Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "High moisture regain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cigarette filter tow and preparation method thereof

ActiveCN102392316AImprove heat resistanceImprove thermal stabilityTobacco smoke filtersArtificial filament heat treatmentPolyesterFiber

The invention discloses a cigarette filter tow and a preparation method thereof. The cigarette filter tow comprises the main component of a blending modified polylactic acid material. The blending modified polylactic acid material comprises the following components in parts by weight: 100 parts of temperature resistant lactic acid polyester mixture, 0.5-1.2 parts of polyethylene glycol, 0.5-1.2 parts of polyhydroxyalkanoate, 2-2.75 parts of mixture of thermal stabilizer and antioxidant additive, 0.3-0.7 part of adsorbent and 0.3-0.7 part of titanium dioxide. The invention has the advantages that the thermal resistance and thermal stability of the polylactic acid material are improved because of the temperature resistant additive or a polylactic acid nucleater and the mixture of the thermal stabilizer and the antioxidant additive; in addition, the tension thermoforming is carried out on a thermal steam box at 97-103 DEG C through a stretched fiber tow, the fiber tow is sprayed by using cold water before entering a crimping machine to avoid nodositas and stiffness of the fiber tow; the curled tow is sprayed by using a spraying device which is placed behind a crimping knife, and an anti-toxic smoke solution is placed in the spraying device, therefore, the affinity and the adsorbability of the cigarette filter tow on a toxic substance can be improved.

Owner:浙江恩实生物科技有限公司

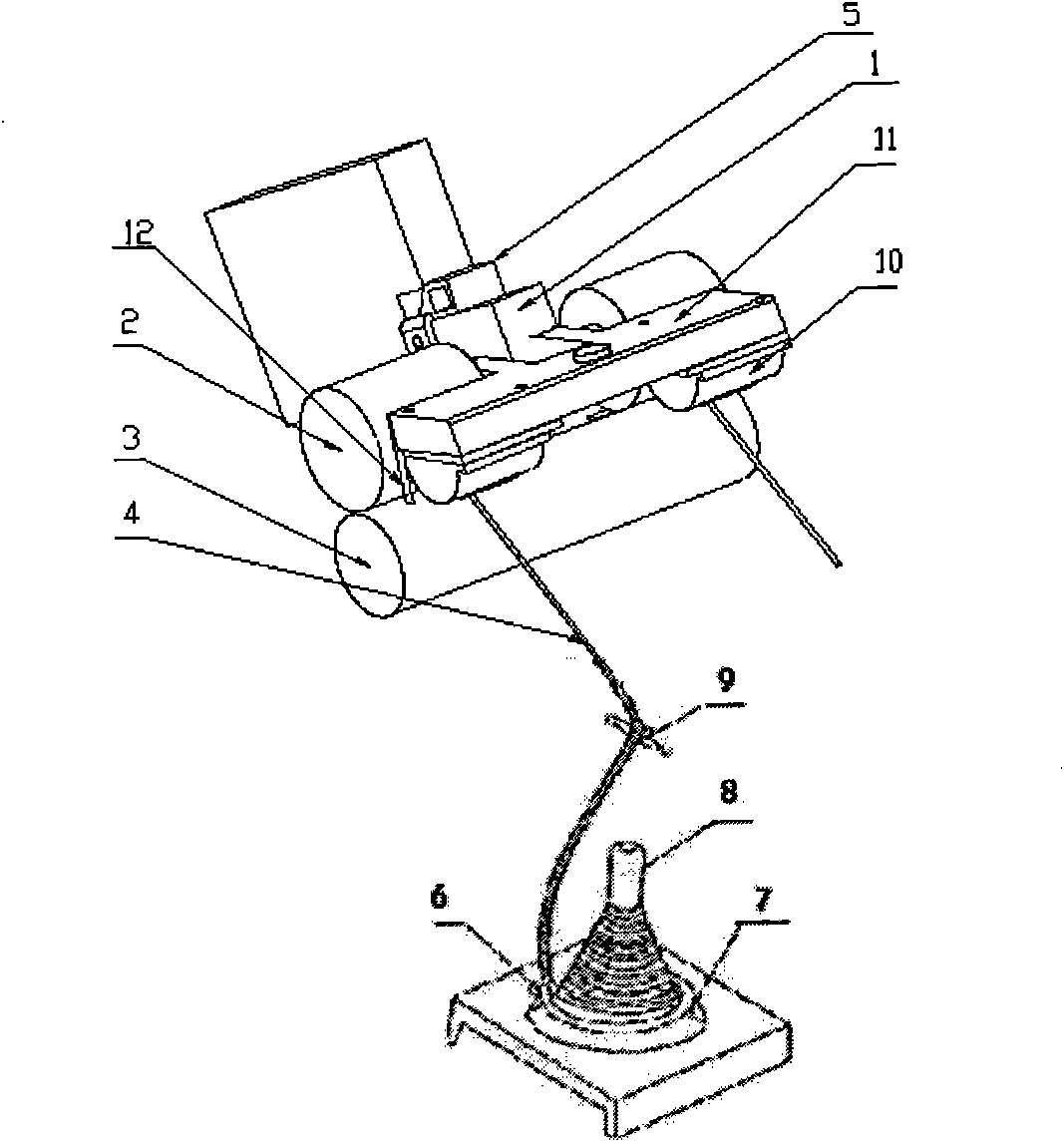

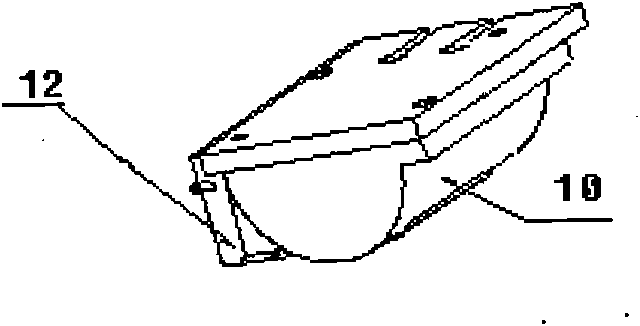

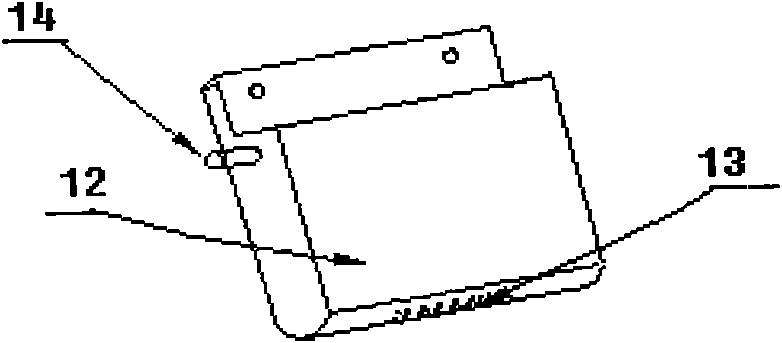

Spinning method for performing damp heat ironing treatment to fiber strands

The invention relates to a spinning method for performing damp heat ironing treatment to fiber strands, and belongs to the technical field of textile processing. A damp heat ironing treatment device is additionally installed in a twist trigonal zone in front of a front leather roller and a front roller of a ring spinning frame and used for performing damp heat ironing treatment to fibers in the fiber strands; the damp heat ironing treatment device comprises a base, a humidifying component and an ironing treatment component; the damp heat ironing treatment device can perform humidifying to the fibers in the fiber strands in the twist trigonal zone and then perform high-temperature ironing treatment, so that the rigidity of the fibers is instantaneously reduced, and the flexibility of the fibers is enhanced; and meanwhile, the movement of the fibers in the fiber strands in the twist trigonal zone is controlled. The spinning method can remarkably reduce the fibrous yarn of resultant yarn, enhance the strength of yarn formation and reduce the phenomenon of kinking due to twisting. The damp heat ironing treatment device is convenient for a knitter to operate, has little influence on the operation of the knitter, and is suitable for cotton fibers, wool fibers, fibrilia, polyester fibers, polyamide fibers and acrylic fibers.

Owner:WUHAN TEXTILE UNIV

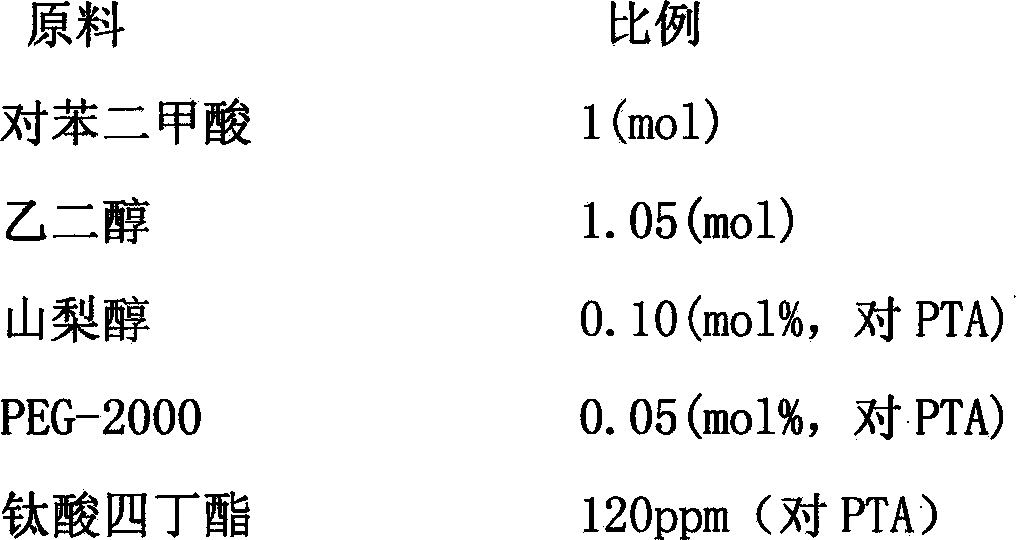

Preparation method for multi-functional hydrophilic polyester fibers

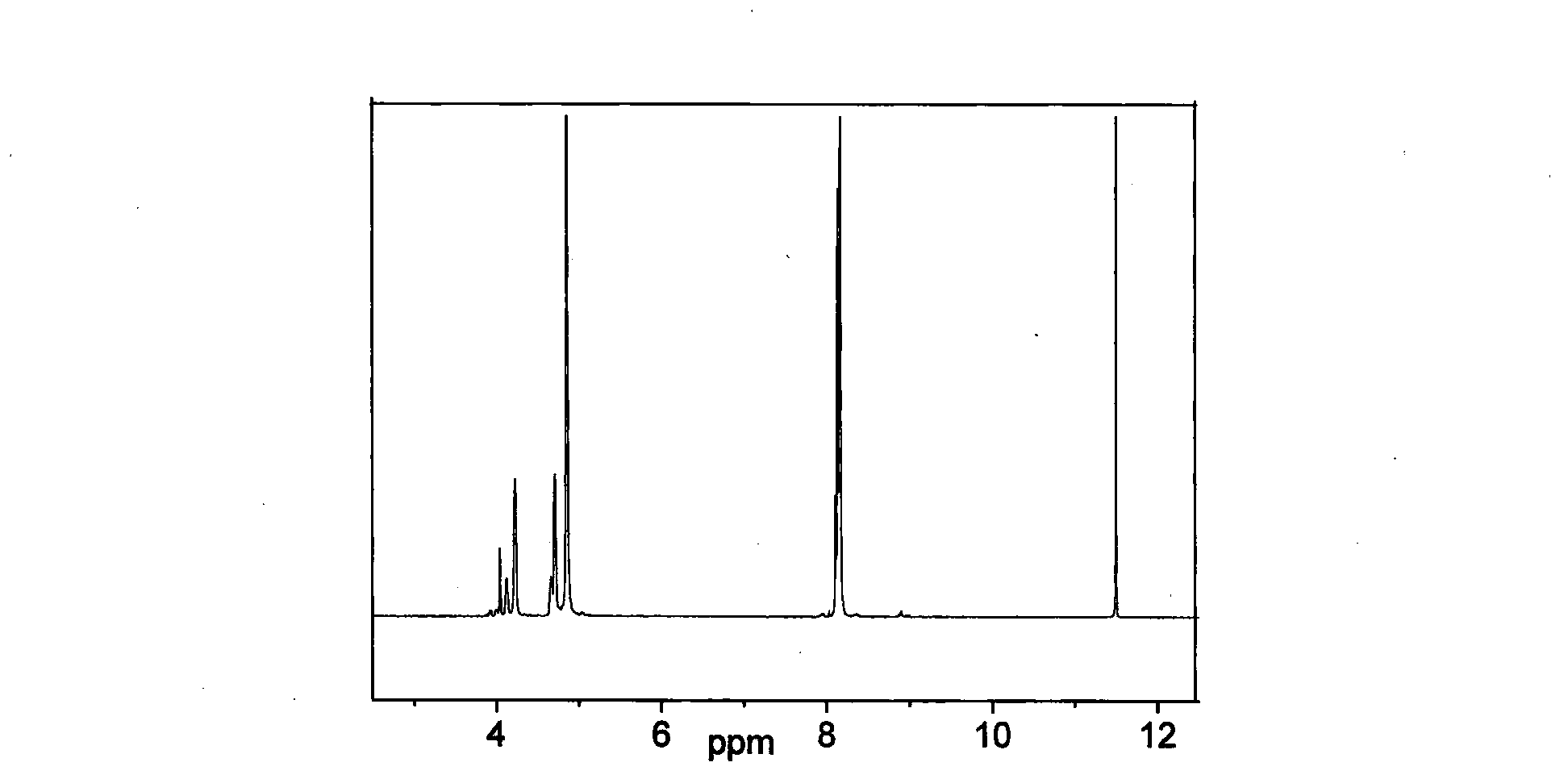

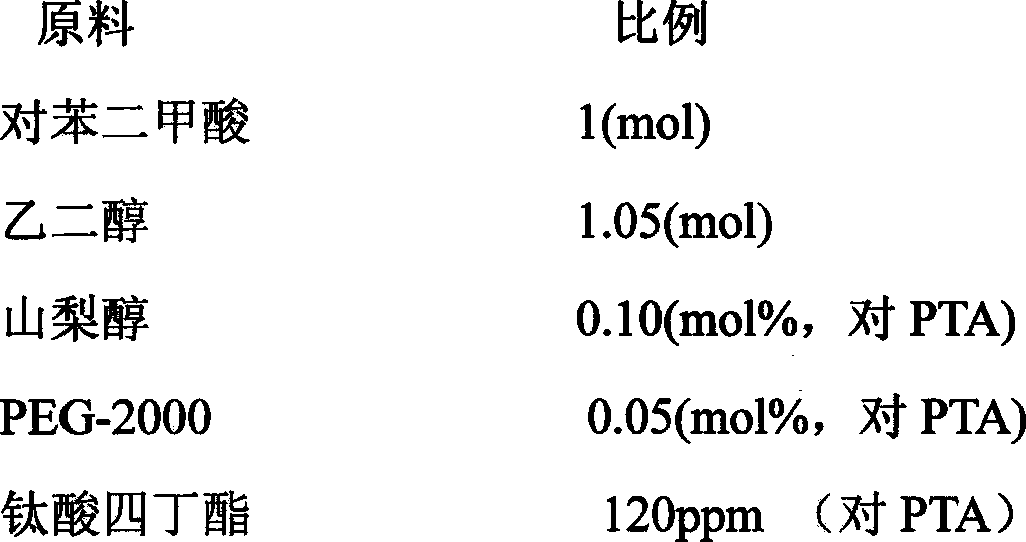

ActiveCN103820878AImprove hydrophilicityNo reactionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyethylene glycolEthylene glycol

The invention provides a preparation method for multi-functional hydrophilic polyester fibers. The method is characterized by specifically comprising the following steps: firstly, mixing terephthalic acid with ethylene glycol to prepare a paste; adding into an esterfying reactor to carry out first esterfying reaction; when the collecting quantity of byproducts reaches 82-95% of a theoretical value, adding sorbitol and polyethylene glycol to carry out second esterfying reaction; after finishing esterfying reaction, performing polycondensation reaction on obtained esterfied products so as to obtain a hydrophilic polyester chip; secondly, preparing nanometer coffee carbon powder; thirdly, preparing nanometer bamboo charcoal powder containing an ultraviolet resistor; fourthly, performing fusing granulation on the nanometer bamboo charcoal powder containing the ultraviolet resistor and the hydrophilic polyester chip so as to obtain functional master batch; fifthly, performing fusing spinning on the functional master batch and the hydrophilic polyester chip so as to obtain the multi-functional hydrophilic polyester fibers. The multi-functional hydrophilic polyester fibers have great hydrophilic performance and continuously have the functions of the ultraviolet resistor and the bamboo charcoal for a long term.

Owner:江苏三联新材料股份有限公司

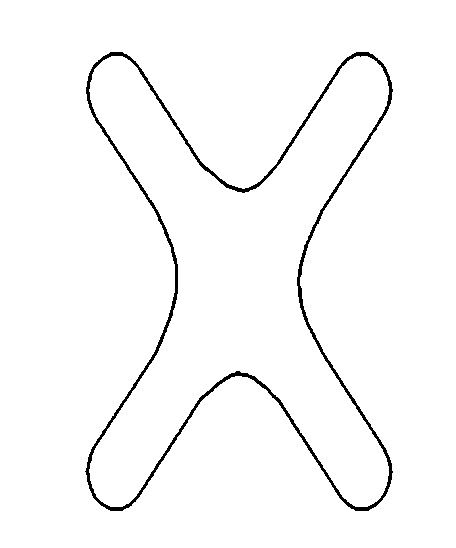

Porous ultrafine X-shaped polyester fiber and preparation method thereof

InactiveCN102851762AHigh porosityHigh degree of abnormalityFilament/thread formingMonocomponent polyesters artificial filamentPolyesterHeat setting

The invention discloses a porous ultrafine X-shaped polyester fiber and a preparation method of the porous ultrafine X-shaped polyester fiber. According to the porous ultrafine X-shaped polyester fiber, a spinning micropore structure of a spinning jet is in a shape of symmetric X blades; an obtuse angle ranges from100 to 110 degrees, and the length-width ratio of the blade is 5 to 8: 1; a cooling formation technology is the combination of annealing and cross air blow cooling; a first hot roll temperature under a thermal forming technology is at 88 to 92 DEG C, and a second hot roll temperature is at 125 to 130 DEG C, and the coiling is carried out at a speed of 3800 to 4200m / min. The fiber prepared by the preparation method provided by the invention is high in profile degree, and different fine groove capillary shapes are formed on the section; high porosity among the fibers is ensured, and the fibers are light in weight; the humidity conductivity and humidity absorbing performance of the fibers are effectively improved, and the water retaining performance and air permeability are effectively improved as well; and meanwhile, the fiber and fabric manufactured by the fiber have good effect of dyeing, and are easily dyed, and have the characteristics of being full in color and bright in gloss; and the fabric touches fluffy and elastic.

Owner:吴江赴东扬程化纤有限公司

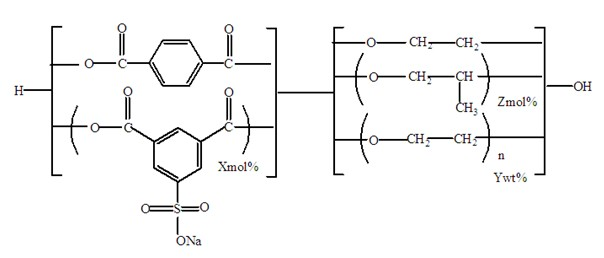

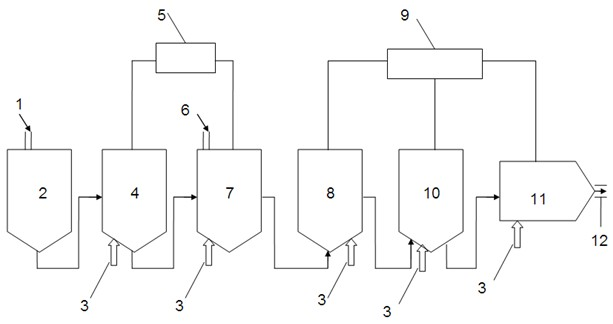

Hydrophilic copolyester slices prepared by continuous method and preparation method thereof

InactiveCN102504224AChange molecular structureImprove hydrophilicityMonocomponent polyesters artificial filamentArtifical filament manufactureCopolyesterDibasic acid

The invention discloses a continuous method for preparing hydrophilic copolyester slices and the hydrophilic copolyester slices prepared by the preparation method. The preparation method of the hydrophilic copolyester slices prepared by the continuous method comprises the following steps: continuously and uniformly adding pure terephthalic acid, ethylene glycol, benzene dibasic acid binary alcohol ester-5-sodium sulfonate, polydibasic alcohol, other dibasic alcohols, a delustering agent and the like into a beating kettle in proportion, performing esterification, prepolycondensation and polycondensation reactions, discharging, pelletizing and drying to get the hydrophilic copolyester slices. A continuous polymerization device is adopted for synthesis; and in the prepared hydrophilic copolyester slices, the molecular structure of polyester is changed by adding hydroxyl-containing components and inorganic powder into copolyester slices, thus the hydrophilic property is good. The preparation method is simple, the manufacturing process has no special requirements on the polymerization device, and the hydrophilic copolyester slices can be produced on existing domestic or imported equipment, so that the production cost is slow and industrial production is easy to realize.

Owner:DONGHUA UNIV

Hydrophilic polyester fiber containing coffee carbon and preparation method of hydrophilic polyester fiber

ActiveCN103820879AFine structureEffective absorptionMonocomponent polyesters artificial filamentArtifical filament manufactureChemistryPolyester

The invention provides a hydrophilic polyester fiber containing coffee carbon and a preparation method of the hydrophilic polyester fiber. The hydrophilic polyester fiber containing coffee carbon is characterized by comprising a hydrophilic polyester fiber body and nanoscale coffee carbon powder scattered in the hydrophilic polyester fiber body. The hydrophilic polyester fiber containing coffee carbon is good in hydrophilicity, can be used for deodorizing, warming and is dried quickly, and brings touch sensation of enjoying refreshing and comfort to consumers.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Flame-retardant antistatic yarn and fabric thereof

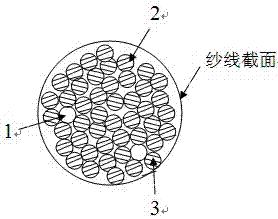

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Cashmere cotton face fabric and production technique thereof

InactiveCN101158080AIncrease color varietiesHigh moisture regainWeft knittingBiochemical fibre treatmentPerspirationEngineering

The invention relates to a fabric and a production technology thereof, in particular to a cashmere cotton fabric and a production technology thereof. The fabric is made by cashmere and purified cotton in a blending way, wherein, the weight percentages by content are 5 percent to 20 percent of the cashmere and 80 percent of 95 percent of the purified cotton, which are formed by tatting or knitting. The technological processes of the invention are that: 1. a base cloth processing process, a tatting method or a knitting method is adopted to weave the base cloth according to different thread count and requirements of specification; 2. a handling process of the base cloth, a. a singeing process; b. a desizing process; c. a refinement process; d. an oxygen bleaching process: e. a coloration process; and f. a post handling process. The clothes produced by cashmere cotton fabric have wet permeability, air permeability, perspiration and no peculiar smell in summer; when being worn in winter, the clothes are smooth and comfortable, warmth-preserving and thick, which plays a role as a synovium between skin and warmth preservation, thereby causing people to feel easy and comfortable; when being worn in spring, the clothes are light, gentle, and thin, and have good sense of sagging.

Owner:杨竹园

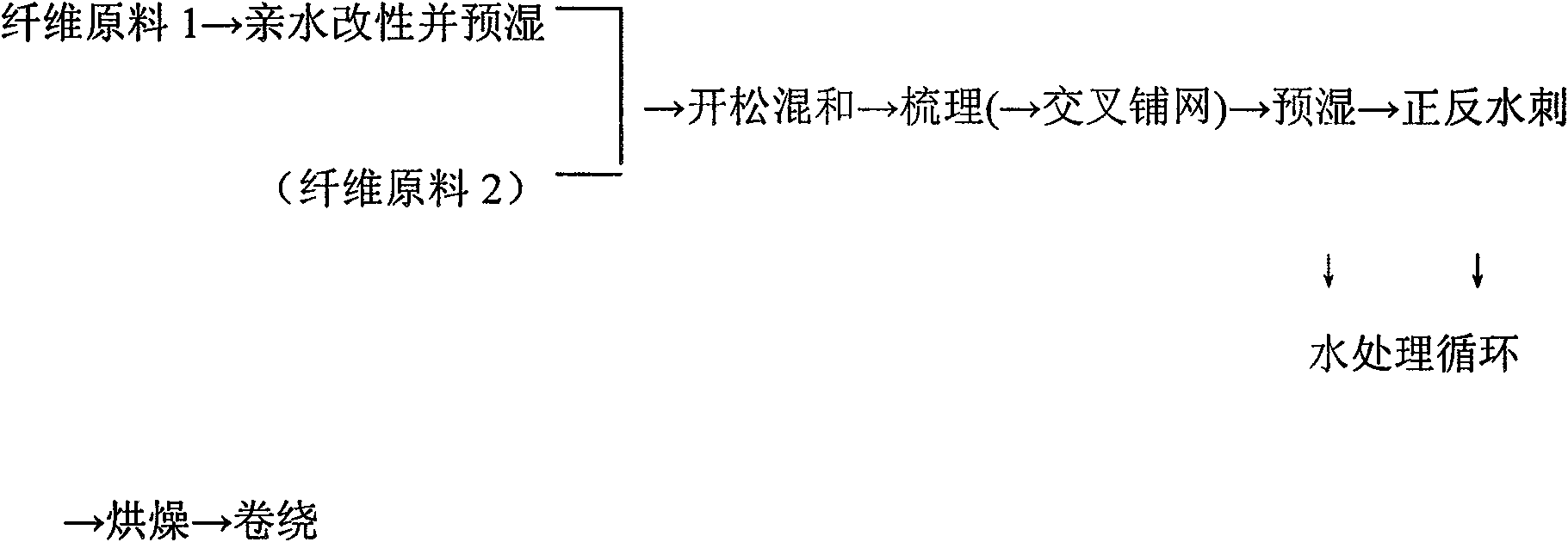

Modification method for preparing highly-hydrophilic real silk fiber spunlace non-woven material

The invention relates to a modification method for preparing a highly-hydrophilic real silk fiber spunlace non-woven material, which comprises the following steps: soaking real silk in hydrophilic modification solution for 8 to 10 minutes, taking out the real silk, dehydrating and drying the real silk, and cutting the real silk into short fibers of 30 to 50 millimeters in length; and spraying water to prewet the real silk short fibers, controlling the moisture regain to be less than or equal to 17 percent, sealing the real silk short fibers for 24 hours and then taking out the real silk short fibers, and processing the real silk short fibers in a carding machine of which the linear velocity is between 30 and 120 meters per minute and the hydraulic pressure is between 30 and 100 bars. The highly-hydrophilic real silk fiber spunlace non-woven material prepared by the modification method has the advantages of soft texture, good gloss, no off-flavor, good moisture absorption, air permeability and no chemical additives, and belongs to green environment-friendly products.

Owner:DONGHUA UNIV

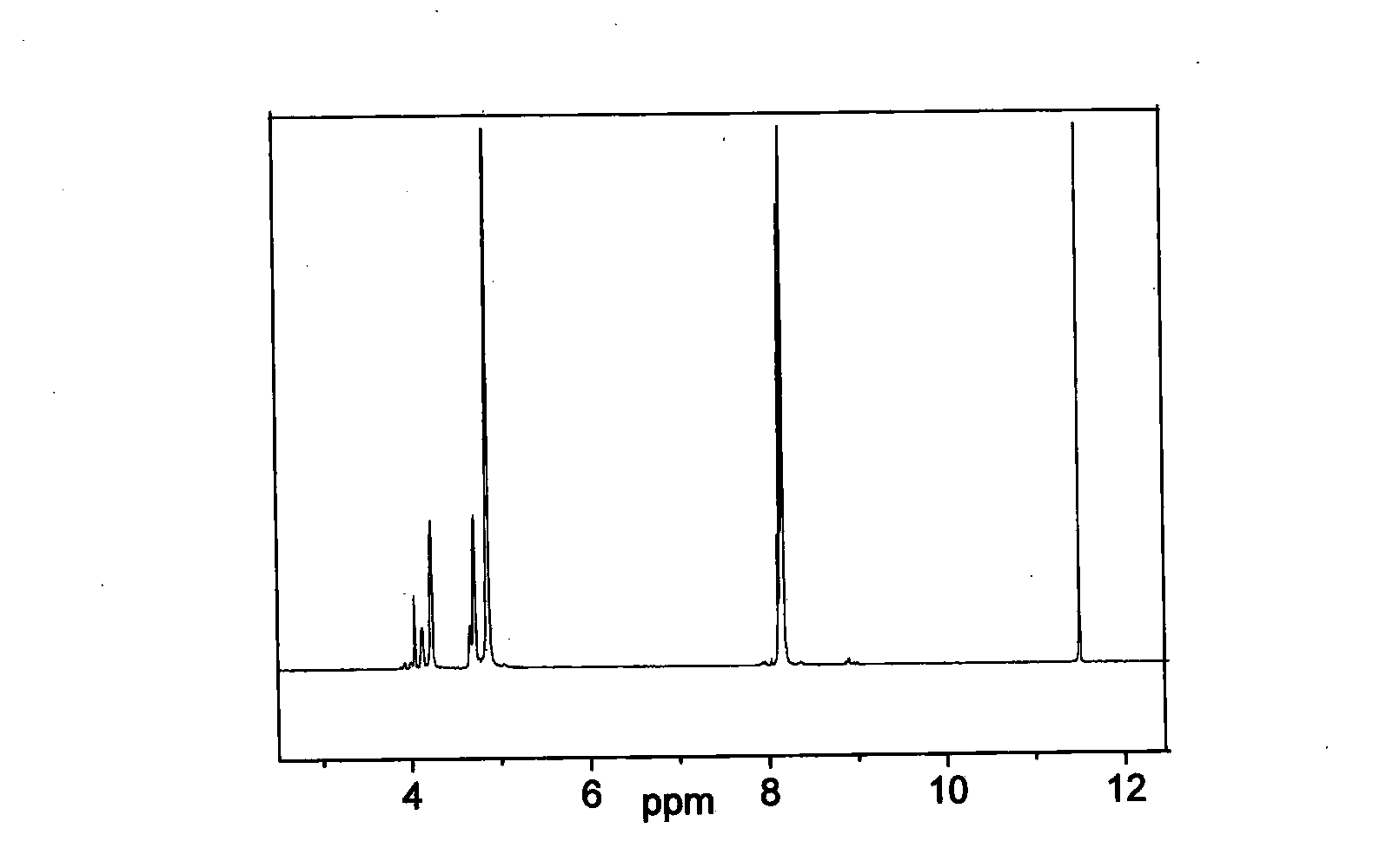

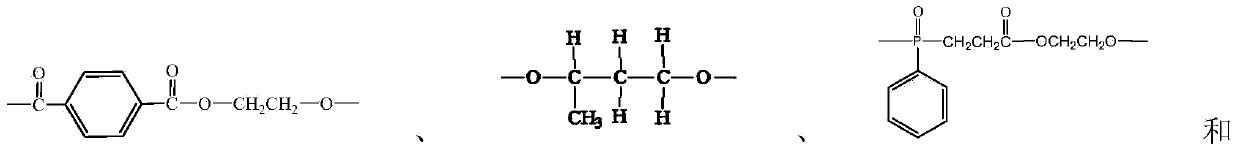

Preparation method of high-hydrophilicity flame-retardant polyester fiber

ActiveCN103628173AImprove hydrophilicityNo reactionArtificial filament heat treatmentMonocomponent copolyesters artificial filamentPolyesterPolymer science

The invention relates to a preparation method of high-hydrophilicity flame-retardant polyester fiber, which comprises the steps of (1) enabling a copolymer flame retardant to react with polyalcohol to obtain CEPPA (carboxethyl phenylphosphinic acid)-polyalcohol; (2) enabling hydroxyl-terminated siloxane to react with ethylene glycol in the presence of a catalyst to obtain a hydroxyl-terminated siloxane-ethylene glycol solution; (3) preparing slurry, and adding the prepared slurry into an esterification reaction kettle to perform a first esterification reaction; (4) when the quantity of the collected byproducts reaches 82-95% of the theoretical value, adding polyalcohol, sodium sulfo bis(hydroxyethyl) isophthalate (SIPE) and polyethylene glycol (PEG) to perform a second esterification reaction; (5) after the esterification reaction, adding the products obtained by the steps (1) and (2) into a reaction kettle, and after the condensation polymerization reaction, performing melt spinning to obtain the high-hydrophilicity flame-retardant polyester fiber. The limit oxygen index of the polyester fiber prepared by the method provided by the invention is over 30%, the moisture regain is 0.6-2.0%, and the fiber has relatively high moisture regain and is comfortable to wear.

Owner:DONGHUA UNIV

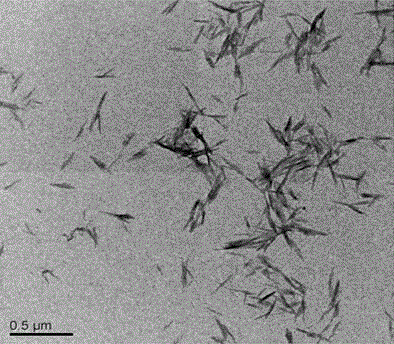

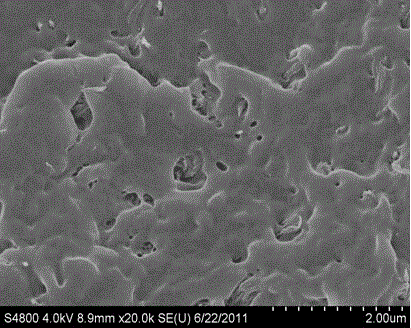

Hydrophilic polyester fiber modified by cellulose nanocrystal and preparation method thereof

ActiveCN104404647AImprove accessibilityGood dispersionMonocomponent polyesters artificial filamentArtifical filament manufactureCelluloseAlcohol

The invention relates to a hydrophilic polyester fiber modified by cellulose nanocrystal and a preparation method thereof and aims to solve a problem of a poor hydrophilicity of conventional polyester. The preparation method includes following steps: (1) mixing a cellulose nanocrystal aqueous suspension liquid and 75-85% by weight of ethylene glycol and removing water from a mixed liquid to prepare an ethylene glycol suspension liquid of the cellulose nanocrystal; (2) preparing a mixed slurry liquid from the ethylene glycol suspension liquid of the cellulose nanocrystal and terephthalic acid; (3) preparing a catalyst liquid form the balanced ethylene glycol and a catalyst; (4) mixing the mixed slurry liquid, the catalyst liquid and a thermal stabilizing agent, and performing a first esterification reaction in a reaction kettle with stirring and heating; (5) performing a secondary esterification reaction with addition of a polyhydroxy-alcohol; (6) performing vacuumizing condensation polymerization to obtain a hydrophilic polyester melt, and cooling and pelleting the melt to obtain a hydrophilic polyester chip; and (7) performing melt spinning to the hydrophilic polyester chip to prepare the hydrophilic polyester fiber.

Owner:嘉兴逸鹏化纤有限公司

Method for manufacturing yarns with aramid fiber 1414 waste silk short fibers

The invention relates to the technical field of spinning, dyeing and finishing, and discloses a method for manufacturing aramid fiber yarns with aramid fiber 1414 waste silk short fibers. According to the characteristics of aramid fiber 1414 waste silks, on the basis of the traditional work flow, a set of suitable spinning technologies are provided through control over the fiber moisture regain, control over temperature and humidity of each spinning working procedure, allocation of card clothing of a carding machine, control over the speed of a drawing frame and allocation of the hardness of a rubber covered roller. The method can effectively improve the spinning performance of the aramid fiber 1414 waste silk short fibers, and the spinning quality of the aramid fiber 1414 waste silk short fibers can be guaranteed.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Weaving of core-spun yarn

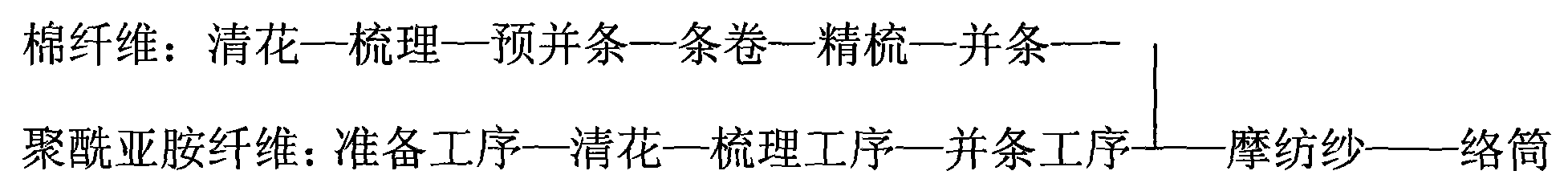

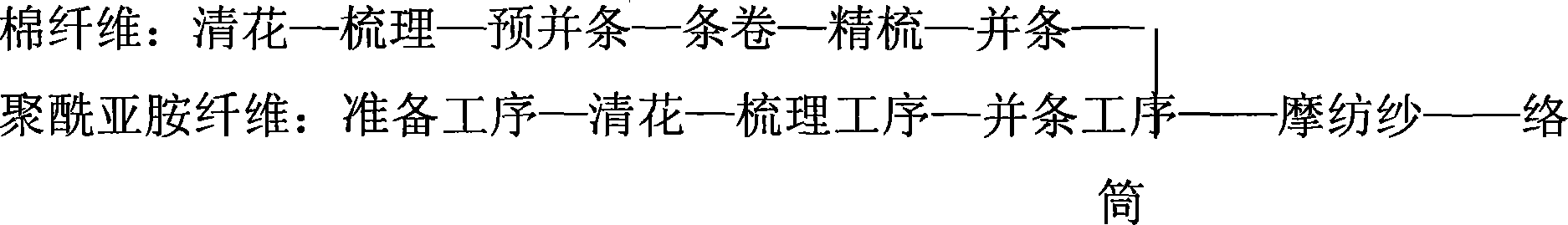

The invention provides a brand novel weaving concept of the fabrics of polyimide and cotton fiber core-spun yarn variety; polyimide functional fiber and natural cotton fiber are used as raw material, and the process that leads the natural cotton fiber and the polyimide fiber into cleaning cotton, carding, pre-drawing, sliver lap, combing and drawing respectively is adopted. The spinning process is carried out on a friction spinning machine; polyimide fiber rod is put into the twisting area of a dust cage after being drafted, thus forming core yarns. Cotton fiber rod, after being drafted by a roller, is combed into single fiber condition by a combing roller and is coated outside the core yarns under the function of the dust cage, so as to form the structure of coating core yarns externally and shortening the technical process; meanwhile the adding of natural fiber improves the whole moisture regain of the yarns, reducing the electrostatic phenomena, improving the cloth performance and strengthening the dyeing ability of the yarns. The produced yarns can be used as clothing material, etc. for outdoor work, thus improving the producing value of the products.

Owner:SHENGHONG GRP CO LTD

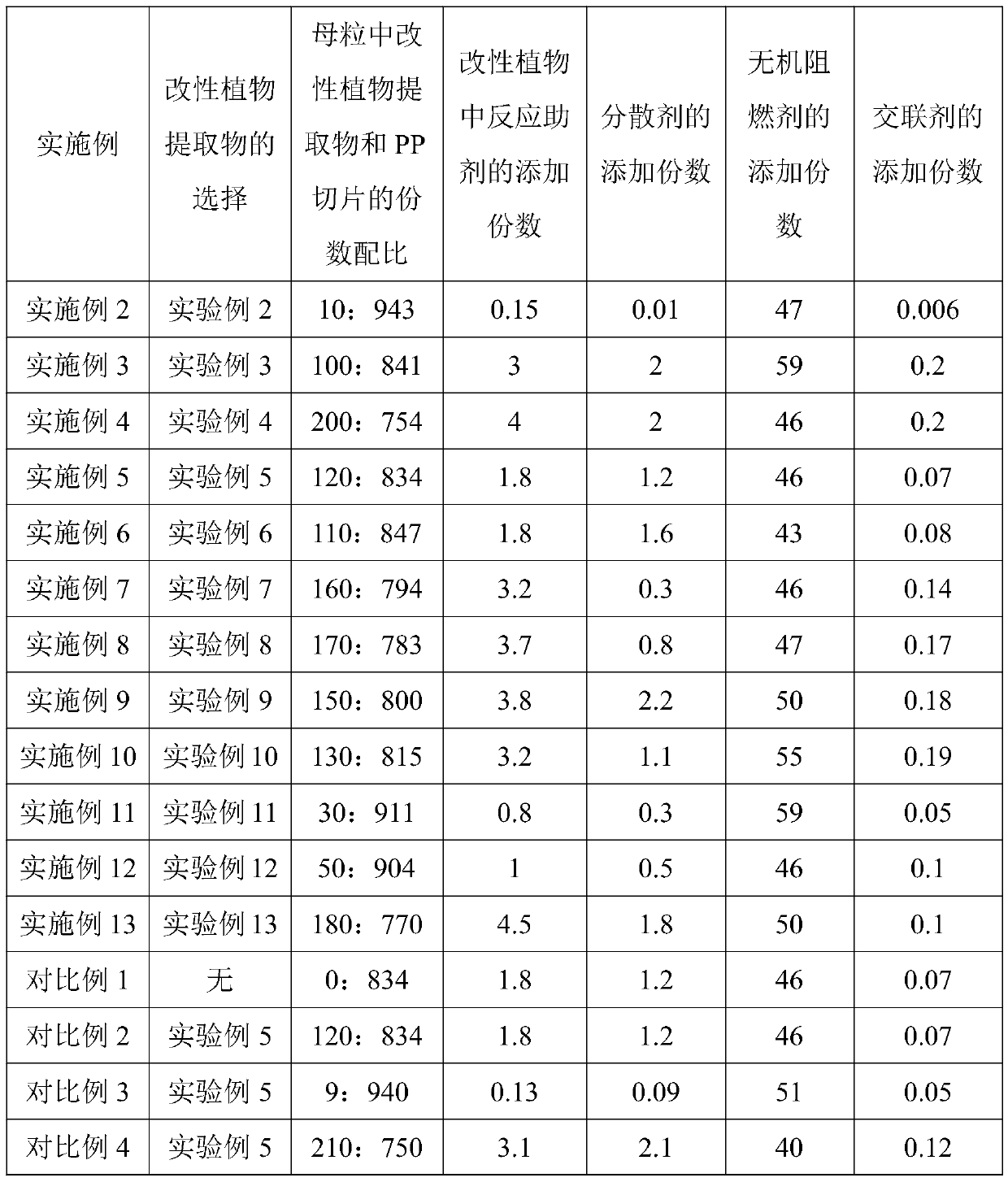

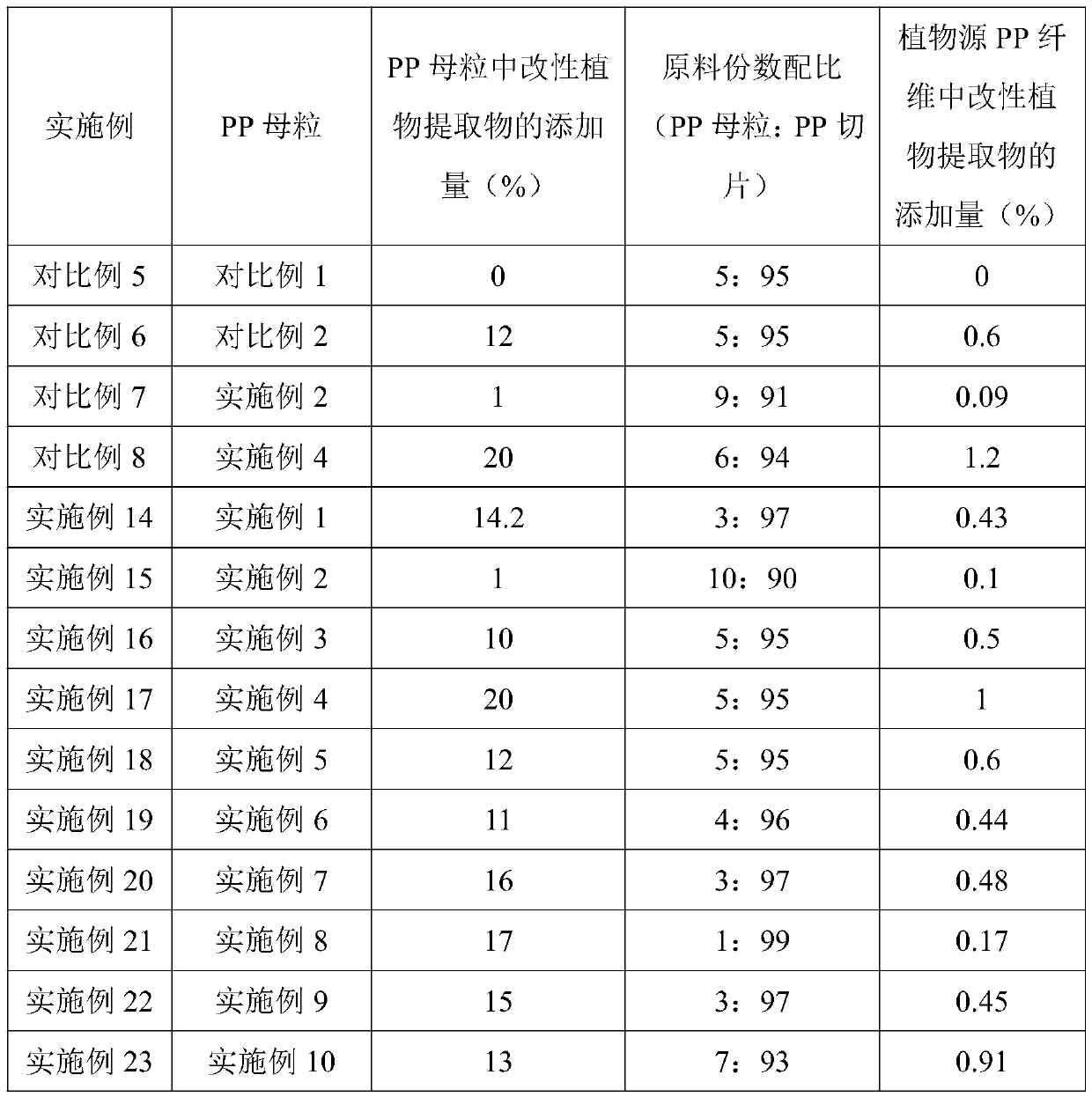

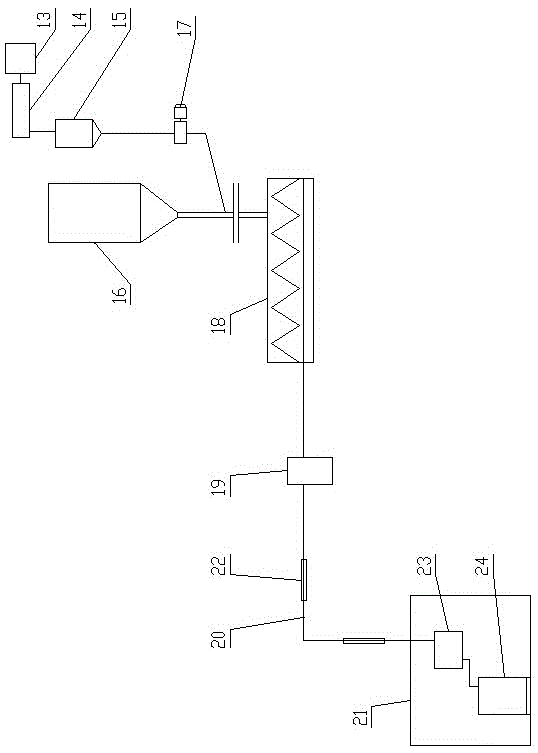

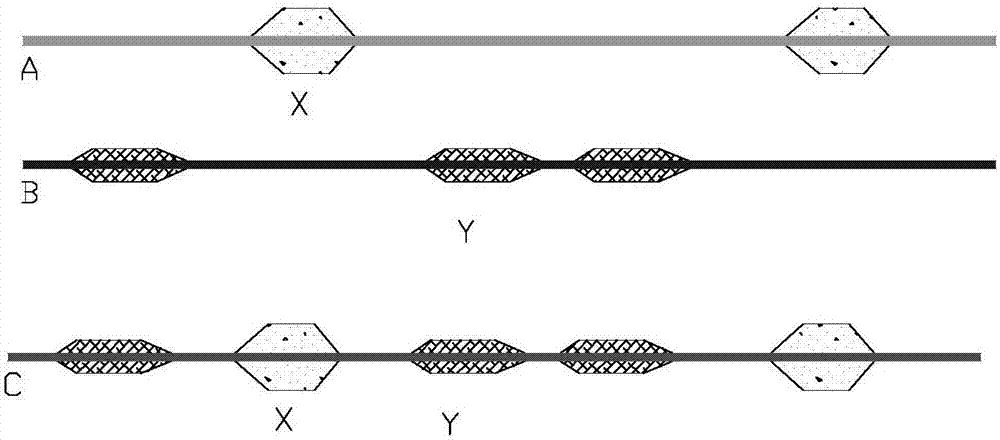

Plant-derived PP master batch, preparation method and application thereof

The invention provides a plant-derived PP master batch, a preparation method and application thereof. According to the method, anti-carbonization additives chitin and starch are added into plant extract powder, and a modified plant extract is obtained after internal mixing of an internal mixer, so that carbonization in the subsequent high-temperature melting process is reduced; and the modified plant extract and PP slices are blended and melted to prepare plant-derived PP master batches, and products containing the modified plant extract, such as polypropylene fibers, films or plastics, are prepared through spinning, injection molding, extrusion, blow molding, thermal forming and other methods. According to the invention, the plant-derived PP master batch is uniform in particle and smoothin surface; the prepared product has the advantages that the mechanical property is reduced, the normal use is not influenced, the functions of fragrance, antisepsis, anti-inflammation, cooling, health care and the like of plants can be realized, the moisture regain of the prepared polypropylene fiber is improved, and the comfort is enhanced.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Bamboo charcoal polylactic acid particle spinning technology

ActiveCN105463589AImprove scraping efficiencyEasy to manufactureSpinning head liquid feederMelt spinning methodsHigh wear resistanceMoisture regain

A bamboo charcoal polylactic acid particle spinning technology comprises the steps that bamboo charcoal micro powder and polylactic acid particles are mixed and then sent to a granulation screw extruder to be produced into a bamboo charcoal polylactic acid master batch; the bamboo charcoal polylactic acid master batch is dried; the bamboo charcoal polylactic acid master batch is subjected to quantitative metering of a micro-meter and then sent into a spinning screw extruder together with polylactic acid dry chips to be processed into a bamboo charcoal polylactic acid melt; the bamboo charcoal polylactic acid melt is filtered through a melt filter; the filtered bamboo charcoal polylactic acid melt is sent into a spinning manifold through a melt pipeline; the bamboo charcoal polylactic acid melt is spun into bamboo charcoal polylactic acid fiber through a spinning component in the spinning manifold. According to the spinning technology, polylactic acid is modified through nanoscale bamboo charcoal micro powder, so that the prepared fiber has lower initial modulus, higher moisture regain, higher wear resistance, higher air permeability and better hand feeling.

Owner:HENAN LONGDU BIOLOGY TECH

Hollow soft antibacterial yarn

PendingCN109183225AImprove breathabilityGood air permeability, good antibacterial and deodorizing propertiesYarnYarnCarbon fibers

The invention discloses a hollow soft antibacterial yarn. The yarn includes a yarn body, wherein the yarn body is of a sheath core structure, the yarn body is a hollow yarn, an inner portion is a hollow core, the yarn body sequentially includes a bamboo charcoal fiber layer, a coffee carbon fiber layer and a colored cotton fiber layer from the inside to the outside in the radial direction of the yarn body, the hollow core of the yarn body is formed through hydrolysis of a core yarn made of the water-soluble vinylon fiber, the bamboo charcoal fiber layer is formed by spirally winding raw bamboofibers, the bamboo charcoal fiber layer is internally filled with silver nano particles, the coffee carbon fiber layer is formed through spirally covering the coffee carbon fiber outside the bamboo charcoal fiber layer, and the colored cotton fiber layer is formed by spirally covering the colored cotton fiber outside the coffee carbon fiber layer. The yarn is advantaged in that the hollow yarn structure is utilized, the bamboo charcoal fiber layer and the coffee carbon fiber layer are arranged internally, and the yarn is super soft and super fluffy, has good warmth keeping effect, breathability, good antibacterial and deodorizing performance, the bright color and no dye need and can realize environmental protection and energy saving.

Owner:苏州璟珮新材料科技有限公司

Novel manufacturing method for linen-cotton blended yarn

The invention relates to a novel manufacturing method for a linen-cotton blended yarn. The novel manufacturing method comprises raw material pretreatment, treatment before blending and treatment after bending. The raw material pretreatment comprises firstly softening a fibrilia, blowing, carding and packaging the fibrilia, secondly softening the fibrilia, and blowing, carding and packaging a cotton fiber. The treatment before blending comprises arranging and mixing packages of the fibrilia and the cotton fiber which have been pretreated respectively on a disc cotton picking according to a set weight ratio, and blowing, carding and drawing in order using a blowing machine, a carding machine and a drawing frame to obtain linen-cotton fiber strips. The treatment after bending comprises roving, spinning, winding and packing the linen-cotton fiber strips. According to the novel manufacturing method for the linen-cotton blended yarn, the fibrilia are softened twice, the spinnability of the fibrilia is improved, the work efficiency is raised, the cost of production is reduced, at the same time, the quality of the yarn is raised, the minimal brute force and the average brute force of the yarn can be increased, the uniformity of the yarn is improved, and the hairiness value, nep and other indexes are distinctly improved.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

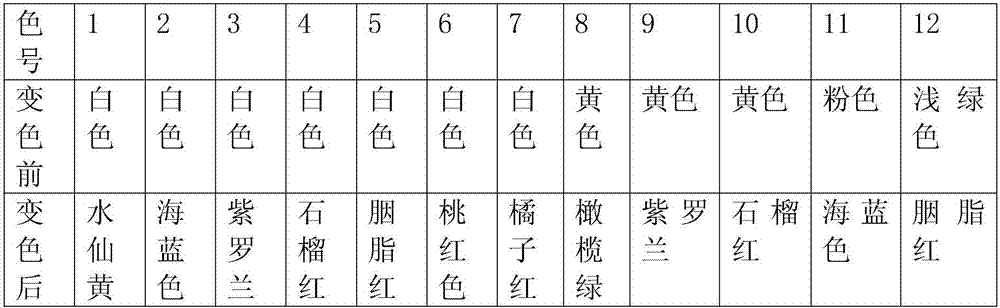

Production technology of discoloring antibacterial anti-ultraviolet fabric

The invention discloses a production technology of discoloring antibacterial anti-ultraviolet fabric. Through a yarn design, by using color characteristics of functional fiber, fancy yarn is developed and prepared to produce the fabric, and the textile meets functional requirements of the market and has fashion characteristics, so that the market space of the functional fiber is expanded. The production technology of discoloring antibacterial anti-ultraviolet fabric is antibacterial, anti-ultraviolet, cool, permeable in moisture and air, discoloring, fashionable and unique in fabric style, and can be used in both sides.

Owner:南通北岸纺织科技有限公司

Mono-fiber yarn process for Chinese hemp fiber

The invention provides a mono-fiber yarn process for Chinese hemp fiber. The process is characterized by comprising the following steps of: selecting 2,500 to 3,000 metric counts of good-quality Chinese hemp fibers, tearing the Chinese hemp fibers into uniform pieces, uniformly a spraying solution which is 8 percent of the weight of the Chinese hemp fiber on the pile of the Chinese hemp fiber, and performing enzymatic treatment on the Chinese hemp fiber for 72 hours and then putting into production in a tank; and performing Chinese hemp fiber, blowing, cotton carding, drawing, roving and spinning. In all procedures, the relative humidity is kept between 58 to 65 percent. The products produced by the process provided by the invention can be made into various blended fabric, and a purely natural and comfortable textile product is added to the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

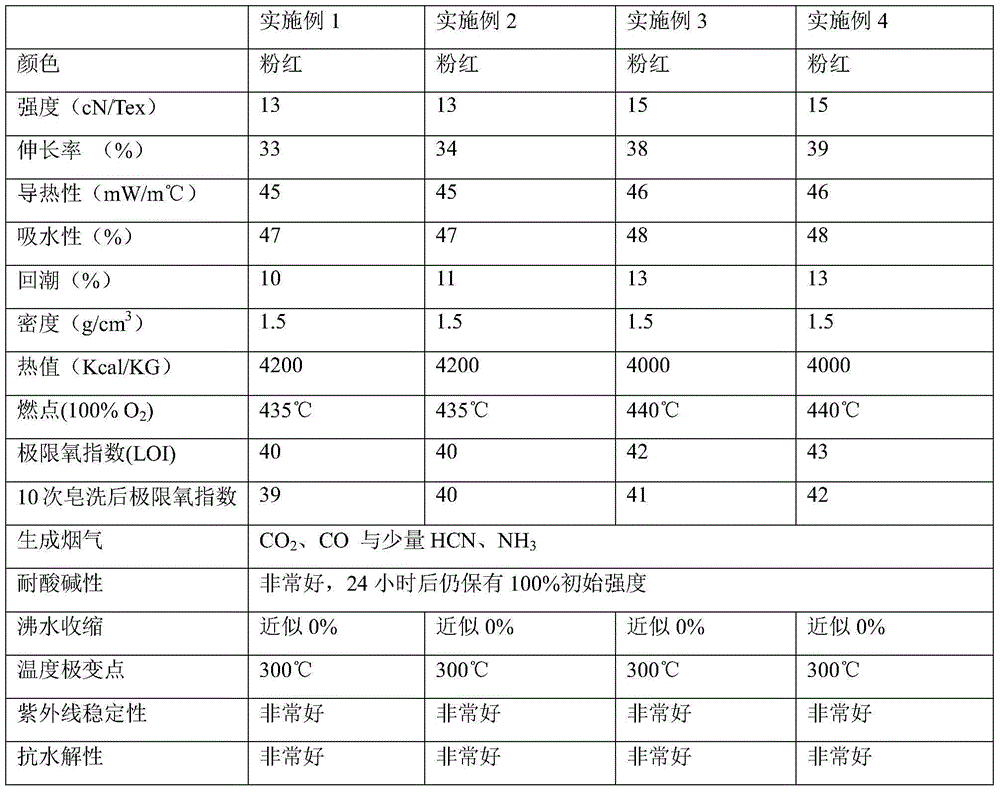

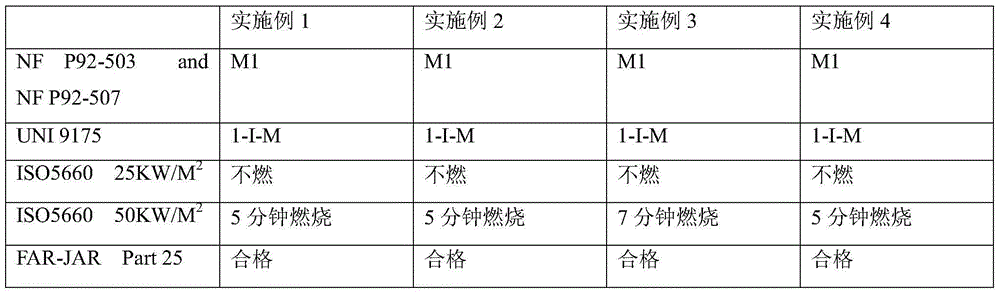

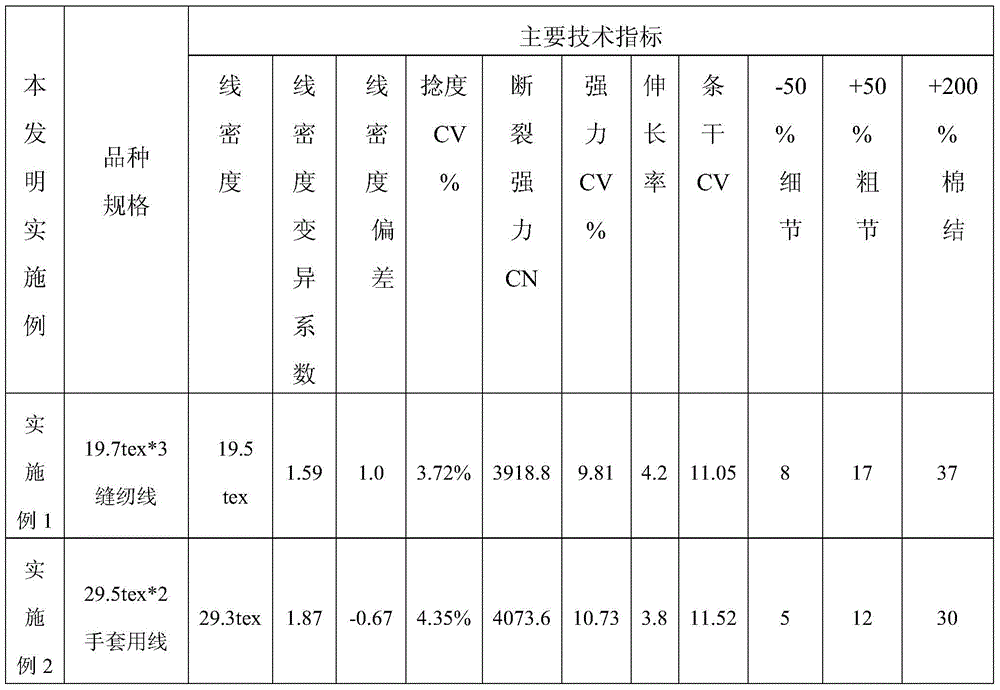

High temperature-resistant flame retardation polyacrylonitrile fiber and production method thereof

ActiveCN105986474AHigh limiting oxygen indexWon't meltFibre typesDyeing processPolymer scienceMoisture regain

The invention relates to a polyacrylonitrile fiber, and concretely relates to a high temperature-resistant flame retardation polyacrylonitrile fiber and a production method thereof. The method concretely comprises the following steps: processing a polyacrylonitrile fiber in a hydrazine solution with the concentration of 7-20wt%, processing the hydrazine processed fiber in an alkaline solution with the concentration of 3-10wt%, washing the alkali processed fiber with water until the fiber is neutral, processing the neutral fiber in an aqueous metal ion salt solution with the concentration of 3-10wt%, oiling the metal salt processed fiber, dehydrating the oiled fiber, and drying the dehydrated fiber to obtain the high temperature-resistant flame retardation polyacrylonitrile fiber. The flame retardation performance LOI of the flame retardation fiber obtained in the invention can reach 40-45, the flame retardation grade is M1, and the amount of smoke generated in the combustion process is very small, the grade of toxic gases is FO, and the smoke amount of the flame retardation fiber in the invention is lower than that of other flame retardation fibers. The flame retardation fiber in the invention has the advantages of high moisture regain rate, high water absorption rate, good dyeability and low shrinkage in boiling water.

Owner:JILIN ACRYLIC FIBERS CO LTD

Flame-retardant antistatic blended yarn and production method thereof

ActiveCN106048800AGood flame retardant and antistatic effectFunction increaseYarnYarnEconomic benefits

The invention discloses flame-retardant antistatic blended yarn and production method thereof, and the blended yarn has a good antistatic effect, durable functions, good wearability and low production cost. The blended yarn is manufactured by blending the following materials in mass percent: 20% to 70% of flame-retardant viscose, 20% to 70% of flame-retardant acrylic fiber and 5% to 10% of stainless steel fiber. The production method includes raw material pretreatment, an opening picking process, a cotton carding process, a drawing process, a roving process and a spinning process. The flame-retardant antistatic blended yarn produced by the production method is light grey, and a test shows that the quality indexes of the blended yarn reach the first-class yarn level. A flame-retardant antistatic effect is good, and the blended yarn is suitable for industry requirements having special flame-retardant antistatic requirements, and has good economic benefits and market application prospects.

Owner:HENAN INST OF ENG

Novel method for controlling moisture regain of wool yarns

ActiveCN102560934AHigh moisture regainProtect interestsLiquid/gas/vapor removalYarnPulp and paper industry

The invention discloses a novel method for controlling moisture regain of wool yarns, which mainly comprises a yarn steaming machine. The power of a negative-pressure pump of the yarn steaming machine is increased under negative pressure of the yarn steaming machine, so that vacuum degree of the yarn steaming machine is promoted. Wool requiring moisture regain is placed in the yarn steaming machine, and steam is fed into the yarn steaming machine at 50-60 DEG C for circulation for two to three times. Moisture regain of the wool can be increased effectively to reach commercial moisture regain without affecting the wool yarns and shaping. Different wool yarns require different moisture regains, which can be met by changing vacuum degrees, temperature and circulation times. The method is simple, convenient, short in usage time and effective in moisture regain, enormous benefits can be brought for enterprises, and profits of the enterprises can be maintained.

Owner:ZHEJIANG XINAO

Novel gertrude fabric having functions of stain repellence, skin affinity, moisture permeability and breathability

ActiveCN105239260AAbsorb in timeKeep dryWeft knittingUndergarmentsActivated carbonMoisture permeability

The invention provides novel gertrude fabric having functions of stain repellence, skin affinity, moisture permeability and breathability. The raw material of the gertrude fabric comprises the following components: 40-80 parts by weight of silkworm pupa protein viscose, 30-50 parts by weight of soft silk fibers, 15-25 parts by weight of superfine activated carbon fibers, 50-60 parts by weight of soybean fibers and 50-60 parts by weight of milk fibers. The concrete preparation technology comprises following steps: putting raw material into a workshop and allowing raw material to stand for 24 hours and combing; and forming the gertrude fabric by knitting technology or weaving technology through a machine. The novel gertrude fabric having functions of stain repellence, skin affinity, moisture permeability and breathability has following beneficial effects: raw material of the gertrude fabric is eco-friendly fibers; fine moisture absorption and breathability of the fabric are obtained; and the function of skin affinity, sterilization and stain repellence are fulfilled so that the gertrude fabric has functions of stain repellence, skin affinity, moisture permeability and breathability which can satisfy various needs of infants' clothing and is excellent in functionality and is beneficial to marketing.

Owner:广东普利诗内衣实业有限公司

A method for preparing yarn from aramid 1414 waste short fiber

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Cellulose modal and colored cotton blended spinning technique

The invention relates to a cospinning spinning technology with the Modal fiber and color cotton belonging to the spinning technology field, comprising the following working procedure: opening, carding cotton, combing, sliver lap, drawing, roving, yarn, cheese winding, the front four working procedures are independent aiming at the Modal fiber and color cotton respectively, the rest working procedures are combined into a common working procedure, the whole working procedure adjusts and improves the parameter and condition of the technology according to the property of the two raw materials, including: a plucker, an opener, and a lap former which are in the opening working procedure; a cotton feeder in the carding cotton working procedure; a drawing frame, a lap former, and a combing machine which are in the combing working procedure; the drawing working procedure adopts a triple drawing and the Rolla Gauge, the roving and yarn working procedures is adjusted through the Rolla Gauge. The invention offsets the disadvantage of the raw material through the improvement to the processing technic, the final yarn has good intensity and uniformity, the fabric feels smooth, the color is natural, which is an ideal environmentally friendly products.

Owner:DONGYING QILONG TEXTILE

Production method of antistatic nylon 56 fibers

PendingCN111321481ADoes not affect mechanical strengthGood compatibilityElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSpinning

The invention discloses a production method of antistatic nylon 56 fibers. The method comprises the following steps: (1) under the protection of nitrogen, bio-based pentane diamine reacts with adipicacid in water to obtain a nylon 56 saline solution; (2) the nylon 56 saline solution reacts with a molecular weight regulator, then an antistatic agent is added, vacuumizing is performed, and nylon 56polymer melt is obtained by stirring; and (3) the nylon 56 polymer melt is put into a spinning manifold and the antistatic nylon 56 fibers are obtained by spinning, cooling, oiling and moistening, drafting, tension heat setting, curling, oiling, relaxation heat setting and cutting. The antistatic nylon 56 fibers obtained by the invention have the advantages of excellent antistatic performance, good fabric air permeability, high moisture regain, wear resistance and comfort and can be widely applied to the aspects of textiles, general engineering materials, automobile manufacturing, sports equipment, aviation and space navigation.

Owner:优纤科技(丹东)有限公司

Antistatic fabric and preparation method thereof

ActiveCN112779660ALarge specific surface areaSmall sizeElectroconductive/antistatic filament manufactureWarp knittingPolyesterFiber

The invention aims to provide an antistatic fabric and a preparation method thereof. The antistatic fabric is formed by warp-knitting antistatic yarns and polyamide yarns, wherein the density of the antistatic yarns is 80-100 yarns / cm, and the density of the polyamide yarns is 50-90 yarns / cm; and the antistatic yarns are prepared from antistatic polyester fibers, and the antistatic polyester fibers are prepared from polyester chips and antistatic polyester master batches through a melt blending spinning method. The antistatic PET polyester fibers are added into a carbon nanotube with a conductive filler; the carbon nanotube has the advantages of large specific surface area and small size and has a special macroscopic quantum tunnel effect, a quantum size effect and a surface effect; and the prepared PET polyester fibers have excellent antistatic performance and good comprehensive performance. Meanwhile, the antistatic PET polyester fibers are made into yarns and then the yarns and polyamide are woven into the composite antistatic fabric, the advantages of the yarns and the polyamide are combined, and the performance of a PET polyester material is further improved.

Owner:吴江嘉伦织造有限公司

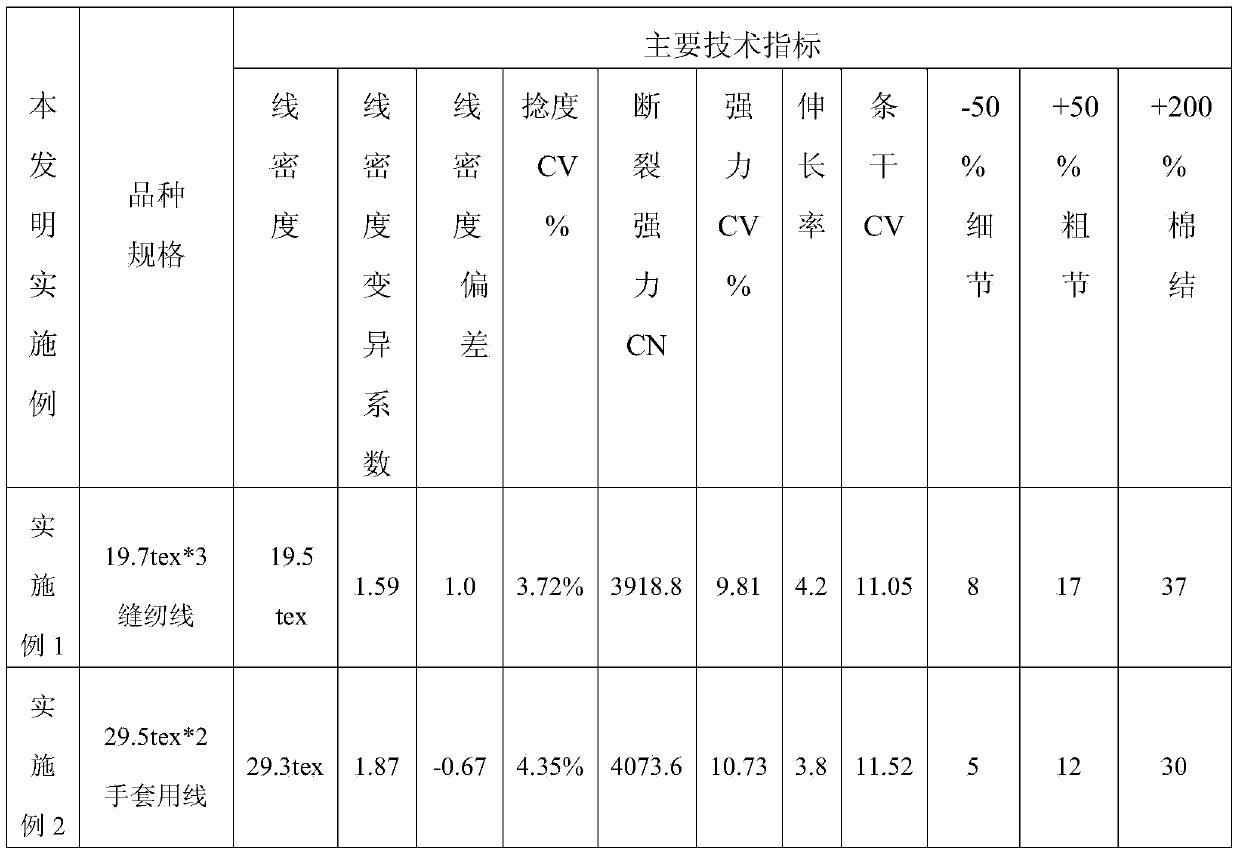

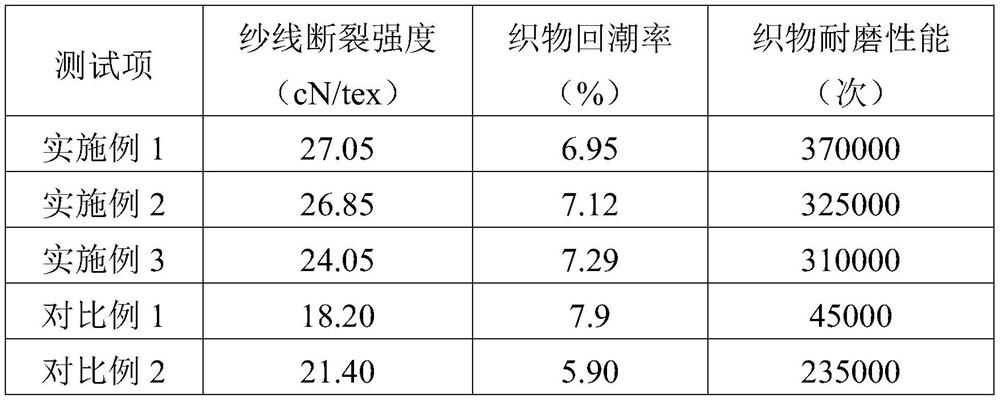

Blended yarn of polyamide fiber and cotton as well as preparation method and application of blended yarn

The invention provides a blended yarn of polyamide fiber and cotton as well as a preparation method and application of the blended yarn. The blended yarn comprises, by weight, 10-90 parts of polyamide56 fibers and 10-90 parts of cotton fibers, preferably, 20 to 50 parts by weight of polyamide 56 fiber and 50 to 80 parts by weight of cotton fiber, wherein the total weight of the polyamide 56 fibers and the cotton fibers accounts for 10-100 wt% of the total weight of the blended yarn, and / or the breaking strength of the polyamide 56 fiber is greater than 5.5 cN / dtex. Fabric prepared from the blended yarn can greatly improve the wear resistance and durability of the fabric while maintaining good moisture absorption, softness and comfort, and is suitable for the application field with high requirements for the wear resistance and comfort of the fabric.

Owner:CATHAY R&D CENT CO LTD +1

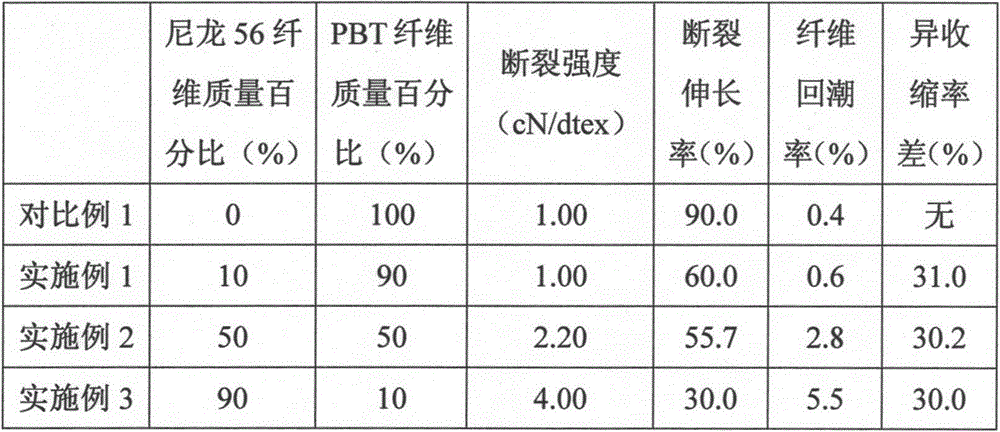

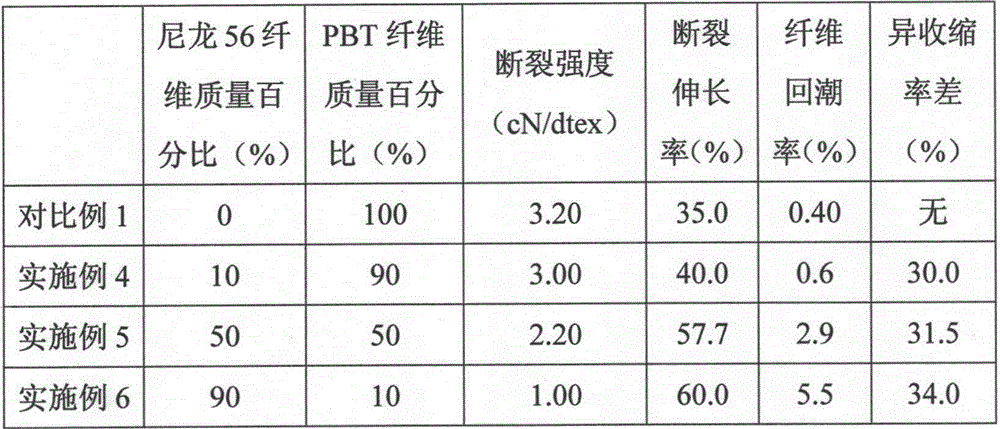

FDY/POY differential shrinkage blended filament of biomass nylon 56 fiber/PBT fiber, and preparation method thereof

InactiveCN105862166AHigh moisture regainIncrease elasticityConjugated synthetic polymer artificial filamentsFiberMaterials science

The invention discloses an FDY / POY differential shrinkage blended filament of a biomass nylon 56 fiber / PBT fiber. The FDY / POY differential shrinkage blended filament is prepared through spinning biomass nylon 56 slices and PBT slices; the biomass nylon 56 fiber is an FDY fiber and the PBT fiber is a POY fiber, or the biomass nylon 56 fiber is the POY fiber and the PBT fiber is the FDY fiber; and a difference between the boiling water shrinkage of the biomass nylon 56 fiber and the boiling water shrinkage of the PBT fiber is not smaller than 30%. The FDY / POY differential shrinkage blended filament of the biomass nylon 56 fiber / PBT fiber has the advantages of fine natural curling surface and greatly improved hydrophilicity, and can be used in development of cotton-like and silk-like textiles.

Owner:DONGHUA UNIV +2

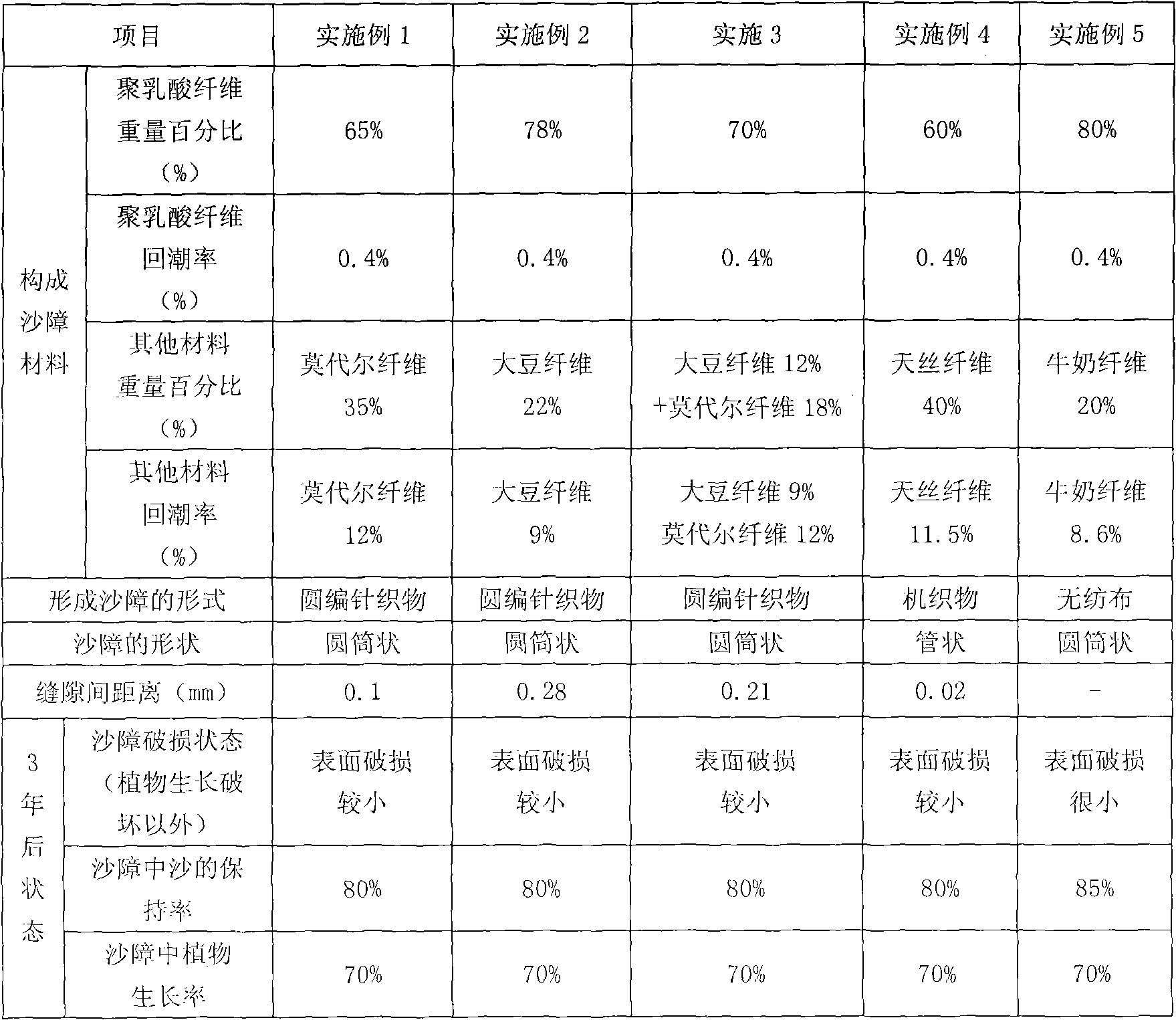

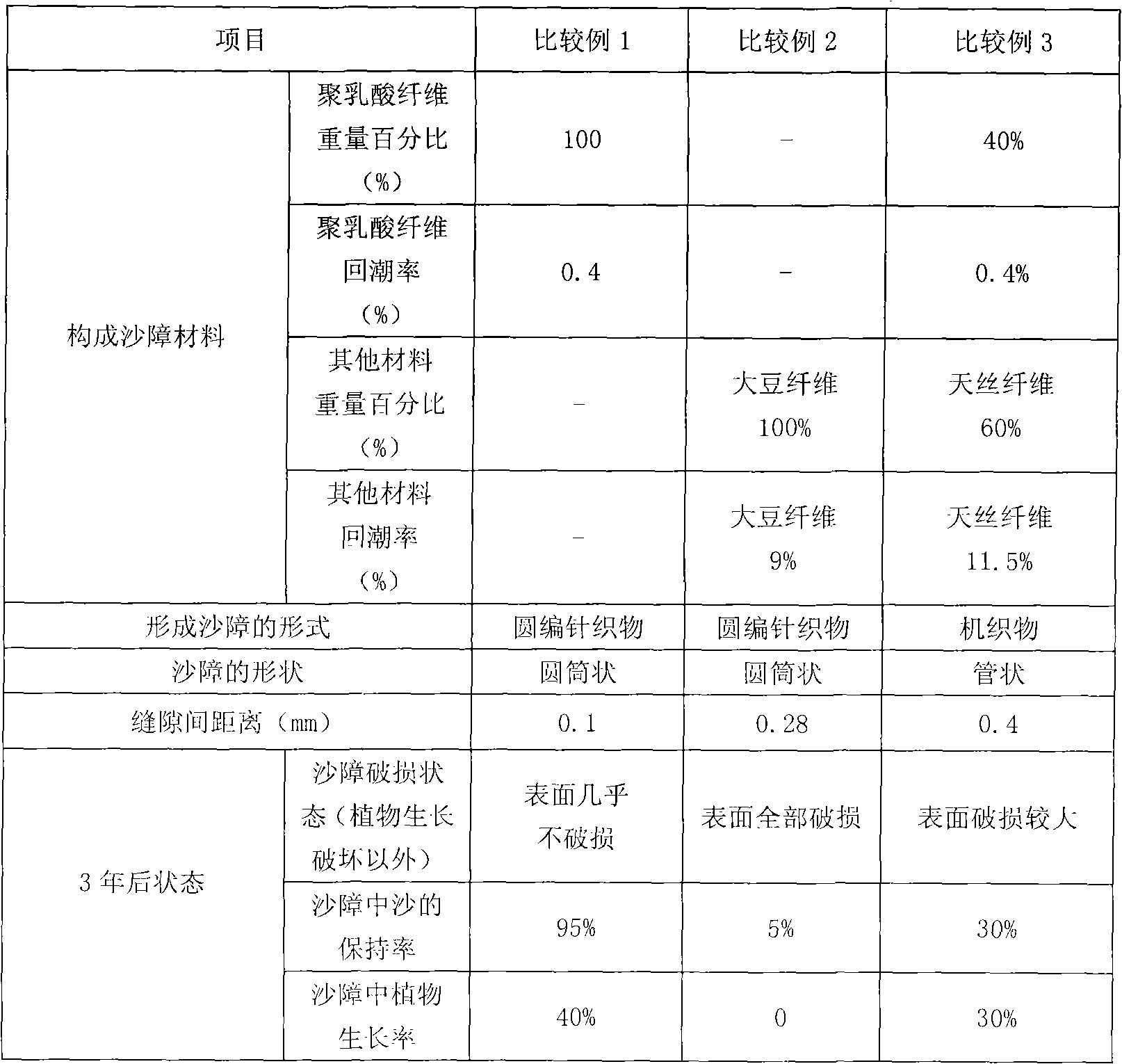

Sand-barrier manufactured by biodegradable material

InactiveCN102839646AHigh moisture regainReduce environmental pollutionWeft knittingWarp knittingNatural fiberRegenerated cellulose

The invention discloses a sand-barrier manufactured by a biodegradable material. The biodegradable material is a fabric mixed by at least one of a polylactic acid fiber and a regenerated protein fiber, a regenerated cellulose fiber or a natural fiber. The sand-barrier manufactured by the biodegradable material has the characteristics of high moisture regain, little environment pollution and long time in wind preventing and sand stabilizing.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com