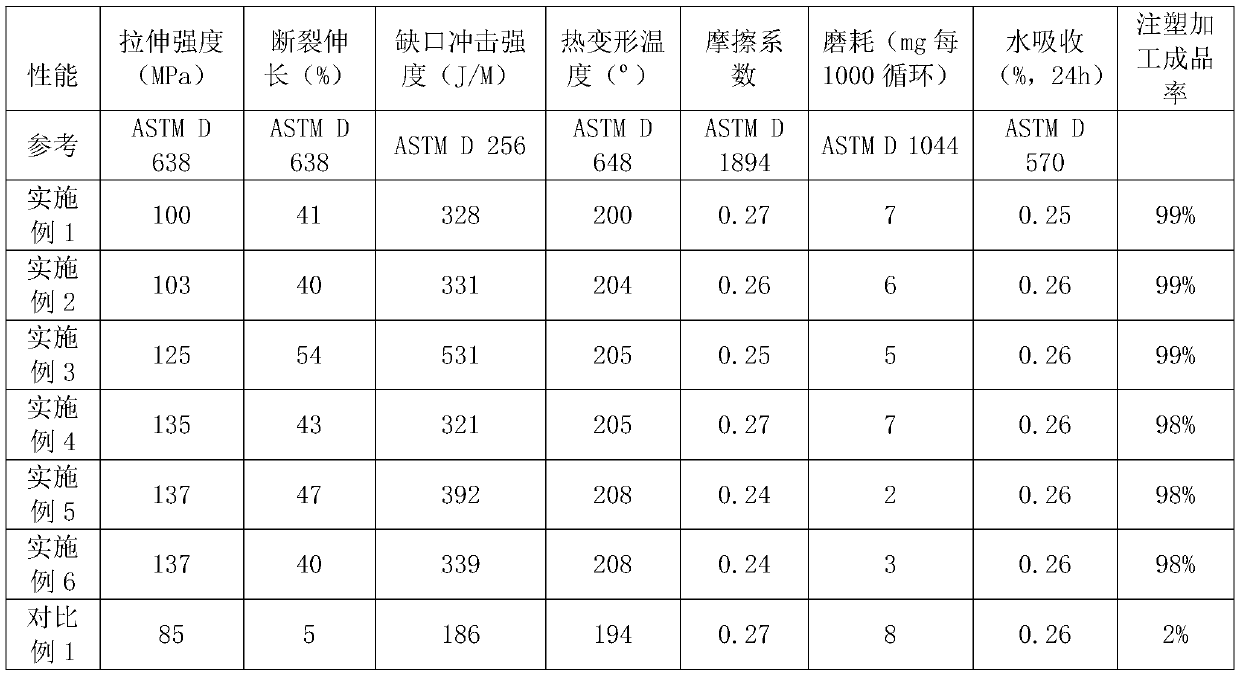

Examples

preparation example Construction

[0041] On the basis of the above, the present application further provides a method for preparing a wear-resistant self-lubricating thermoplastic polyimide composite material, comprising the following steps:

[0042]S1. Weigh polyimide, ether bond-containing polar resin, non-polar crystalline resin, self-lubricating agent, wear-resistant agent, processing aid and antioxidant according to the aforementioned parts by weight and mix to obtain a mixture,

[0043] S2. Add the mixture into the main feed of the twin-screw extruder, add the reinforcing fiber into the side feed of the twin-screw extruder, and draw it out from the outlet of the die after melt extrusion. Pelletizing after water cooling to obtain wear-resistant self-lubricating thermoplastic polyimide composite particles, wherein the melt extrusion temperature of the twin-screw extruder is 300-380° C., and the screw speed is 250-350 rpm / min.

Embodiment 1

[0046] S1. Weigh 50 parts of polyimide (Ningbo Institute of Chinese Academy of Sciences), 5 parts of polyethersulfone, 30 parts of polypropylene, 5 parts of polytetrafluoroethylene powder, 5 parts of graphite, 0.2 part of PETS, 0.8 part of anti- 1010, mix uniformly to obtain a mixture.

[0047] S2. Add the mixture to the main feed of the twin-screw extruder, add 5 parts of glass fiber to the side feed of the twin-screw extruder, melt and extrude it from the outlet of the die head, and pelletize it after water cooling to obtain High wear-resistant self-lubricating thermoplastic polyimide composite particles.

[0048] Wherein, the melt extrusion temperature of the twin-screw extruder is 300-350° C., and the screw speed is 250 rpm / min.

[0049] Put the granular material into the barrel of the injection molding machine. The temperature of the barrel is about 350-380°C. After heating, melting, and plasticizing, it is injected into the mold under the strong push of the screw or plu...

Embodiment 2

[0051] S1. Weigh 50 parts of polyimide (Changchun Gaoqi), 15 parts of polyphenylene ether, 15 parts of polyether ketone ketone, 5 parts of LLDPE (linear low density polyethylene), 5 parts of polyperfluoroethylene according to parts by weight. After propylene powder, 5 parts of molybdenum disulfide, 0.2 part of erucamide, 0.2 part of anti-1076, and 0.6 part of anti-168, mix them evenly to obtain a mixture.

[0052] S2. Add the mixture to the main feed of the twin-screw extruder, add 5 parts of composite crystal fiber to the side feed of the twin-screw extruder, melt and extrude it from the outlet of the die head, and cut into pellets after water cooling High wear-resistant self-lubricating thermoplastic polyimide composite material particles are obtained.

[0053] Wherein, the melt extrusion temperature of the twin-screw extruder is 300-350° C., and the screw speed is 250 rpm / min.

[0054] Put the granular material into the barrel of the injection molding machine. The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com