Dyeability modified meta-aramid fibers and preparation method therefor

A modified aramid fiber technology, which is applied in the field of dyeable modified meta-aramid fiber and its preparation, can solve the problems of poor flame retardancy, low fiber strength, and difficult dyeing, and achieve good light fastness and dyeing High dyeing rate, improving dye uptake and color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

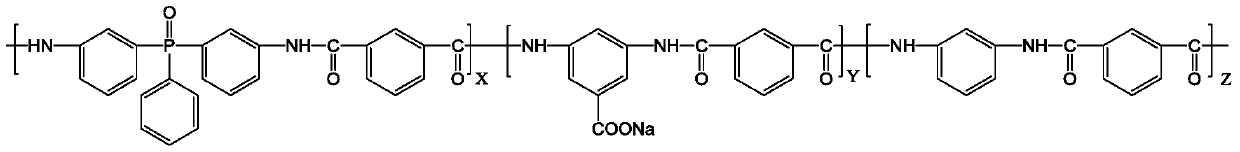

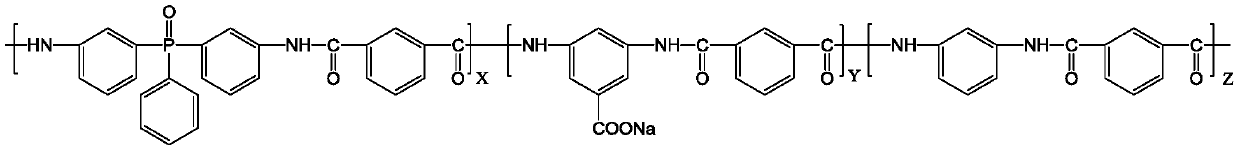

[0030] The preparation process of this easily dyeable meta-aramid fiber comprises the following steps:

[0031] Step 1: Add MPD, DABAS and BAPPO in an organic solvent according to the molar ratio (85-94): (1-5): (5-10) at room temperature and in a nitrogen-drying environment, and machine at a speed of 200-2000r / min After stirring and dissolving, cool the system to -20~-10°C to form a diamine solution; the organic solvents are N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc) , one or more of N-methylpyrrolidone (NMP) and dimethyl sulfoxide (DMSO);

[0032] Step 2. Add IPC to the diamine solution twice within 30 minutes. The molar ratio of the added IPC to the total amount of MPD, DABAS and BAPPO added is (1.002-1.01): 1. The first time IPC is added to the total 0.3-0.7% of the mass of IPC is added, and the remaining IPC is added for the second time. During the addition of IPC, the reaction temperature is controlled to be -20--10°C. After reacting for 10-30 minutes, r...

Embodiment 1

[0036]Add MPD, DABAS, BAPPO and DMAc into a 250mL four-neck flask at room temperature and nitrogen dry environment, mechanically stir at a speed of 800r / min until dissolved, then cool the system to -15°C, add MPD, DABAS and BAPPO The molar ratio is 94:1:5.

[0037] Add IPC to the diamine solution of MPD, DABAS and BAPPO twice within 30 minutes. The mass proportion of IPC added for the first time is 50%. The solution is neutralized by adding calcium hydroxide, the temperature of the whole system is slowly raised to 70° C., and the pH value of the whole system is 7.1 to prepare a modified polym-phenylene isophthalamide polymer solution. The amount of IPC added is 0.2mol, and the molar ratio of IPC to MPD, DABAS and BAPPO is 1.002:1.

[0038] The prepared modified polym-phenylene isophthalamide polymer solution has a solid content of 17.58% and a viscosity of 62.7 Pa·s.

[0039] The modified poly-m-phenylene isophthalamide spinning solution is wet-spun to obtain an easy-to-dye ...

Embodiment 2

[0041] Add MPD, DABAS, BAPPO and DMAc into a 250mL four-neck flask at room temperature and in a nitrogen-dried environment, mechanically stir at a speed of 1000r / min until dissolved, then cool the system to -15°C, add MPD, DABAS and BAPPO The molar ratio is 94:1:5.

[0042] Add IPC to the diamine solution of MPD, DABAS and BAPPO twice within 30 minutes. The mass proportion of IPC added for the first time is 50%. Calcium hydroxide is added to the solution for neutralization, the temperature of the whole system is slowly raised to 70° C., and the pH value of the whole system is 7.5 to prepare a polymer solution of modified polym-phenylene isophthalamide. The amount of IPC added is 0.2mol, and the molar ratio of IPC to MPD, DABAS and BAPPO is 1.002:1.

[0043] The prepared modified polym-phenylene isophthalamide polymer solution has a solid content of 18.35% and a viscosity of 63.1 Pa·s.

[0044] The modified poly-m-phenylene isophthalamide spinning solution is wet-spun to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com