Bionic high-density-fluff warp-knitted fabric and preparation method thereof

A high-density velvet and fabric technology, applied in warp knitting, dyeing, fabric surface trimming, etc., can solve the problems of non-hygroscopic and breathable, unsuitable seat fabrics, low fastness, etc., and achieve dense, soft and wear-resistant velvet Sexy, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] A bionic high-density velvet warp knitted fabric, which is composed of 40%-20% polyester sea-island yarn, 33%-43% ultra-fine denier polyester low-elasticity yarn and 27%-37% polyester filament. In the base fabric layer, the ultra-fine denier polyester low-elasticity yarn is exposed on the surface of the base fabric layer to form fluff, and the polyester sea-island yarn forms fluff in the inner layer, and the density of the fluff is 700,000 to 1,000,000 per square centimeter. In this embodiment, the bionic high-density velvet warp-knitted fabric includes 30% polyester sea-island yarn, 38% ultra-fine denier polyester low-elasticity yarn and 32% polyester filament by weight. The imaging image under the microscope is as figure 1 shown.

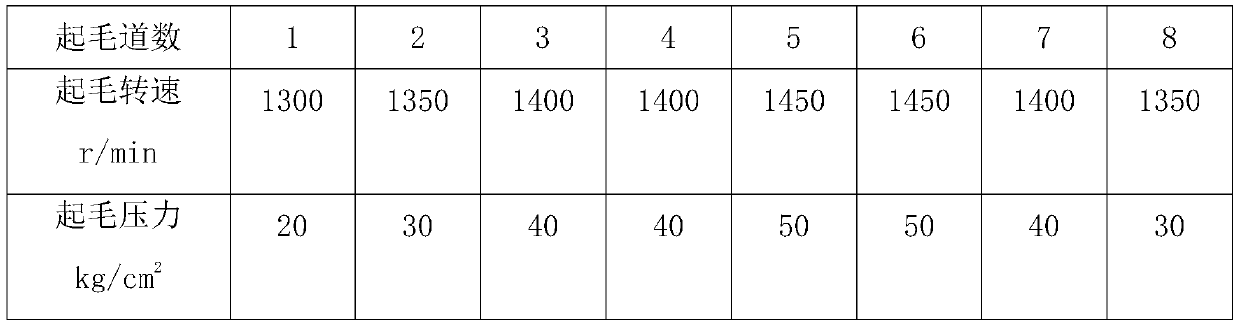

[0037] A preparation method of bionic high-density velvet warp knitted fabric, comprising the following process steps:

[0038] (1) Raw material preparation: prepare polyester sea-island yarn, superfine denier polyester low elastic yarn a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com