Laminating and edge covering device and process for automatic gold paper production line

An automatic production line and hemming device technology, which is applied to lamination devices, layered products, household appliances, etc., can solve problems affecting gold paper processing and production, low degree of automation, low production efficiency, etc., and achieve production efficiency Improve, save labor, and solve the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

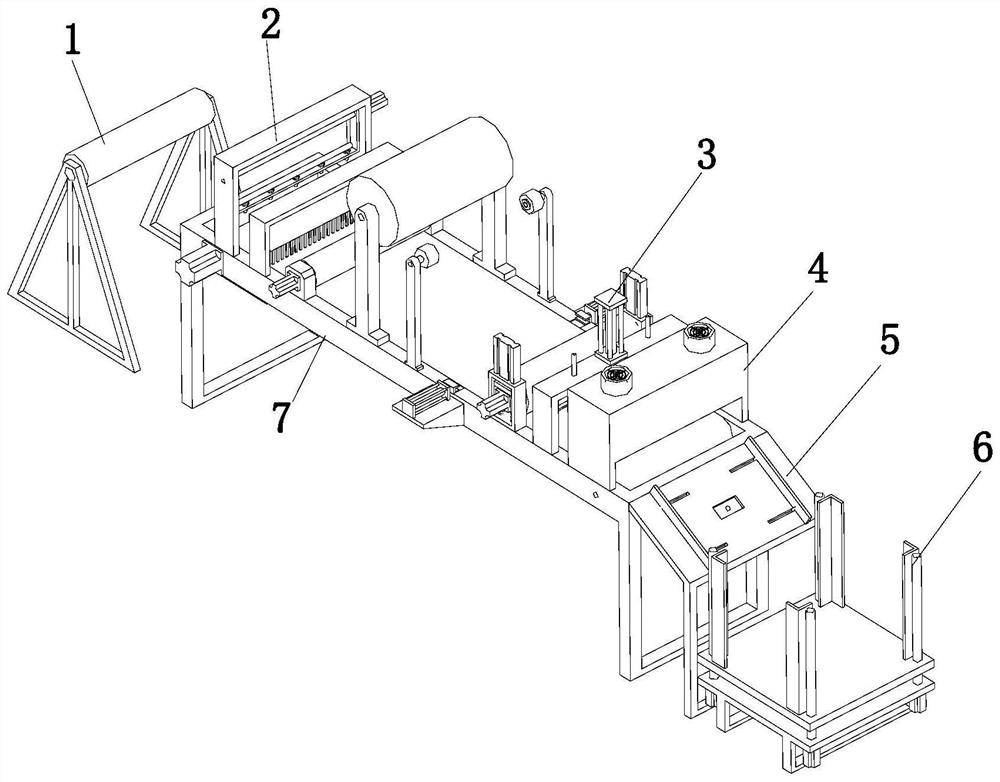

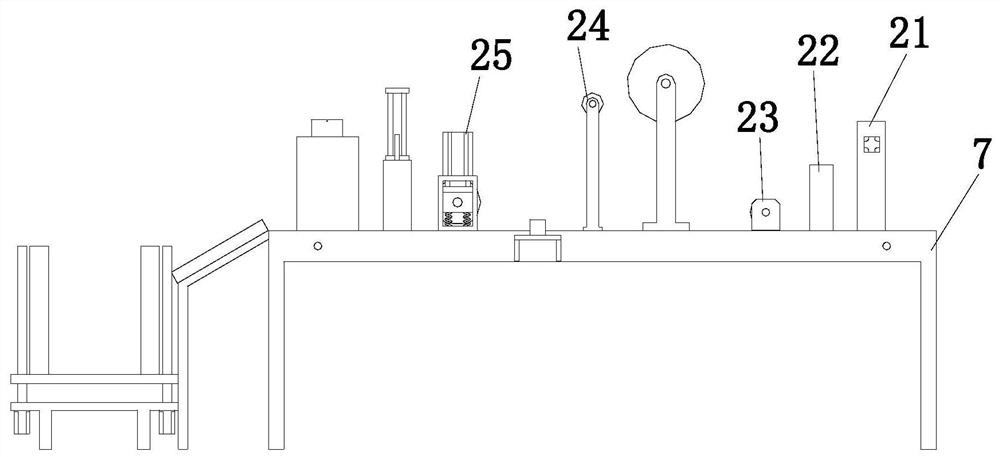

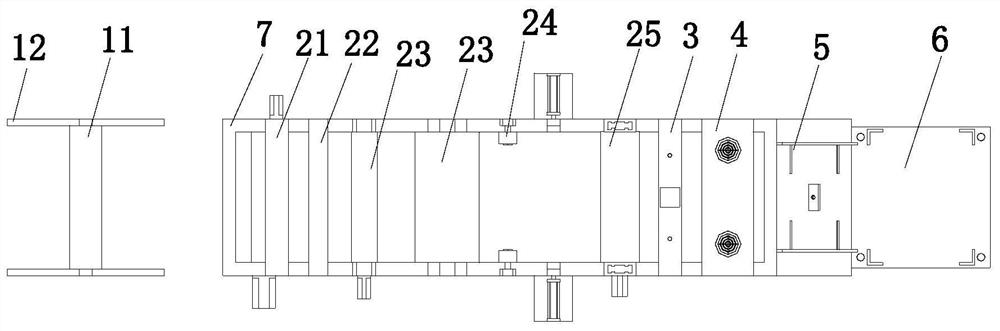

[0049] Combine below Figure 1 to Figure 12 As shown, the embodiment of the present invention provides an automatic production line for gold paper, including a conveying device 7, a feeding device 1, a gold paper bonding and hemming device 2, a gold paper cutting device 3, a gold paper drying device 4, a gold paper The counting device 5 and the gold paper unloading device 6, the conveying device 7 is vertically arranged, the feeding device 1 is arranged on the side of the conveying device 7, and the gold paper laminating and wrapping device 2 is arranged on the conveying device 7, the gold paper cutting device 3 is arranged on the top of the conveying device 7 and is positioned at the side of the gold paper pasting and wrapping device 2, and the gold paper drying device 4 is arranged on the top of the conveying device 7 and is located at the gold paper The side of the paper drying device 4, the gold paper counting device 5 is arranged on the side of the conveying device 7 and ...

Embodiment 2

[0066] Working principle of the present invention: a process for laminating and wrapping device of a gold paper automatic production line, comprising the following steps:

[0067] First of all, when the present invention is in use, the feeding roller 11 is used to store the yellow paper required for production, and the feeding roller 11 rotates on the two feeding racks 12 to continuously move the yellow paper to the conveying device 7 for subsequent use. Gold paper processing operations;

[0068] Step 1. The paste is evenly sprayed on the yellow paper: when the paste is applied on the yellow paper, the paste enters the connecting pipe 215 through the feed pipe, and the connecting pipe 215 transports the paste to several spraying nozzles 216, A number of spraying nozzles 216 evenly spray the paste on the yellow paper, and while spraying, the swing motor 212 works to drive the swing shaft 213 to rotate, and the swing shaft 213 rotates to drive the swing frame 214 to swing, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com