Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Guaranteed water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Putty powder used for walls in house

InactiveCN101705027AExcellent scratch coating construction performanceGuaranteed crack resistanceFilling pastesCalcium hydroxideSodium Bentonite

The invention provides putty powder used for walls in a house. The putty powder comprises the following ingredients: ground calcium carbonate, sodium-base bentonite, 1788 powder of polyving akohol, hydroxypropyl methyl cellulose and talcum powder, besides, white cement or / and calcium hydroxide powder is / are added therein as a reinforcing material, and also, sodium hexametaphosphate powder and / or tourmaline powder are / is added in the product. The putty powder has excellent scraping construction performance, long-acting mould-proof performance and excellent dense degree of the putty coating as well as the function of releasing negative ions for a long time, can effectively adsorb various harmful substances in the air and purify the air, and has excellent environment-friendly performance.

Owner:毕家新

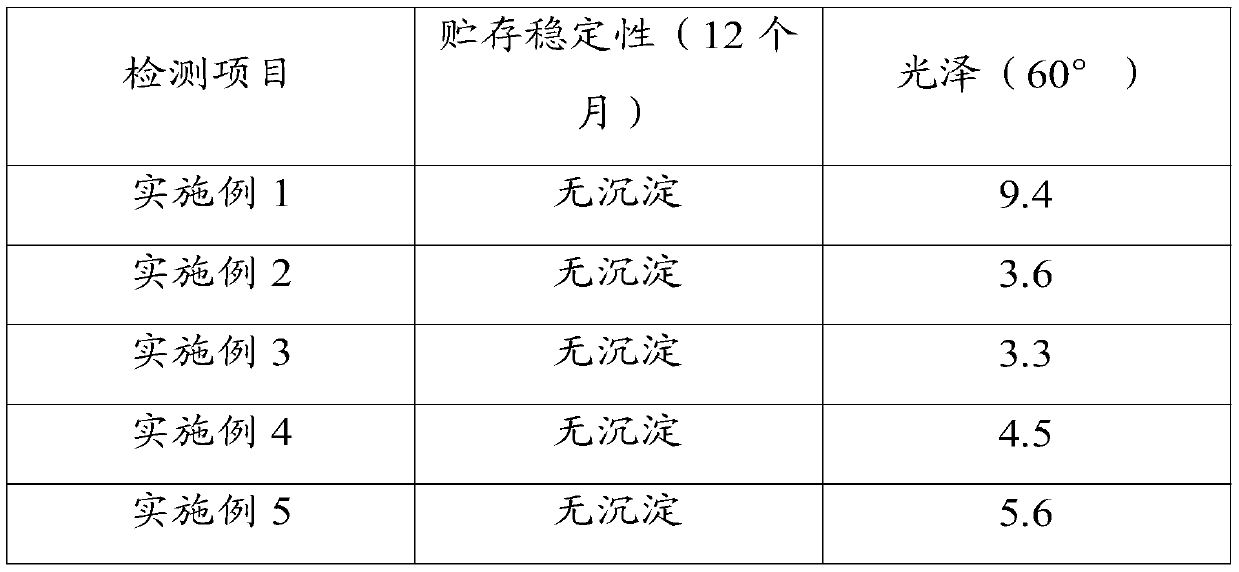

Delustering waterborne polyurethane leather finishing agent and preparation method thereof

ActiveCN105506997AImprove compactnessImprove stabilityFibre treatmentLeather surface finishingMechanical propertyRaw material

The invention provides a delustering waterborne polyurethane leather finishing agent and a preparation method thereof. The delustering waterborne polyurethane leather finishing agent is mainly prepared from diisocyanate, polyether glycol, organosiloxane, a hydrophilic chain extender, a catalyst and a neutralizer. According to the delustering waterborne polyurethane leather finishing agent, the specific raw material composition and dosage are adopted, and an excellent delustering effect is obtained without adding a delusterant. The delustering waterborne polyurethane leather finishing agent is good in compactness, stability and coating property, can guarantee the mechanical property and waster resistance of a leather coating and is environmentally friendly, nontoxic and safe. The preparation method of the delustering waterborne polyurethane leather finishing agent is simple in technology, the waterborne polyurethane leather finishing agent with an excellent delustering property is synthesized in a step-by-step feeding reaction mode, and the preparation method is suitable for large-scale production.

Owner:优美特(北京)环境材料科技股份公司

Preparation method for high-hardness waterborne polyurethane dispersion

ActiveCN104231209AImprove water resistanceImprove adhesionPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method for high-hardness waterborne polyurethane dispersion. An inorganic nano material and waterborne polyurethane are grafted through an in-situ polymerization method, so that the hybridization reaction of inorganic materials and the organic materials is realized and complementary advantages are realized. The preparation method comprises the following operation steps: adding polyisocyanate, macromolecule polyol, a catalyst, a chain extender and a silane coupling agent according to certain weight ratio in a flask for reacting to obtain a polyurethane prepolymer; after the reaction is ended, sequentially adding a neutralizer, inorganic nano material dispersion liquid and deionized water under the condition of low-temperature and high-speed stirring; finally, heating under the vacuum condition for removing the solvent to obtain the high-hardness waterborne polyurethane dispersion. Compared with the traditional inorganic and organic blending process, the preparation method has the characteristics that products prepared through the preparation method have the advantages of good stability, excellent water resistance, long-time aging resistance, excellent and high adhesion, high drying speed, high hardness, good fullness, higher light transmittance and the like, and are wide in application range.

Owner:江苏日出化工有限公司

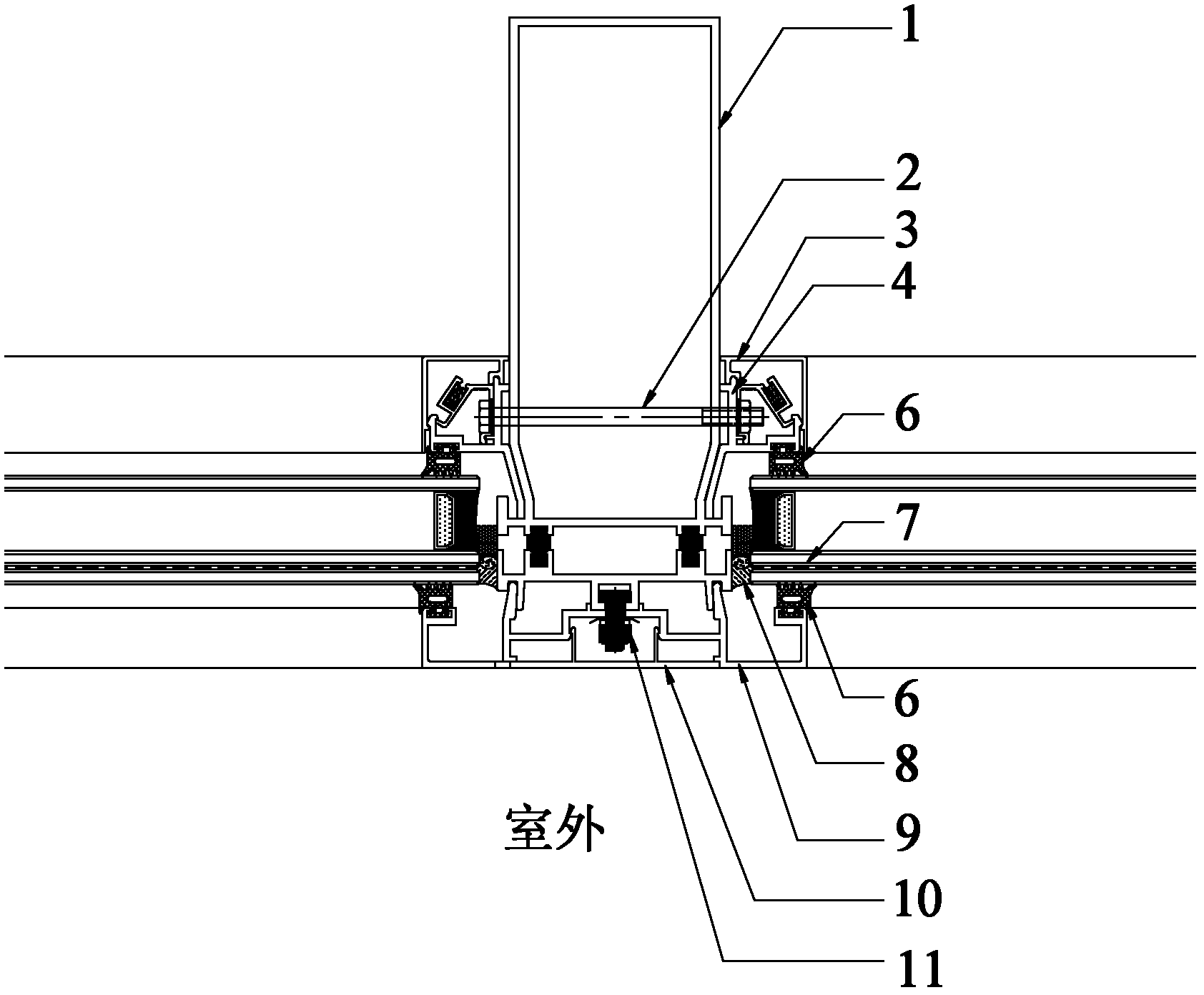

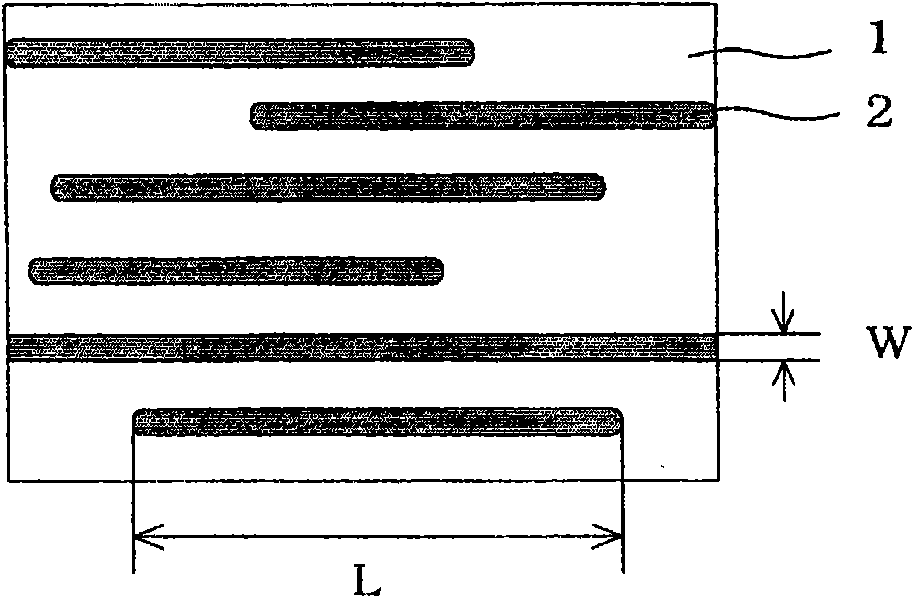

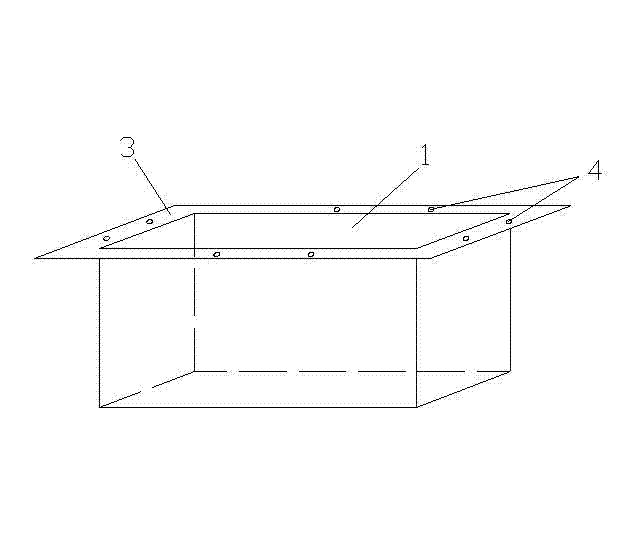

Glass curtain wall structure for indoor maintenance and change

The invention relates to a curtain wall structure for indoor maintenance and change. The curtain wall structure comprises a curtain wall framework consisting of an aluminum alloy vertical keel and an aluminum alloy transverse keel which are connected each other, wherein an aluminum subframe is fixed on a master keel through machine wires or through bolts, and a rubber bar is inserted into the aluminum subframe; and a glass plate block is pushed into the subframe from the outer side, and is effectively connected with the master keel through an external decoration bar so as to be limited and fixed. Compared with the prior art, the curtain wall structure has the advantages that: the glass plate block can be changed or maintained in a room; the efficiency is improved; convenience and quickness are realized, and the maintenance cost of a curtain wall plate block is reduced greatly; and great breakthrough is supplied to maintenance and change of the curtain wall plate block.

Owner:SHANGHAI BRIGHT INTELLIGENT CURTAIN WALL

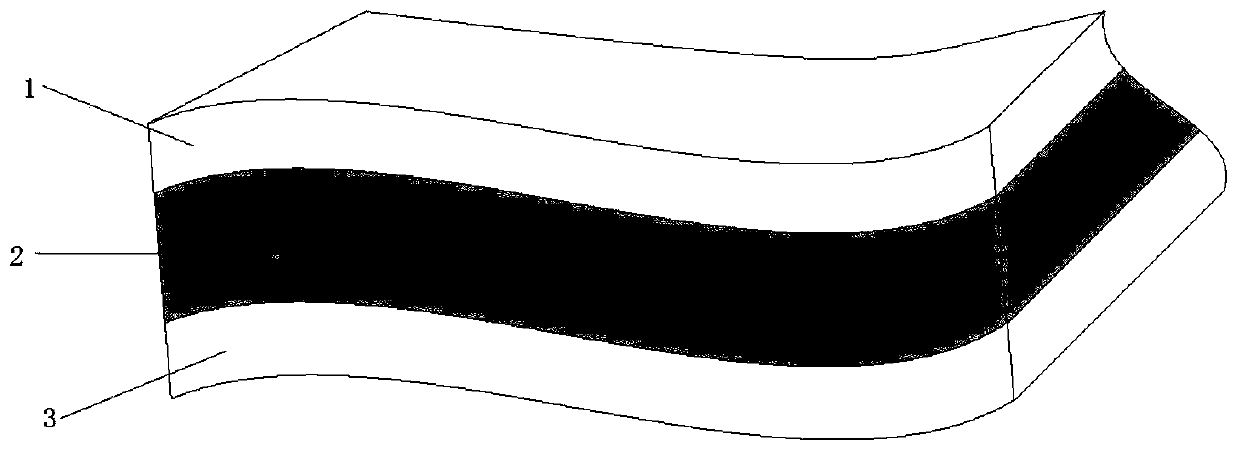

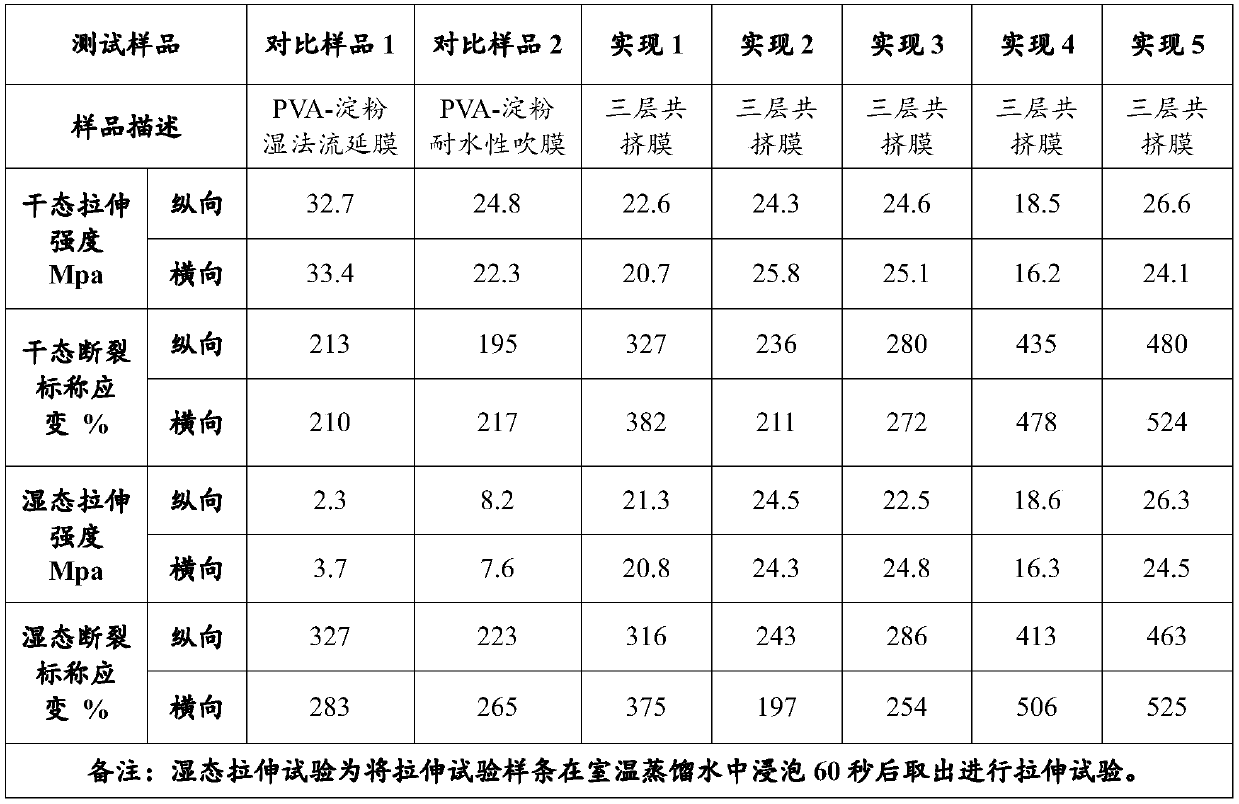

Biodegradable film and manufacturing method thereof

InactiveCN110626038ALow costExpand sourceSynthetic resin layered productsPolyvinyl alcoholMaterials science

The invention provides a biodegradable film and a manufacturing method thereof. The biodegradable film comprises an inner layer and an outer layer, and the inner layer and the outer layer are respectively composed of the following components by weight percentage: 20%-100% of PBAT, 0%-35% of PLA, 0%-30% of starch, 0%-30% of inorganic powder, 0%-50% of other biodegradable material and 0%-15% of a modification assistant; a middle layer is composed of the following components: 30%-75% of PVA, 0%-60% of PLA, 0%-60% of PBAT, 0%-30% of starch, 0%-30% of inorganic powder, 0%-50% of a biodegradable material and 10%-40% of a modification additive. On the premise of ensuring the water resistance of the biodegradable films, the PVA (polyvinyl alcohol) material is utilized to achieve the goals of increasing the sources of the biodegradable materials and lowering the cost of the biodegradable films.

Owner:广东崇熙环保科技有限公司

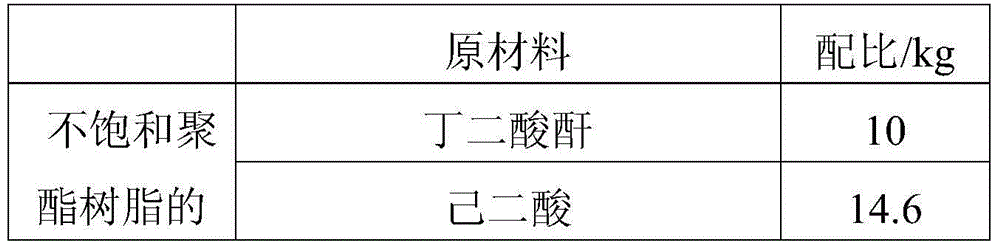

Sulphonic acid type water-based unsaturated polyester and application of sulphonic acid type water-based unsaturated polyester in coating

The invention discloses sulphonic acid type water-based unsaturated polyester and application of the sulphonic acid type water-based unsaturated polyester in coating. The sulphonic acid type water-based unsaturated polyester is formed by polymerizing the following components in parts by weight: 35.52-42.35 parts of dihydric alcohol, 0-13.35 parts of saturated binary acid, 24.77-46.02 parts of saturated acid anhydride, 0-24.31 parts of unsaturated binary acid, 0-25.37 parts of unsaturated acid anhydride, 1.71-3.60 parts of water-based monomer, 0.010-0.049 part of polymerization inhibitor and 0.010-0.052 part of antioxidant; emulsification is carried out, then a cross-linking and curing reaction is carried out on emulsion and reactive diluent, wherein sulphonic acid type water-based unsaturated polyester emulsion accounts for 70-90%, and the reactive diluent accounts for 8-28%. The sulphonic acid type water-based unsaturated polyester has the advantages that raw materials are available and a technology is simple, the prepared sulphonic acid type water-based unsaturated polyester coating has good mechanical properties, water resistance and low VOC (volatile organic compounds) content of the coating are guaranteed, and the characteristics of good flexibility, high hardness and high drying speed are maintained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

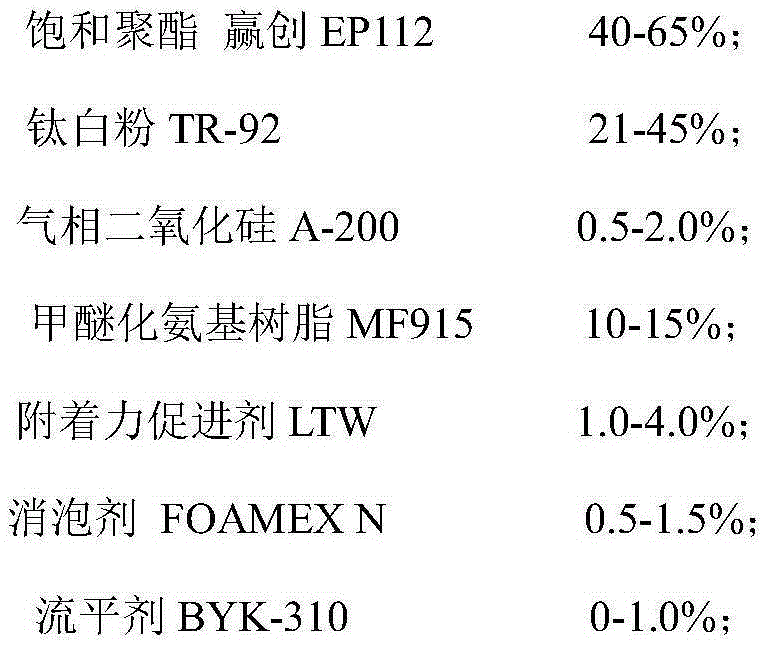

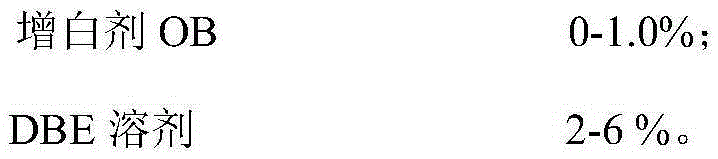

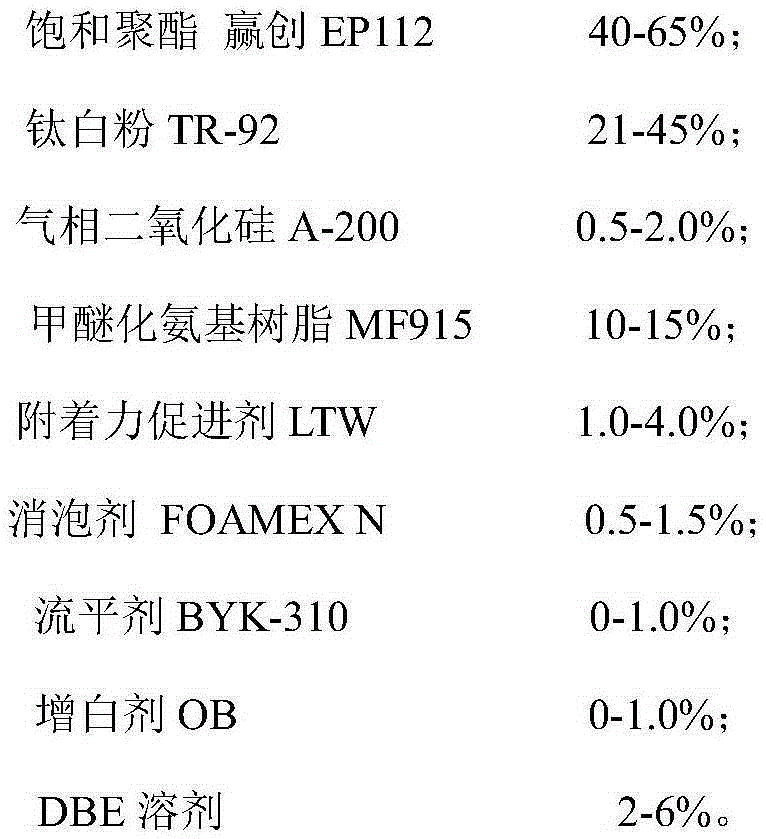

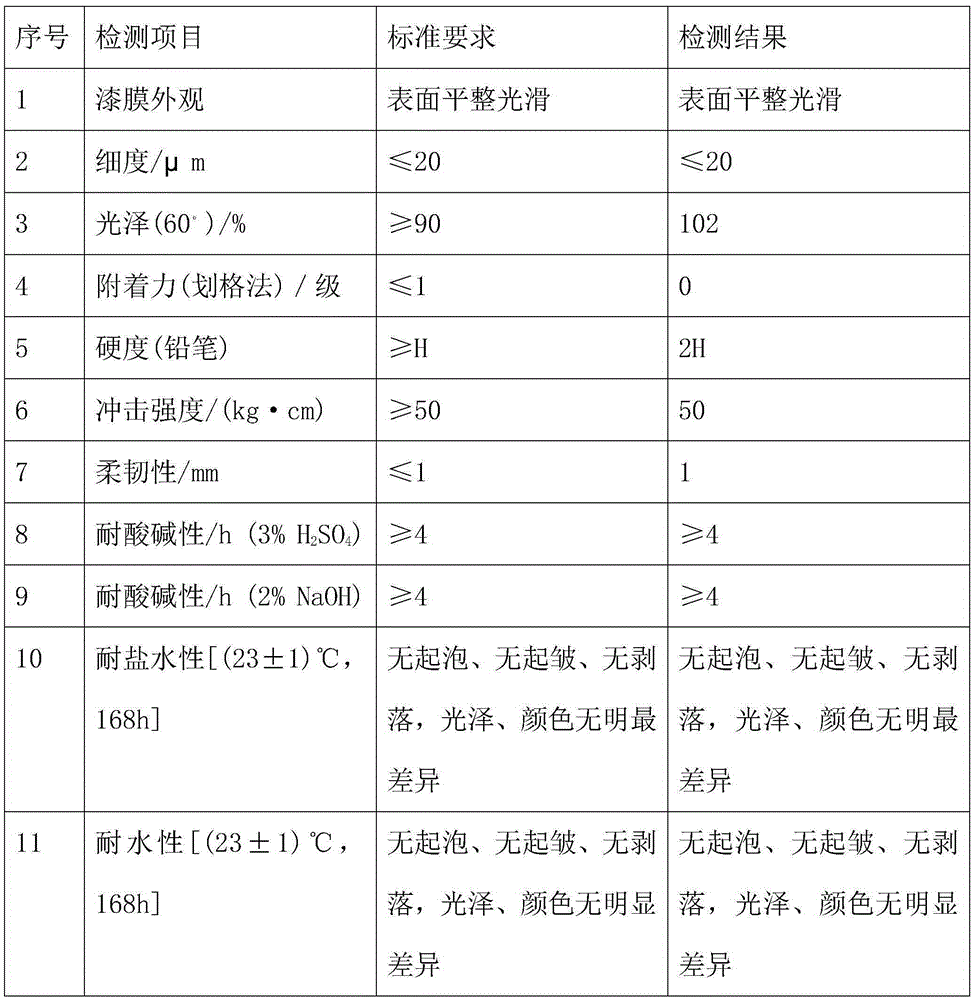

Thermosetting type glass screen printing ink and preparation method thereof

The invention discloses thermosetting type glass screen printing ink. The thermosetting type glass screen printing ink includes, by weight, 40%-65% of Evonik EP112 saturated polyester, 21%-45% of titanium dioxide TR-92, 0.5%-2.0% of fumed silica A-200, 10%-15% of methylated amino resin MF915, 1.0%-4.0% of adhesion promoters LTW, 0.5%-1.5% of antifoaming agents FOAMEXN, 0-1.0% of flatting agents BYK-310, 0-1.0% of brightening agents OB and 2%-6% of DBE solutions. A preparation method of the thermosetting type glass screen printing ink includes the steps that the saturated polyester, the titanium dioxide and the fumed silica are firstly stirred evenly, then the methylated amino resin, the adhesion promoters, the antifoaming agents, and / or the flatting agents, and / or the brightening agents are added into the mixture, and the DBE solutions are added finally. The thermosetting type glass screen printing ink has good adhesion, water resistance, acid and alkali resistance, cold and hot impact resistance, butanone dissolution resistance, fast yellowing resistance, high temperature yellowing resistance, flexibility, constructability and ultraviolet resistance.

Owner:WUHU CHUNFENG NEW MATERIAL

Adhesive for digital inkjet printing ink-absorption coating and preparation method thereof

The invention discloses an adhesive for a digital inkjet printing ink-absorption coating, which is prepared from soft monomers, hard monomers, an emulsifying agent, protection glue, an initiator, a pH regulating agent and water. The adhesive for the digital inkjet printing ink-absorption coating, which is prepared by the invention, has the advantages of uniform latex particle distribution, stable product quality, good compatibility and no demulsification and can be mixed with a cation system; the water resistance of a digital inkjet printing ink-absorption coating which is subsequently prepared is guaranteed; and as soon as the adhesive is put in a printing machine, the adhesive is cured immediately without placement for solidification, and the printing color is vivid.

Owner:JIANGSU GEMEIGAO DEV CO LTD

Powder type white emulsion and preparation method thereof

ActiveCN103468162AGuaranteed water resistanceImprove water resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAmylasePolymer science

The invention discloses powder type white emulsion and a preparation method thereof, and particularly provides the powder type white emulsion which can be quickly resolved in cold water, form white emulsion type glue solution and can substitute traditional liquid white emulsion. The powder type white emulsion comprises the following raw materials: by weight, 65-80 parts of amylose, 10-25 parts of polyurethane rubber powder, 3-8 parts of water resistant modifiers, 3-5 parts of quick drying agents, 0.5-1 part of alpha-amylase, 1-2 parts of cross-linking agents, 0.5-1 part of catalyst, and 0.5-1 part of defoamer. The preparation method of the powder type white emulsion comprises the steps of utilizing alpha-amylase to activate the interface polar group of amylose and the interface polar group of polyurethane rubber powder in a dry powder state, and making amylose to be in cross-linking reaction with polyurethane rubber powder through mechanochemistry under the action of cross-linking agents and catalyst. Consequently, preparing the powder type white emulsion which can be quickly resolved in cold water is further prepared.

Owner:CHONGQING JIANGBEI GONGNONG CHEM CO LTD

Water-based benzoic acid modified alkyd resin for air-dry paint and preparation method of water-based benzoic acid modified alkyd resin

InactiveCN106978049AFast dry timeImprove water resistanceEmulsion paintsPolyester coatingsWater basedBenzoic acid

The invention provides water-based benzoic acid modified alkyd resin for an air-dry paint and a preparation method of the water-based benzoic acid modified alkyd resin and belongs to the technical field of paints. The water-based benzoic acid modified alkyd resin is prepared from the following raw materials of oleic acid, benzoic acid, polyhydric alcohol, polybasic acid, a catalyst, trimellitic anhydride, ethylene glycol butyl ether and sec-butyl alcohol at the mass ratio of (20-35):(5-20):(20-30):(15-30):(0.01-0.05):(4-10):(8-12):(6-8), wherein the oleic acid is any one or more of soya oil acid, tall oil acid, linoleic acid, linseed oil acid, calophyllum inophyllum oleic acid and dehydrated ricinolic acid. According to the water-based benzoic acid modified alkyd resin for the air-dry paint and the preparation method of the water-based benzoic acid modified alkyd resin, the prepared water-based benzoic acid modified alkyd resin has the beneficial effects of short surface drying time, high hardness and excellent water resistance and yellowing resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Baking-free insulating brick and production method thereof

The invention relates to a baking-free insulating brick and a production method thereof. The baking-free insulating brick provided by the invention comprises the following raw materials in parts by weight: 490-590 parts of fragment, 260-320 parts of portland cement, 20-60 parts of dried sludge, 4-5 parts of lime, 1.8-30 parts of expanded perlite, 2-5 parts of straw, 3-5 parts of nut shell, 2.1-1.9 parts of animal wool fiber and 107-130 parts of water. The baking-free insulating brick provided by the invention is prepared by the following production steps: firstly, dewatering and drying sludge; adding lime to the dry sludge to be uniformly mixed; piling; stirring; deodorizing and sterilizing; simultaneously grinding straw, nut shell and animal wool fiber into microparticles; sequentially adding all the raw materials to a stirrer to be uniformly mixed; and finally, carrying out extrusion molding and maintenance on the mixture to obtain a finished baking-free insulating brick. The baking-free insulating brick produced by the invention has good heat insulation property and compressive strength and strong freezing resistance and crack resistance, and the radiation quantity of the baking-free insulating brick is far lower than industrial specified standards.

Owner:无锡市康顺节能材料科技有限公司

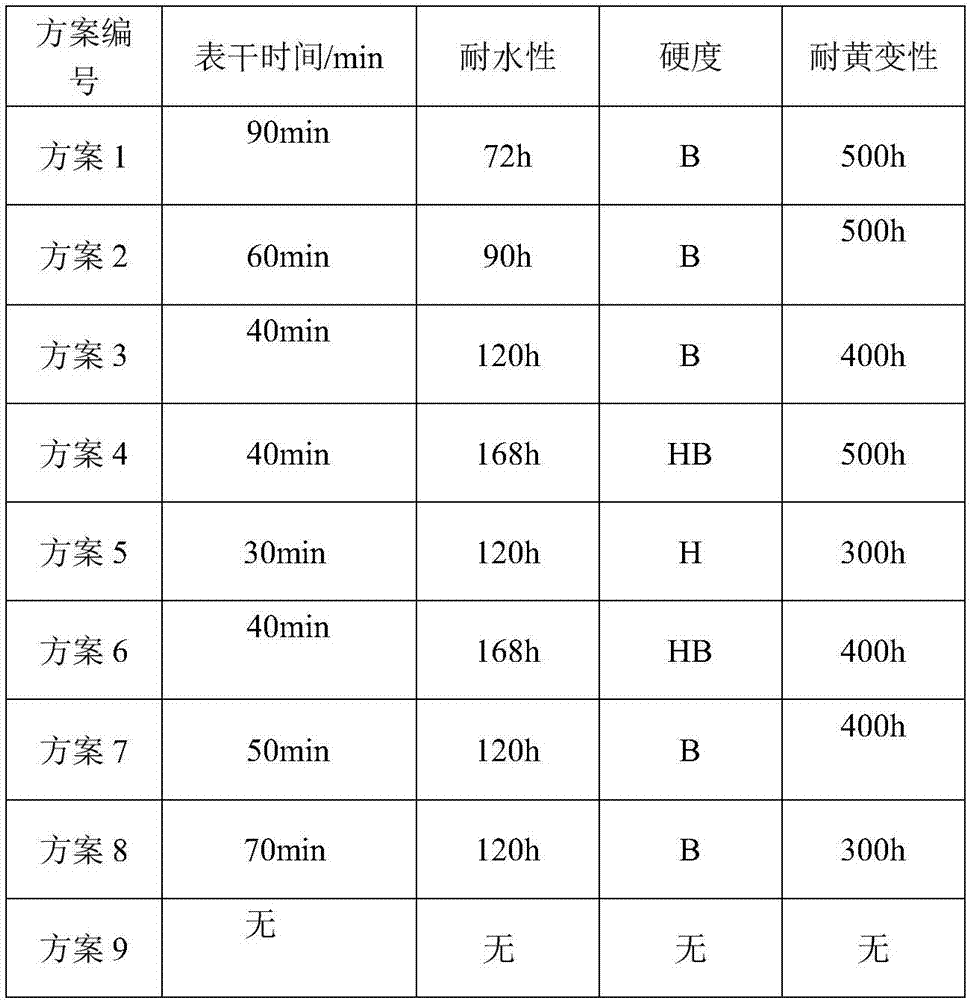

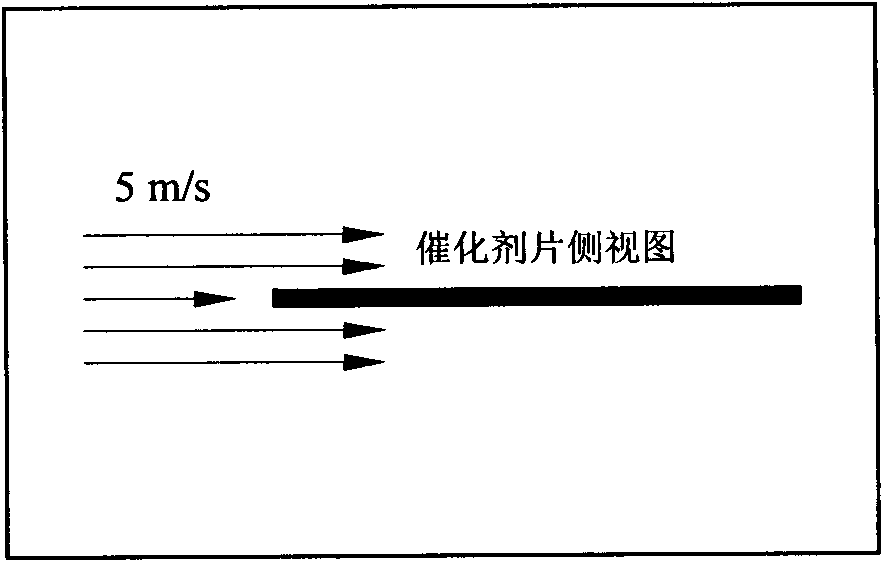

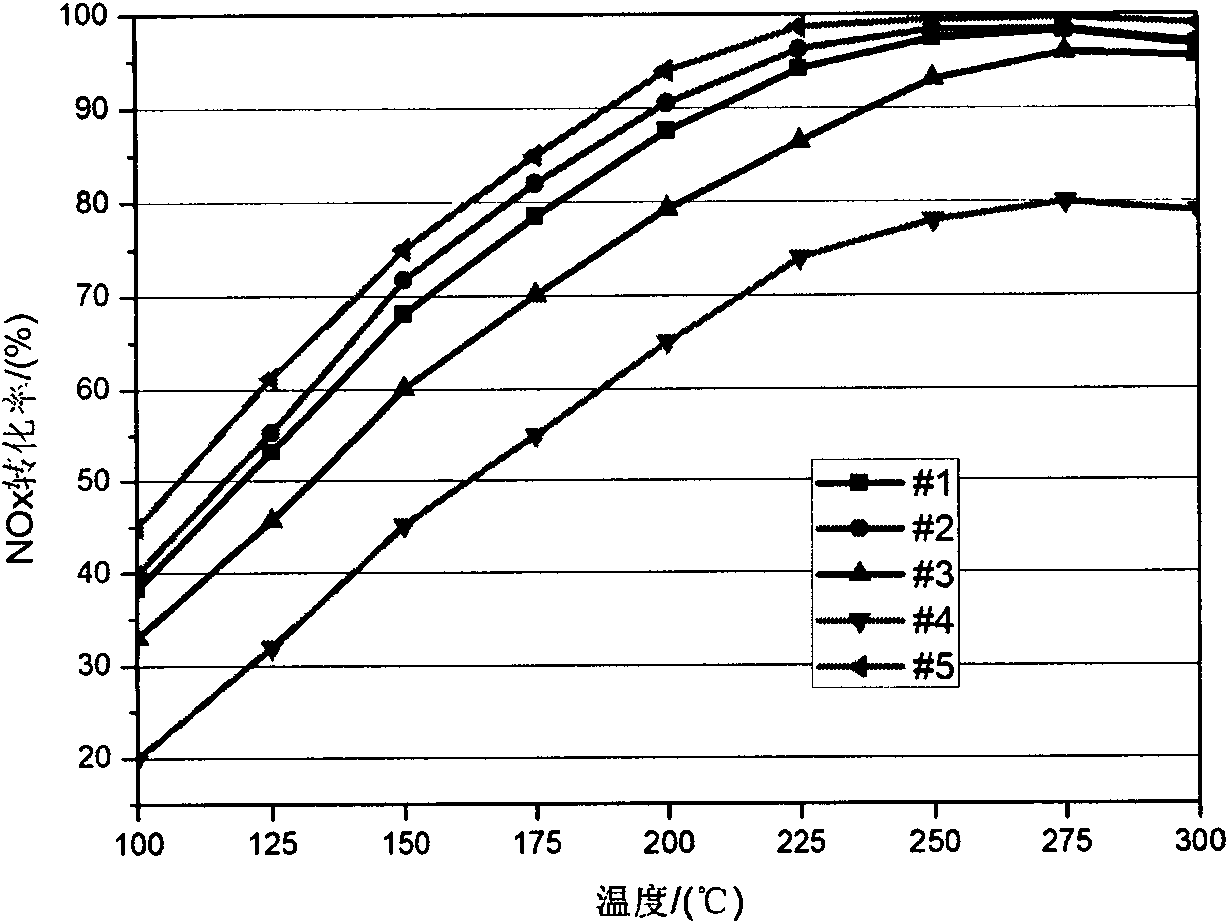

Binder as well as application thereof in catalyst for removing nitric oxide in smoke gas

InactiveCN102000556ALow costEasy to applyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideNitrogen oxide

The invention discloses a binder, which comprises the following component contents in percentage by weight: 20-85 percent of bentonite and 15-80 percent of cement. The application of the binder in a catalyst for removing nitric oxide in smoke gas comprises the following steps of: fully mixing the binder with catalyst powder for removing the nitric oxide in the smoke gas according to the mass ratio of 0.18:1-0.25:1; adding water content, and mixing into slurry; and uniformly coating on slide glass, and drying at 150-300 DEG C. The binder is low in cost and is safe without toxicity, and the application method of the binder in the catalyst for removing the nitric oxide in the smoke gas is simple, and the prepared flakes have better denitration performance, with certain intensity and water resistance ensured at the same time.

Owner:浙江德纳希环保科技股份有限公司

Cereal-based edible tableware and making method thereof

ActiveCN106954663AIncrease gelatinization temperature and gelatinization viscosityPromote aggregationDough treatmentBakery productsMillet flourRice flour

The invention discloses cereal-based edible tableware and a making method thereof. The cereal-based edible tableware comprises cereal powder and auxiliary materials, wherein the cereal powder comprises the following components in parts by weight of 60-80 parts of whole wheat flour, 5-20 parts of sorghum flour, 5-15 parts of rice flour, 0-10 parts of millet flour and 0-10 parts of purple sweet potato flour; and the auxiliary materials comprise the following components in parts by mass: 30-40 parts of water, 3-5 parts of butter and 0-5 parts of seasonings. The making method comprises the following steps of mixing the cereal powder which is subjected to microwave-assisted treatment and then roasting and precooking treatment or dry heat precooking treatment with the auxiliary materials to make dough; putting the made dough in a mold, performing heat-preservation shaping, conveying the shaped dough into an oven, performing roasting, and in the roasting process, performing pressurization for 1-2 times; and performing roasting until shaped dough is 90% cooked, performing film painting with rice flour dextrinization fluid or starch dextrinization fluid of which the concentration is 2-5%, and continuing roasting for 1-2 min so as to obtain finished products. According to the cereal-based edible tableware and the making method thereof disclosed by the invention, used raw materials are natural cereals, are rich in nutrition and can be directly eaten, so that environmental pollution is avoided; the used technology is simple, industrial production is easy to realize, and the cost is low; and the cereal-based edible tableware is compact in texture and is not deformed.

Owner:QINGDAO AGRI UNIV

PU automobile leather easy to clean and preparation method thereof

The invention discloses a PU automobile leather easy to clean and a preparation method thereof. The PU automobile leather easy to clean comprises a base cloth, a bonding layer, a middle layer, a surface layer, a first surface layer and a second surface layer which are arranged in sequence; the first surface layer comprises the following components of 5-95 parts of hydrophobic aliphatic self-matting polycarbonate polyurethane, 5-95 parts of hydrophobic aliphatic polyurethane gloss surface treatment agent, 0.5-8 parts of isocyanate cross-linking agent, 3-8 parts of silane coupling agent, 0.1-2 parts of leveling agent and 1.1-15 parts of other auxiliaries in parts by weight; the total amount of the hydrophobic aliphatic polyurethane gloss surface treatment agent and the hydrophobic aliphaticself-matting polycarbonate polyurethane is 100 parts; the second surface layer comprises the following components of 40-75 parts of side-chain fluorine-containing vinyl silicone resin, 2-25 parts of polysilazane, 3-20 parts of hydrogen containing silicone oil, 30-70 parts of organic solvents, 0.5-18 parts of adhesive agent, 0.001-1 parts of platinum catalyst, 0.5-10 parts of accelerator, 8-40 parts of packing and 0.1-2 parts of wear-resistant agent in parts by weight. The PU automobile leather easy to clean has the advantages that the PU automobile leather easy to clean is easy to clean, and meanwhile, the PU automobile leather easy to clean possesses excellent hydrolysis resistance, wear resistance and weather resistance.

Owner:浙江康成新材料科技有限公司

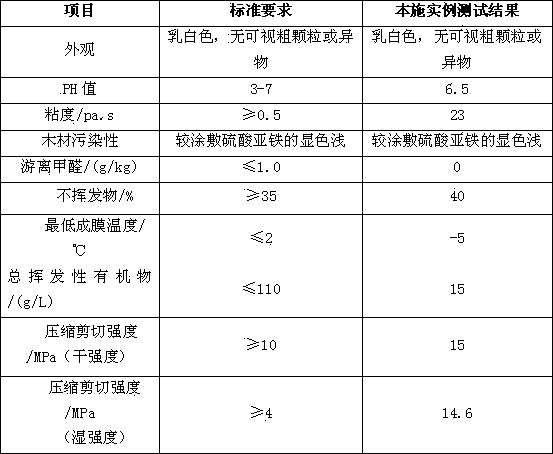

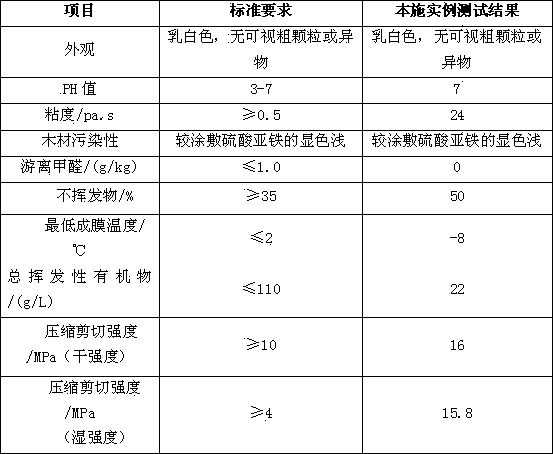

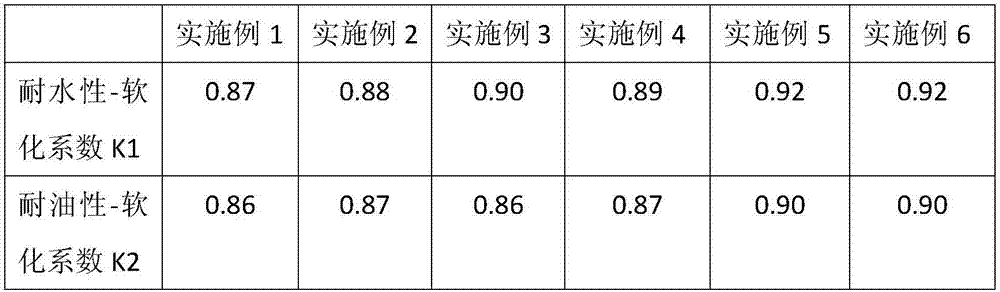

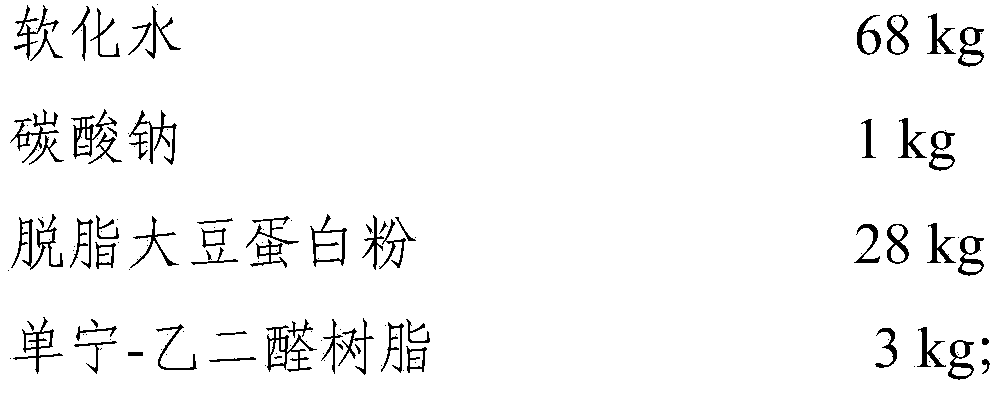

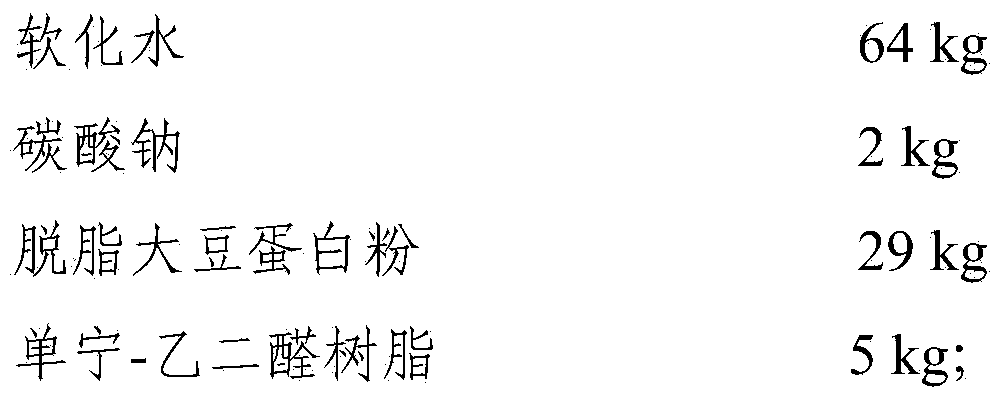

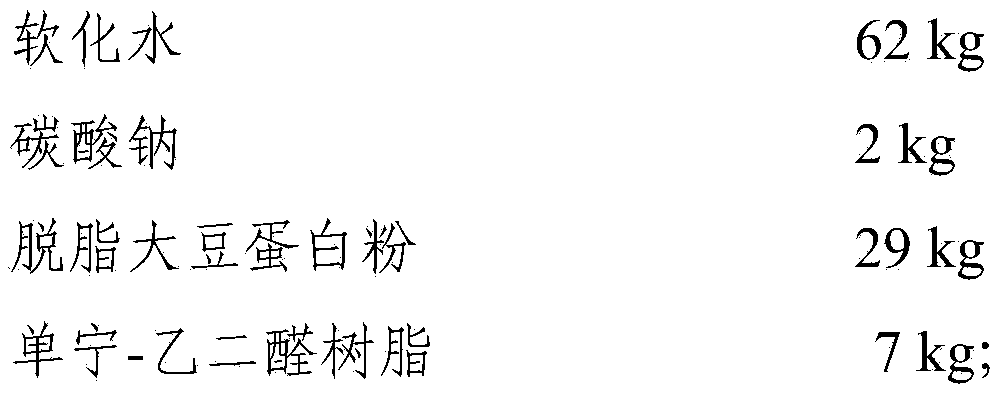

Adhesive for artificial boards, and preparation method and application thereof

ActiveCN103740324AComprehensive utilization of resourcesReduce manufacturing costNon-macromolecular adhesive additivesProtein adhesivesChemistryWater resistance

The invention relates to an adhesive for artificial boards, and a preparation method and application thereof. The adhesive for artificial boards is prepared from a dispersion medium, a protein substance, an alkaline compound and a crosslinking reinforcer, wherein the crosslinking reinforcer is a tannin-glyoxal resin. The adhesive for artificial boards is free of formaldehyde, is mainly prepared from renewable substances, and thus, is an environment-friendly adhesive for artificial boards; the adhesive provided by the invention thoroughly solves the problem of formaldehyde pollution when in use, and ensures water resistance, adhesion strength and other practical properties of the adhesive; compared with the prior art, the components have favorable synergetic effects, so that the effect is enhanced; the preparation method is simple, does not need very long curing time, is convenient to operate and has high production efficiency; and generally, the method comprehensively utilizes the resources, saves the production cost, conforms to the principles of environmental protection and sustainable development, and has favorable application prospects.

Owner:XUZHOU ANLIAN WOOD

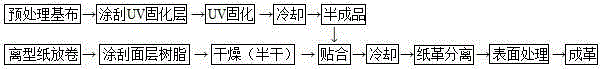

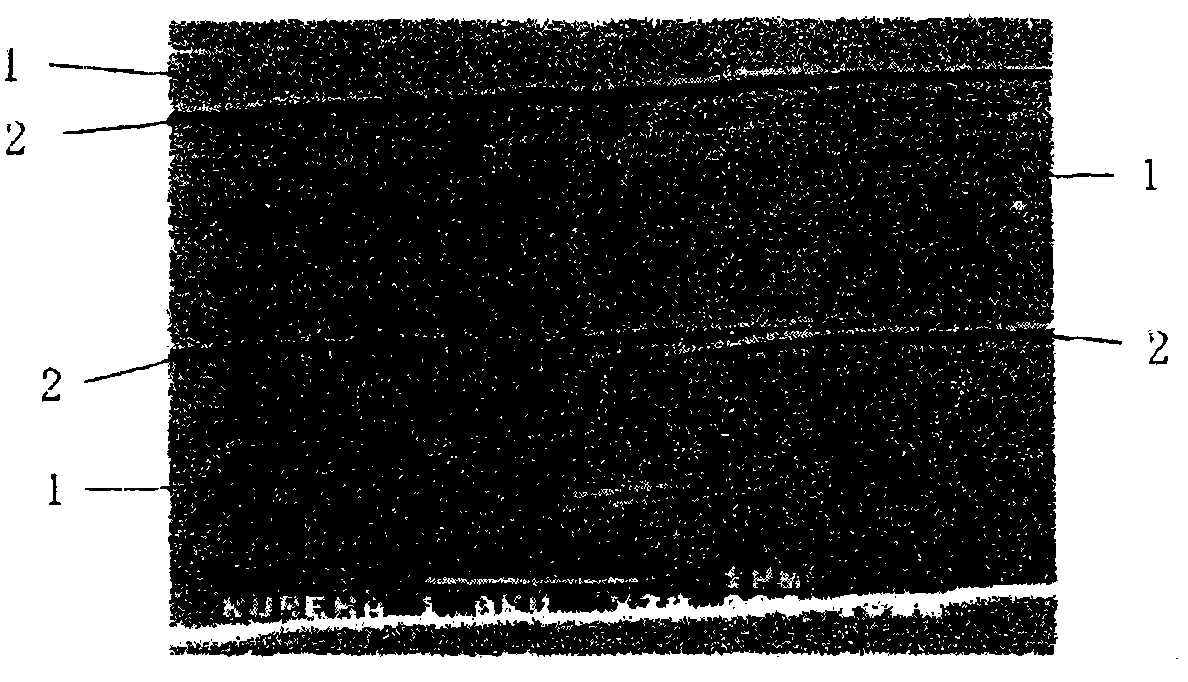

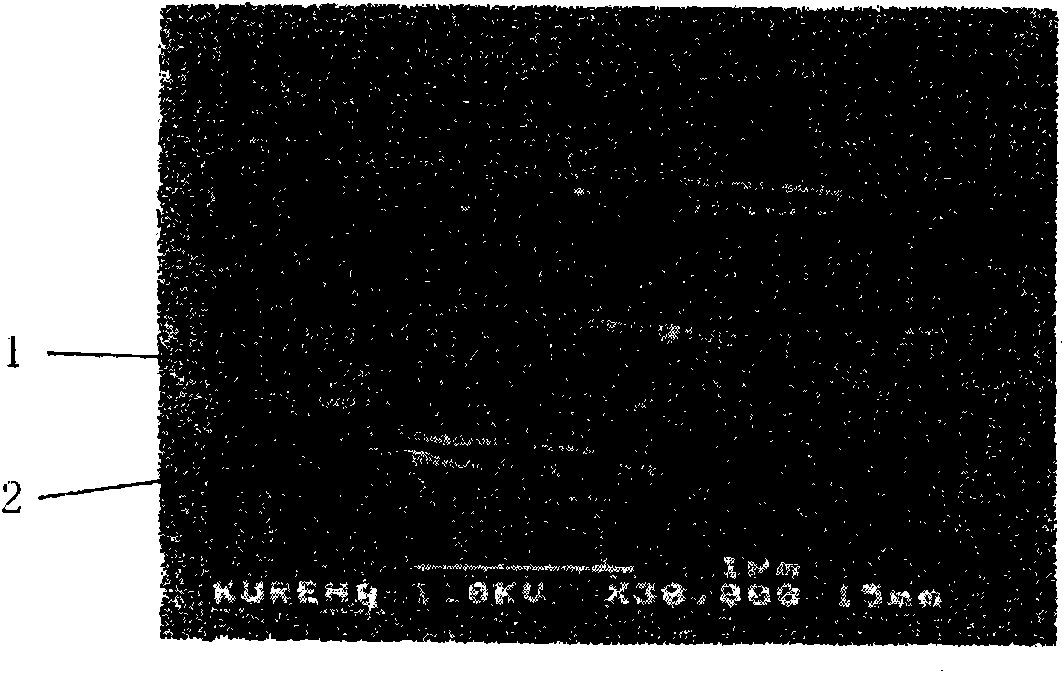

UV curing technology based solvent-free synthetic leather manufacturing method

The invention discloses a UV curing technology based solvent-free synthetic leather manufacturing method. The method is characterized by: firstly coating a pre-treated base cloth with a photosensitive group containing solvent-free polyurethane slurry, and performing ultraviolet curing to obtain a semi-finished product; and then taking waterborne polyurethane as the surface layer resin, and conducting dry (i.e. transfer coating) overlaying to obtain the environment friendly polyurethane synthetic leather product. The method provided by the invention adopts the UV curing technology to coat the base cloth with the polyurethane free of any organic solvent and performs UV curing to obtain the synthetic leather product. The method has the characteristics of high curing efficiency, environmental friendliness, low energy consumption and the like. By adopting solvent-free UV curable resin and waterborne polyurethane to substitute the traditional solvent type polyurethane, organic solvent pollution is eliminated from the source, the organic solvent source is saved, the product does not contain VOC, and the ecological level and international market competitiveness of synthetic leather are enhanced.

Owner:SICHUAN UNIV

Composite foaming cement board used for external thermal insulation system of external wall and production method thereof

The invention provides a composite foaming cement board used for an external thermal insulation system of an external wall and a production method of the composite foaming cement board. The composite foaming cement board is mainly made of the following materials in parts by weight: 220-170 parts of cement, 40-70 parts of coal ash, 0.2-0.5 parts of water repellent, 0.9-1.5 parts of high-efficiency water reducing agent, 0.4-0.7 parts of propyl benzene emulsion, 5-10 parts of calcium chloride, 4-8 parts of aluminum sulfate, 1.5-2.2 parts of pp fiber, 10-15 parts of foaming agent, 1.2-1.5 parts of nanometer modified calcium stearate, and 100-120 parts of water. The composite foaming cement board has high tensile strength and compressive strength, good in water resistance and excellent heat insulation performance and hardly cracks when used in external wall thermal insulation construction.

Owner:南京天印科技股份有限公司

Acrylic emulsion of novel transfer adhesive and preparation method of acrylic emulsion

ActiveCN104193888AGood adhesionGood transferabilityEster polymer adhesivesPolyethylene terephthalate glycolSodium sulfate

The invention discloses an acrylic emulsion of a novel transfer adhesive. The acrylic emulsion comprises the following raw materials: alkyl alcohol polyether, lauryl sodium sulfate, a pH regulator, ammonium persulfate, tert-butyl hydroperoxide, sodium hydrogen sulfite, ammonia water and isothiazolinone; inner-core monomers comprise styrene, methyl methacrylate, butyl acrylate, acrylic acid and N-hydroxymethyl acrylamide; and outer-shell monomers comprise styrene, methyl methacrylate, butyl acrylate, acrylic acid and N-hydroxymethyl acrylamide. The acrylic emulsion has the beneficial effect that the solid content is not less than 50%, and the characteristics such as adhesion, transfer and folding resistance are excellent; the acrylic emulsion can be widely applied to transferring to paper products from aluminum-coated layers on polymer base materials such as BOPP (biaxially-oriented Polypropylene) and PET (polyethylene terephthalate), is safe and environmentally friendly, low in VOC (volatile organic compounds) and capable of satisfying the industries with safety and sanitation requirements such as cigarette packaging.

Owner:ETABONG QINGDAO INDAL

Polypropylene resin composition, molded article produced from the resin composition, and method for production of the molded article

InactiveCN101910287AExcellent gas barrier performanceIncrease freedomFlat articlesPolypropylenePolymer chemistry

Disclosed is a polypropylene resin composition which comprises: a resin component comprising 55 to 99 mass% of polypropylene and 1 to 45 mass% of polyglycolic acid; and a reactive compatibilizing agent in an amount of 0.3 to 30 parts by mass relative to 100 parts by mass of the resin component. Also disclosed is a molded article which is produced from the polypropylene resin composition. In the molded article, a dispersion phase composed of polyglycolic acid is present in a matrix composed of polypropylene, wherein polyglycolic acid is dispersed in the matrix in the form of separate thin films. Further disclosed is a method for producing the molded article.

Owner:KUREHA KAGAKU KOGYO KK

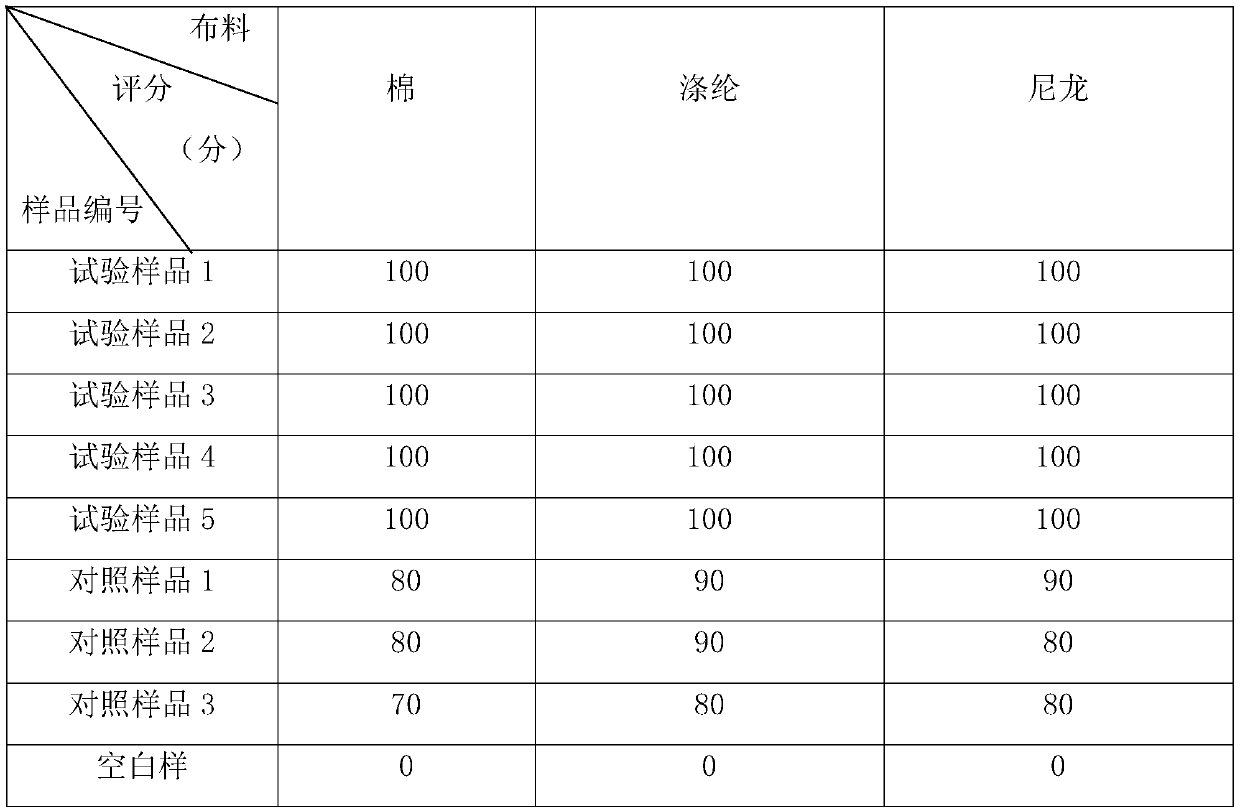

Water soluble polyester slurry for sizing DTY polyester low elastic filaments and preparation method thereof

The invention discloses a water soluble polyester slurry for sizing DTY polyester low elastic filaments and a preparation method thereof, and belongs to the technical field of water soluble polyester slurry. The invention aims to solve the problems that the solid contents of acrylic acid slurry can only reach 30% or so, and the bonding force between the acrylic acid slurry and hydrophobic polyester fibers is weak. The water soluble polyester slurry is characterized by being composed of recycled polyester, glycol accounting for 5 to 10 wt% of polyester, m-phthalic acid-5-sulfonate or derivatives thereof accounting for 10 to 20 wt% of polyester, m-phthalic acid accounting for 3 to 15 wt% of polyester, other dibasic alcohols accounting for 5 to 10 wt% of polyester, a catalyst accounting for 0.03 to 0.15 wt% of polyester, and polyoxyethylene and / or polytetrahydrofuran accounting for 0 to 5 wt% of polyester. The slurry is prepared through steps of alcoholysis, copolymerization, cooling, and grinding. The slurry has a high glass-transition temperature, excellent chemical stability, anti-hydrolysis performance, and thermal stability, thus is convenient for transportation and storage, also has strong flexibility and a large breaking elongation rate, and is mainly used to size polyester low elastic filaments (DTY).

Owner:湖北山特莱新材料有限公司

Method for preparing honeycomb enhanced phenolic foam composite materials

The invention relates to a method for preparing honeycomb enhanced phenolic foam composite materials. The method is characterized by including the steps of: (1) pouring phenolic resin foam composite into a die; (2) vertically placing a honeycomb in the phenolic resin foam composite in the die; (3) placing the die with the phenolic resin foam composite and the honeycomb in the step (2) into a baking oven at the temperature of 50-100 DEG C for foaming for 5-10h, and obtaining the honeycomb enhanced phenolic foam composite material. Via one-time soaking and heating consolidation, the method is capable of preparing the honeycomb enhanced foam composite materials with phenolic foam ingredients in the honeycomb materials and phenolic foam filled in honeycomb lattice holes, the operation procedure is extremely simple, only the die and the baking oven are utilized as equipment, so that the method has the advantages of efficiency and low cost, meanwhile, the composite material products can be guaranteed to have the advantages of good combination properties like light weight, sound insulation, heat insulation, specific strength, specific modulus, water resistance and flame retardance.

Owner:ARAMICORE COMPOSITE

Flash photo frame

InactiveCN105331234AImprove corrosion resistanceAccelerated corrosionAnti-corrosive paintsWater basedMetal particle

The invention discloses a flash photo frame. The flash photo frame comprises a photo frame body and a flash coating on the photo frame body, wherein the flash coating is formed by spraying the flash coating on the surface of the photo frame body; the flash coating comprises the following raw materials: water-based polyacrylate emulsion, water-based amino resin, coated aluminum powder, nano-titanium dioxide, vermiculite power, pearlite powder, wax dispersion, isopropyl alcohol, ethylene glycol monobutyl ether, sodium hexametaphosphate, dispersant SN5040, sodium tripolyphosphate, associated polyurethane thickener, AMP-95, silane coupling agent, flatting agent BYK-331, defoaming agent and deionized water. According to the flash photo frame, the flash coating formed by spraying the flash coating on the surface of the photo frame body increases the aesthetic degree of the photo frame, and the flash photo frame also has the advantages of uniform dispersion of metal particles, high glossiness and excellent mechanical property.

Owner:蚌埠市禹会区贵宾装饰材料商行

Cationic paraffin emulsion as well as preparation method and application thereof

ActiveCN109912813AGuaranteed water resistanceGuaranteed waterproof performanceVegetal fibresParaffin waxThermal insulation

The invention discloses a cationic paraffin emulsion as well as a preparation method and an application thereof and belongs to the technical field of paraffin emulsion processing. The cationic paraffin emulsion is technically characterized by being prepared from components in percentage by weight as follows: 42%-43.5% of paraffin, 1.3%-2.15% of fatty amine polyoxyethylene ether, 0.01%-0.22% of glacial acetic acid and 54.5%-55.0% of water. The preparation method of the cationic paraffin emulsion comprises operation steps as follows: step 1, water, paraffin, fatty amine polyoxyethylene ether andglacial acetic acid are added to a reaction kettle, and the reaction kettle is sealed; step 2, the reaction kettle is heated to 80-105 DEG C, a thermal insulation reaction is performed for 1-5 h until the paraffin and the fatty amine polyoxyethylene ether in the reaction kettle are fully melt; step 3, stirring is started and the temperature in the reaction kettle is controlled at 70-95 DEG C; step 4, homogenization and discharging are performed, a product is cooled to the room temperature, and the cationic paraffin emulsion can be obtained. According to the cationic paraffin emulsion, the total content of fatty amine polyoxyethylene ether is lower; the paraffin is waterproof, but an emulsifier is not waterproof, so that the waterproof property and the lubrication performance of paraffin are guaranteed to the greatest extent.

Owner:上海舜雅化工有限公司

Water-soluble polyester slurry for FDY filament sizing water-jet weaving and preparation method thereof

The invention discloses a water-soluble polyester slurry for FDY filament sizing water-jet weaving and a preparation method thereof, belongs to the technical field of water-soluble polyester slurry, and is used for mainly solving the problems that a conventional acrylic acid slurry has the product solid content of only about 30% and is high in transport costs, severe in environmental pollution, serious in moisture absorption and rebonding, low in adhesive power with hydrophobic polyester fibers and the like. The water-soluble polyester slurry is mainly characterized in that the water-soluble polyester slurry is prepared by alcoholysis, copolymerization, cooling and crushing of recycled polyester, ethylene glycol, m-phthalic acid-5-sulfonate or derivatives thereof, m-phthalic acid, other dihydric alcohols, a catalyst, an inorganic auxiliary agent and polyether with the weight-average molecular weight of 600-10000. The water-soluble polyester slurry has the characteristics of improving the product glass transition temperature, being excellent in chemical stability, hydrolysis resistance and thermal stability, being convenient to store and transport and having no addition and release of ammonia gas in the process of using, and is mainly used for preparation of the water-soluble polyester slurry for FDY filament sizing water-jet weaving.

Owner:湖北山特莱新材料有限公司

Preparation method for AKD (Alkyl Ketene Dimer) emulsion and water-resistant treatment method for paper sheets

InactiveCN105421145AReduce the degree of hydrolysisGuaranteed water resistanceWater-repelling agents additionStarch gelatinizationCreaming

The invention discloses a preparation method for an AKD (Alkyl Ketene Dimer) emulsion and a water-resistant treatment method for paper sheets. The preparation method comprises the following steps of firstly, gelatinizing cationic starch, melting AKD wax powder at the temperature of 70 DEG C, then, pouring the gelatinized starch into the melted AKD wax powder, adding a stabilizer into the melted AKD wax powder, turning on an emulsifying machine to carry out emulsification, carrying out homogenization treatment on the solution, and carrying out rapid cooling, thereby obtaining the AKD emulsion. According to the preparation method for the AKD emulsion, disclosed by the invention, on the premise of guaranteeing the water resistance of the AKD emulsion, no starch etherifying process is carried out, and the gelatinized starch is directly used for emulsifying AKD after the starch is gelatinized, so that the equipment and labor investment of AKD emulsion manufacturers can be reduced, the aging efficiency of the AKD emulsion is high, the degree of hydrolysis of the AKD is greatly lowered, the water resisting effect is effectively guaranteed, and the economic benefit is obvious.

Owner:广东志广生物科技有限公司

Biodegradable plastic and preparation method thereof

InactiveCN103483624AGuaranteed water resistanceImprove water resistanceBiodegradable plasticSodium silicate

The invention relates to a biodegradable plastic and a preparation method thereof, and belongs to the technical field of plastic processing. The biodegradable plastic comprises the following raw materials in parts by weight: 16-21 parts of chitin, 2-5 parts of sodium fluosilicate, 2-5 parts of gelatin, 1-3 part(s) of calcium carbonate, 1-3 part(s) of glycerol, 18-22 parts of ultrafine starch, 1-3 part(s) of glycerin, 0.4-0.7 parts of stearic acid, 0.4-0.7 parts of oleic acid, 15-20 parts of low-density polyethylene, 15-20 parts of high-density polyethylene and 0.4-0.7 parts of acetyl acetone manganese. The preparation method comprises the following steps: heating a container to 75-85 DEG C; putting the raw materials into the container, heating the raw materials to 125-130 DEG C within 0.5-0.8 hour, and mixing and reacting for 1.5-1.8 hours at the temperature; adjusting the pH value of a reaction solution to be 5.8-6.5 by hydrochloric acid to obtain a uniformly dispersed solution; pouring the solution into a preheated mould for foaming and forming, thermalizing, and demoulding to obtain the biodegradable plastic. Compared with like products on the market, the plastic has the advantages of relatively low production price, relatively high degradation speed, no toxin materials, environmental protection and the like.

Owner:广州市永进塑料有限公司

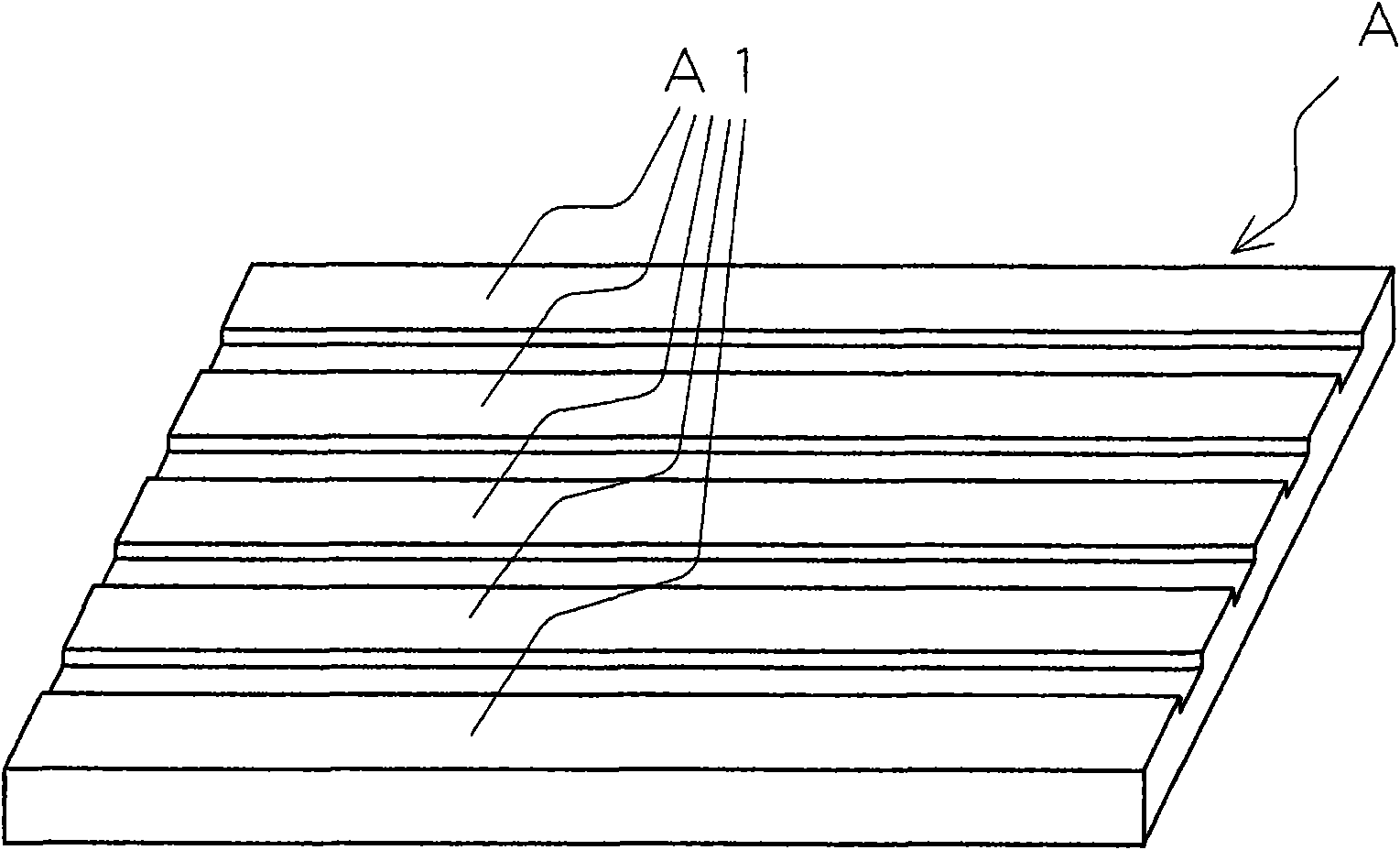

Wood cement board

ActiveCN101550743AAvoid crackingIncrease inhalationConstruction materialSolid waste managementCement boardMaterials science

Provided is a wood cement board that has a pattern of acute-angled and deep recesses and projections on its surface, and that tends not to cause cracking during a hardening and curing process, a drying process, a transportation process and so on. The wood cement board has a pattern of recesses and projections on its surface, in which the distance from the apex of the projections to the rear face is 9 mm or more, and the distance from the apex of the projections to the base point of the recesses is 2 mm or more, and is equal to or less than half the distance from the apex of the projections to the rear face. The average specific gravity of the wood cement board as a whole, and the specific gravities of the projections and the recesses are each 1.1 or more, and the difference between the specific gravity of the projections and the specific gravity of the recesses is less than 0.1.

Owner:NICHIHA CORP

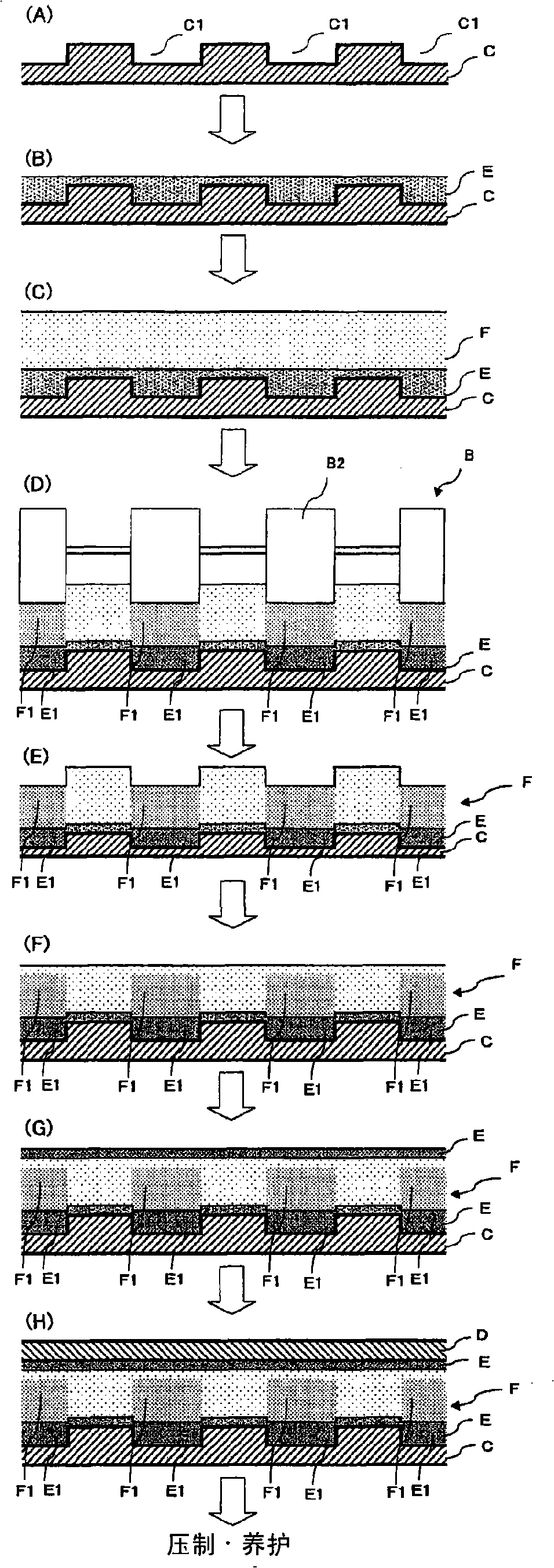

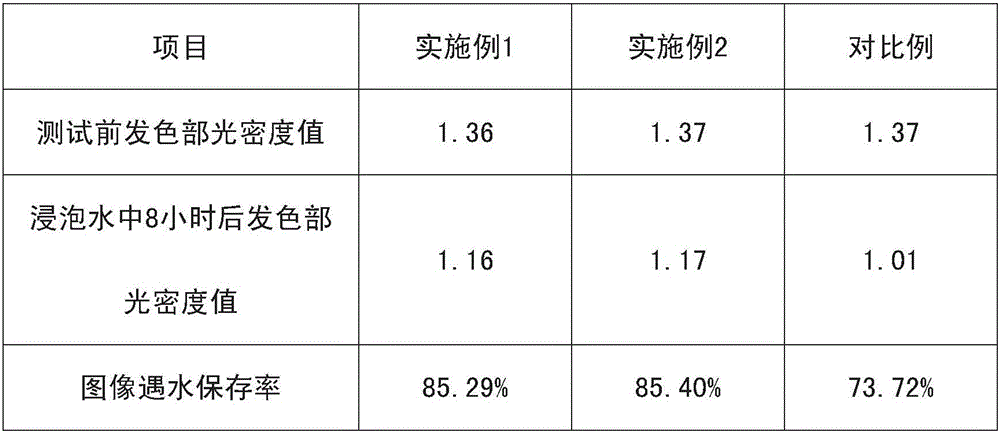

High-stability thermosensitive paper and preparation method thereof

InactiveCN106351069AImprove stabilityGuaranteed water resistanceNon-fibrous pulp additionCoatings with pigmentsWater resistanceOptical density

The invention discloses high-stability thermosensitive paper which comprises a raw paper layer as well as a precoating layer and a color development layer sequentially coating the raw paper layer. In the invention, a stabilizer is added into the color development layer to improve the stability of a color development group so as to guarantee the water resistance of the thermosensitive paper; and after being soaked in water for 8 hours, the thermosensitive paper still has relatively high light density, and the preserving rate of an image in water is high.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Normal-temperature self-crosslinking type core-shell structure acrylate emulsion as well as preparation and application thereof

ActiveCN113292682AImprove water resistanceGood weather resistanceInksEmulsion paintsMethacrylatePolymer science

The invention belongs to the technical field of film printing materials, and discloses a normal-temperature self-crosslinking type core-shell structure acrylate emulsion as well as preparation and application thereof. The preparation method comprises the steps: carrying out dehydrogenation condensation reaction on a vinyl polyether monomer and a hydrogen-containing silane coupling agent to obtain a modified macromonomer; heating a core-layer monomer emulsion composed of styrene, methacrylate and acrylate to 55-85 DEG C, and then adding an initiator solution to carry out polymerization reaction to obtain a core-layer emulsion; and dropwise adding a shell monomer emulsion composed of methacrylate, acrylic acid and a modified macromonomer and an initiator solution, and continuously carrying out a polymerization reaction to obtain the normal-temperature self-crosslinking type core-shell structure acrylate emulsion. According to the invention, the modified macromonomer with the specific structure is used as a shell polymerization monomer, so that the product can be endowed with a normal-temperature cross-linking characteristic, the adhesive force is enhanced, the wettability is improved, and the water resistance is good. The emulsioncan be used for preparing water-based ink and water-based latex paint.

Owner:李星明

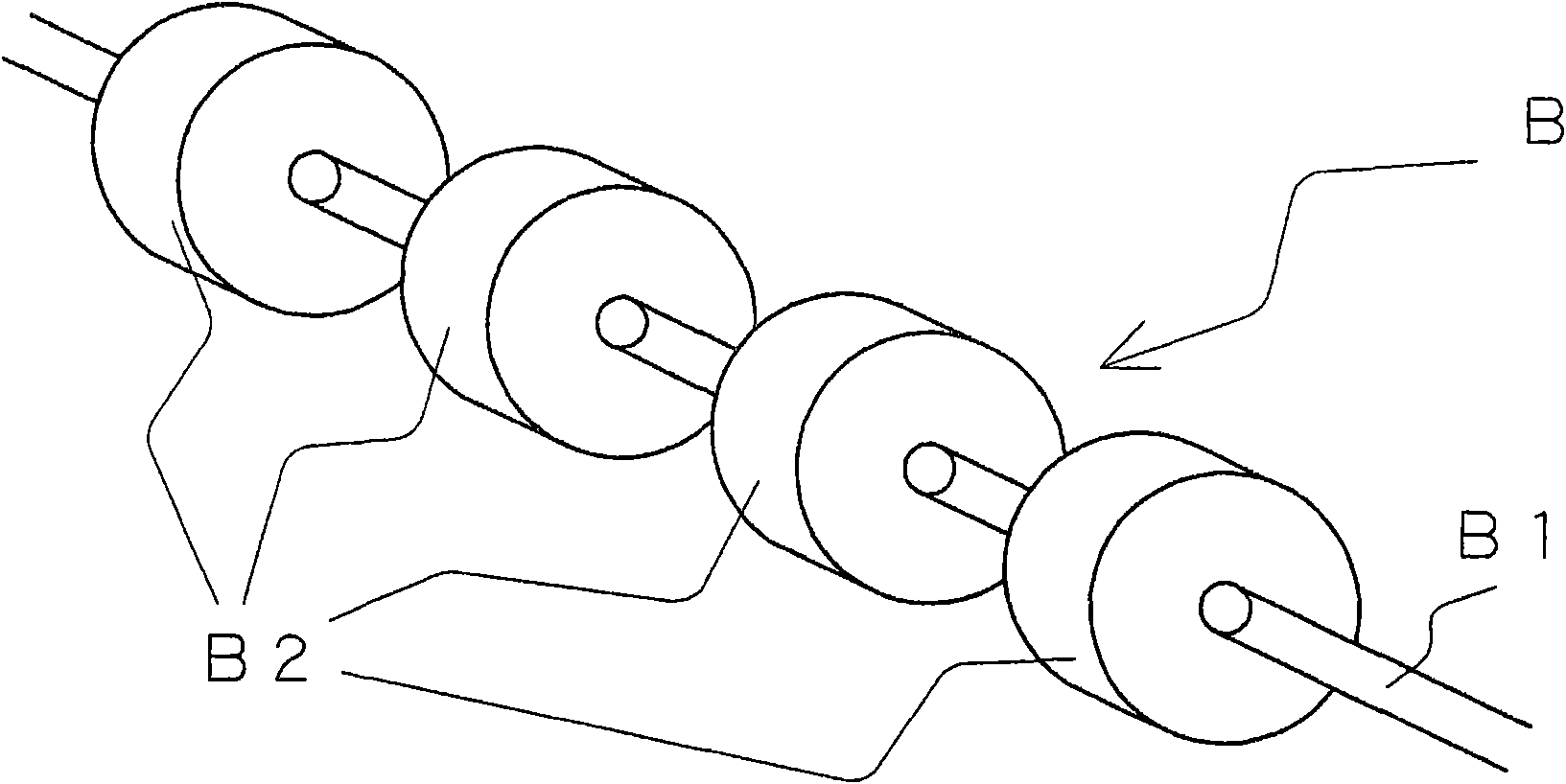

Watertight umbilical and photoelectric hybrid cable

InactiveCN108109755AExtended service lifeGuaranteed mechanical propertiesSubmarine cablesFibre mechanical structuresLow voltageEngineering

A watertight umbilical and photoelectric hybrid cable disclosed by the present invention comprises a cable core and an enhancing layer lapping the cable core, and the cable core comprises an optical fiber, a stainless steel loose tube, the low-voltage watertight electric wires, the high-voltage watertight electric wires and an inner protection layer. The optical fiber is installed in the stainlesssteel loose tube, the multiple strands of low-voltage watertight electric wires are twisted on the stainless steel loose tube, and the inner protection layer wraps the low-voltage watertight electricwires; the high-voltage watertight electric wires are twisted on the inner protection layer, the enhancing layer wraps the watertight electric wires, the curing type water-blocking sealants are filled between the enhancing layer and the high-voltage watertight electric wires and between the stainless steel loose tube and the low-voltage watertight electric wires respectively, and an outer protection layer is arranged on the enhancing layer. The watertight umbilical and photoelectric hybrid cable of the present invention effectively solves the problems that the signal transmission distance andthe communication capacity are limited, the function is single, during the large tension repeated contraction and release, the signal transmission is not stable, and the service life is reduced, andguarantees the overall mechanical performance and the transverse water-pressure resistant capability.

Owner:8TH RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com