Cradle pressurizing component

A technology of cradles and components, which is applied in the direction of textiles and papermaking, drafting equipment, spinning machines, etc. It can solve the problems of inability to ensure that the top rollers and rollers are parallel, the quality of yarn is difficult to control, and the increase in manufacturing costs, etc., to achieve a reasonable structure , good parallelism, and the effect of improving parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

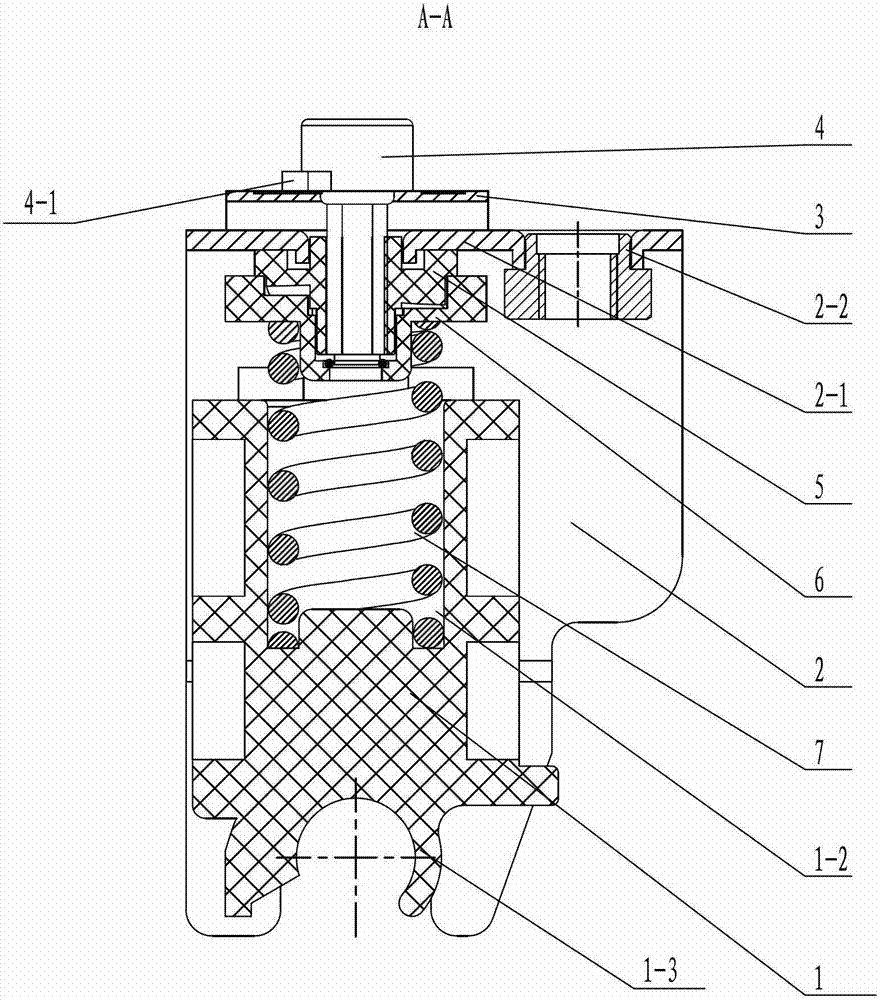

[0018] See Figure 1-7 As shown, the cradle pressurization assembly of the present invention includes a parallel support 2, a top roller seat 1, a spring 7 and a pressure regulating mechanism. The pressurizing assembly is installed at the front, middle, and rear of the lower part of the cradle body 11. The three sets of pressurizing assemblies respectively control the front, middle, and rear three top rollers 8, while the cradle handle 10 and the cradle seat 12 are hinged on the cradle body 11. , by three top rollers 8 pressing respective corresponding rollers 13, a certain frictional force is generated between the top rollers 8 and rollers 13 to realize spinning.

[0019] See Figure 1~2 As shown, the parallel support 2 of the present invention has a top plate 2-1 and side plates 2-4 positioned on both sides of the top plate 2-1, and the top plate 2-1 of the parallel support 2 is provided with a via hole for the pressure regulating rod 4 to pass through and The mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com