Silk fibroin/keratin composite porous material and preparation method thereof

A technology of silk fibroin and porous materials, which can be used in medical science, tissue regeneration, prosthesis, etc. It can solve the problems of unfavorable biocompatibility of silk fibroin porous materials, complicated experimental procedures, allergic reactions, etc., and achieve great development potential. , the process is simple, the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

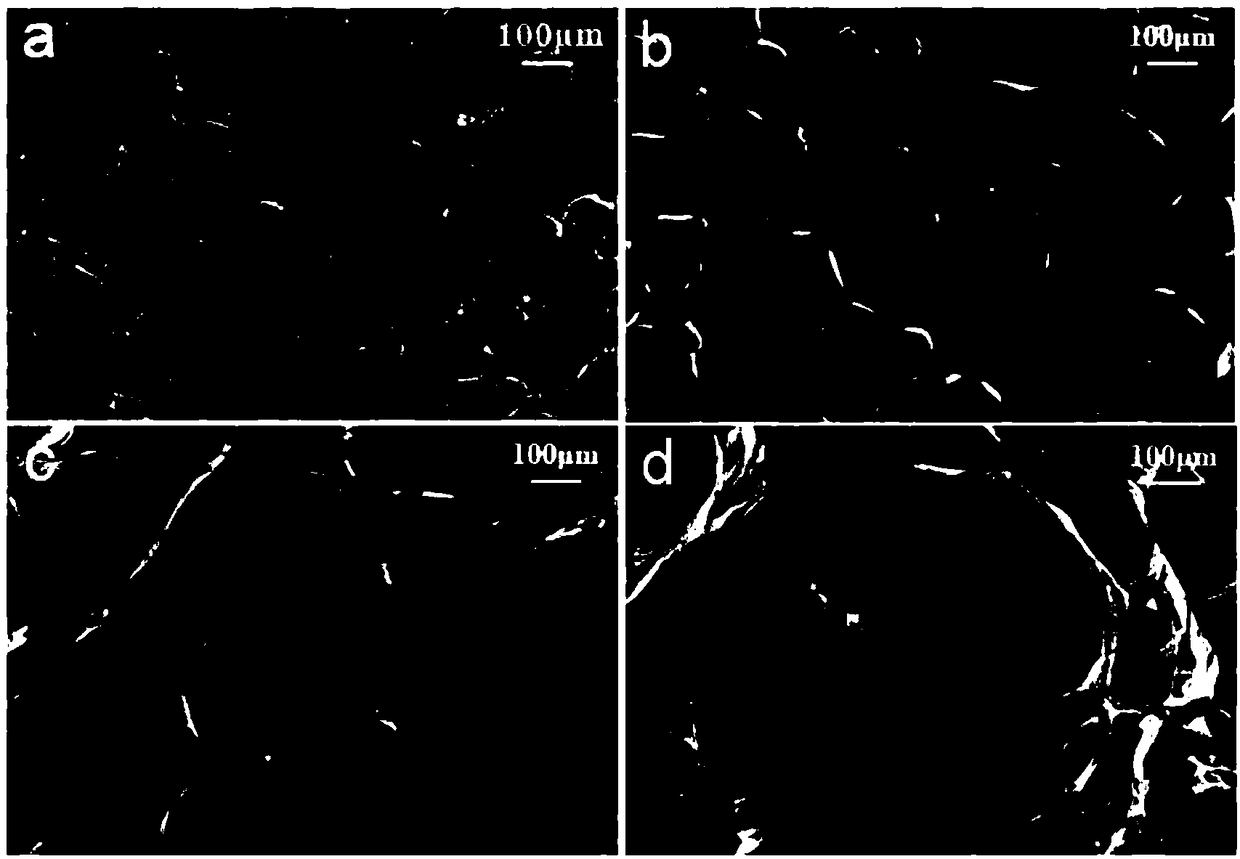

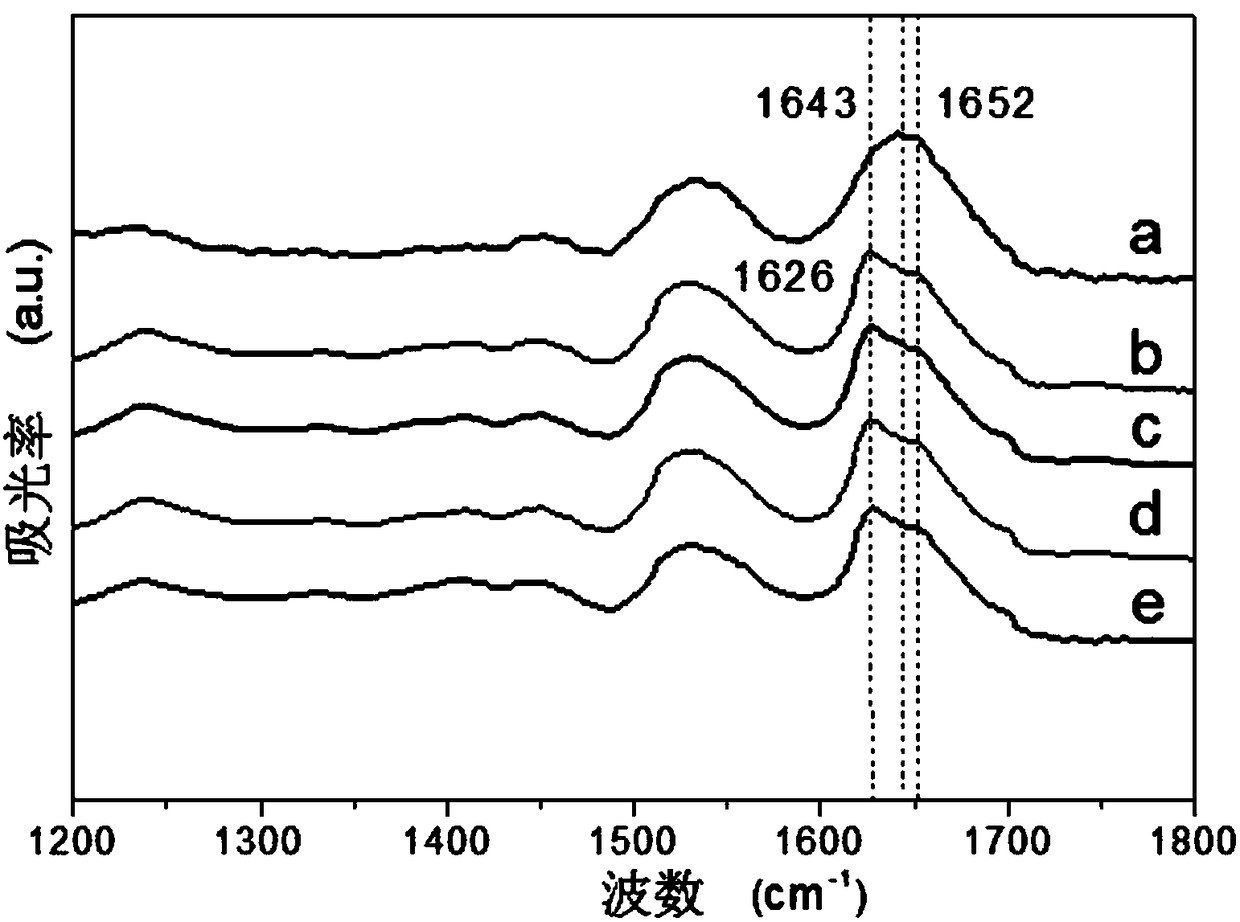

[0032] The invention provides a silk fibroin / keratin composite porous material, which takes silk fibroin and keratin as main raw materials, mixes a certain concentration of silk fibroin and keratin solutions in a certain proportion, then adds an appropriate amount of glycerin, and then The silk fibroin / keratin composite porous material is obtained by freezing and vacuum drying. The prepared composite porous material has a porous structure with uniform pore size, the pore size is between 100µm and 500µm, the porosity is between 80% and 95%, the compressive strength is between 1.5MPa and 3.5MPa, and it is water insoluble. The preparation method of the above-mentioned composite porous material, the steps are as follows:

[0033] (1) Use a specific method (reduction method or alkaline method, etc.) to dissolve a certain amount of wool fiber and then filter it, and then use a dialysis bag with a molecular weight cut-off of 2000Da~20000Da for dialysis for 1~5 days. 6000-20000 polye...

Embodiment 1

[0048] This implementation case shows a preparation method of silk fibroin / keratin composite porous material, including:

[0049] (1) Use 1%~5% NaOH solution to dissolve a certain amount of wool fiber and then filter it, then use a dialysis bag with a molecular weight cut-off of 2000Da~20000Da for dialysis for 1~5 days. The diol solution was concentrated to obtain a wool keratin solution with a mass fraction of 6%.

[0050] (2) Degumming and dissolving the natural silk, dialysis and centrifugation according to the method in step (1), and concentration with a PEG solution with a molecular weight of 20,000 to obtain a silk fibroin solution with a mass fraction of 6%.

[0051] (3) Take a certain amount of silk fibroin solution and wool keratin solution, prepare a mixed solution in a 24-well plate according to the ratio of silk fibroin protein: wool keratin quality = 6:4, and add glycerin The quality of the double protein is 30% of the total mass.

[0052] (4) The mixed solution...

Embodiment 2

[0054] This implementation case shows a preparation method of silk fibroin / keratin composite porous material, including:

[0055] (1) Prepare 100ml of solution with 7M urea, 0.08M Na2S and 0.8g sodium dodecyl sulfate (SDS), then add 5g of wool fiber, and conduct water bath treatment at a water bath temperature of 50°C for 8 hours, then filter, and then use molecular weight cut-off Dialyze a 2000Da-20000Da dialysis bag for 1-5 days, then concentrate with a polyethylene glycol (PEG) solution with a molecular weight of 20000 to obtain a wool keratin solution with a mass fraction of 8%.

[0056] (2) Degumming and dissolving the natural silk, dialysis and centrifugation according to the method in step (1), and concentration with a PEG solution with a molecular weight of 20,000 to obtain a silk fibroin solution with a mass fraction of 8%.

[0057] (3) Take a certain amount of silk fibroin solution and wool keratin solution, prepare a mixed solution in a 24-well plate according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com