Polypropylene resin composition, molded article produced from the resin composition, and method for production of the molded article

A technology of polypropylene resin and composition, which is applied in the direction of flat products, applications, household appliances, etc., and can solve problems such as poor compatibility, film-forming properties of blends, poor stretching processability, poor forming processability, and difficulty in molding. Increased degree of freedom and excellent moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0132] Hereinafter, the present invention will be described more specifically with reference to Examples and Comparative Examples. The measurement method or evaluation method of physical properties and characteristics is as follows.

[0133] (1) Melt viscosity:

[0134] Melt viscosity of polyglycolic acid was measured using Toyo Seiki Kapirograph 1-C equipped with a capillary (1 mmφ×10 mmL) as a melt viscosity measuring device. More specifically, about 20 g of the sample was placed in a measurement device heated to a temperature (Tm+20°C) higher than the melting point of the polyglycolic acid sample by 20°C, the sample was kept at this temperature for 5 minutes, and then Melt viscosity was measured at 122 / sec. The melt viscosity of polypropylene was measured at a temperature of 240°C and a shear rate of 122 / sec.

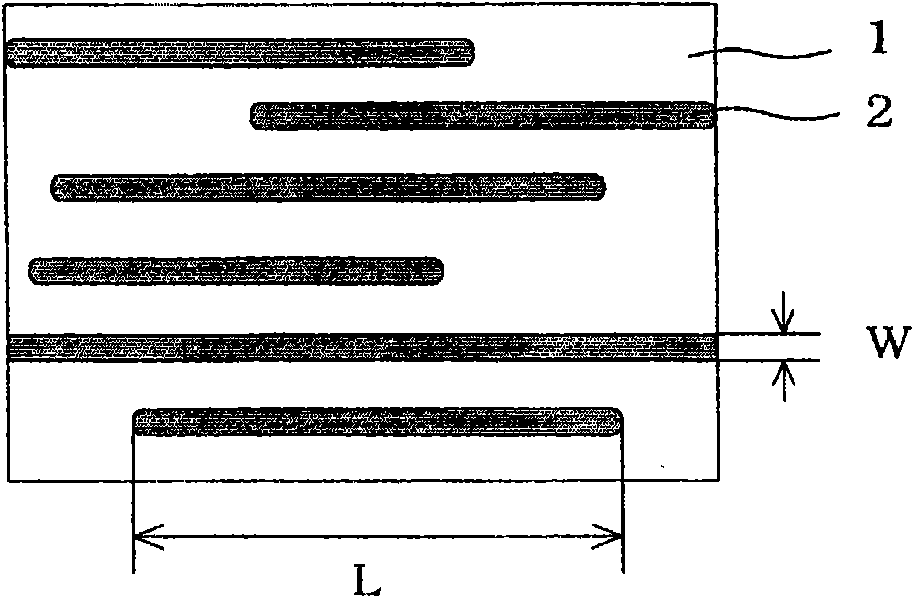

[0135] (2) L / W determination of polyglycolic acid dispersed phase:

[0136] From the stretched and heat-set treated film, a glass knife was used to cut perpendic...

Embodiment 1

[0148] In addition to blending 80 parts by mass of polypropylene particles and 20 parts by mass of polyglycolic acid particles, and 6.5 parts by mass of ethylene / glycidyl methacrylate / methyl acrylate copolymer (manufactured by Sumitomo Chemical Co., Ltd.) Bond Factory) was carried out in the same manner as in Comparative Example 2 to produce a biaxially stretched film with a thickness of 3 μm.

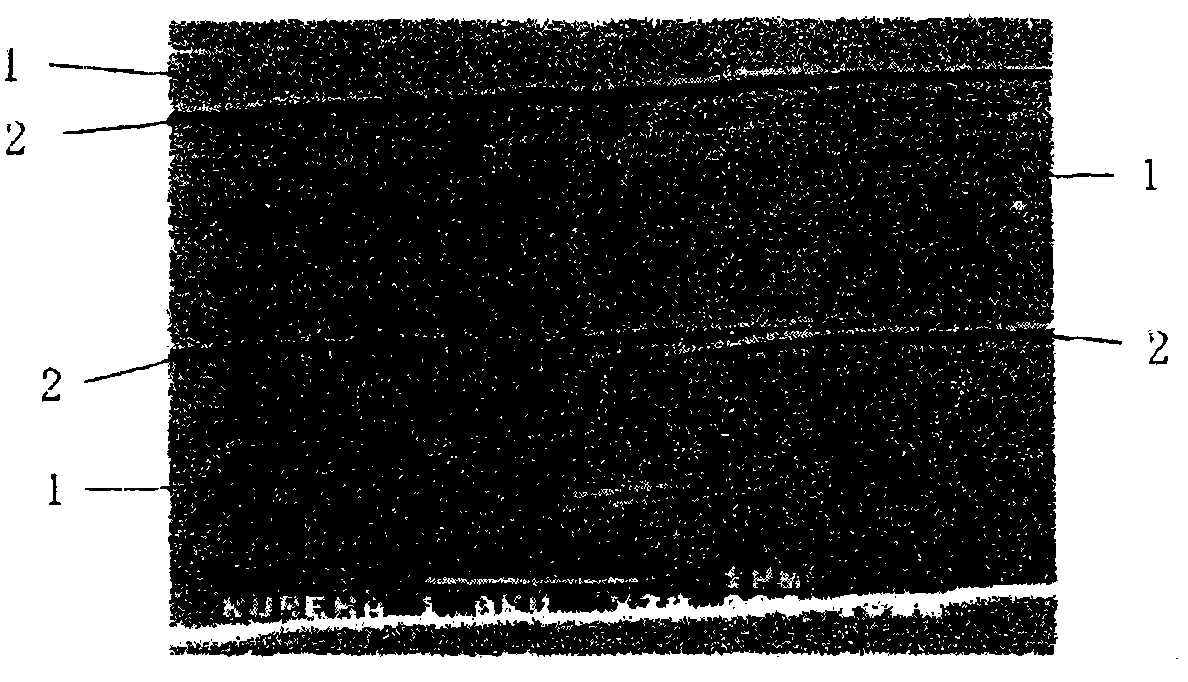

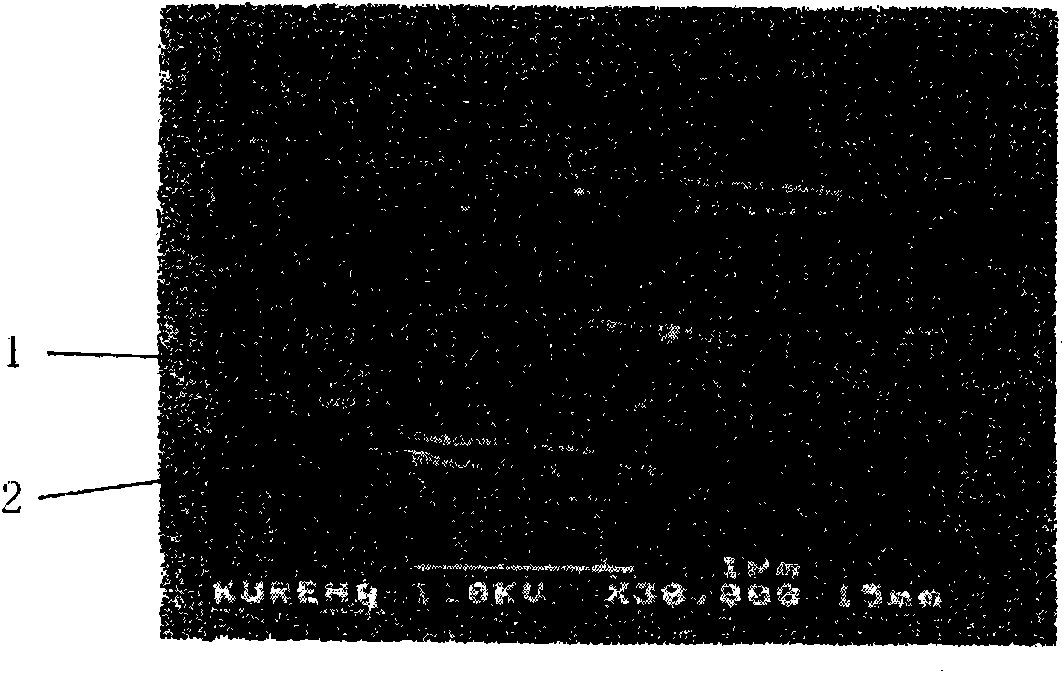

[0149] The SEM photograph (magnification = 30,000 times) of the cross-section in the thickness direction of the obtained biaxially stretched film is shown in figure 1 and 2 . Depend on figure 1 and 2 It is clear that in the cross section of the biaxially stretched film in the thickness direction of MD and the cross section of the thickness direction of TD, the form of polyglycolic acid is such that mutually independent multilayer films are dispersed in a state of being laminated with a polypropylene layer interposed therebetween. . SEM photographs (magnification = 30,000 times) of...

Embodiment 2

[0151] Similar to Comparative Example 2 except that 80 parts by mass of polypropylene particles and 20 parts by mass of polyglycolic acid particles were mixed, and 10 parts by mass of maleic anhydride-grafted polypropylene (Modeik, manufactured by Mitsubishi Chemical Co., Ltd.) was used for 100 parts by mass of these resin components. A biaxially stretched film with a thickness of 3 μm was accurately produced.

[0152] Take the SEM photo (magnification=30,000 times) of the section in the thickness direction of the obtained biaxially stretched film, the result shows that, on the section along the thickness direction of MD and the section along the thickness direction of TD, the form of polyglycolic acid is: Independent multilayer films were dispersed in a state of being laminated with a polypropylene layer interposed therebetween.

[0153] SEM photographs (magnification = 30,000 times) of the cross-section in the thickness direction of the melt-extruded sheet before biaxial str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com