High temperature-resistant flame retardation polyacrylonitrile fiber and production method thereof

A technology of polyacrylonitrile fiber and high temperature resistance, which is applied in fiber type, fiber treatment, dyeing method, etc. It can solve the problems of washing resistance, poor temperature resistance, too high flame retardant content, and difficult selection of flame retardants, etc. Problems, to achieve the effect of good heat insulation, excellent UV resistance, and simplified manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

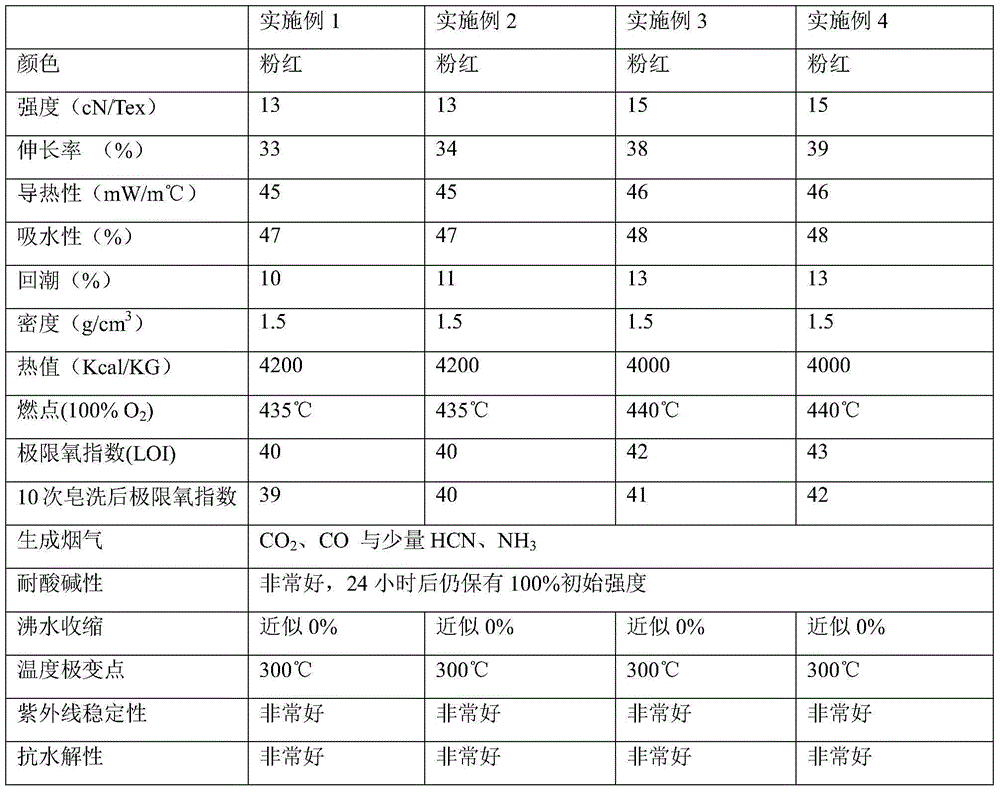

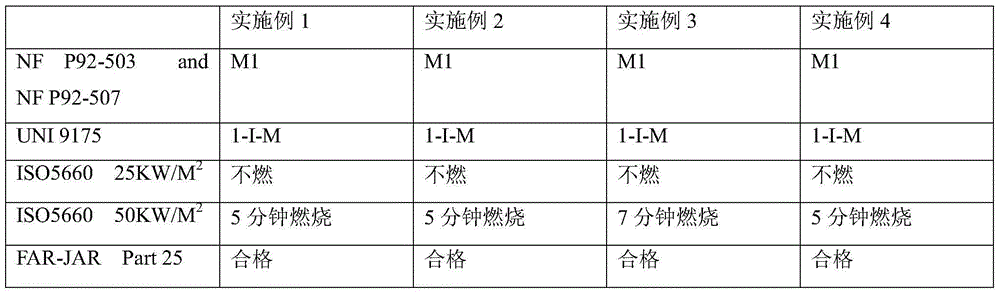

Examples

Embodiment 1

[0043] A kind of high temperature resistant flame retardant polyacrylonitrile fiber, its preparation method is as follows:

[0044] 1. Under the pressure of 0.3Mpa, place the polyacrylonitrile fiber in a hydrazine solution with a concentration of 20wt% for 5 hours at a temperature of 110°C;

[0045] 2. After washing the fiber obtained in step 1, put it into 10wt% sodium hydroxide for treatment for 4 hours at a temperature of 110° C., and then wash it to neutrality;

[0046] 3. Put the washed fibers into an aqueous solution with a concentration of 3wt% calcium ion salt for 1 to 4 hours at a temperature of 120°C, and then wash them with water;

[0047] 4. Put the fiber obtained in step 3 into an oil agent with a concentration of 2% for oiling treatment, the treatment time is 2 hours; finally, dehydrate and dry at a temperature of 90°C. The polyacrylonitrile fiber filament is prepared into a silk cake with a certain quality, height and thickness through the silk cake making equi...

Embodiment 2

[0049] A kind of high temperature resistant flame retardant polyacrylonitrile fiber, its preparation method is as follows:

[0050] 1. Under the pressure of 0.4Mpa, place the polyacrylonitrile fiber in a hydrazine solution with a concentration of 7wt% for 6 hours at a temperature of 120°C;

[0051] 2. After washing the fiber obtained in step 1, put it into a sodium hydroxide solution with a concentration of 5wt% for 1 to 4 hours at a temperature of 120° C., and then wash it until neutral;

[0052] 3. Put the washed fibers into an aqueous solution with a concentration of 5wt% calcium ion salt for 3 hours at a temperature of 80°C, and then wash them with water;

[0053] 4. Put the fiber obtained in step 3 into an oil agent with a concentration of 1% for oiling treatment. The treatment time is 0.5 to 2 hours; finally dehydrate and dry at a temperature of 100°C. The polyacrylonitrile fiber filament is prepared into a silk cake with a certain quality, height and thickness through ...

Embodiment 3

[0055] A kind of high temperature resistant flame retardant polyacrylonitrile fiber, its preparation method is as follows:

[0056] 1. Mix acrylonitrile and vinyl acetate in proportion, and produce polyacrylonitrile fibers through aqueous phase suspension polymerization according to the two-step wet spinning production technology of dimethylacetamide;

[0057] 2. Under the pressure of 0.3Mpa, first place the polyacrylonitrile fibers in a hydrazine solution with a concentration of 15wt% for 1 hour, then dry them at room temperature under ventilated conditions for 2 hours, and then place them in a hydrazine solution with a concentration of 18wt%. Treatment in hydrazine solution for 2 hours; treatment temperature is 110°C;

[0058] 3. After washing the fiber obtained in step 2, put it into a sodium hydroxide solution with a concentration of 8wt% for 4 hours at a temperature of 100° C., and then wash it to neutrality;

[0059] 4. Put the washed fibers into an aqueous solution wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com