Thermoplastic polyimide resin material with low thermal expansion coefficient and preparation method thereof

A technology of polyimide resin and low thermal expansion coefficient, which is applied in the field of low thermal expansion coefficient thermoplastic polyimide material and its preparation, and can solve the problem of decreased mechanical and thermal properties of resin products, decreased high temperature stability of resin, and reduced mechanical properties of resin etc., to achieve the effects of reducing processing temperature and melt viscosity, improving thermoplastic processability, and increasing melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The composition content of a kind of low thermal expansion coefficient thermoplastic polyimide resin is as follows:

[0043] (1) High temperature resistant thermoplastic polyimide resin with a glass transition temperature greater than 250°C and a thermal expansion coefficient less than 40ppm / K: 94% by mass;

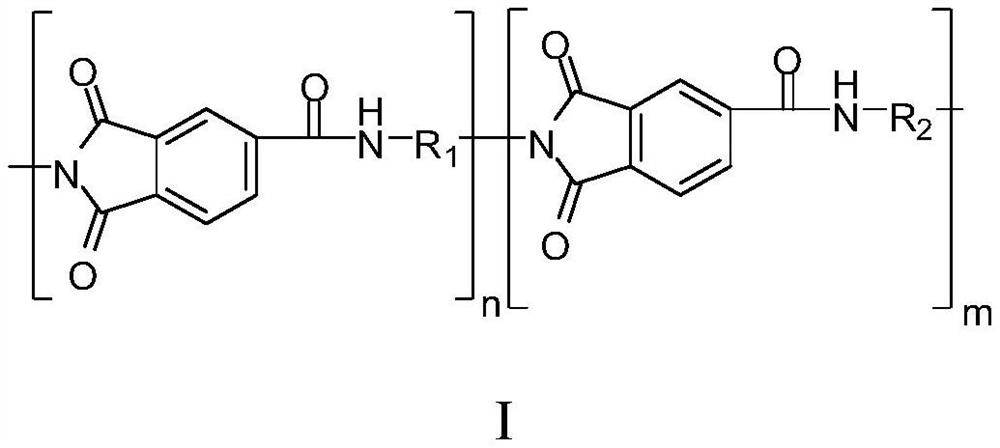

[0044] Its structural formula is as follows:

[0045]

[0046] It is prepared according to the preparation method disclosed in Example 1 of the patent CN 111057236 A (application number 201911214345.6).

[0047] Its inherent viscosity is 0.68dL / g, glass transition temperature is 295°C, and thermal expansion coefficient is 23ppm / K. .

[0048] (2) Antioxidant 1010: 0.5% by mass;

[0049] (3) Lubricant PETS: 0.5% by mass;

[0050](4) Thermoplastic polyimide resin with glass transition temperature lower than 220°C: 5% by mass.

[0051] The commercial polyimide resin Ultem 1000 is used, its glass transition temperature is 217°C, its inherent viscosity is 0.36dL / ...

Embodiment 2

[0054] The composition content of a kind of low thermal expansion coefficient thermoplastic polyimide resin is as follows:

[0055] (1) High temperature resistant thermoplastic polyimide resin with a glass transition temperature greater than 250°C and a thermal expansion coefficient less than 40ppm / K: the content is 90%;

[0056] Its structural formula is as follows:

[0057]

[0058] Its inherent viscosity is 0.68dL / g, glass transition temperature is 295°C, and thermal expansion coefficient is 23ppm / K. .

[0059] (2) Antioxidant 1010: 0.3%;

[0060] (3) Lubricant paraffin: 0.7%;

[0061] (4) Thermoplastic polyimide resin with a glass transition temperature of less than 220°C: 9%.

[0062] The commercial polyimide resin Ultem 1000 is used, its glass transition temperature is 217°C, its inherent viscosity is 0.36dL / g, and its melt index is 5g / 10min under the test condition of 315°C / 12.5kg.

[0063] The extrusion temperature of WELLZOON brand C-type high-temperature desk...

Embodiment 3

[0065] The composition content of a kind of low thermal expansion coefficient thermoplastic polyimide resin is as follows:

[0066] (1) High temperature resistant thermoplastic polyimide resin with a glass transition temperature greater than 250°C and a thermal expansion coefficient less than 40ppm / K: the content is 95%;

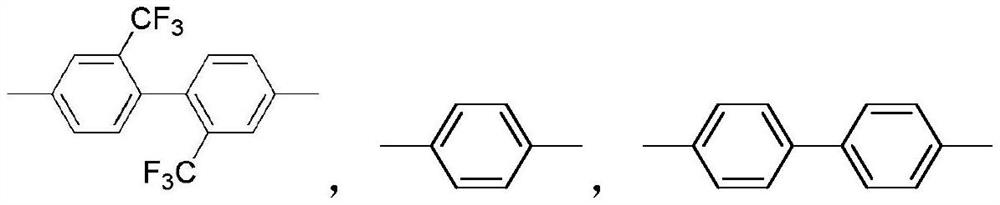

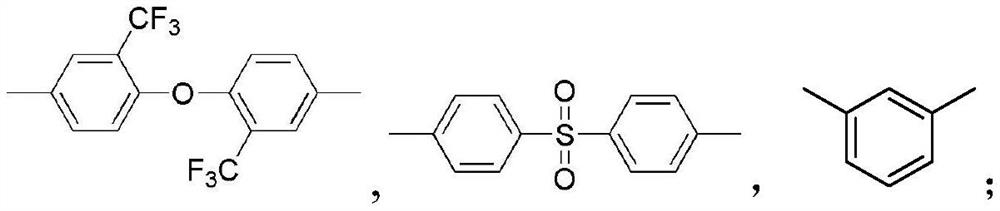

[0067] Its structural formula is as follows (n / m=2:1):

[0068]

[0069] Its inherent viscosity is 0.60dL / g, glass transition temperature is 261°C, and thermal expansion coefficient is 39ppm / K.

[0070] (2) Antioxidant 168: 0.8%;

[0071] (3) Lubricant PETS: 0.2%;

[0072] (4) Thermoplastic polyimide resin with a glass transition temperature of less than 220°C: 4%.

[0073] The commercial polyimide resin Ultem 1010 is used, its glass transition temperature is 217°C, its inherent viscosity is 0.34dL / g, and its melt index is 6g / 10min under the test condition of 315°C / 12.5kg.

[0074] The extrusion temperature of the WELLZOON brand C-type high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com