Antibacterial lyocell fabric and preparation method thereof

A fabric and antibacterial finishing technology, which is applied to plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of single antibacterial agent components and inability to achieve long-term high-activity antibacterial, achieve strong antibacterial performance, wide source of raw materials, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a preparation method of antibacterial lyocell fabric, the preparation method comprises the following steps:

[0030] (1) Preparation of antibacterial finishing solution: Dissolve 1 g of polyhexamethylene biguanide hydrochloride and 8 mL of 7% formaldehyde aqueous solution in 150 mL of tap water, and stir evenly to prepare an antibacterial finishing solution.

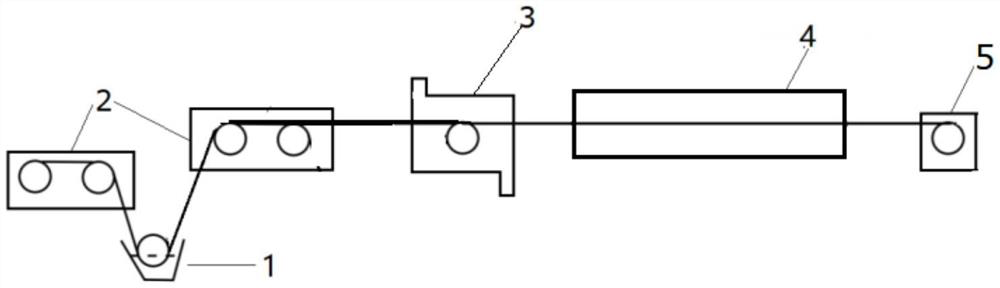

[0031] (2) Antibacterial finishing: Pour the finishing liquid into the dipping tank (1) in the antibacterial finishing device. The schematic diagram of the antibacterial finishing device is as follows figure 1 As shown in the figure, the temperature of the regulating and finishing solution is 45°C; the lyocell fabric is passed through the guide wheel (2) into the dipping tank (1), the dosage ratio of the lyocell fabric and the finishing solution is: 1g: 15mL, and the reaction time is 1.5 minutes ; After the reaction is finished, then washed with water by the washing tank (3), and finally, dried...

Embodiment 2

[0033] In this embodiment, a preparation method of antibacterial lyocell fabric, the preparation method comprises the following steps:

[0034] (1) Preparation of antibacterial finishing liquid: Dissolve 1 g of polyhexamethylene biguanide hydrochloride and 6 mL of a 5% formaldehyde aqueous solution in 100 mL of tap water, and stir evenly to prepare an antibacterial finishing liquid.

[0035] (2) Antibacterial finishing: Pour the finishing liquid into the dipping tank (1) in the antibacterial finishing device. The schematic diagram of the antibacterial finishing device is as follows figure 1 As shown in the figure, the temperature of the adjusting and finishing solution is 40°C; the lyocell fabric is passed through the guide wheel (2) into the dipping tank (1), the dosage ratio of the lyocell fabric and the finishing solution is: 1g:10mL, and the reaction time is 1 minute ; After the reaction is finished, then washed with water by the washing tank (3), and finally, dried by the...

Embodiment 3

[0037] In this embodiment, a preparation method of antibacterial lyocell fabric, the preparation method comprises the following steps:

[0038] (1) Preparation of antibacterial finishing solution: Dissolve 1 g of polyhexamethylene biguanide hydrochloride and 10 mL of 9% formaldehyde aqueous solution in 200 mL of tap water, and stir evenly to prepare an antibacterial finishing solution.

[0039] (2) Antibacterial finishing: Pour the finishing liquid into the dipping tank (1) in the antibacterial finishing device. The schematic diagram of the antibacterial finishing device is as follows figure 1 As shown in the figure, the temperature of the adjusting and finishing solution is 50°C; the lyocell fabric is passed through the guide wheel (2) into the dipping tank (1), and the ratio of the amount of the lyocell fabric to the finishing solution is: 1g: 20mL The reaction time is 2 minutes; After the reaction is completed, the water is then washed in a water washing tank (3), and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com