Templet-making method for garment construction

A technology of clothing and structural lines, which is applied in the field of planar plate making for designing clothing structures based on clothing shapes, which can solve the problems of not being able to reflect the beauty of clothing, affecting the freedom of clothing plate shape, and affecting the integrity of clothing research and development, so as to maintain the design style Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

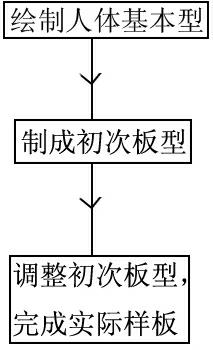

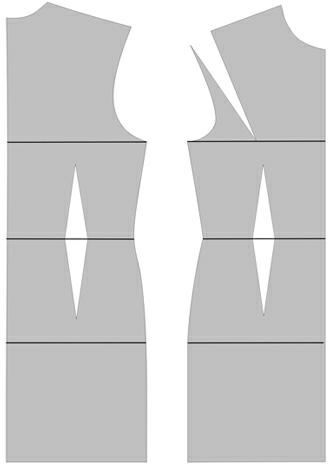

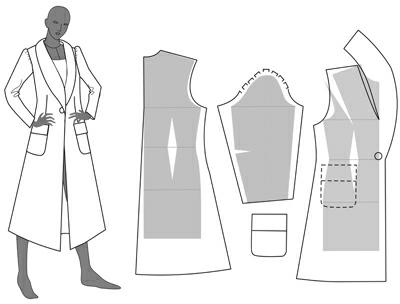

[0012] like figure 1 , figure 2 , image 3 As shown, an embodiment of the clothing structure panel making method of the present invention, the described panel making method is based on the clothing human body data, on the basis of the basic shape of the human body, directly draws the structure line, then arranges the clothing structure position, and then adjusts the structure Data and label clothing data, the specific steps are:

[0013] Step (1): First, according to the actual situation of the human body surface structure, set the bust line, waist line and hip line, and set the front and rear midlines according to the actual situation, and draw the basic human body shape in combination with the clothing size. The basic human body can be drawn in different proportions. Generally, the 1:5 size is suitable for the structural design stage. The adjusted garment shape is determined to determine the final garment data.

[0014] Step (2): According to the silhouette and details ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com