Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Keep the style" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-harm type cigarette capable of reducing cigarette harm and manufacture method thereof

ActiveCN101322579AStay in Style and FragranceComfortable aftertasteTobacco preparationTobacco treatmentTarFlavor

The invention discloses a low-hazard cigarette which can reduce the harm of the cigarette and a preparation method thereof, and the technical problem needs to be solved is to reduce the harm of the cigarette to the human health. The low-hazard cigarette of the invention adds additives in the cut tobacco of the cigarette, the additives are egg flower and coral grass extracts, the weight ratio of the egg flower and the coral grass is 8:2, the prepration method comprises that: the egg flower and the coral grass extracts are extracted, extract liquid is prepared and evenly sprayed on the ordinary cut tobacco, and the cigarette is prepared by adopting the conventional cigarette technology. Compared with the prior art, the egg flower and the coral grass extracts are added in the cut tobacco, the effective ingredients in the egg flower and the coral grass are absorbed in the human body along with the volatilization of the mainstream smoke, thereby maintaining the original style and the flavor of the cigarette, being capable of inhibiting the cancer-causing mutation of the cigarette tar to the human body and timely preventing and mitigating the smoking-induced cough, the shortness of breath, the sputum stasis and other various adverse reactions.

Owner:SHENZHEN DABAIHUI TECH

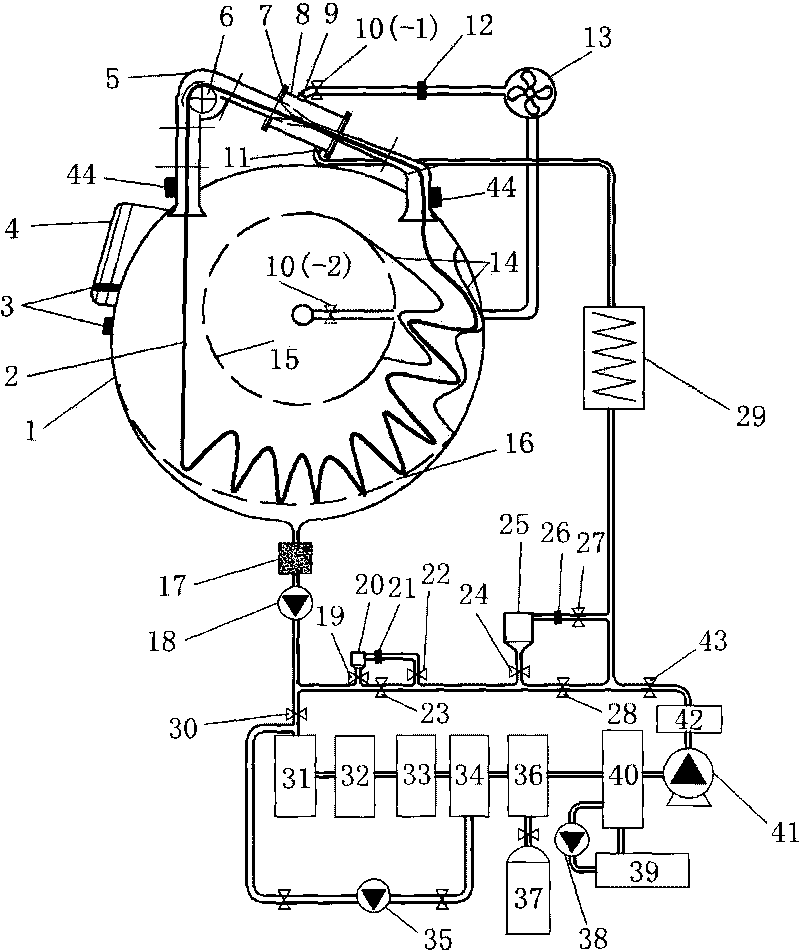

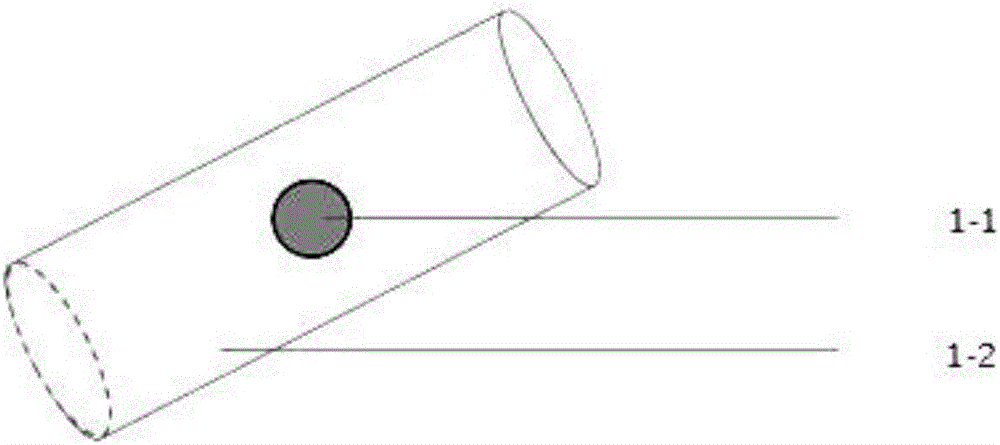

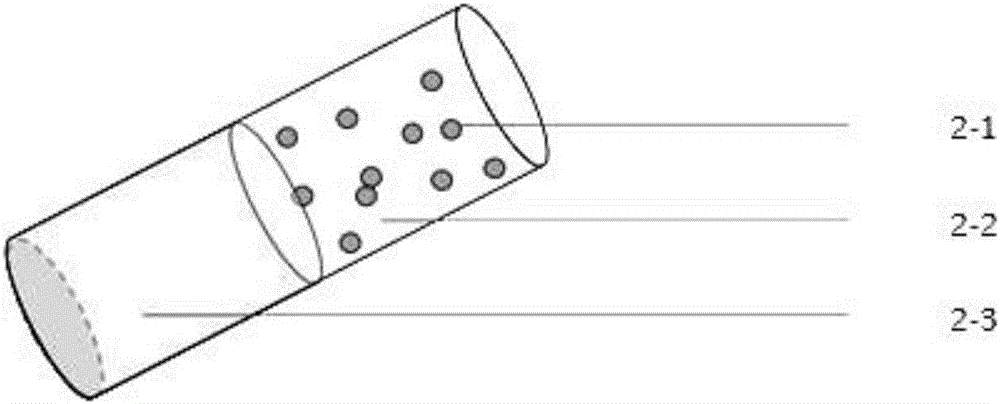

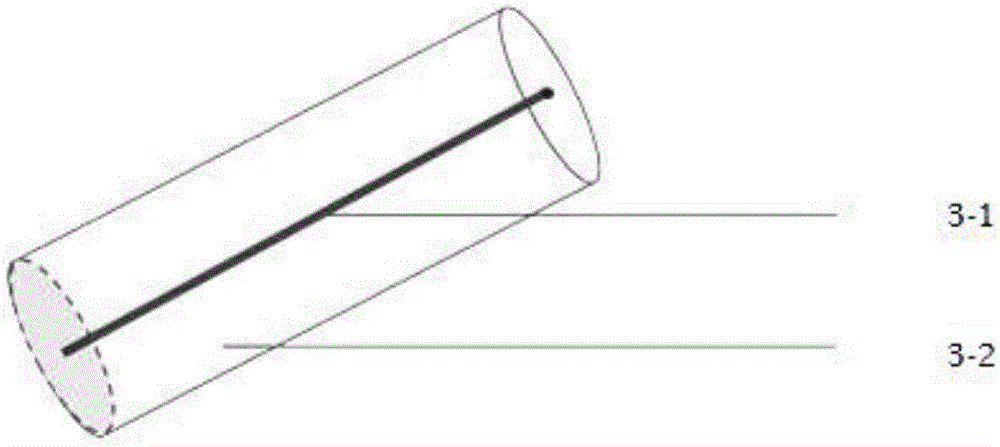

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

PTT fiber and celluse fiber one-bath dyeing method

The invention discloses PTT and cellulose fibers one bath process dyeing method. It includes the following steps: adding dyeing assisted carrier into the bath; dying PTT fiber by disperse dyes; adding auxiliary agent to do reduction clearing; removing loose color; adding activated dye and auxiliary agent to dye cellulose fiber; soaping; washing; and fixing by fixing agent; mellowing; dehydrating; and drying. The invention solves the problem of blending PTT and protein fibers low temperature one bath process dyeing, and the production problem of no corresponding high temperature pressure dyeing device for enterprise, which is the key of deep processing for blending fiber product, the necessary condition for its market popularization and application.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Modified active carbon fiber used as filtering material to lower toxic matter from cigartte, and its prepn. method

A modified activated carbon fiber (ACF), TiO2-Pd-Cu based ACF, for filtering out the tar, nicotin, CO, benzo(a) pyrene, fatty aldehyde, etc from the smoke of cigarette is prepared through adding ethanediol monomether into the solution of titanium sulfate, stirring, adding ACF, heating, adding the saturated solution of ammonium dicarbonate, regulating pH value, baking ACF, sintering, cooling, immersing in the aqueous solution of PbCl2 and CuCl, baking and cooling.

Owner:NANJING NORMAL UNIVERSITY

Aroma sustained-release material composition and sustained-release perfume colloid used in the preparation of cigarette

The invention relates to an aroma sustained-release material composition and a sustained-release perfume colloid used in the preparation of cigarette. The aroma sustained-release material composition is composed of beeswax, cetanol, hydrogenated palm oil, propylene glycol fatty acid ester, propylene glycol and octyl decyl glycerides. The sustained-release perfume colloid are added into filter bars for cigarette products, the loss of aroma components under the condition of production and storage and transportation is delayed, and the aroma style of the cigarette is maintained. Different aroma components are released during smoking, and the aroma richness of cigarettes is improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Fermented beverage of blueberries acetic acid and brewage method

InactiveCN1915111AMaintain nutrientsDoes not destroy nutrientsVinegar preparationPlant ingredientsAcetic acidAlcohol

Owner:LIAONING GUANGTIAN FOOD

Soybean fiber fabric lousiness-pilling-resistance finishing method

InactiveCN1776085AImproved anti-pilling propertiesIncreased durabilityFibre treatmentFiberMethacrylate

This invention discloses a fuzzing-pilling resisting finishing method for soybean fiber fabric. It makes grafting modification to soybean fiber fabric, finishes by resin finishing agent. The monomer for grafting modification is diacritic acid or methacrylate of diatomic alcohol or with other active group, the finishing agent is organic silicon modified polyacrylate dispersion or modified polyurethane like finishing agent. Said invention has fine washing resistance and no formaldehyde in process agent.

Owner:SUZHOU UNIV

Composite additive for raising cigarette smoke moisture and its use

ActiveCN1923066ASufficient sourceImprove wettabilityTobacco treatmentTobacco smoke filtersOrganic acidAlcohol

The invention relates to a composite additive for increasing water content in cigarette smoke and uses thereof, wherein the composite additive comprises the constituents of organic acid and derivative 0-60%, condensate or polymer of ethylene alcohol 10-90%, pyrrolidone compounds 0-30%, gourmet powder 0.1-5%, and deionized water 0-40%.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Semi-fine spinning rabbit hair yarn and method of processing the same

InactiveCN101368329AStay Styled and OrnamentalQuality improvementBiochemical fibre treatmentYarnLower intensityHydrogen peroxide

The invention discloses semi-worsted rabbit hair yarn and a processing method thereof, belonging to treatment and processing field of animal fiber, in particular relates to a semi-worsted rabbit hair yarn product which is processed by taking natural rabbit hair as material through the processes of oxidation treatment by hydrogen peroxide and modification treatment by 1398 neutral subtilisin, and a processing method thereof. The processing method includes the following steps: materials pretreatment; oxidation and enzyme treatment; combining the hair and adding oil for health preserving; three times of drawing; roving; spinning; and winding. The invention successfully solves the problem of small friction coefficient, small crimp frequency, low intensity and low cohesion on rabbit hair, which leads to poor spinnability on rabbit hair fiber, and provides a high quality and high yarn count half-worsted rabbit hair yarn product which takes rabbit hair as material, and the processing method thereof. The half-worsted rabbit hair yarn provides high quality material for weaving, knitting, sewing, broidering and tufting industries, and the rabbit hair product is free from hair falling and pilling, thus maintaining the characteristics of rabbit hair.

Owner:山东恒泰纺织有限公司

Frangipani shaped Cigarette with egg extraction for reducing

PendingCN101044918AKeep the styleKeep the scentTobacco treatmentAntinoxious agentsEnvironmental healthTar

A frangipani type cigarette without toxic by-effect to human body is prepared from the tobacco shreds and the component A chosen from the volatile oil, liquid extract and shreds of frangipani, and their mixture through spraying said component A onto or mixing it with said tobacco shreds, and conventionally making cigarettes.

Owner:温纯青 +2

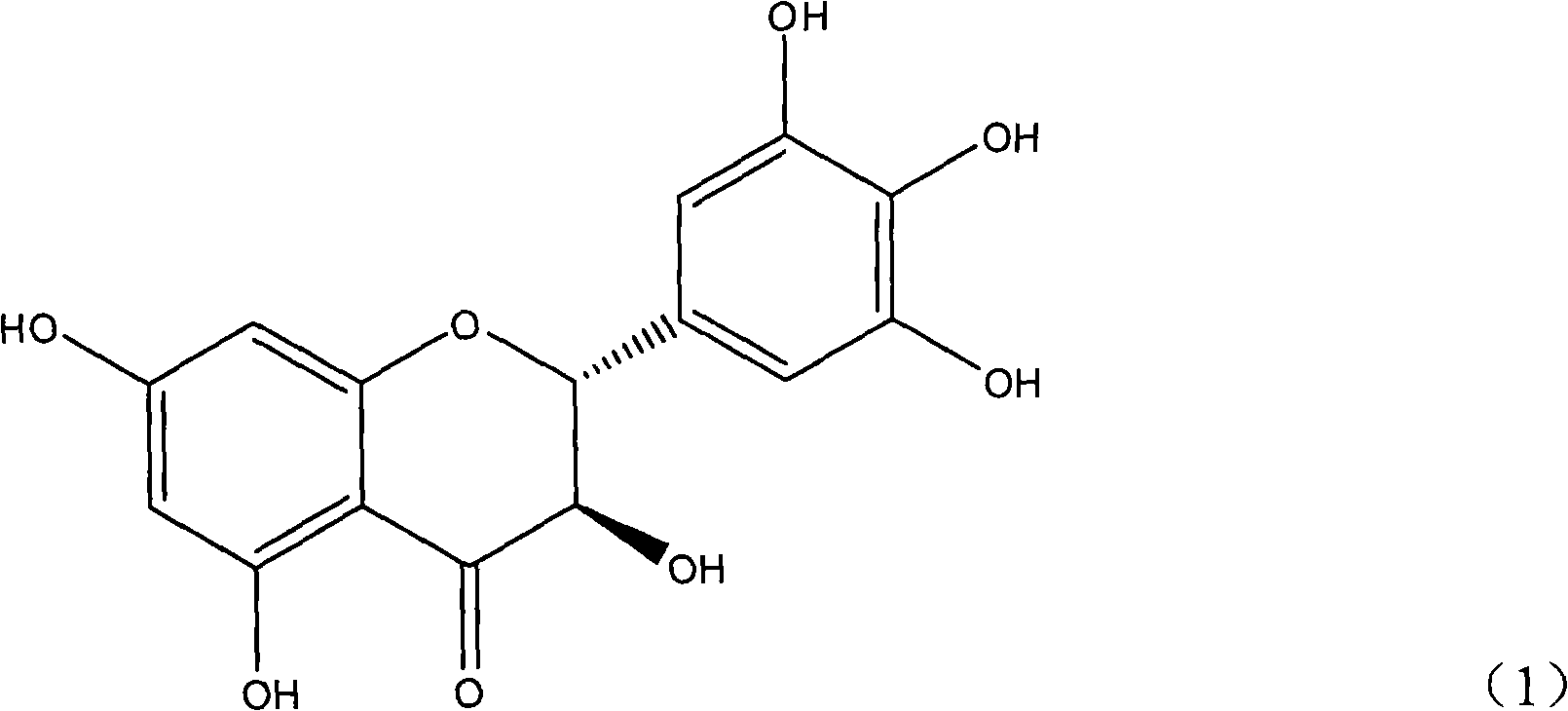

Natural extract added into cigarettes, extracting method thereof and cigarettes

The invention discloses a natural extract added into cigarettes, an extracting method thereof and cigarettes, which aim at solving the technical problem of reducing harms to the human body from the cigarettes. The natural extract can be prepared by adopting the following steps: crushing dried stem leaves of ampelopsis grossedentata, refluxing by ethanol, decompressing and concentrating at 0.05MPaand 80 DEG C for 2 hours, adding water, heating, dissolving, filtering, adding macroporous resin columns, eluting by ethanol, and recrystallizing eluant at 0-10 DEG C to obtain 99 percent of natural extract of dihydromyricetin. The cigarettes contain the natural extract of the dihydromyricetin, which accounts for 0.01-10 percent of cut tobaccos in weight percent. Compared with the prior art, the invention keeps the original taste and style of the cigarettes, can reduce the contents of nitrosamine, CO, phenol and crotonic aldehyde in cigarette smoke, and releases the adverse reactions of cough,asthma, phlegm stasis, throat obstruction, and the like caused by smoking.

Owner:SHENZHEN DABAIHUI TECH

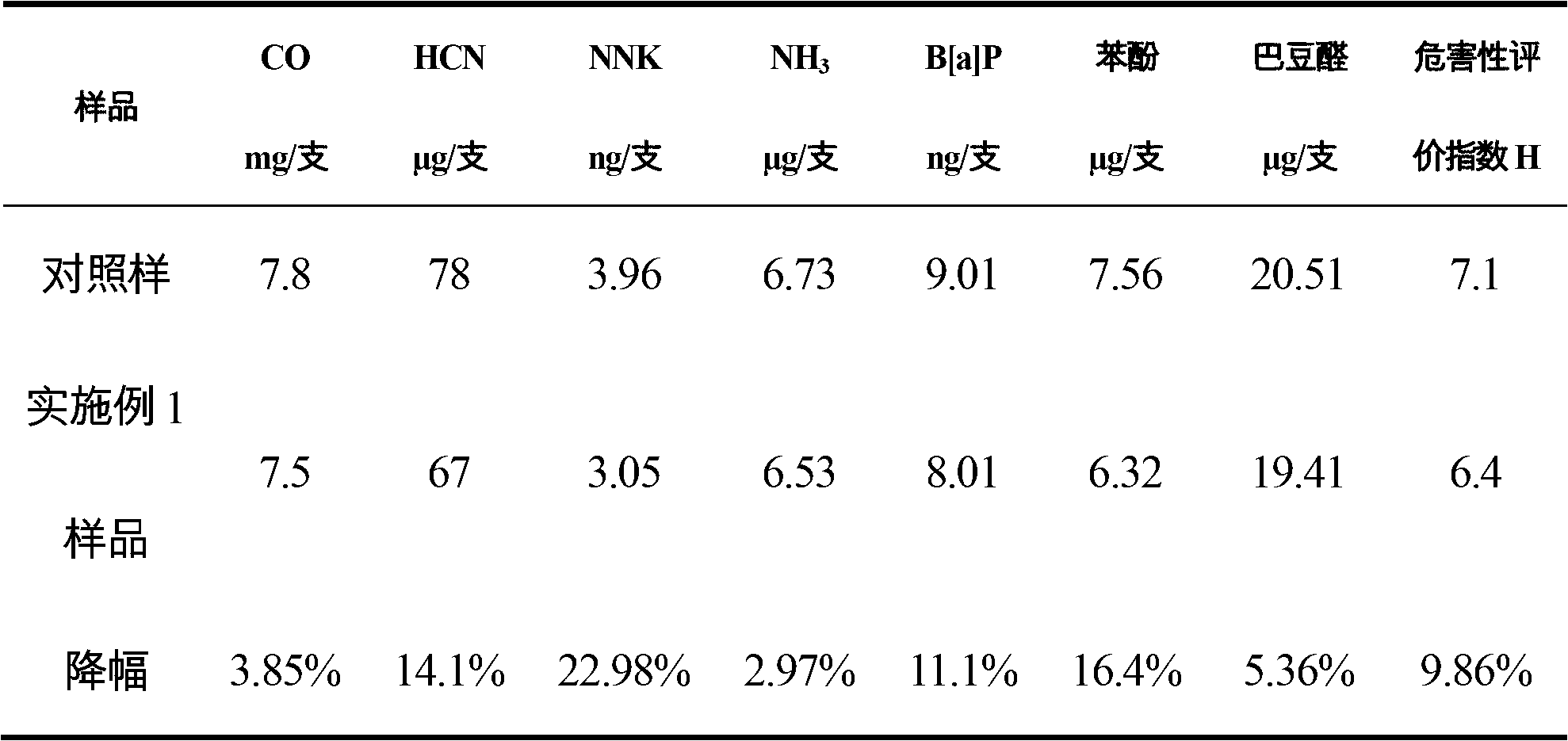

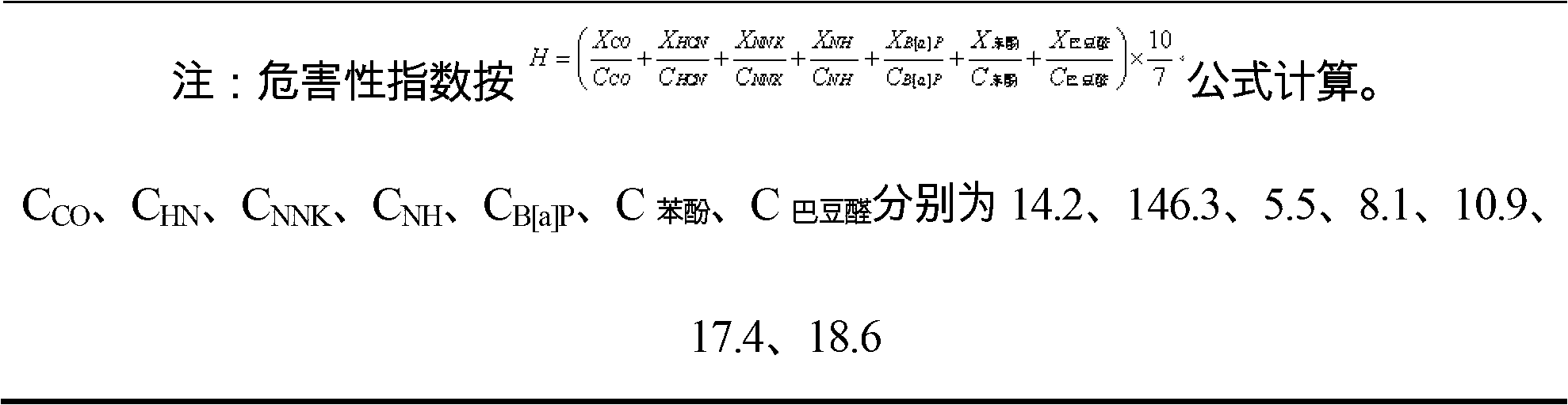

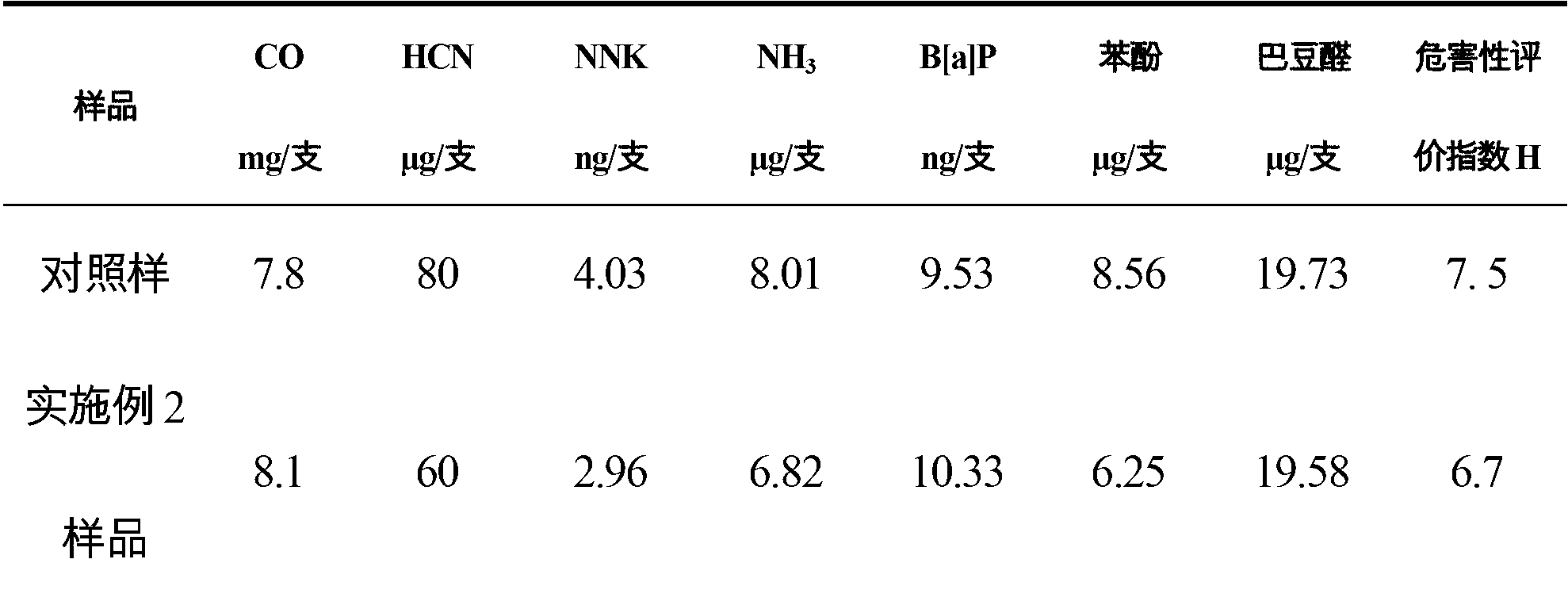

Cigarette paper additive for reducing harmful ingredients of cigarette mainstream smoke and application thereof

ActiveCN102839565AKeep the styleMaintain suction qualityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCombustion

The invention relates to a cigarette paper additive for reducing harmful ingredients of cigarette mainstream smoke. The cigarette paper additive is prepared by the following components in percentage by weight: 5-20% of tobacco extract, 5-20% of tea extract, 10-30% of air permeability regulator and 30-60% of efficient combustion improver. The cigarette paper additive for reducing harmful ingredients of cigarette mainstream smoke majors in tobacco fiber cigarette paper; after the additive is applied to the cigarette, at least four harmful ingredients in seven harmful ingredients, such as CO, HCN, NNK, NH3, benzo [a] pyrene, phenol and crotonaldehyde of the cigarette can be obviously reduced; decreasing amplitude is above 10%; and the decreasing amplitude of an H value of cigarette hazardous index is above 5%.

Owner:CHINA TOBACCO GUANGDONG IND +1

Machining method of wrapped structural flax and polyester filament section color composite yarn and composite yarn

The invention provides a machining method of a wrapped structural flax and polyester filament section color composite yarn and a composite yarn. A section color effect principle of fusing and twistingtwo yarns with different colors, a specific false twisting effect of core yarns when a hollow ingot is subjected to wrap spinning of an externally-wrapped yarn and the core yarns are wound, a twist instability principle of the specific false twisting effect and an uneven distribution principle of a twist on a plucked yarn are comprehensively utilized; by enabling double core yarns to generate anirregular section color effect and adopting the colorless excellent-transparency filament (monofilament or less-number multifilament) externally-wrapped yarn to carry out wrapping consolidation, the flax composite yarn with section color characteristics is obtained. Wrinkle resistance of flax fabric can be effectively improved, yarn hairiness is reduced, hairiness regeneration is reduced, weavability is improved, section color appearance is given to the yarn and the fabric thereof, and the fabric is woven in a dyeing-free and sizing-free mode.

Owner:JIAXING UNIV

A non-ironing finishing liquid for a ready-to-wear shirt and a non-ironing finishing method for a ready-to-wear shirt

InactiveCN105839414AEasy ironingImprove wrinkle resistanceWrinkle resistant fibresVegetal fibresNational standardPre washing

The invention relates to a non-ironing finishing liquid for a ready-to-wear shirt. The non-ironing finishing liquid is characterized by comprising 10-50% by mass of a crosslinking agent, 0.5-5% by mass of an improver, 5-10% by mass of a softening agent and 1-5% by mass of a penetrant, with the balance being deionized water the impurity content of which is less than 20 ppm. A non-ironing finishing method for a ready-to-wear shirt by adopting the non-ironing finishing liquid is also disclosed. The method includes steps of (1) pre-washing, (2) drying, (3) processing with the non-ironing finishing liquid, (4) drying to certain humidity, (5) finishing and ironing, (6) baking, (7) allowing the ready-to-wear shirt to stand, (8) washing again, and (9) drying. Through the non-ironing finishing liquid and the method, non-ironing shirts are free of formaldehyde really, the content of free formaldehyde meets the undetected grade of the textile product formaldehyde testing national standard GB / T2912.1-2009, crease resistance of shirts is improved, and the appearance of a finished shirt is made durable.

Owner:SANCANAL GARMENT CO LTD

Synchronous coloring burn-out printing and moire infiltrating burn-out printing technique for denim fabrics

InactiveCN103031753AComfortable to wearModel features are perfectBiochemical fibre treatmentDyeing processPre treatmentBurning out

The invention belongs to the field of post technique of burn-out printing on fabrics in the textile industrial production, in particular to a synchronous coloring burn-out printing and moire infiltrating burn-out printing technique for denim fabrics. The technique is characterized in that the burn-out printing pretreatment is implemented firstly, that is, grey fabrics of the denim fabrics are desized by using amylase at the temperature of 40-60 DEG C, and are printed by screens to produce synchronous coloring burn-out printing screens or moire infiltrating burn-out printing screens with different styles, and burn-out printing size is prepared; and then, the synchronous coloring burn-out printing and moire infiltrating burn-out printing processing is implemented on the grey fabrics of the denim fabrics by adopting the prepared burn-out printing size through the synchronous coloring burn-out printing screens or the moire infiltrating burn-out printing screens. The technique achieves that products thereof are more beautiful and unique than original denim products, are comfortable to wear, and are perfect in style and characteristics; and the labor force and the secondary production pollution are reduced in the production link, so that the production cost is reduced, and the novel way of environmental friendliness of the denim fabrics is achieved.

Owner:王志刚

Blended yarn made of PET (polyethylene terephthalate) and PTT (polytrimethylene terephthalate) composite filament and preparing method thereof

InactiveCN104480596AGood flexibilityExcellent wrinkle resistance and dimensional stabilityYarnYarnPolyethylene terephthalate glycol

The invention discloses a blended yarn made of a PET (polyethylene terephthalate) and PTT (polytrimethylene terephthalate) composite filament and a preparing method thereof. The blended yarn comprises stable fibers of the PET and PTT composite filament; the content of the staple fibers is greater than 0 and not greater than 100%. The blended yarn further comprises a mixed component not less than 0 and less than 100%. The mixed component is cotton, hemp, cellulose fiber, or multi-component mixture of wool, cashmere and cellulose fiber. The preparing method includes mixing, cleaning, combing, drawing and doubling, roving and spinning; the mixing step is to mix the stable fibers of the PET and PTT composite filament and the mixed component; a cleaning beater for pre-spinning is a combing needle.

Owner:福建省海兴凯晟科技有限公司

Ultraviolet-proof finishing method of fabric for umbrellas

InactiveCN104233783AGood long-lasting UV protectionSoft touchFibre typesHeating/cooling textile fabricsWater basedSurface layer

The invention discloses an ultraviolet-proof finishing method of a fabric for umbrellas. A gray fabric of the fabric for the umbrellas is made of a 190T cationic fabric; the ultraviolet-proof finishing method is characterized by comprising the following steps: (1) desizing; (2) adding dyes in a dye vat; (3) adding aqueous dispersion of nanoscale water-based ultraviolet shield agents in the dye vat, wherein the aqueous dispersion of nanoscale water-based ultraviolet shield agents comprises the following materials by weight parts: 30 parts of ionized water, 0.3 part of a dispersing agent, and 3-3.5 parts of TiO2 nanoparticles; (4) dyeing and preserving heat for 30min; (5) shaping; (6) carrying out waterproof treatment; and (7) coating a surface layer. According to the method, a nano material can be successfully applied to the fabric with an ultraviolet-proof function for the umbrellas, and the finished fabric for the umbrellas has the ultraviolet screening rate reaching more than 95%, has the ultraviolet-proof function of the nano material enduringly, and can ensure the original style of a textile fabric.

Owner:HANGZHOU PARADISE UMBRELLA GROUP

Acanthopanax sessiliflorus fruit wine and brewing method thereof

InactiveCN101649284AReduce aging brewing timeKeep the aromaAlcoholic beverage preparationDiseaseFruit wine

The invention relates to acanthopanax sessiliflorus fruit wine and a brewing method thereof. The acanthopanax sessiliflorus fruit wine is brewed from the following raw materials: acanthopanax sessiliflorus fruit, granulated sugar, red grape wine base, and the like. The brewing method comprises the following steps: pumping the acanthopanax sessiliflorus fruits into heating equipment to heat to 40 DEG C to 50 DEG C by a screw pump, enzymolyzing, squeezing, enzymolyzing for the second time, killing enzyme, cooling, filtering, infusing in alcohol, storing, and adding an appropriate amount of red grape wine base, syrup, and the like when preparing. The product has the advantages of mellow fruity flavour, transparency, brightness, pure taste and rich nutrition, has the functions of resisting theaging and tumors and enhancing the immunity, has the significant effect on preventing cardio-cerebrovascular diseases especially, can improve the human immunity after being drunk frequently and is beneficial to health.

Owner:辽宁千山酒业集团有限公司

Polyester Chenille yarn and textile technology and application of polyester Chenille yarn

The invention provides a textile technology of polyester Chenille yarn. The textile technology comprises the steps that firstly, low-melting-point hot-melting binder fibers and polyester fibers are blended, and center yarn is prepared; secondly, decoration yarn is sandwiched between the center yarn for spinning through twisting, and a semi-finished product of the polyester Chenille yarn is obtained, wherein the decoration yarn is made of polyester fibers; thirdly, the semi-finished product of the polyester Chenille yarn is heated at the temperature of 0-200 DEGC, and the polyester Chenille yarn is obtained. According to the polyester Chenille yarn, the center yarn is prepared in the mode that the low-melting-point hot-melting binder fibers and the polyester fibers are blended, the polyester fibers are used as the decoration yarn, and after heat treatment, the low-melting-point hot-melting binder fiber skin layer is melted while the central layer is not changed, so that point-like bonding structures are formed between the fibers, the binding power of the fibers is increased, the slippage phenomena of the fibers are reduced, and the picking-resistant effect is good. The polyester Chenille fabric prepared from the yarn is not prone to picking, and the original hand feeling and style are maintained; meanwhile, the textile technology is simple and easy to implement, no auxiliary equipment is needed, and the cost is low.

Owner:三问家居股份有限公司

Hair care composition

InactiveUS20070166258A1Reduce hair damageKeep the styleCosmetic preparationsHair cosmeticsFatty acidFatty alcohol

A hair styling cream comprising: i) an aqueous lamellar phase comprising a) cationic surfactant and b) fatty alcohol having a melting point greater than 35° C. and / or fatty acid having a melting point greater than 40° C.; and ii) 20 wt % or greater of one or more non-volatile liquid emollient(s), the viscosity of any single non-volatile emollient or the viscosity of a blend of non-volatile emollients being less than 1000 mPa·s at 35° C. and 5 s−l.

Owner:CONOPCO INC D B A UNILEVER

Blueberry acanthopanax sessiliflorus fruit wine and brewing method thereof

InactiveCN101649281AReduce aging brewing timeMaintain aroma and styleAlcoholic beverage preparationHorticultureEnzyme

The invention relates to blueberry acanthopanax sessiliflorus fruit wine and a brewing method thereof. The blueberry acanthopanax sessiliflorus fruit wine is brewed from the following raw materials: blueberry fruit, acanthopanax sessiliflorus fruit, granulated sugar, red grape wine base, and the like. The brewing method comprises the following steps: after mixing the blueberry fruits with the acanthopanax sessiliflorus fruits according to a certain proportion, pumping the blueberry fruits and the acanthopanax sessiliflorus fruits into heating equipment to heat to 40 DEG C to 50 DEG C by a screw pump, enzymolyzing, squeezing, enzymolyzing for the second time, killing enzyme, cooling, filtering, infusing in alcohol, storing, and adding an appropriate amount of red grape wine base, syrup, andthe like when preparing. The product has the advantages of mellow fruity flavour, transparency, brightness, pure taste and rich nutrition, has the functions of resisting the aging and tumors and enhancing the immunity, has the significant effect on preventing cardio-cerebrovascular diseases especially, can improve the human immunity after being drunk frequently and is beneficial to health.

Owner:DANDONG HUANING TIANJIAN FOOD

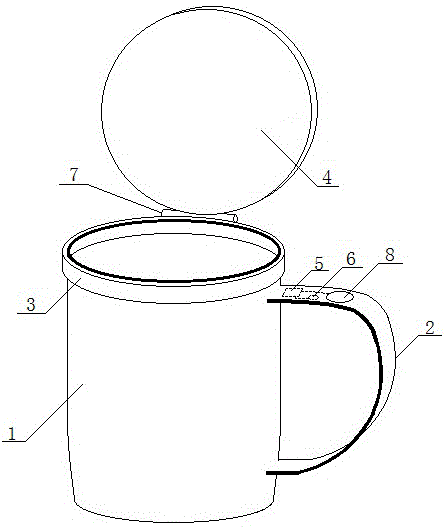

Intelligent cover turnover water cup

InactiveCN104783615ACausing pollutionGuaranteed cleanlinessDrinking vesselsElectric machineryIndustrial engineering

The invention relates to an intelligent cover turnover water cup. An existing cup is improved, an cup mouth sleeve ring (3) is designed and introduced, a cup cover (4) is movably connected to a cup mouth of a water cup body (1), a designed and introduced intelligent electronic control structure is combined, and the motion that a user uses the water cup can be sensed through a touch switch (8) on the outer surface of a handle (2). Therefore, a motor rotary shaft (7) is designed, automatic cover turnover operation is achieved on the cup cover (4), the operation of manually using the cup cover (4) is omitted, the whole operation process is controlled by the intelligent electronic control structure and completed at a time, the situation that due to the fact that the cup cover (4) is forgotten to be used or no cup cover (4) exists, the water cup is contaminated can be avoided, and cleanness and sanitation in the water cup are effectively guaranteed.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

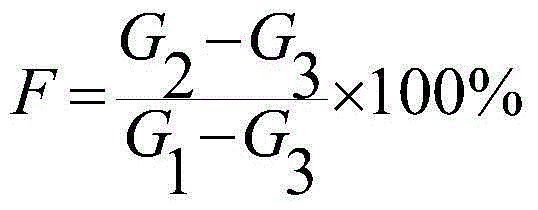

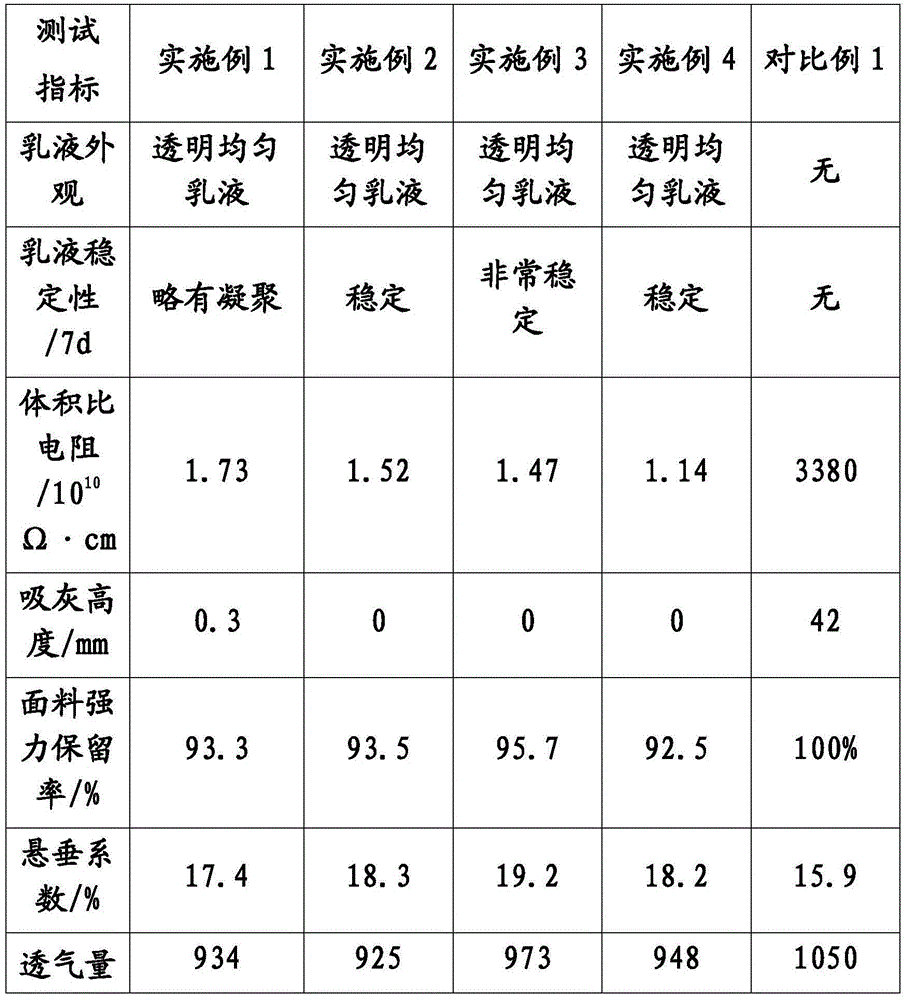

Preparation method of antistatic acrylic plus material

InactiveCN104631107ANo significant change in strengthNo significant change in extensibilitySucessive textile treatmentsFibre typesPolymer scienceLow volume

The invention relates to a preparation method of an antistatic acrylic plus material. The preparation method comprises the following steps: cleaning and drying acrylic knitted fabric with a detergent; dipping the acrylic knitted fabric into an antistatic finishing agent, heating and carrying out heat preservation for a certain period of time; taking out the acrylic knitted fabric, and mangling by virtue of a padder; and drying, baking, washing and drying. The antistatic acrylic plus material prepared by the preparation method has relatively good antistatic property and relatively low volume specific resistance, and can be applied to high-grade acrylic plus materials and the fields of industries with high antistatic requirements.

Owner:JIANGSU HUAYI GARMENT CO LTD

Graphene composite fiber and cashmere fiber blended yarn production method

The invention discloses a graphene composite fiber and cashmere fiber blended yarn production method, and relates to the technical field of textile. A napped yarn with graphene fibers is acquired by six main steps. Compared with the prior art, the yarn prepared by the method enriches the types of cashmere products, the additional value of the cashmere products is improved, and woven clothes have functionality. The original style of a cashmere yarn is kept, and the yarn has good tensile strength and excellent flexibility of the graphene composite fibers and can be washed to some extent.

Owner:CONSINEE GRP CO LTD

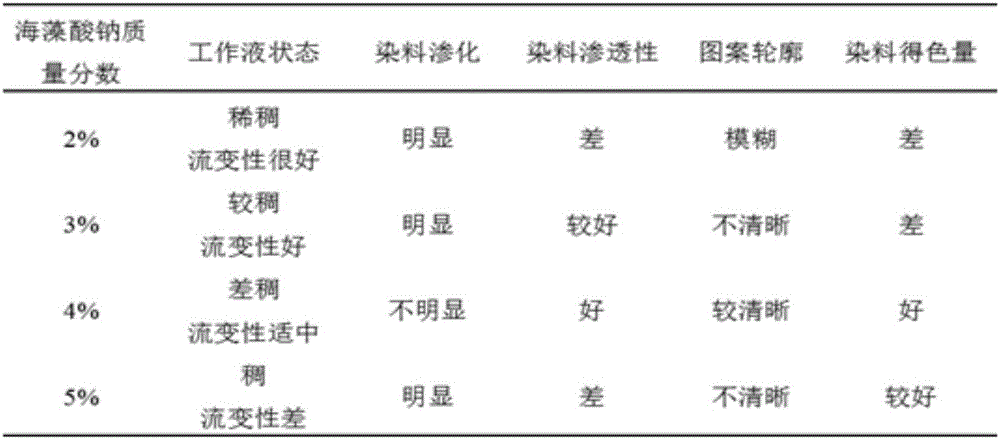

Digital printing sizing agent of suede wool fabric and technology thereof

The invention belongs to the technical field of dye printing, and particularly relates to a digital printing sizing agent of a suede wool fabric, and a preparation method of the digital printing sizing agent. The digital printing sizing agent of the suede wool fabric is prepared from the following raw materials in parts by weight: 4 to 9 parts of sodium sulfite, 8 to 12 parts of urea, 2 to 6 parts of sodium alginate, 2 to 6 parts of DGT-7, 4 to 7 parts of penetrant, 2 to 5 parts of ammonia sulfate, 1 to 3 parts of glacial acetic acid, and 60 to 72 parts of water. The digital printing size of the suede wool fabric has the advantages that the suede wool fabric is treated; after sizing, the nap at the surface of the fabric is tightly attached to the surface, and the surface of the fabric is flat; during printing, the color staining is avoided; the water-retention property and dyeing uniformity of the fabric treated by the sizing agent provided by the invention are good, the influence to dyeing of dye is little, and the fine, uniform and colorful printing effect is obtained.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

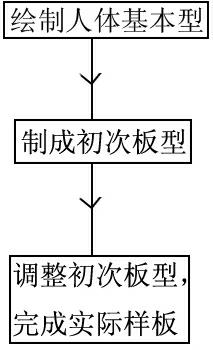

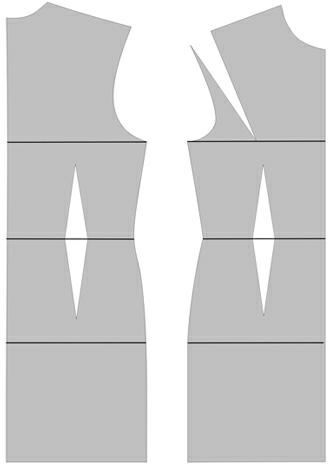

Templet-making method for garment construction

The invention discloses a templet-making method for a garment construction, which is based on garment human body data. On the basis of a human body basic model, structure lines are directly drawn, the position of the garment construction is arranged, structure data is adjusted, and garment data is labeled. The method comprises the following detailed steps of: (1) drawing the human body basic model according to a human body curve structure combined with a garment size designation; (2) directly drawing structure lines on the human body basic model according to the profile and details of a garment to form a primary templet; and (3) determining the garment data by combining a garment specification, and adjusting the primary templet into a practical templet. The method is based on garment human body data, on the basis of the human body basic model, the structure lines are directly drawn, the position of the garment construction is arranged, the structure data is adjusted, and the garment data is labeled, so the style of a costume design is embodied in the lines of the structural templet more vividly and expressively, the influence of specified data on the structure line form is avoided, and the design style of the structure templet is kept to a greater extent.

Owner:WENZHOU POLYTECHNIC

Flower and tea food as well as making method and application thereof

The invention belongs to the field of food processing, and particularly discloses a flower and tea food as well as a making method and application thereof. The food is made from main raw materials offresh plant flowers and newly-picked fresh tender tea leaves, and is made through the following steps of performing mixing, performing soaking, performing distillation, collecting distillate, and performing clathration through beta-cyclodextrin so as to obtain a solution; then performing natural fermentation on distilled raw material residues and remaining fluid under natural conditions, performing pressure filtration, performing centrifugal separation, performing filtration, and performing concentration so as to obtain concentrate; and combining the concentrate with the cyclodextrin clathration solution, and performing homogenizing so as to obtain the product namely the flower and tea food, wherein the weight percentage of the plant flowers in the raw material components is 20-50%, and the weight percentage of tea in the raw material components is 50-80%. The flower and tea food disclosed by the invention has the technological characteristics that the dissolution rate of the raw materials is high, the conversion rate is high, few losses are generated, the application effect of products is strengthened, the mouth feel is improved, the quality of the products is improved, and a newraw material product is provided for the processing industry of food products, seasoning products, beverages, wine processed products, cosmetics and the like.

Owner:徐州绿之野生物食品有限公司

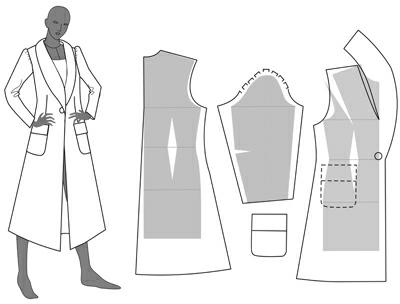

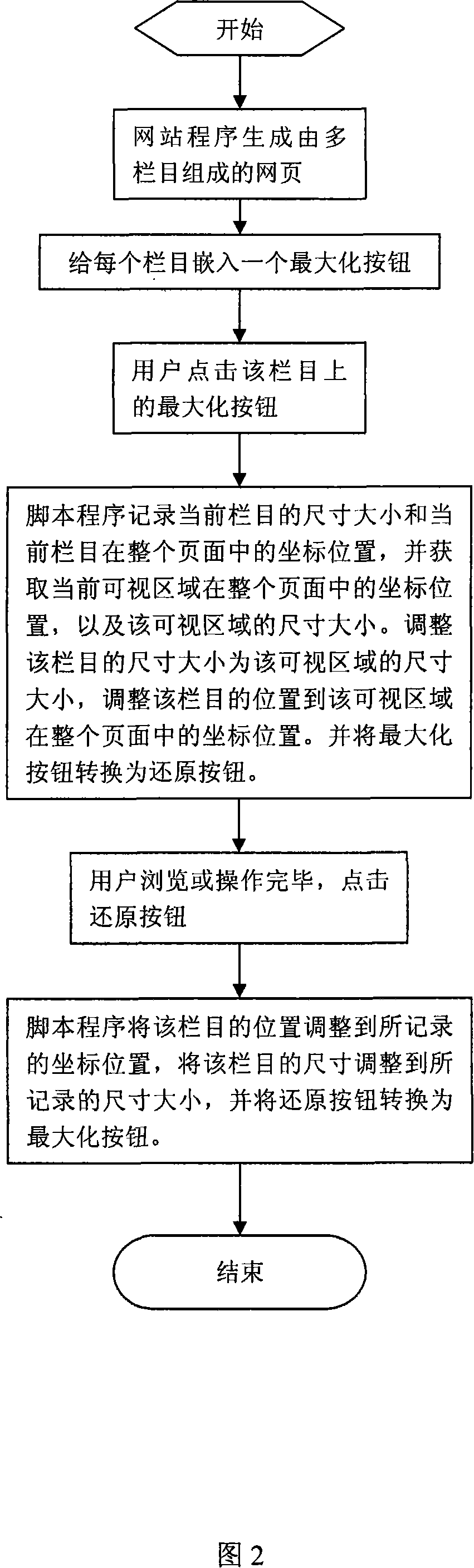

Web page column maximization and rehabilitation method

InactiveCN101216816AEasy to browseEasy to operateSpecial data processing applicationsInput/output processes for data processingWeb siteWeb page

The identifier name of the invention is a method for maximizing and recovering a web page column, belonging to the network technology field. The invention aims at solving the technical problem of providing the method for maximizing and recovering the web page column. The method for maximizing and recovering the web page column is adopted as the technical proposal. The invention provides the effective method that the web page column is maximized and the column is recovered after the browse and the operation are completed according to the browse or operation needs of a user. The invention has the steps as follows: a web page composed of a plurality of columns is generated by a web site program first; then the columns reach a whole visible range of the current web page when a user clicks a maximizing button on the columns; when the operation to the columns is completed by the user, a recovering button is clicked, the columns can be recovered to the original position and size. The invention leads the user to fully utilize screen space when browsing or operating the web page columns, keeps stable web page and no content alteration, and greatly increases the experience feeling of the user and the efficiency of the network.

Owner:SUZHOU CODYY NETWORK SCI & TECH

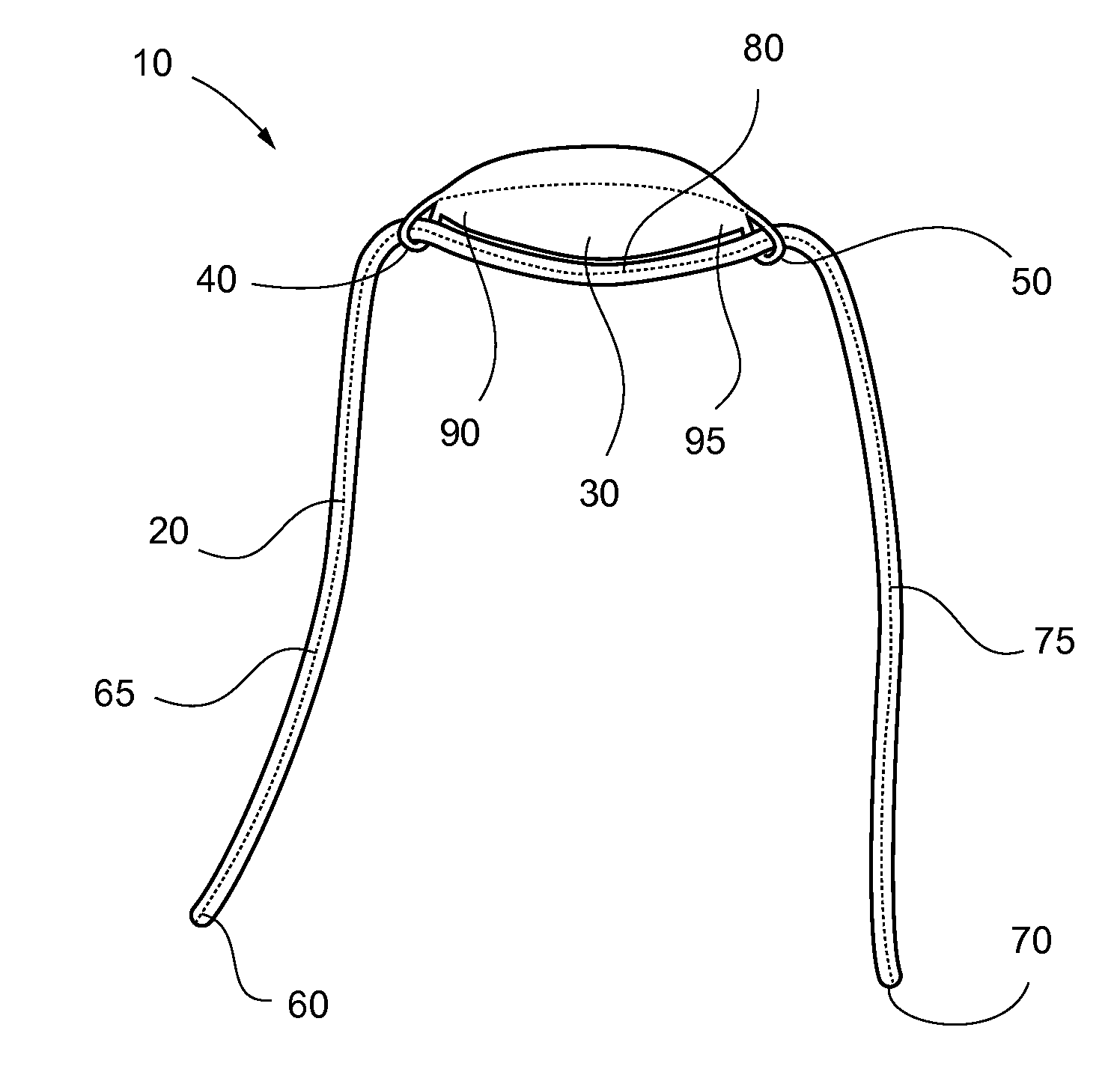

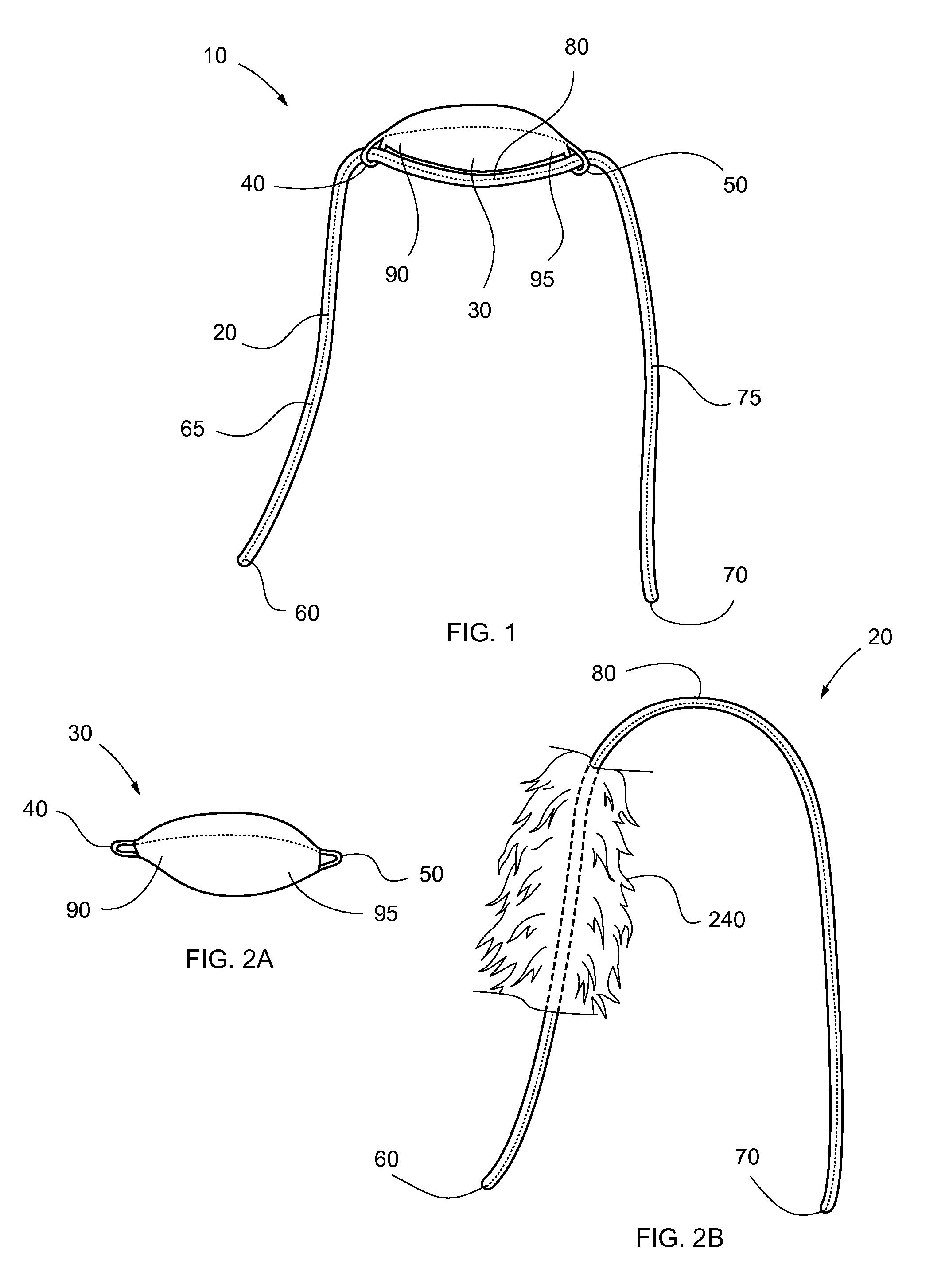

Hair Fashioning Apparatus and Method of Use Thereof

A hair fashioning or styling apparatus covered in velvet or similar material, the apparatus comprising an elongated section that is flexible, but which retains its shape once formed, along with a pillow section that is either removable or integral to the elongated section. The hair fashioning apparatus may include earphones, earplugs, earmuffs or a holder for a media player. The hair fashioning apparatus is utilized to form a “poof” of hair on the top of the head, or, alternatively, pigtails or ponytails.

Owner:MOSLEY TERESA GEE

Health-care synsepalum dulcificum rice dumplings with blood sugar reducing effect

ActiveCN103859288AAuxiliary hypoglycemicWith hypolipidemicFood ingredient functionsFood preparationCelluloseResistant starch

The invention belongs to the technical field of health-care foods and in particular relates to health-care synsepalum dulcificum rice dumplings with a blood sugar reducing effect. The rice dumplings comprise the following raw materials: 10kg of yams, 2kg of red beans, 2kg of semen coicis, 2kg of buckwheat powder, 0.3kg of corn grit fibers, 2kg of resistant starch, 1kg of konjaku flour, 0.5kg of synsepalum dulcificum and 0.5kg of synsepalum dulcificum leaves. The rice dumplings are prepared by dicing the yams, soaking the raw materials, boiling the synsepalum dulcificum leaves for extracting, grinding the synsepalum dulcificum, fully mixing the raw materials, binding by rice dumpling leaves and stewing, are rich in cellulose and free of sticky rice, and have a function of assisting in reducing blood sugar.

Owner:蚌埠中知知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com