Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Animal wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wool, fleece, and fiber can be harvested from a number of wool-yielding animals, including sheep, goats, rabbits, camels, llamas, alpaca, bison, and yak! The fiber from bison, camels, and yak are the more rare fibers. The fiber from the camelid family of animals is very soft and fine.

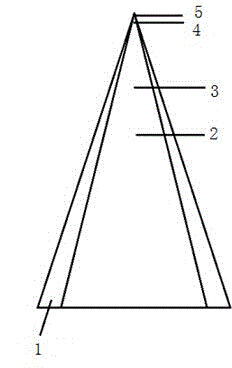

Writing brush head coupling toughness with softness, writing brush and manufacturing method thereof

The invention discloses a writing brush head coupling toughness with softness, a writing brush and a manufacturing method thereof, and belongs to the technical field of writing brush manufacturing. The writing brush head comprises, by weight: the outer layer of the writing brush head: 10 percents to 15 percents of goat hair; the center part of the writing brush head: 1 percent to 8 percents of nylon fur, 20 percents to 40 percents of goat hair, 1 percent to 8 percents of horse hair, 20 percents to 45 percents of sheep mustache and 10 percents to 20 percents of bristles. According to the writing brush head coupling toughness with softness, the writing brush and the manufacturing method thereof, the animal hair is mainly used as the raw material, a new debinding method in which the natural debinding plays a leading role and the artificial debinding plays a subsidiary role is adopted, the elastic and hard sheep mustache, horse hair and bristles are mixed matched with goat hair, so that the product is neither too hard nor too soft, couples toughness with softness, elastic without branches, durable and large in the amount of ink content; changing on the ink rhyme of the painting and calligraphy is good, the writing and drawing are free, and the addition of the small amount of the nylon fur is for strengthening the flexibility of a writing brush point.

Owner:湖州千金湖笔有限公司

Hairbrush and manufacturing process thereof

The invention discloses a hairbrush and a manufacturing process of the hairbrush. By completely optimizing the processing of nylon wool, treatment of animal wool and variety selection and match of the wool, the obtained hairbrush has high elasticity and high ink holding capacity in both writing and painting, a user can write words comfortably, the words written with the hairbrush are vigorous and forceful, stretch long and have a high artistic effect, and the hairbrush varies in hardness when used for writing. The hairbrush has high quality and good market prospects. As the nylon wool technology is improved and damage to the animal wool is reduced by improving the animal wool technology, the hairbrush is more elastic and durable and can be kept for a long period.

Owner:湖州市善琏心远笔斋股份有限公司

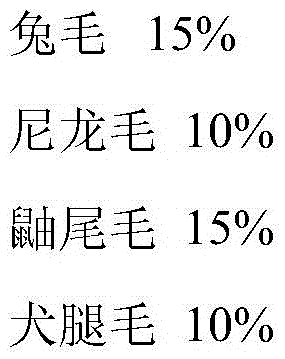

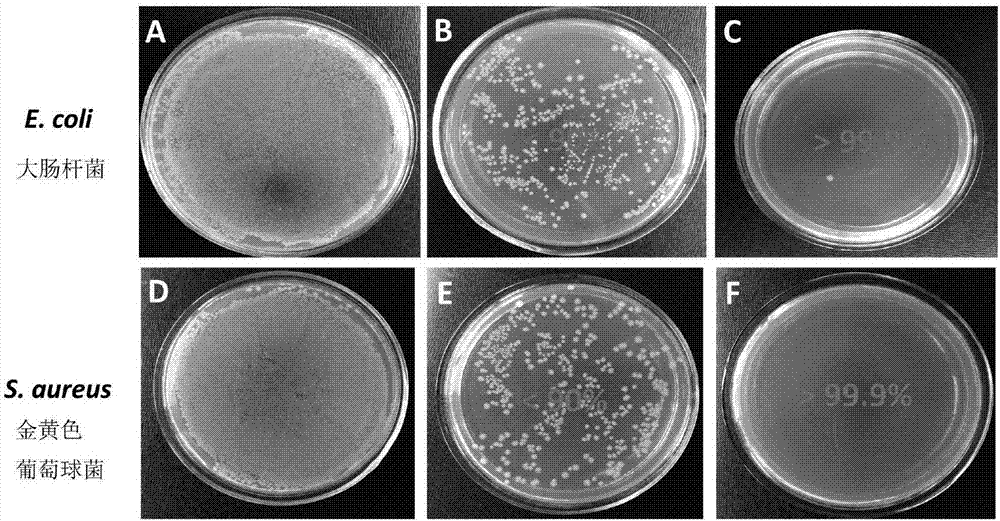

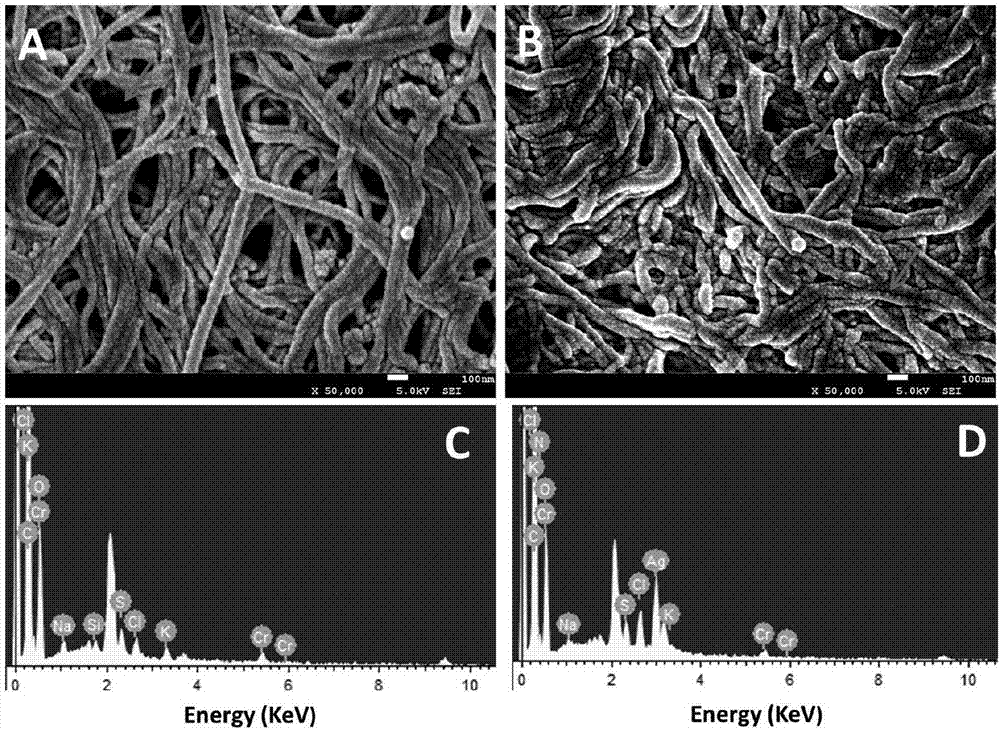

Long-acting anti-microbial leather and preparing method thereof

ActiveCN107354251ANo change in antibacterial propertiesEasy to prepareBiocideTanning treatmentGallic acid esterAnimal fur

The invention provides a preparing method of long-acting anti-microbial leather. According to the preparing method, after tanning is carried out, before washing is carried out, a nano-silver solution modified by gallic acid is added, the adding amount is 50% to 120% of the weight of animal fur, the grain diameter of the nano-silver modified by the gallic acid is 4 nm to 10 nm, and the concentration of the nano-silver modified by the gallic acid in the nano-silver solution modified by the gallic acid is 150 ppm to 5000 ppm. After the long-acting anti-microbial leather is washed with a solution with the soap concentration being 1 g / L at 40 DEG C at least three times, washing is carried out 60 minutes each time, the excellent anti-microbial effect still exists. The preparing method is simple, the process requirement is not strict, and implementation is easy.

Owner:深圳市左右家私有限公司

Green high-efficient organic fertilizer and production process thereof

InactiveCN101514127AEasy to prepareReduce dosageCalcareous fertilisersClimate change adaptationBiotechnologyAnimal feces

The invention provides a green high-efficient organic fertilizer and production process thereof. The green high-efficient organic fertilizer is a high-efficient organic fertilizer of green ecological agriculture prepared by utilizing excreta of breeding and culture livestock and environment pollution refuse such as discarded animal bone, oil, blood, hire and meet, and is characterized in that the organic fertilizer is prepared by mixing and fermenting raw materials of chicken feces, sheep feces, pig feces, peat, animal bone oil, terrestrial animal bone powder, animal blood powder, fish bone powder, egg shell powder, animal hair powder and animal meet powder. The invention utilizes refuse which pollutes environment to produce green pollution-free organic fertilizer with good effect, overcomes disadvantages of fertilizer and farm manure, and synthetically treats refuse. By applying the present invention, soil is not hardened, soil fertility is enhanced, amount of fertilizer is less, fertilizer efficiency is long, output is high, taste is good, quality of agricultural product is improved, and the organic fertilizer is very suitable for producing green pollution-free agricultural products. The invention has advantages of simple process, short fermentation time, low cost, wide raw material source, significant economic benefit and social benefit, and is suitable for small enterprise especially small towns enterprise.

Owner:北京奇育阳光生物科技有限公司

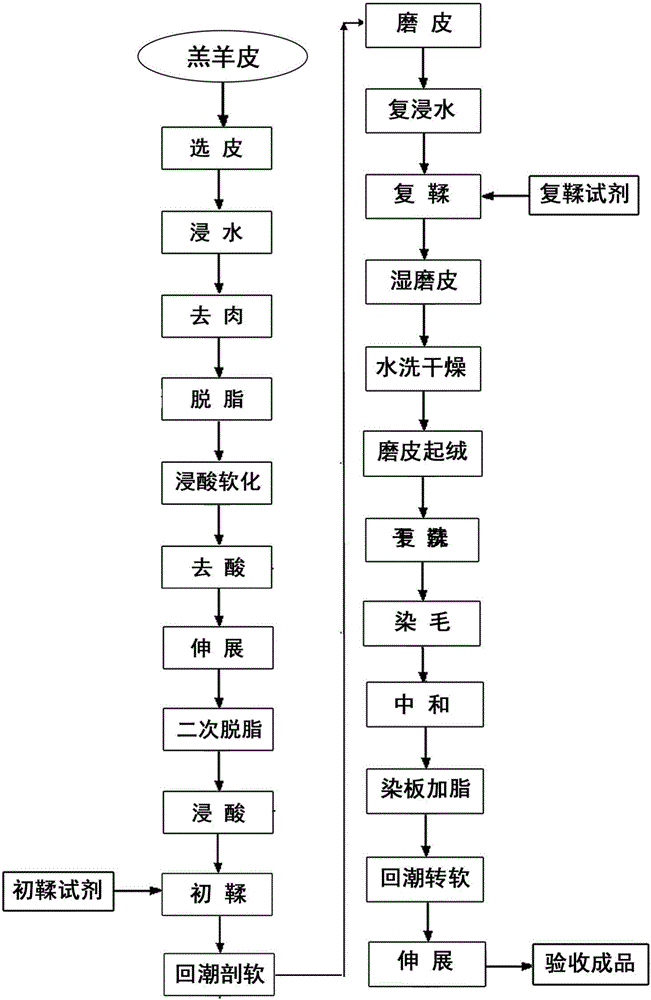

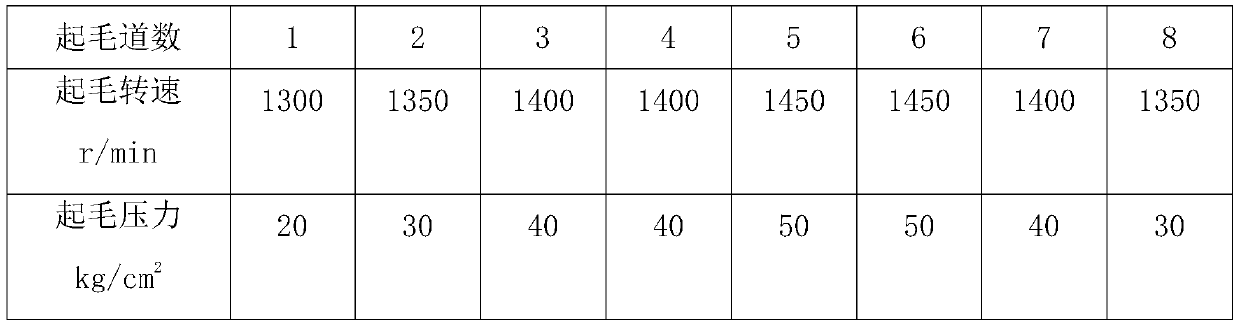

Double-face leather integrated dyeing technology for lambskin

ActiveCN106521048ASolve Yi LuqingSolve the phenomenon of hair retentionTanning treatmentPre-tanning chemical treatmentAnimal furAlum

The invention relates to the technical field of processing of animal fur, in particular to a double-face leather integrated dyeing technology for lambskin. The double-face leather integrated dyeing technology for the lambskin comprises the following steps of selecting skin, dipping the skin in water, removing meat, conducting degreasing, conducting acid maceration, conducting deacidification, stretching the skin, conducting secondary degreasing, conducting pickling, conducting primary tanning, conducting moisture regaining shaving softness, conducting buffing, dipping the skin in water again, conducting retanning, conducting wet buffing, conducting washing and drying, conducting sanding to achieve raising, conducting dry cleaning, dyeing fur, conducting neutralization, conducting board dyeing and fat liquoring, conducting moisture regaining and softening, conducting stretching and inspecting and accepting finished products. According to the double-face leather integrated dyeing technology for the lambskin, lambskin double-face leather raw materials are selected for the double-face leather integrated dyeing process, tanning and dyeing treatment are conducted on fleece and leather boards in a segmented manner, the temperature, the time, the addition of auxiliaries and the like are controlled to be in the best range, and the phenomena that the lambskin is prone to show green and fur is prone to remain are avoided; and besides, in the tanning process, ammonium alum and zirconium are used for primary tanning, then the technological process of low-chromium-content retanning is conducted, in this way, the softness of the lambskin as the double-face leather is greatly improved, and the thickness of the leather board is greatly improved.

Owner:宁夏成丰农业科技开发股份有限公司

Livestock and poultry feather keratin based coextruded film and method for preparing same

The invention relates to an animal wool keratin based composite membrane. The compositions by weight portion of the animal wool keratin based composite membrane are: 10 to 29 portions of animal wool keratin solution, 1 portion of filmerformer, 0 to 1 portion of cross linker and 0 to 0.5 portion of plasticizer. The preparation method comprises the following processing steps of: preparation of keratin stock solution by utilization of animal feathers through the reduction hydrolytic method or the oxydrolysis method, ultrasonic treatment of the keratin stock solution, preparation of composite solution and preparation of the membrane. The method uses abandoned animal feathers as raw materials and adopts ultrasonic hydrolyzation to prepare the keratin stock solution to prepare the keratin composite membrane after mixing of the keratin stock solution and polyvinyl alcohol. The preparation method has the advantages of simple technique, simple and convenient operation and so on; the keratin composite membrane prepared by adoption of the preparation method has high tensile strength and low elongation at break, can be degraded and can be used as materials for manufacturing a package; the package is buried underground, can be degraded and converted into organic fertilizer and then absorbed by crops and solve the problem of environmental pollution of plastic bags.

Owner:SHAANXI NORMAL UNIV

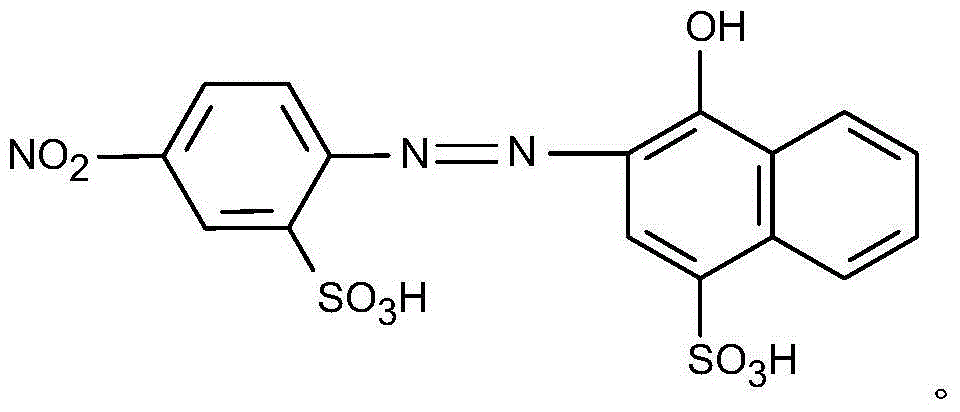

Novel environment-friendly acid blue-light red dye applied to furs and synthesis method of dye

ActiveCN104448895ANon-allergenicFull colorMonoazo dyesDyeing processEnvironmental resistanceSynthesis methods

The invention relates to the field of processing processes of animal furs and in particular relates to a novel environment-friendly acid blue-light red dye applied to furs and a synthesis method of the dye. The structural formula of the novel environment-friendly acid blue-light red dye is as shown in the description. The method comprises the following steps: (1) carrying out diazo-reaction; and (2) coupling. The dye can be widely used for dyeing various furs. The blue-light red dye has a series of advantages of high dyeing degree, high net adsorption rate, good compatibility and full color and luster; meanwhile, the dye is free of 24 aromatic hydrocarbons banned by European Union; the dye is environmentally friendly; by tests, the dye is free of sensitization; the safety is ensured.

Owner:BEIJING FANBO CHEM

Method for manufacturing writing brush through palm fibers

The invention discloses a method for manufacturing a writing brush through palm fibers. The method has the advantages that the palm fibers are purely natural plant materials and have the advantages of being high in toughness and high in elasticity; not like wool and other animal hair, the palm fibers are easily stored and not easily damaged by worms; the palm fibers are high in corrosion prevention, convenient to store and pick, and unseasonal; with the adoption of the palm fibers for manufacturing the writing brush, the cost can be greatly decreased; the palm fibers can completely replace the animal hair; the writing brush manufactured by the palm fibers is high in elasticity, good in a tip, and high in ink absorbing capacity; in addition, the writing brush can be cleaned easier than a writing brush manufactured from the animal hair; when in cleaning, the writing brush is simply put into water, and the ink can quickly automatically disperse and hard to attach to the writing brush, and such property is a good property of the palm fibers.

Owner:NANXUN SHANLIAN SONGBAI LAKE PEN FACTORY

Method of preparing sheepskin clothing face garment leather with small liquor ratio

ActiveCN104313199AReduce water consumptionWhite coatLeather manufacturingTanning treatmentPruningPre treatment

The invention relates to the treatment field of animal furs and particularly relates to a method of preparing sheepskin clothing face garment leather with a small liquor ratio. The method comprises the following steps: pre-treating soil-species sheepskin in a paddle-tumbler, wherein the pretreatment includes the steps of soaking in water, washing the skin, re-soaking in water, shearing, removing meat and degassing, and a weight ratio of the water to the raw material kin in each pretreatment step is 9-11; then, performing pickling, depickling, re-pickling, tanning, re-tanning, neutralizing and oiling in a rotary drum in sequence, wherein a weight ratio of the water to the raw material skin in each treatment step is 5-7; and performing the processes of drying, moisture regaining, staking, dry cleaning, fine pruning, scalding, dry grinding and clearing to obtain the sheepskin clothing face garment leather. According to the method disclosed by the invention, the soil-species sheepskin is prepared into the sheepskin clothing face garment leather by adopting a small liquid ratio in the paddle-tumbler and the rotary drum, so that the water consumption in the process is reduced, the chemical materials are reduced correspondingly; and the finally prepared sheepskin clothing face garment leather is white in fur color, fine in dermatotome, full, soft and elastic in hand feeling and high in quality.

Owner:青铜峡市祥云皮草有限责任公司

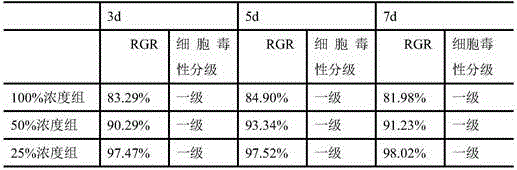

Method for quickly identifying donkey skin

ActiveCN102608117AAvoid mixingImprove accuracyMaterial analysis by optical meansAnimal scienceColla corii asini

The invention discloses a method for quickly identifying donkey skin. The method comprises the following steps of: (1) taking a hair sample from animal fur to be detected; (2) observing the surface and scale of the obtained hair sample; and (3) determining that the fur to be detected is the donkey skin when the surface and scale of the hair sample on the fur to be detected have the following characteristics: the hair surface is rough; and the scale of the hair is not distributed clearly, the scale has large rake angle and good luster, and the scale is spinous, sheet-like or spore-like, extends to the outer side of the dry hair and is not distributed uniformly. By utilizing the method, the donkey skin is distinguished from other animal furs very accurately, the accuracy and reliability of the raw donkey skin material are ensured, and the animal furs such as horse skin, cattle skin and pigskin in a process of preparing donkey-hide gelatin are prevented from being mixed. The method has the advantages of high accuracy, low detection cost, quickness, convenience and the like, is easy to operate, and is convenient to popularize and apply in reality.

Owner:SHAN DONG DONG E E JIAO

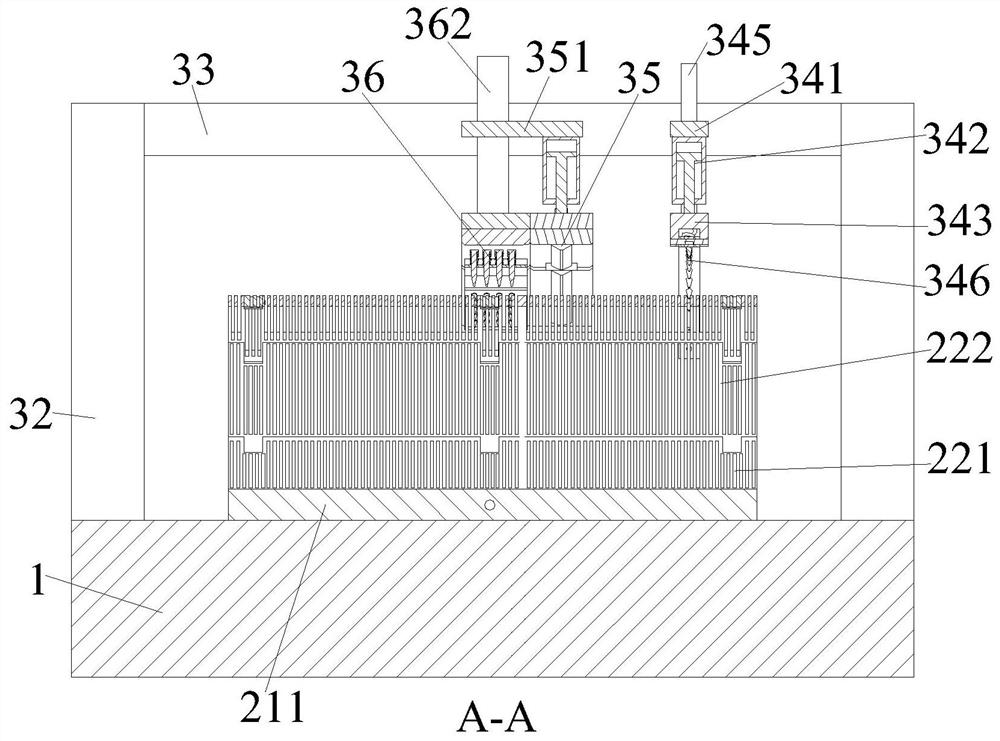

Silk fibroin/keratin composite porous material and preparation method thereof

InactiveCN108273132AGood biocompatibilityFulfil requirementsTissue regenerationProsthesisPore distributionBone tissue engineering

The invention discloses a silk fibroin / keratin composite porous material and a preparation method of the composite porous material. The composite porous structure material with uniform pore distribution and a controllable size is prepared by taking silk, animal wool, human hair and poultry and bird feather as major raw materials. The material is natural, safe, nontoxic, good in biocompatibility, suitable for extensive application in the fields of muscle tendons, nerves, blood vessels, skin and soft and hard bone tissue engineering and the like, complies with the development and interdisciplinary planning of the national biomedical industry and belongs to an emerging industry field with great development potentials and wide market prospects.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Detergent for cleaning animal hair

InactiveCN105200166AEfficient removalOvercome the disadvantage that sticky hair cannot be dry-cleanedSurface-active non-soap compounds and soap mixture detergentsLeather degreasingAlkaneSolvent

The invention relates to the field of treatment processes for animal fur and particularly relates to a detergent for cleaning animal hair. The detergent is prepared from the following raw materials in parts by weight: 10-50 parts of solvent oil, 5-20 parts of emulsifier, 1-10 parts of stabilizer and 20-100 parts of deionized water, wherein the solvent oil is one or a mixture of more of petroleum solvent D60, odorless turpentine oil and dodec-alkane; the emulsifier is one or a mixture of more of AEO9, AEO7, dodec-alkyl amide propyl betaine and coconut-oil fatty acid diglycolamide, and the stabilizer is 1,2-propylene glycol or hexadecanol or a mixture of both. The detergent can be used for effectively removing fats and oils from fine leather after oil tanning and is high in degreasing power, so that the fur can be clean and smooth; the detergent is safe and environment-friendly, is an environment-friendly detergent, is free of unpleasant smells and is convenient in use.

Owner:安徽中福毛纺制帽有限公司

Fertilizer capable of improving soil pH

InactiveCN104291951ARaise the pHImprove the growing environmentCalcareous fertilisersAnimal corpse fertilisersBacilliChemistry

The invention relates to a fertilizer capable of improving soil pH, which is prepared from the following components in parts by weight: 2-7 parts of Bacillus subtilis, 3-6 parts of kieselguhr, 6-10 parts of calcium biphosphate, 1-5 parts of sodium glutamate, 3-8 parts of peat soil, 2-5 parts of animal wool powder, 3-9 parts of ammonium molybdate tetrahydrate, 5-9 parts of white vitriol, 5-8 parts of polyaspartic acid, 8-14 parts of potato straw, 1-5 parts of straw ash, 2-8 parts of soybean powder, 3-6 parts of ammonium chloride, 5-11 parts of kongpo monkshood root and 1-6 parts of limestone. The fertilizer can improve the soil pH, enhance the soil fertility and improve the growth environment of crops.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

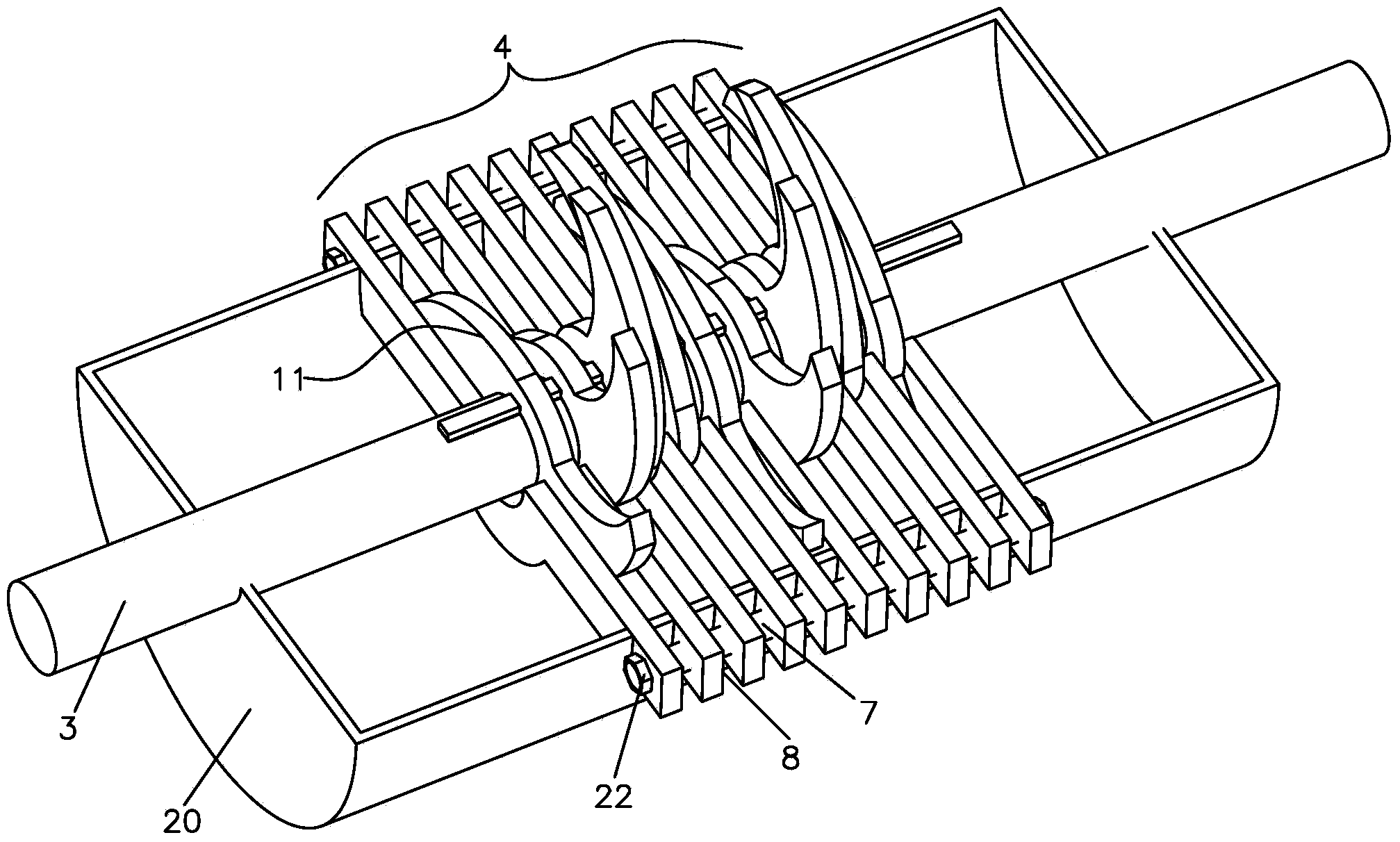

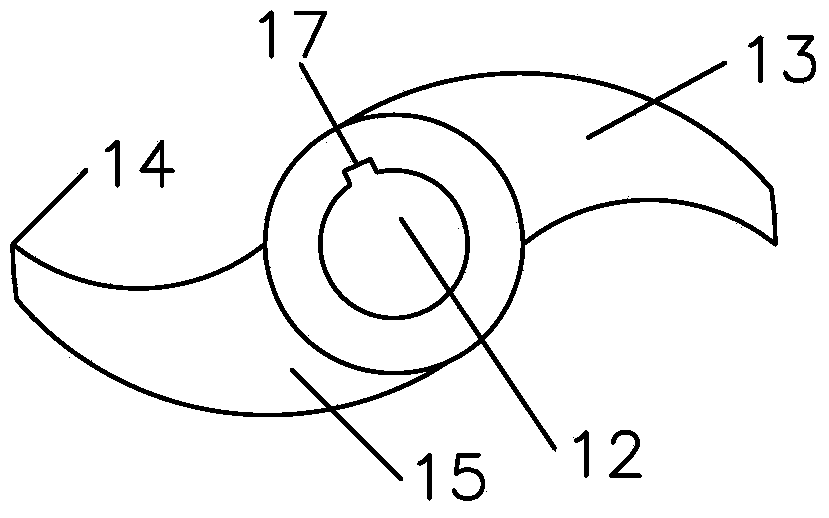

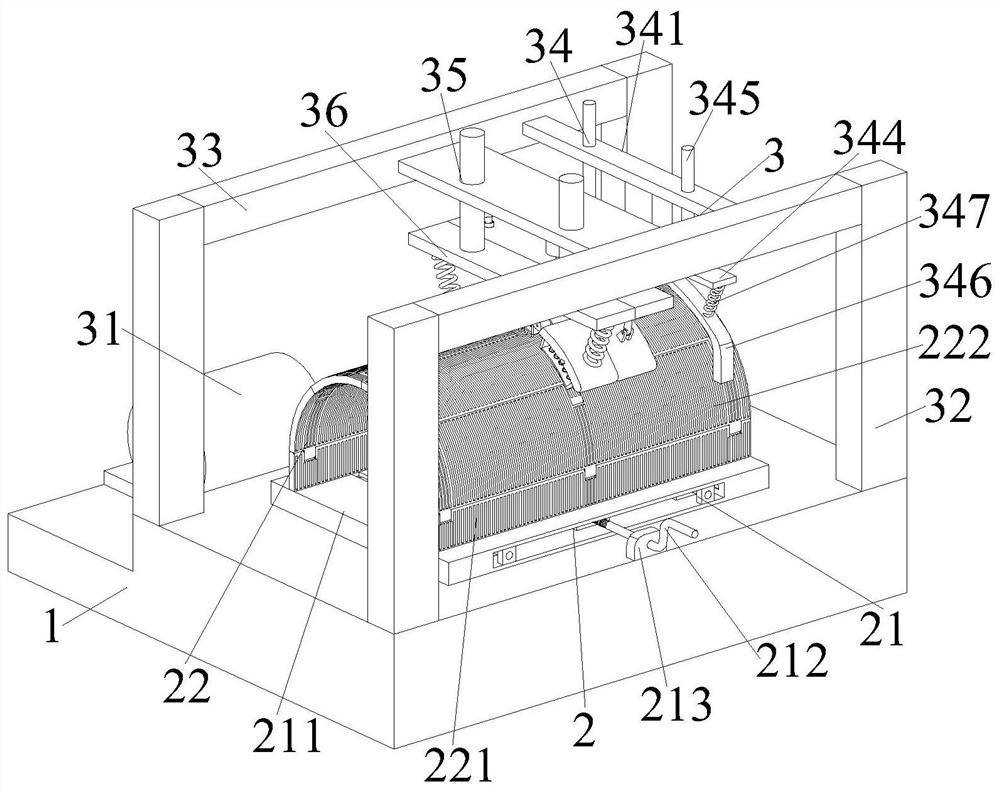

Reutilization crushing machine for animal wool and excrement

A related reutilization crushing machine for animal wool and excrement comprises a pedestal, a power apparatus, a barrel, a stirring shaft and an auxiliary knife rest; the barrel is installed on the pedestal; the upper part of the barrel is provided with a hopper for feeding, and the lower part of the barrel is provided with a discharging port for discharging a material; the auxiliary knife rest comprises a plurality of auxiliary knives; the knives comprise a shaft seat and blades horizontally connected with two wings of the shaft seat; the auxiliary knives are arranged alternately side by side for forming the auxiliary knife rest; two ends of the auxiliary knife rest are fixedly installed on the barrel; the stirring shaft penetrates the shaft seat of the auxiliary knife rest and is supported by two ends of the barrel in a transmission way; the stirring-shaft part stretching out of the barrel is in transmission connection with the power apparatus; and the intervals among the auxiliary knives are all provided with main cutting knives coaxially installed on the stirring shaft. The reutilization crushing machine is capable of effectively crushing long fiber or wool in excrement, and the crushed excrement is easy for fermentation processing.

Owner:CHANGZHOU YUNTAI DRYING EQUIP

Bionic high-density-fluff warp-knitted fabric and preparation method thereof

ActiveCN111118725AFeel goodNot easy to generate static electricityWarp knittingHeating/cooling textile fabricsPolyesterPolymer science

The present invention provides a bionic high-density-fluff warp-knitted fabric with excellent hand feeling and good abrasion resistance. The invention also provides a preparation method of the bionichigh-density-fluff warp-knitted fabric. The bionic high-density-fluff warp-knitted fabric comprises a base cloth layer formed by interweaving 40-20wt% of polyester sea-island filaments, 33-43wt% of superfine denier polyester low-elastic filaments and 27-37wt% of polyester filaments, wherein the superfine denier polyester low-elastic filaments are exposed to the surface of base cloth layer and formfluffs, the polyester sea-island filaments form fluffs in an inner layer, and the fluff density is 0.7-1 million fluffs / cm<2>. According to the bionic high-density-fluff warp-knitted fabric, by adjusting the reasonable tissue structure, the fluffs on the surface of the fabric are the superfine denier polyester low-elastic filaments, the polyester sea-island filaments are located in the fluff inner layer, such structure is similar to animal fur, and the fabric is excellent in hand feeling and good in wear resistance.

Owner:ZHEJIANG ADIENT WANFANG TEXTILE TECH CO LTD

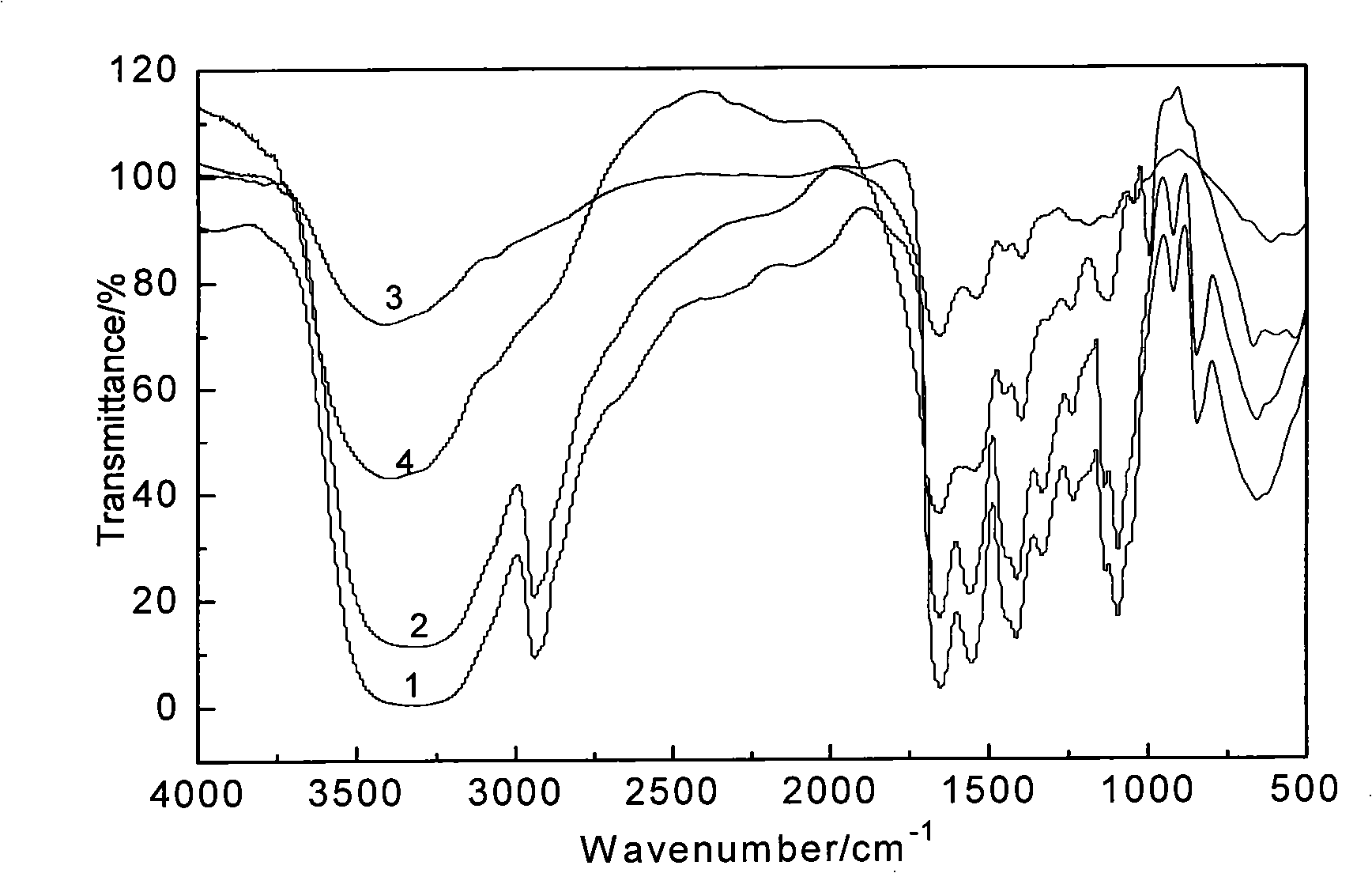

Resource utilization method of waste animal wool and vinyl retanned material based on keratin hydrolysate and application

ActiveCN108342524ARealize resource utilizationIncrease hydrolysis rateTanning treatmentResource utilizationHydrolysate

The invention provides a resource utilization method of waste animal wool and belongs to the field of resource utilization of waste biomass. The method comprises the following steps: processing the waste animal wool with hydrogen peroxide to play double roles of decoloring and oxidation hydrolysis; carrying out alkaline hydrolysis combining sodium hydroxide, sodium hydrogen sulfite and sodium metabisulfite, wherein the hydrolysis rate of keratin is improved greatly to 92-95%; and carrying out a polymerization reaction on vinyl monomers such as acrylic acid, acrylamide and itaconic acid and concentrated liquor to obtain a vinyl retanned material based on keratin hydrolysate. The retanned material can endow leather with good retanning and filling properties, and the sense of plastics of product leather which is retanned by the vinyl polymer retanning agent can be reduced greatly, so that resource utilization of the waste animal wool is achieved, and the pollution on human and environmentof the waste animal wool can be reduced.

Owner:JIAXING UNIV

Test strip for screening specific animal fur and scurf allergens IgE (Immunoglobulin E) and preparation method thereof

The invention provides a test strip for screening specific animal fur and scurf allergens IgE (Immunoglobulin E). The test strip is coated with an animal fur and scurf antigen marked by colloidal gold. The test strip utilizes a colloidal gold marking technology; firstly, the colloidal gold mark is used for marking the specific animal fur and scurf allergens; then the marked allergens are uniformly sprayed on a cellulose acetate membrane or a nitrocellulose membrane to prepare a test strip product to carry out allergen detection; the test strip is simple and convenient to operate, accurate in result and low in cost and can realize multi-term free detection.

Owner:BIOSINO BIO TECH & SCI

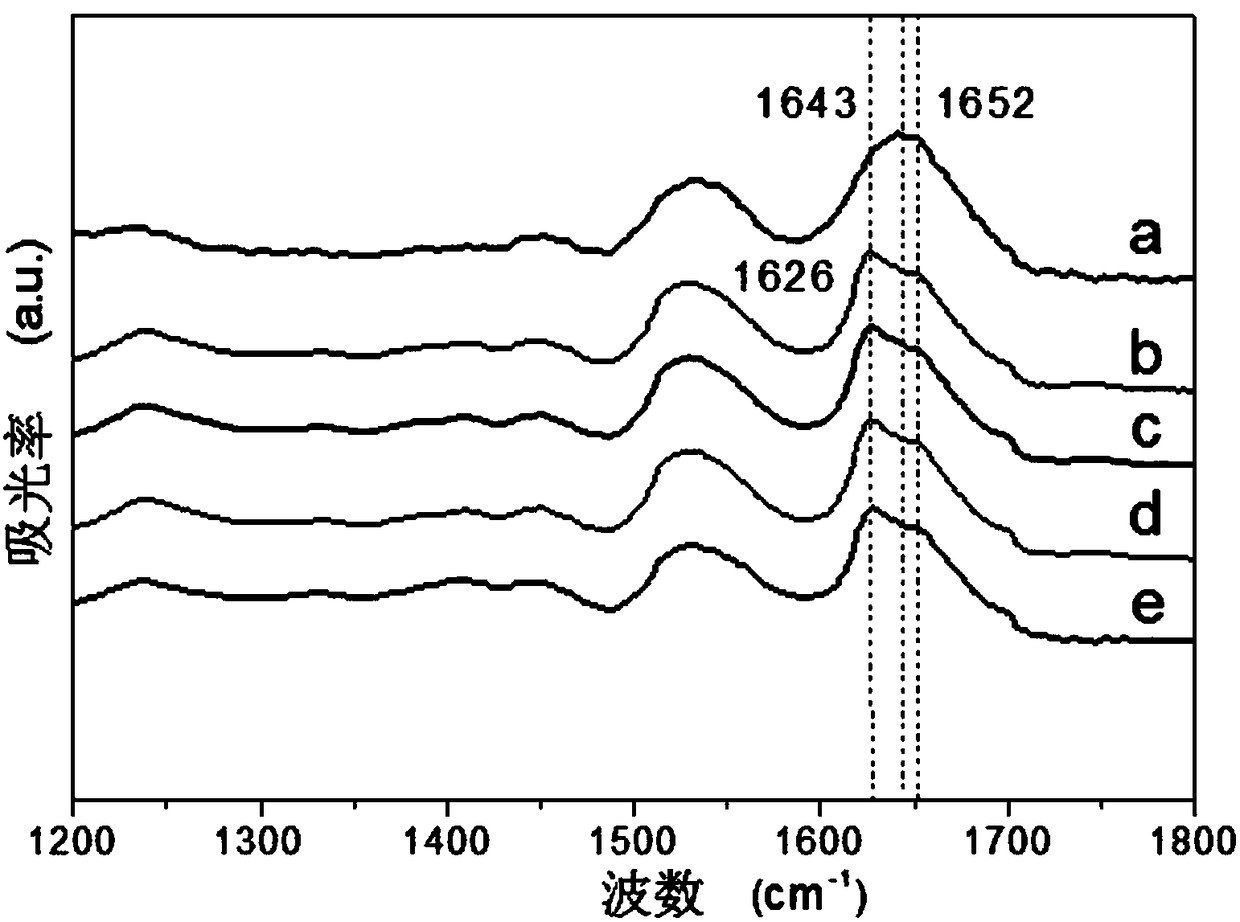

Ultrasonic-assisted supercritical CO2 (carbon dioxide) wool fiber dyeing process

InactiveCN102817252AAvoid damageThe process steps are simpleBiochemical fibre treatmentUltrasonic/sonic fibre treatmentUltrasonic assistedTreated animal

The invention discloses an ultrasonic-assisted supercritical CO2 (carbon dioxide) wool fiber dyeing process. The ultrasonic-assisted supercritical CO2 wool fiber dyeing process includes the steps of firstly, pretreating, namely performing sorting, scouring and grading of animal wool; secondly, performing ultrasonic treatment of the pretreated animal wool in an ultrasonic cell disruptor; and thirdly, performing supercritical CO2 dyeing to the treated animal wool. The ultrasonic-assisted supercritical CO2 wool fiber dyeing process abandoning the traditional dyeing process has simple steps, short dyeing time and low damage of wool fiber.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

Collar fabric

The invention discloses a collar fabric comprising a fabric body. The collar fabric innovates in a way that a plurality of concave-convex structures are arranged on the fabric body; the concave-convex structures are embedded in a plane where the fabric main body lies, and are integrated; the concave-convex structures are covered with animal wool fibers; the animal wool fibers are evenly distributed on the concave-convex structures; preferably, the number of the concave-convex structures is seven; and the animal wool fibers are sheep wool or rabbit hair. The collar fabric is laminated and possesses warming and wind resisting performance; collar fabric stereoscopic impression can be enhanced via the concave-convex structures; and warming property of the collar fabric can be strengthened via the animal wool fibers on the fabric body and the back surfaces of the concave-convex structures.

Owner:JIANGSU JUWEI NEW MATERIALS

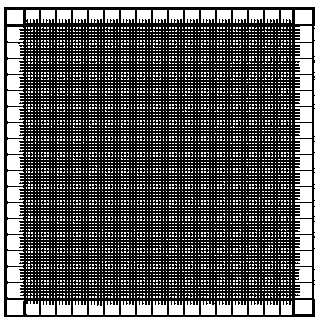

Wool and cashmere array diagram length test board

ActiveCN103837060APortable test sampleThe test sample is durableMechanical measuring arrangementsRough surfaceFiber

The invention discloses a test board used for determining or measuring the length of fibers, in particular the length of animal wool fibers in the textile industry or the animal husbandry industry. The test board is made of black or white transparent high polymer materials. The surface of the test board is polished to be a rough surface, the edges of the test board are provided with scale marks with a millimeter as a unit, and coordinate grids are formed at the part, located in the scale marks, of the test board. The test board is light, durable, free of deformation, easy to clean and capable of testing the animal wool fibers in different colors conveniently.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Method for preparing nano-fibers from animal wool

ActiveCN107287666AEasy to oxidizeReduce oxidationMonocomponent protein artificial filamentElectro-spinningFiberReduction treatment

The invention provides a method for preparing nano-fibers from animal wool. The method comprises the following steps: washing raw material wool for several times by virtue of water so as to remove impurities, spin-drying the raw material wool by virtue of a centrifugal machine, and drying for later use; crushing the dried raw material wool by virtue of a hair crusher; putting the crushed raw material wool into pretreatment liquid for treatment; putting the raw material wool into reduction treatment liquid for treatment, so as to obtain keratin powder; dissolving the keratin powder into hexafluoroisopropanol, adding a certain amount of polyurethane, stirring at 20-25 DEG C for 10-15 minutes, adding a certain amount of epoxy acrylate, uniformly mixing, heating to 60-80 DEG C, and continuing to stir for 1 hour, so as to obtain a spinning solution; and carrying out electrostatic spinning by virtue of the obtain spinning solution. According to the method, the problems that a spinning raw solution of existing animal wool nano-fibers is poor in stability, the extraction rate of keratin is low, and the fiber forming quality is relatively poor are effectively solved.

Owner:TIANJIN ZHONGZHI TECH DEV CO LTD

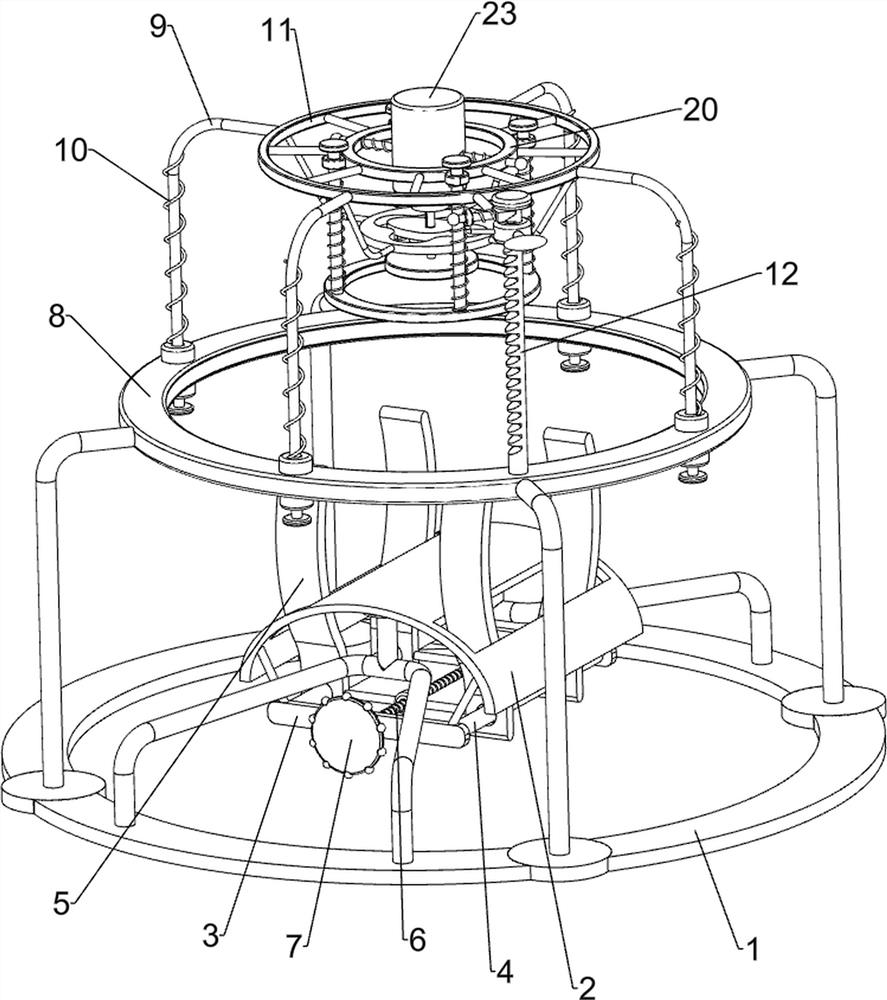

Animal hair trimming device for animal husbandry

ActiveCN111903553AAvoid the tedious process of manual hair trimmingAvoid situations where pruning is difficultOther apparatusTaming and training devicesAnimal scienceEngineering

The invention relates to an animal hair trimming device for animal husbandry. The device comprises a workbench, a tightening device and a trimming device, the tightening device is installed in the middle of the upper end of the workbench, the trimming device is arranged above the tightening device, and the trimming device is installed at the upper end of the workbench. According to the animal hairtrimming device for animal husbandry, the problems that when animal hair is trimmed manually, hair on an animal body is generally trimmed manually directly, and in the manual trimming process, due tothe fact that an animal is prone to walking during hair trimming, the manual hair trimming process is tedious, the animal hair trimming efficiency is lowed, when existing animal hair trimming equipment carries out trimming on the animal hair, the animal hair is directly subjected to trimming through the existing animal hair trimming equipment, the trimming equipment easily scratches the animal, before trimming, the animal hair is not carded, hair bonding is caused, the trimming process is difficultly carried out, and the animal hair trimming efficiency is further reduced are solved.

Owner:HUANGHUAI UNIV

Manufacturing method of Modundai mink knitted velour

The invention relates to a manufacturing method of Modundai mink knitted velour, which belongs to the technical field of textile industry. Dyeing washable velour, spinning and mellowing to obtain the mink fur single yarn, and dampening the mink velour single yarn at constant temperature; and washing, mercerizing, dyeing, dampening the lamb wool strand yarn at constant temperature, twisting the mink velour single yarn and the lamb wool strand yarn, redrawing the bobbin winder to obtain a cheese, dampening the cheese, and balling on a ball forming machine, wherein the mink velour single yarn has two strands, the lamb wool strand yarn has 1 strand, the twist of yarn is 80-200 t / m, and the twisting is in an S twist way. The knitted velour, which is blended by pashm animal wool, high-count Australasian wool and natural fibers, is smooth, soft, comfortable, ventilated, bright and warm-keeping, has the advantage of favorable fabric resilience and overcomes the fundamental defect that fabrics can easily shed hair and pill on the premise that the serviceability is ensured. The Modundai mink knitted velour is made from the materials from animal velour and wool in nature, thereby being an environment-friendly product and worthy of popularization.

Owner:WUXI BAIFANG WOOL

Composite dressing applied to wound and preparation method thereof

InactiveCN106474533AGood hemostatic effectPromote wound healingSurgical adhesivesPharmaceutical delivery mechanismBorneolBiomaterial

The invention relates to a composite dressing applied to a wound and a preparation method thereof. The dressing comprises hair keratin and a traditional Chinese medicine component, wherein hair comprises any one selected from a group consisting of human hair and animal wool, and the traditional Chinese medicine component comprises pseudo-ginseng, Rhizoma Paridis, Psammosilene tunicoides, borneol and musk. The preparation method comprises the following steps: preparation of the hair keratin; preparation of the traditional Chinese medicine component; and preparation of the dressing. According to the invention, traditional Chinese medicine is combined with a biomaterial, and hair keratin gel and the like are used as a carrier for wound healing via the traditional Chinese medicine component, so a wound covering material with the properties of a biological dressing can be formed; the prepared composite dressing is a wound covering material with excellent effect; and along with slow healing of a wound and skin growth, the composite dressing provides a wound healing environment for promotion of skin regeneration.

Owner:北京东方艾美生物技术股份有限公司

Artificial mink hair material, preparation method thereof and false eyelashes

InactiveCN112080810AReduce usageEffective protectionHair accessoriesToupeesPolytetramethylene terephthalatePolymer science

The invention is applicable to the technical field of cosmetics, and provides an artificial mink wool material, a preparation method thereof and false eyelashes. The preparation method of the false eyelashes comprises the following steps of taking polybutylene terephthalate resin, drying, and mixing with titanium dioxide and a transparent agent to obtain a mixture; carrying out melting treatment on the mixture, and then carrying out spinning treatment to obtain a silk material; cooling the silk material, carrying out drawing treatment, and then carrying out bending treatment to obtain an artificial mink hair material; making artificial mink hair material into a false eyelashes semi-finished product through a mold or an artificial arranging method; and after carrying out thread combining treatment on the false eyelashes semi-finished product, carrying out hair cutting, pipe rolling, steaming and shaping treatment to obtain the false eyelashes. According to the preparation method of thefalse eyelashes, the softness, the brightness and the planar three-dimensional effect of the false eyelashes made of the artificial mink hairs are very similar to those of the false eyelashes made ofpure animal hairs, so that the false eyelashes made of the pure animal hairs can be completely replaced, and the use of the pure animal hairs is greatly reduced.

Owner:王海波

Biological medical fertilizer special for corn and preparation method

InactiveCN108046916ALow costPromote absorptionSuperphosphatesCalcareous fertilisersBiotechnologyEggshell

The invention discloses a biological medical fertilizer special for corn. The fertilizer comprises, according to a weight ratio, 15-25 parts of chicken manure, 8-14 parts of pig manure, 8-14 parts ofsheep manure, 10-15 parts of rice chaff, 8-14 parts of straw, 6-12 parts of peat soil, 5-10 parts of animal bone meal, 3-5 parts of animal wool powder, 5-7 parts of leaves, 4-6 parts of mushroom residue, 13-16 parts of urea, 10-12 parts of calcium superphosphate, 12-14 parts of calcium nitrate, 8-10 parts of potassium sulfate, 0.08-0.12 part of ammonium molybdate, 1.9-2.4 parts of copper sulphate,0.8-1.2 parts of manganese sulfate, 3-5 parts of ferrous sulphate, 10-13 parts of potassium humate, 3-5 parts of eggshell powder, 0.4-0.6 part of glucose, 0.03-0.06 part of borax, 10-12 parts of fur,and 3-4 parts of a microorganism ferment. The fertilizer integrates fertilization and sterilization into one body, is low in cost, and is eco-friendly and pollution-free.

Owner:袁梅芳

Chinese medicine flax-wool multifunctional felt material and application thereof

The invention relates to a Chinese medicine flax-wool multifunctional felt material and application thereof. The material is prepared from the following steps that 1, by weight, 20-30 parts of radix sophorae flavescentis, 5-10 parts of cloves, 10-15 parts of cotex dictamni, 5-10 parts of lemongrass, 5-10 parts of jasmine flowers and 10-15 parts of lavenders are weighed, decocted and extracted to have effective components, and then a liquefied stock solution is prepared; 2, the liquefied stock solution is diluted by 30 times and then heated to 40 DEG C-50 DEG C for preparation; 3, animal wool and flax are sterilized with steam, the heated herbal stock solution is added to make dipping for 10-72 hours for medicine usage, and finally drying is made for preparation; 4, wrinkled gianthyssop herbs, folium artemisiae argyi and the lemongrass are subjected to fibrillation treatment to obtain a plant fiber; 5, with the treated plant fiber, animal wool and flax being raw materials, felt is prepared, and namely the Chinese medicine flax-wool multifunctional felt material is obtained. The material as a finished product has good effects on resistance to bacteria and odor, and is novel based ontraditional flax-wool felt.

Owner:河南纳美纺织科技有限公司

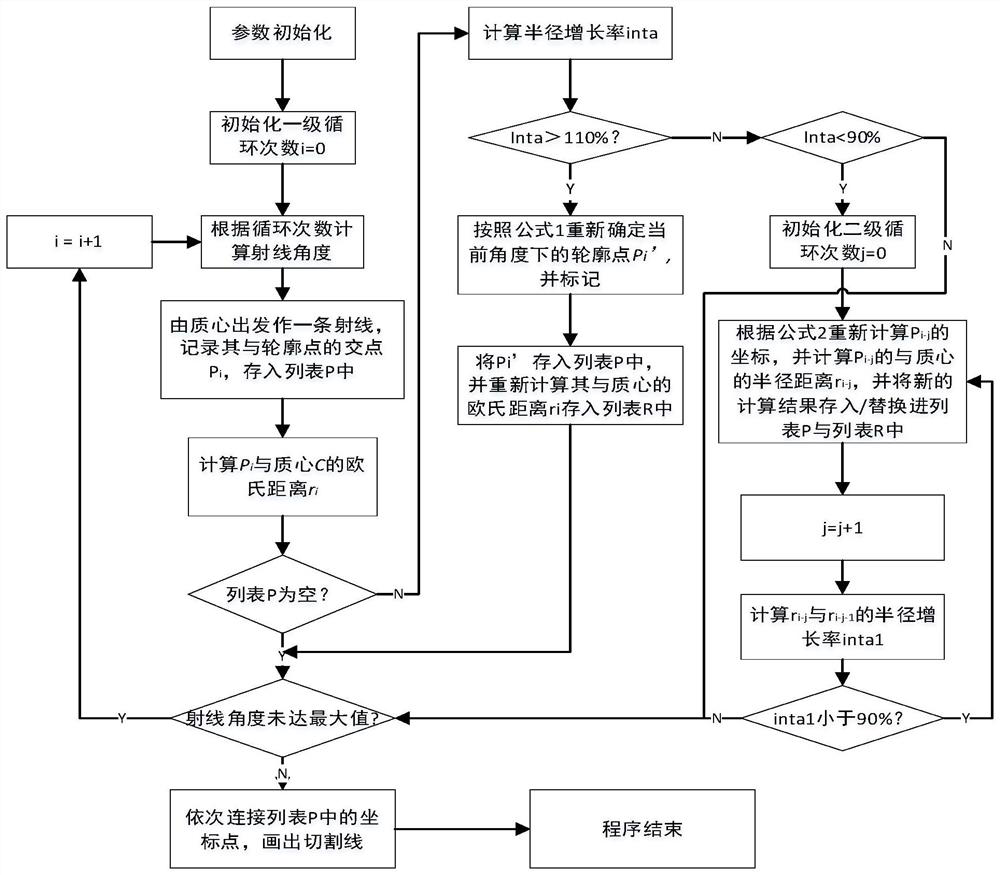

Large-area animal fur contour image cutting method based on radius increment constraint

InactiveCN114418975AImprove discriminationPrecise positioningImage enhancementImage analysisComputer graphics (images)Algorithm

The invention discloses a large-area animal fur contour image cutting method based on radius increment constraint, and the method comprises the steps: horizontally placing animal fur on a rubber plate for preprocessing, and obtaining a contour image of the image; establishing a corresponding coordinate system to obtain a centroid coordinate, setting the centroid coordinate as a new coordinate system origin, and establishing a new coordinate system; taking the origin of coordinates as the center, drawing a ray clockwise along the positive direction of the X axis, dividing the contour into n equal parts with the same angle, marking the intersection point of the ray and the edge contour point as an initial point, and defining the Euclidean distance between the initial point and the center of mass as the radius length of the contour; defining the ratio of the contour radius length of the current initial point to the contour radius length of the previous initial point as the contour radius growth rate of the current initial point, detecting the contour initial points in sequence, and removing non-conforming points; and the satisfied points are reserved, and the points are connected to form a final cutting route. According to the invention, animal fur images with different shapes and sizes can be cut, and corresponding cutting lines are provided.

Owner:SHAANXI UNIV OF SCI & TECH

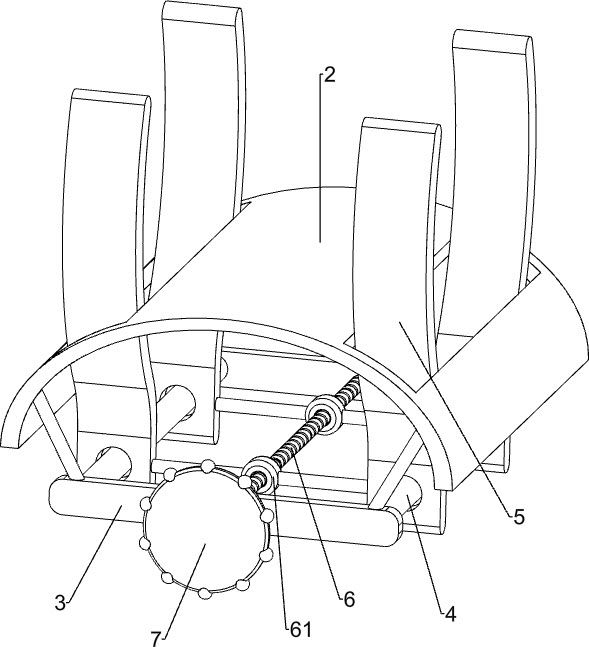

Animal hair scraping device for livestock breeding veterinarians

InactiveCN111869591AEasy to fixEasy to shaveAnimal fetteringOther apparatusAnimal scienceCrop livestock

The invention relates to an animal hair scraping device, in particular to an animal hair scraping device for livestock breeding veterinarians. The technical problem to be solved by the invention is toprovide the animal hair scraping device for livestock breeding veterinarians, wherein the device can better fix animals and is high in working efficiency. The animal hair scraping device for the livestock breeding veterinarians comprises a mounting frame, a fixing assembly mounted on the mounting frame and fixed in a rotating mode, a height adjusting assembly mounted on the mounting frame and used for adjusting the height in a sliding manner, and a hair scraping assembly mounted on the height adjusting assembly and conducting hair scraping in a rotating mode. Animals of different sizes needing hair scraping can be fixed through the fixing assembly, the height of the device can be adjusted through the height adjusting assembly, people can fix the animals or take down the animals more conveniently, and meanwhile the device can be used for scraping hair of the animals of different sizes more conveniently.

Owner:王剑

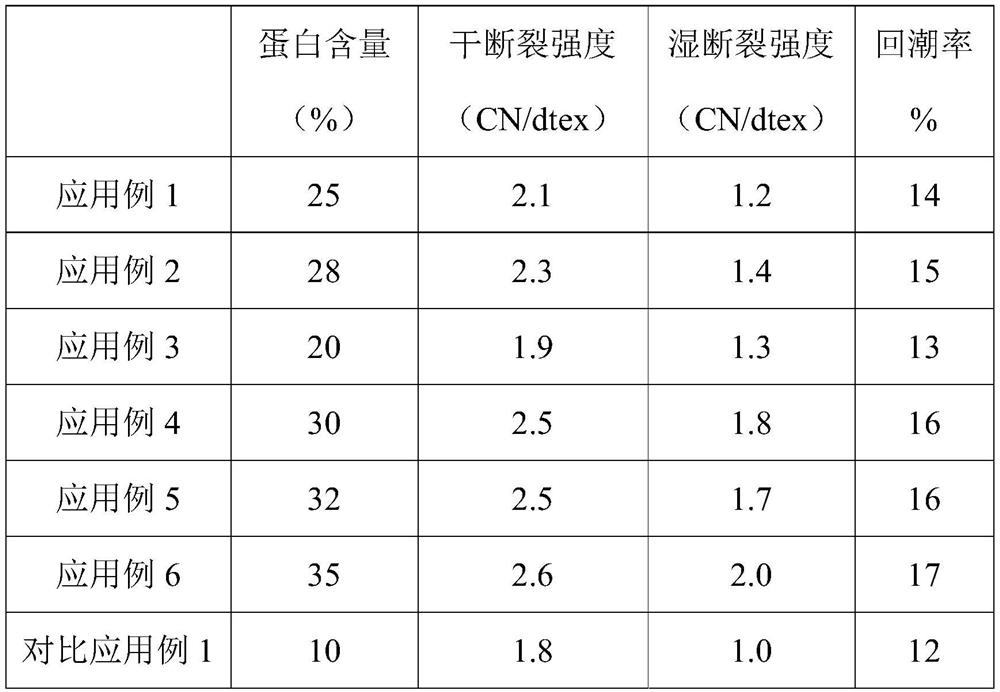

Compound protein and preparation method and application thereof

InactiveCN112322051AHigh molecular weightNot easy to loseMonocomponent protein artificial filamentArtificial filaments from viscoseFiberPolymer science

The invention provides a compound protein and a preparation method and application thereof. The compound protein is obtained by reaction of corn protein, animal hair keratin and a chain extender, andthe compound protein with higher molecular weight is obtained by grafting reaction of the corn protein, the animal hair keratin and the chain extender; when the composite protein is spun into fibers,the protein is not easy to lose, so that the prepared fiber product is high in protein content, and has excellent drapability, antistatic property, moisture absorption property, moisture conductivity,air permeability and the like; the preparation method of the compound protein is simple, convenient to operate and suitable for mass production and extraction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com