Cathode material of mid-temperature solid-oxide fuel battery and uses thereof

A fuel cell cathode, solid oxide technology, used in solid electrolyte fuel cells, fuel cells, fuel cell components, etc. The effect of reducing the cathodic polarization resistance and increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] LDC modified LSM-YSZ for composite cathode of intermediate temperature solid oxide fuel cell

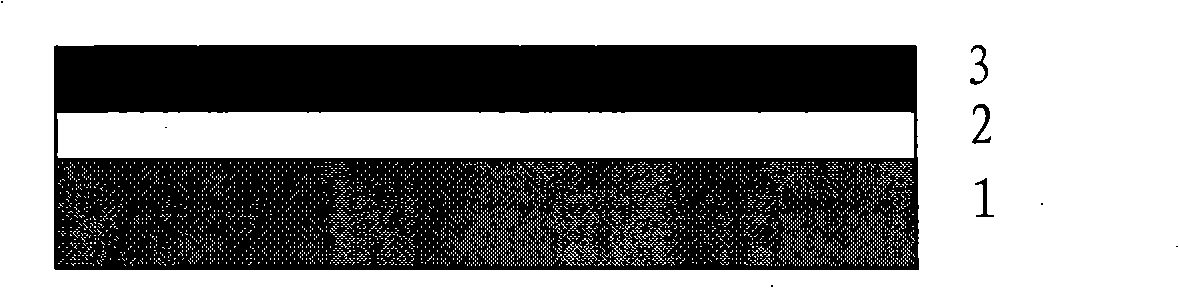

[0024] Such as figure 1Shown is a schematic structural diagram of an intermediate temperature solid oxide fuel cell, including an anode substrate 1 , an electrolyte membrane 2 and a cathode 3 . The anode substrate is composed of 50% NiO and 50% YSZ. An 800 micron thick NiO-YSZ anode substrate is prepared by rolling film method, and a layer of organic slurry containing 25 micron YSZ is coated on it. After drying, it was pressed under a pressure of 100 MPa, and the two-in-one was co-fired at 1450° C. for 5 hours to obtain an anode / electrolyte assembly.

[0025] LDC powder was synthesized by citric acid method. where La 2 o 3 The molar doping amount is 40%. After mixing LSM, YSZ, and LDC, the content of LSM is 60%, and the mass ratio of LDC to YSZ is 1:3, and then uniformly mixed with the binder to make a slurry, which is coated on YSZ by screen printing. The surface of the...

Embodiment 2

[0028] SDC Modified LSM-YSZ Used as Composite Cathode for Intermediate Temperature Solid Oxide Fuel Cells

[0029] The anode substrate is composed of 60% NiO and 40% YSZ. A NiO-YSZ anode substrate with a thickness of 1000 microns is prepared by casting method, and a layer of organic slurry containing YSZ with a thickness of 25 microns is coated on it. After drying, it was pressed under a pressure of 100 MPa, and the two-in-one was co-fired at 1400° C. for 5 hours to obtain an anode / electrolyte assembly.

[0030] SDC powder was synthesized by hydrothermal method, in which Sm 2 o 3 The molar doping amount is 20%. After mixing LSM, YSZ, and SDC, the content of LSM is 60%, the mass ratio of SDC to YSZ is 1:2, and then uniformly mixed with the binder to make a slurry, and the YSZ electrolyte membrane is prepared by coating method The surface was fired at 1150°C for 2 hours to obtain a cathode with a thickness of 50 microns.

Embodiment 3

[0033] GDC-modified LSM-YSZ for composite cathodes of intermediate temperature solid oxide fuel cells

[0034] The anode substrate is composed of 50% NiO and 50% YSZ. An 800-micron thick tubular NiO-YSZ anode substrate is prepared by extrusion molding, and a layer of organic slurry with a thickness of 20 microns YSZ is loaded on the anode by spraying. After drying, the two-in-one was co-fired at 1450° C. for 5 hours to obtain an anode / electrolyte assembly.

[0035] Gd and Ce nitrate were impregnated on the LSM-YSZ composite by nitrate impregnation method, in which Gd(NO 3 ) 3 with Ce(NO 3 ) 3 The molar ratio of GDC and YSZ is 1:9, the content of LSM is 60%, the mass ratio of GDC and YSZ is 1:4, and the GDC modified LSM-YSZ powder is obtained by roasting at 850°C. Then it is uniformly mixed with a binder to form a slurry, prepared on the surface of the YSZ electrolyte membrane by plasma spraying method, and fired at 1000° C. for 2 hours to obtain a cathode with a thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com