Energy-saving loose fiber cake opener

A loose fiber and energy-saving technology, which is applied in the field of energy-saving loose fiber cake opener, can solve the problems of low production efficiency, high labor intensity, and high electricity consumption, so as to improve production efficiency, reduce labor intensity, and avoid hand injury Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

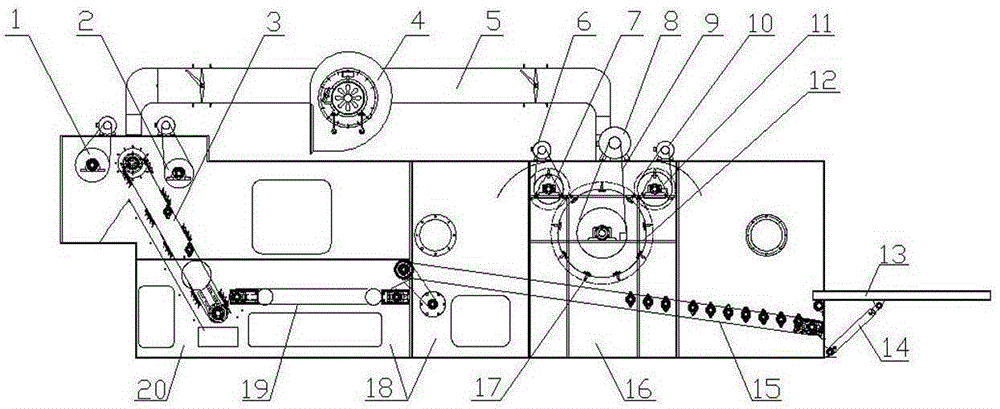

[0017] like figure 1 As shown, the energy-saving loose fiber cake opener of the present invention comprises an opening unit, a cotton bin unit and a feeding unit, between the discharge opening of the opening unit and the feeding port of the cotton bin unit, the discharge of the cotton bin unit The mouth is connected with the feed port of the feeding unit. The opening unit, the cotton bin unit and the feeding unit respectively contain the opening bin 16, the cotton bin 18 and the feeding bin 20 which are rectangular in cross section and arranged horizontally, and the opening bin 16, the cotton bin 18 and the feeding bin The feeding bin 20 is separated by metal cylinders whose cross section is rectangular and arranged horizontally. Wherein, the opening bin 16 is provided with a first belt conveyor 15, and the inner end of the first belt conveyor 15 in the moving direction is higher than its outer end. An opening mechanism is arranged on the first belt conveyor 15, and the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com