UV curing technology based solvent-free synthetic leather manufacturing method

A technology of curing technology and manufacturing method, which is applied in the field of synthetic leather manufacturing to achieve the effects of simple production process, unique structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

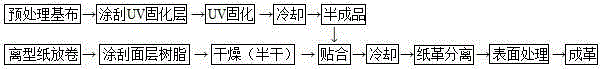

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 The manufacture of solvent-free synthetic leather for sofa

[0038] (1) Preparation of UV curable slurry and water-based surface layer slurry (parts by weight)

[0039] a) Preparation of UV curing slurry: 100 parts of IPDI type solvent-free UV curing polyurethane, 5 parts of photoinitiator 2-hydroxy-2-methyl-1-phenylacetone, 5 parts of color paste, 3 parts of light calcium carbonate 1 part, 1 part of montmorillonite, 5 parts of lignin powder, 3 parts of Span-80 surfactant and mix well;

[0040] b) Preparation of water-based surface layer slurry: 100 parts of polyurethane for aromatic water-based surface layer with a modulus of 60Mpa and a solid content of 40%, 0.2 parts of DC-57 water-based leveling agent, 20 parts of water-based color paste, Foamex840 water-based 0.1 part of defoamer, 0.5 part of water-based polyurethane thickener, and 5 parts of Bayhydur3100 crosslinking agent are mixed evenly to prepare a surface layer slurry with a viscosity of 3000mPa...

Embodiment 2

[0047] The manufacture of embodiment 2 clothing solvent-free synthetic leather

[0048] (1) Preparation of UV curable slurry and water-based surface layer slurry (parts by weight)

[0049] a) Preparation of UV curing slurry: 100 parts of HDI solvent-free UV curing polyurethane, 2 parts of photoinitiator 1-hydroxy-1-cyclohexyl benzophenone, 3 parts of color paste, 5 parts of montmorillonite, Tween-60 0.5 part of type surfactant is mixed evenly;

[0050] b) Preparation of water-based surface layer slurry: 100 parts of polyurethane for aliphatic water-based surface layer with 50Mpa and 30% solid content, 0.5 parts of TegoGlide410 water-based leveling agent, 20 parts of water-based color paste, 0.3 parts of BYK028 water-based defoamer 1 part, 0.15 parts each of water-based polyurethane and acrylic thickener, and 2 parts of XR-500 cross-linking agent, mixed evenly, and made into a surface layer slurry with a viscosity of 2500mPa.s (temperature 25°C);

[0051] (2) Base cloth pretr...

Embodiment 3

[0057] Embodiment 3 Manufacture of solvent-free synthetic leather for automotive interior

[0058] (1) Preparation of UV curable slurry and water-based surface layer slurry (parts by weight)

[0059] a) Preparation of UV curable slurry: H 12 100 parts of MDI type solvent-free UV curing polyurethane, 3 parts of photoinitiator isopropyl thioxanthone, 4 parts of water-based color paste, 2 parts of fumed silica, 2 parts of carbon black, 4 parts of lignin powder, Pingpingjia OS Mix 1.5 parts of -15 surfactant evenly;

[0060] b) Preparation of water-based surface layer slurry: 100 parts of polyurethane for aliphatic water-based surface layer with a modulus of 55Mpa and a solid content of 35%, 0.3 parts of Coatsil7602 type water-based leveling agent, 25 parts of water-based color paste, DefoamerA13 type water-based defoaming 0.2 parts of water-based acrylic thickener, 0.4 parts of water-based acrylic thickener, and 4 parts of SAC-100 cross-linking agent are mixed evenly to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com