Plant-derived PP master batch, preparation method and application thereof

A plant source and masterbatch technology, applied in the field of resin, can solve the problems of reduced active ingredient content, limited plant use, large molecular weight of PP, etc., to achieve the effect of improving efficacy, reducing the impact of carbonization, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

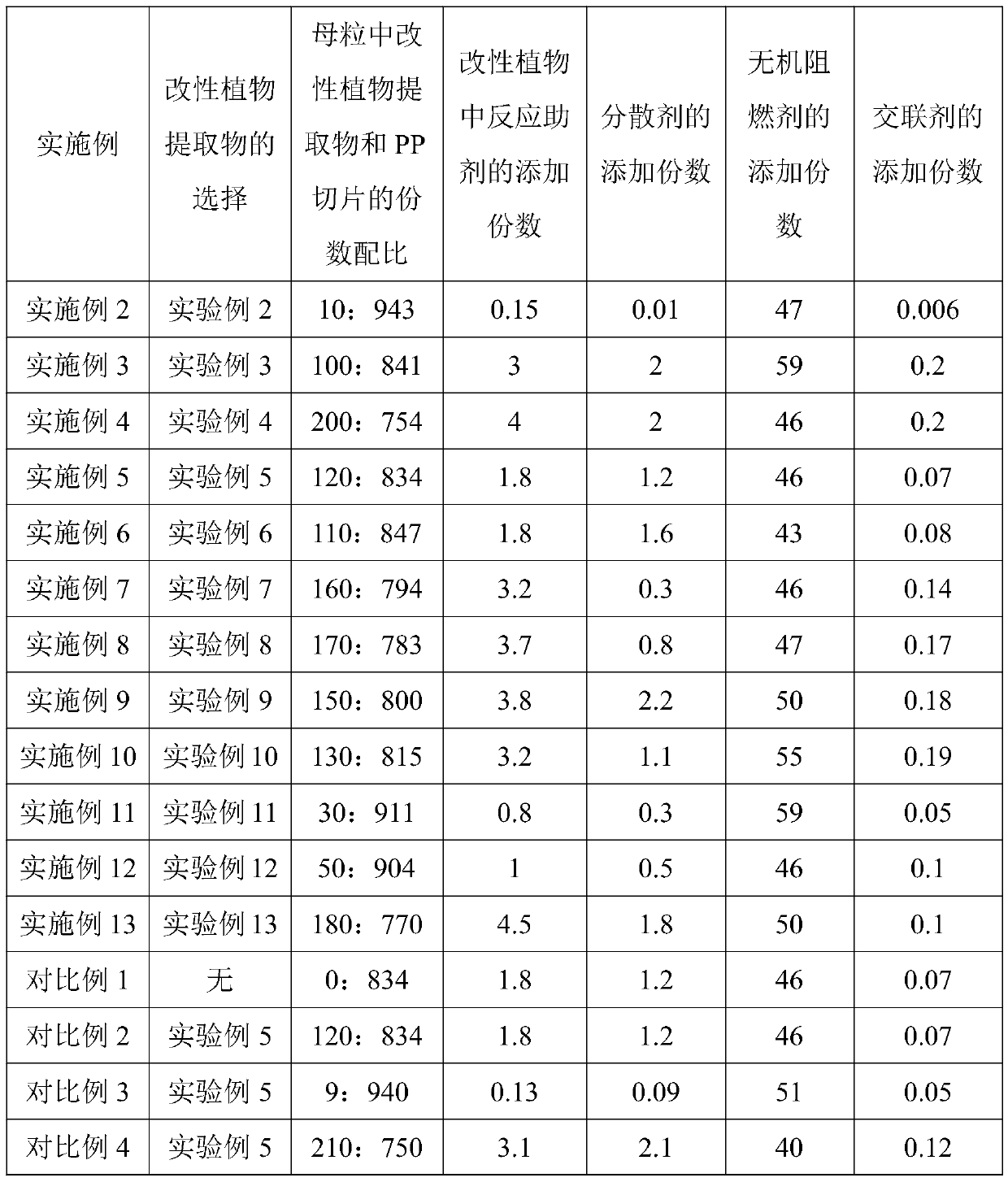

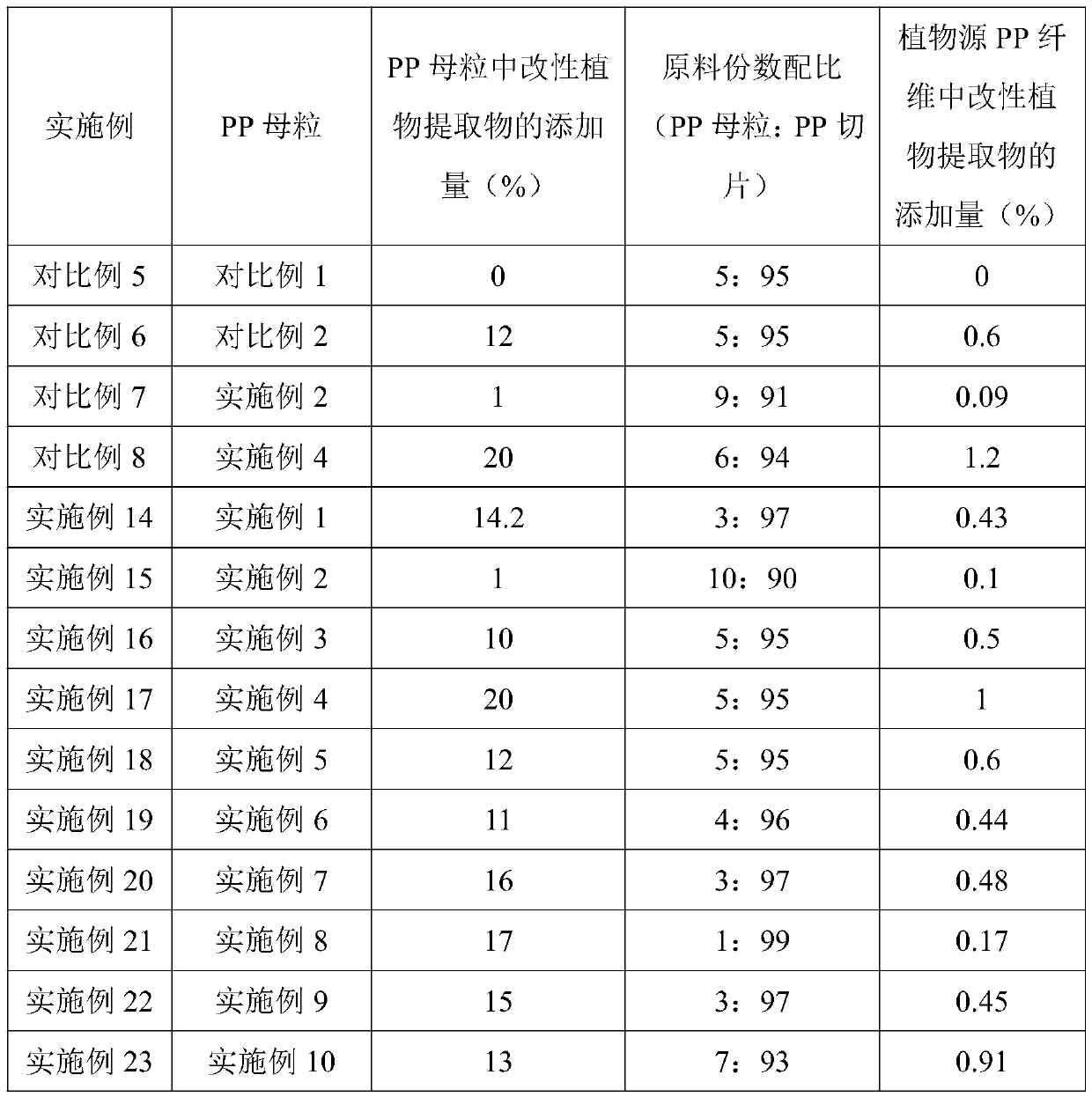

Examples

Embodiment 1

[0038] Example 1 A preparation of honeysuckle PP masterbatch

[0039] 1.1 Experimental Example 1 Preparation of modified honeysuckle extract

[0040] Honeysuckle extract powder was selected as the plant source material of this embodiment. Mix 50 parts of honeysuckle extract powder with 15 parts of chitin and 4 parts of starch, add 50 parts of deionized water, adjust the pH to 7.1 with sodium carbonate, and heat to 51°C and mix for 30 minutes. The resultant is shaken. Distill under reduced pressure for 0.5 hours, then dissolve in 40 parts of deionized water, filter through a semi-permeable membrane for 0.8 hours, add 10 parts of acrylic acid into the internal mixer and mix for 1.0 hour, then dry naturally. Crush to obtain a modified honeysuckle extract. The prepared modified honeysuckle extract has good compatibility, the mesh number is 10000 mesh, and the density is 1.08-1.25g / cm 3 , The apparent viscosity is 30-50mPa.s, the cellulose content of honeysuckle is 20.7-26.0%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com