Long-acting anti-microbial leather and preparing method thereof

A leather and long-acting technology, applied in the field of long-acting antibacterial leather and its preparation, can solve the problems of lack of long-acting antibacterial stability and the like, and achieve the effects of easy implementation, simple preparation method and less demanding process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

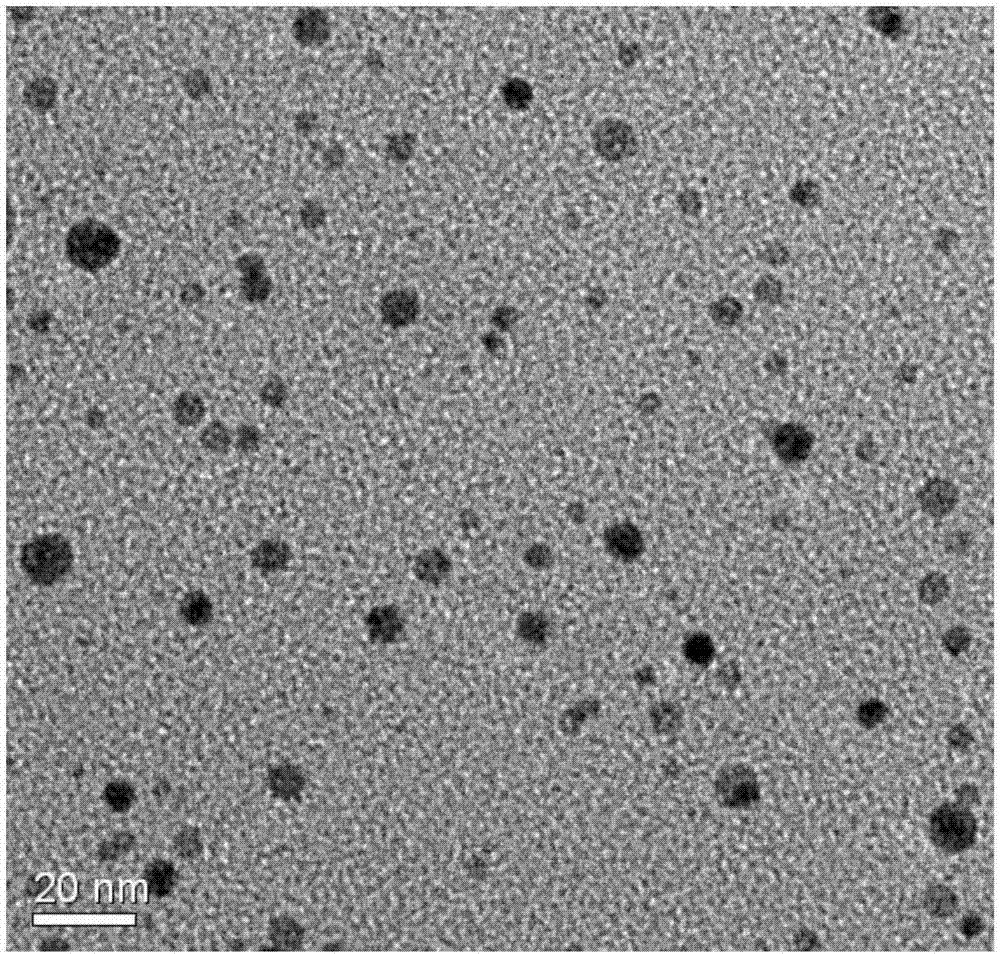

[0034] Mix 1 mole part of gallic acid and 1 mole part of silver nitrate to make an aqueous solution, slowly drop into water with a pH value of 11 at 25 ° C, and react in the dark for 30 minutes, and adjust the pH value of the solution system to neutral , adding heptanediamine to make the final concentration 10-14mM, and then adding butylamine to make the final concentration 8-15mM, finally preparing the nano-silver solution modified by gallic acid. Wherein, the silver-containing solid content is 1000ppm. Such as figure 1 As shown, the transmission electron microscope (TEM) scanning results show that the average particle size of the nano-silver is 6nm, and it can be stored stably at room temperature for more than 180 days without precipitation.

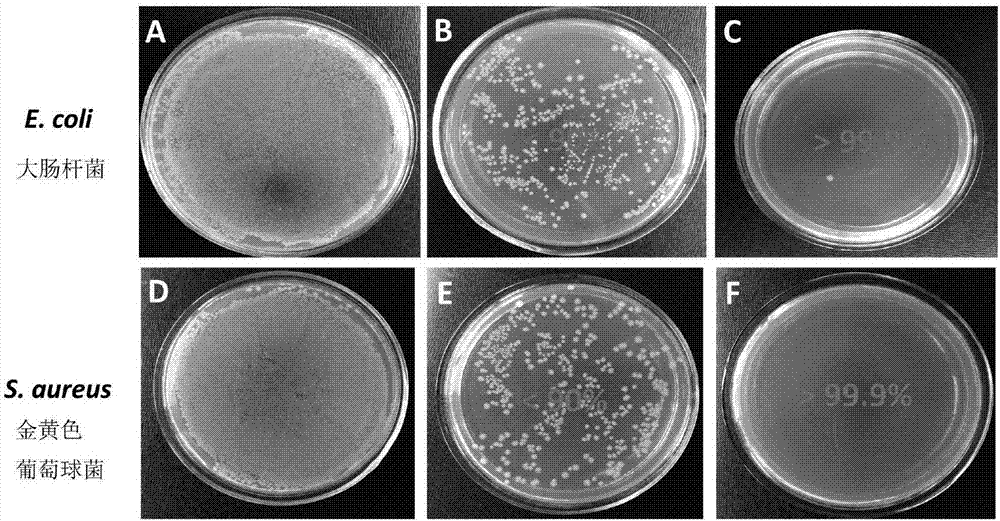

[0035] Escherichia coli (ATCC25922) and Staphylococcus aureus (ATCC6538) were used as bacterial models. First, prepare nano-silver solutions with concentrations of 50ppm, 30ppm, 20ppm, 10ppm, and 5ppm, and sterile water as a blank re...

Embodiment 2

[0037] Utilize the nano-silver modified by the gallic acid obtained in Example 1 to prepare long-acting antibacterial leather:

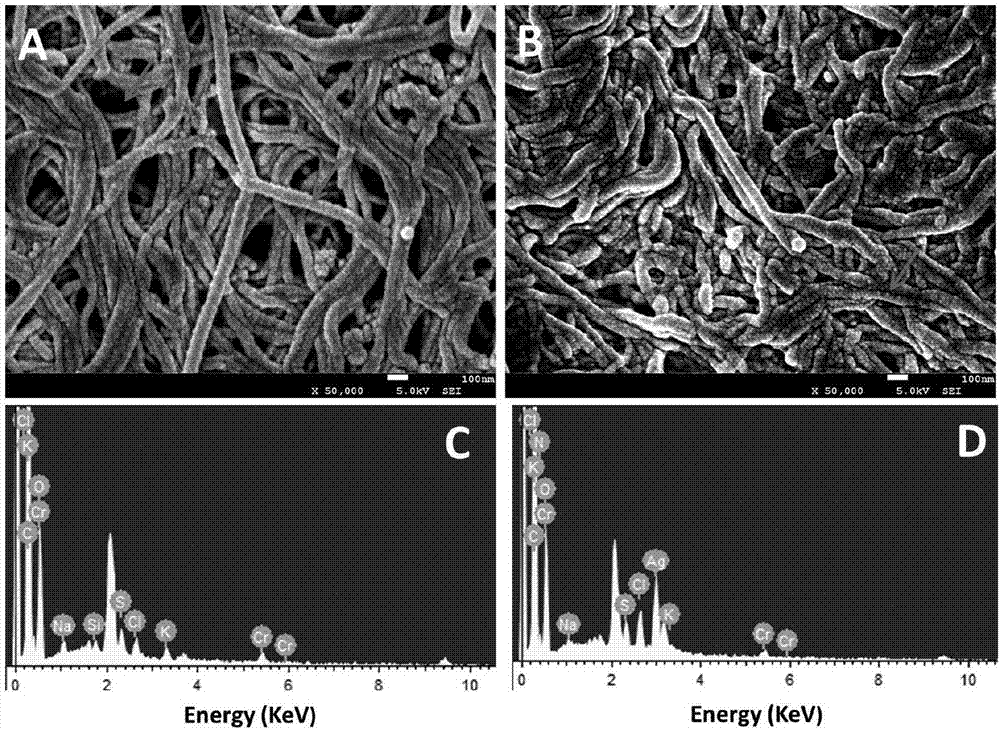

[0038]After weighing the raw sheep skin, tanning is carried out according to the tanning process shown in Table 1 to obtain sheep wet blue leather filled with and fixed nano-silver; The weight of the skin is the same, and the content of nano-silver modified by gallic acid (hereinafter referred to as nano-silver) is 200ppm; when the nano-silver is filled between the leather collagen fibers, the chrome tanning agent in the leather chemically fixes the nano-silver on the leather through covalent complexation. Collagen fibers; Finally, wet blue leather containing nano-silver is made, which has the characteristics of "nano-silver sponge" and has long-term antibacterial effect (such as Figure 6 schematic diagram shown).

[0039]

[0040]

[0041] The prepared sheepskin wet blue leather containing nano-silver was sectioned, and its section layer was...

Embodiment 3

[0048] The prickly-acid hides are weighed after being squeezed with water, and then the weight is increased by 50% as the raw material benchmark. Carry out tanning with reference to the technology shown in table 3, make the cowhide vegetable tanned leather of filling and fixing nano silver; The nano-silver content is 150ppm; when the nano-silver modified by gallic acid is filled between the leather collagen fibers, the vegetable tannin contained in the vegetable tanning agent in the leather can form a hydrogen bond with the gallic acid on the surface of the nano-silver, and then Nano-silver is chemically fixed on the skin collagen fibers; finally, vegetable-tanned leather containing nano-silver is obtained, which has the characteristics of "nano-silver sponge" and has long-term antibacterial effect.

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com