Modified polyvinyl alcohol and preparation method thereof

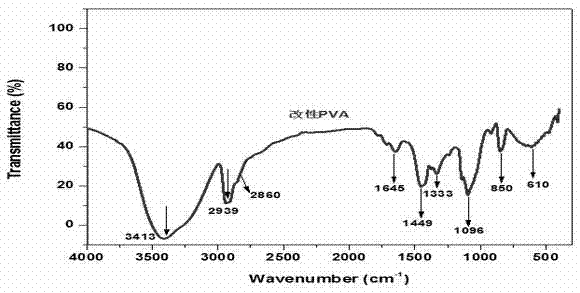

A polyvinyl alcohol, modification technology, applied in the field of polymer chemistry, can solve the problems of difficult melting processing, narrow processing window, etc., and achieve the effect of facilitating industrial production, changing structure and regularity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

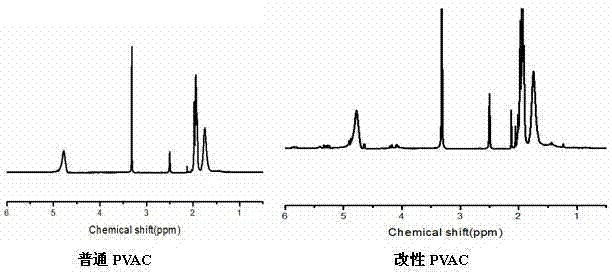

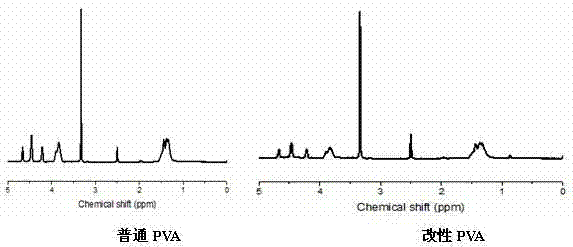

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing melt-processable modified polyvinyl alcohol, as follows:

[0047] (1) Initial feeding

[0048] 45 parts of methanol, 55 parts of vinyl acetate monomer, 0.2 part of composite initiator (AIBN: benzoyl peroxide=2:5) are put into the reactor; then 4 parts of vinyl ethylene carbonate monomer, Feed at one time into the reaction system over 1.5 hours, slowly raise the temperature to 63°C, polymerize for 5 hours, and add 0.6 parts of sorbic acid after the reaction.

[0049] (2) Blow out residual orders

[0050] Raise the external temperature to 85°C, remove unreacted monomers in the reaction product, and obtain a resin solution of polyvinyl acetate copolymer.

[0051] (3) Dissolving saponification

[0052] The resin solution of vinyl acetate-branched vinyl random copolymer obtained above is prepared into a solution with a mass fraction of 20% by methanol, and the product of modified polyvinyl alcohol copolymer is obtained by adding lye for alcoholysis ...

Embodiment 2

[0081] Each parameter selection is as shown in Table 1 below, and other operating steps are the same as in Example 1.

[0082]

[0083]

[0084]

[0085]

[0086] Note: A1: Vinyl isobutyl ether; A2: Vinyl tert-butyl ether; A3: Vinyl ethylene carbonate; A4: Butyl acrylate; A5: Vinyl cyclohexyl ether;

[0087] A6: ethylene glycol monoallyl ether; A7: butyl acrylate: ethyl acrylate = 3: 1; A8: vinyl isobutyl ether: vinyl tertiary butyl ether = 2: 1; A9: 3,4-di Acetoxy-1-butene; A10: vinyl ethylene carbonate: vinyl ethyl carbonate = 1:2

[0088] From group 1 to group 16 schemes in Table 1, it can be seen that the scheme of group 3 is relatively excellent, that is, methanol system, composite initiator (AIBN: tert-butyl peroxyacetate=1:3), reaction temperature 65 ℃, reaction 5 hours, the conversion rate can be controlled at about 70%, the modified PVA obtained by alcoholysis has moderate crystallinity and melting point, and the sample is soluble in water; if the branche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com