Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

443 results about "Mechanochemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanochemistry or mechanical chemistry is the coupling of mechanical and chemical phenomena on a molecular scale and includes mechanical breakage, chemical behaviour of mechanically stressed solids (e.g., stress-corrosion cracking or enhanced oxidation), tribology, polymer degradation under shear, cavitation-related phenomena (e.g., sonochemistry and sonoluminescence), shock wave chemistry and physics, and even the burgeoning field of molecular machines. Mechanochemistry can be seen as an interface between chemistry and mechanical engineering. It is possible to synthesize chemical products by using only mechanical action. The mechanisms of mechanochemical transformations are often complex and different from usual thermal or photochemical mechanisms. The method of ball milling is a widely used process in which mechanical force is used to achieve chemical processing and transformations. The special issue of Chemical Society Review (vol. 42, 2013, Issue 18) is dedicated to the theme of mechanochemistry. Fundamentals and applications ranging from nano materials to technology have been reviewed. The mechanochemical approach has been used to synthesize metallic nanoparticles, catalysts, magnets, γ‐graphyne, metal iodates, nickel–vanadium carbide and molybdenum–vanadium carbide nanocomposite powders...

Edge-functionalized graphitic material through mechanochemical process and manufacturing method thereof

InactiveUS20130018204A1High degree of commercializationRaise the potentialMaterial nanotechnologyOrganic compound preparationGas phaseMaterials science

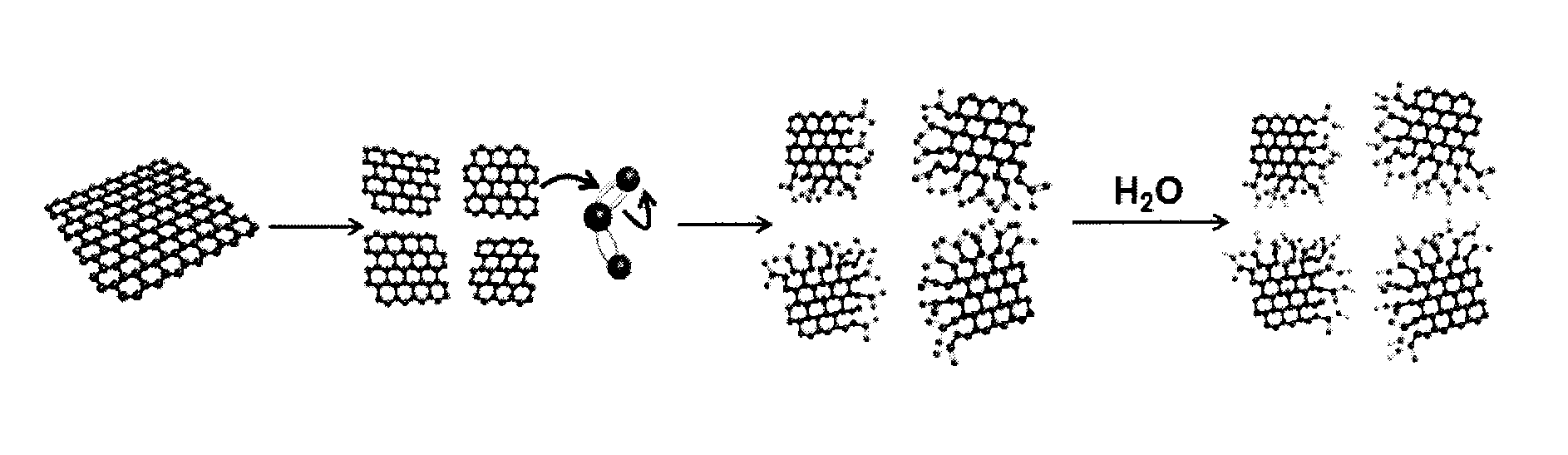

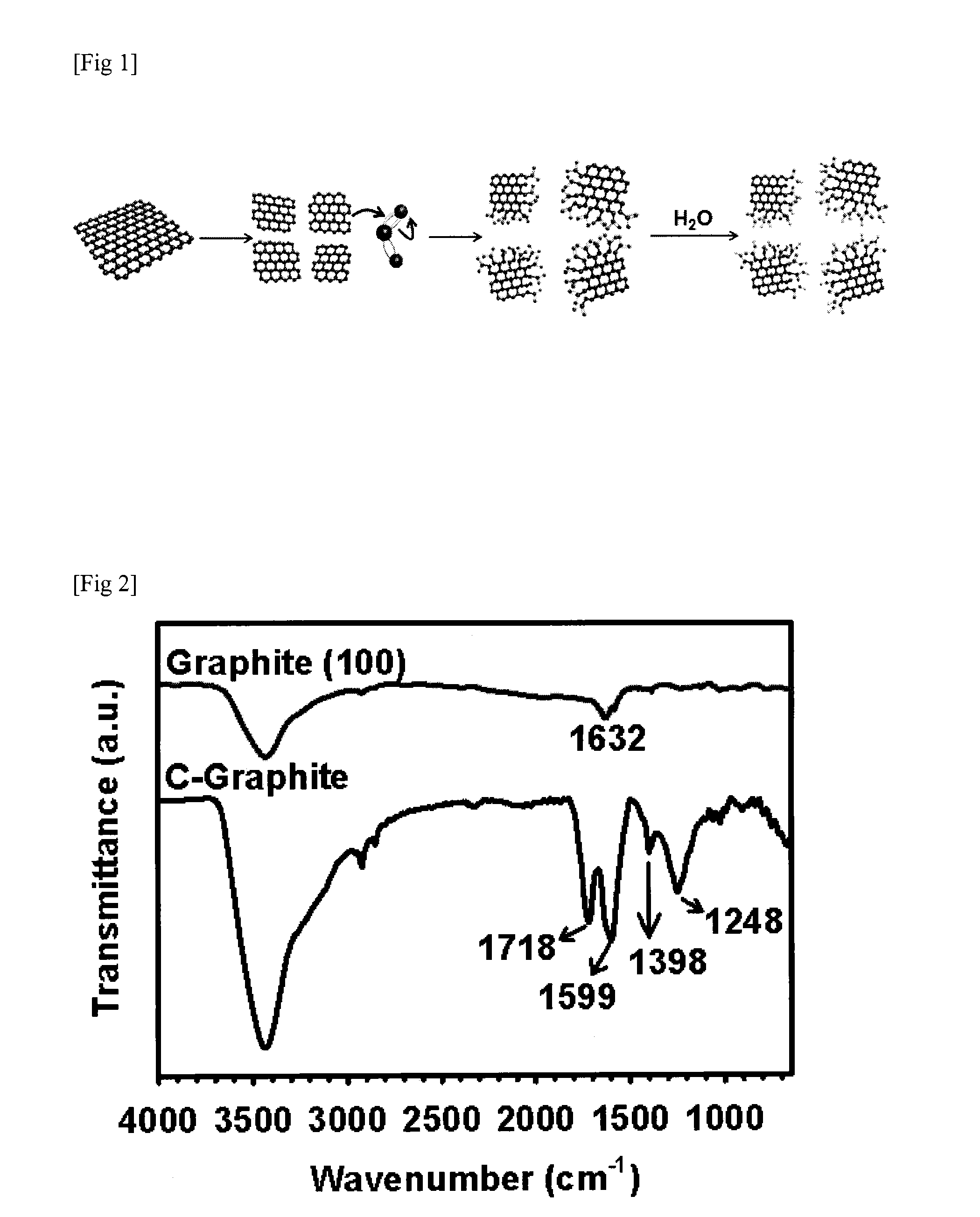

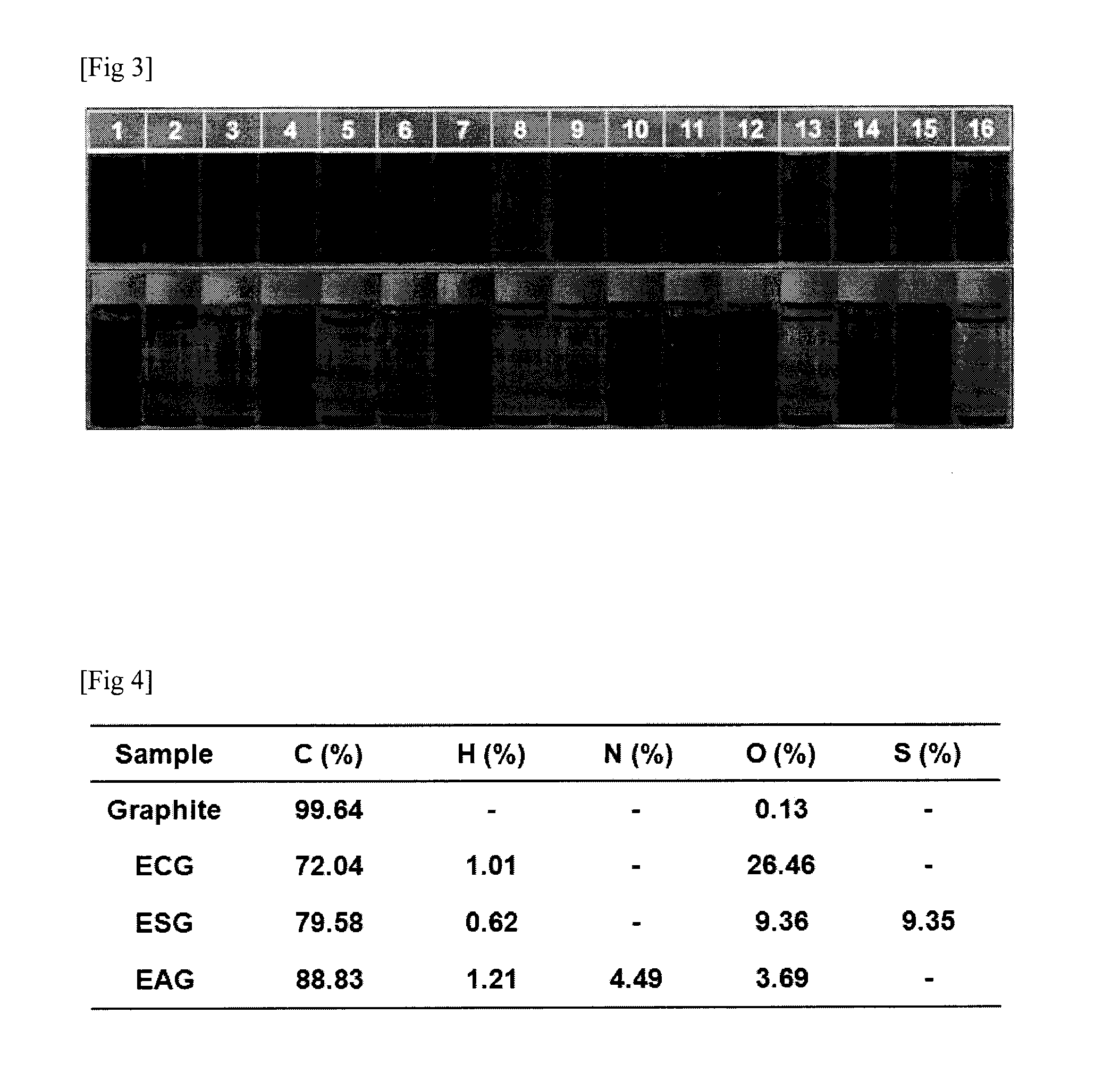

Disclosed is an edge-functionalized graphitic material manufactured by using a mechanochemical process. The edge-functionalized graphitic material is manufactured by pulverizing graphite in the presence of a variety of atmospheric agents in the form of gas phase, liquid phase, or solid phase. The edge-functionalized graphitic material, which is a precursor applicable into various fields, is expected to replace the prior art oxidized graphite.

Owner:DEOKYANG ECO LTD

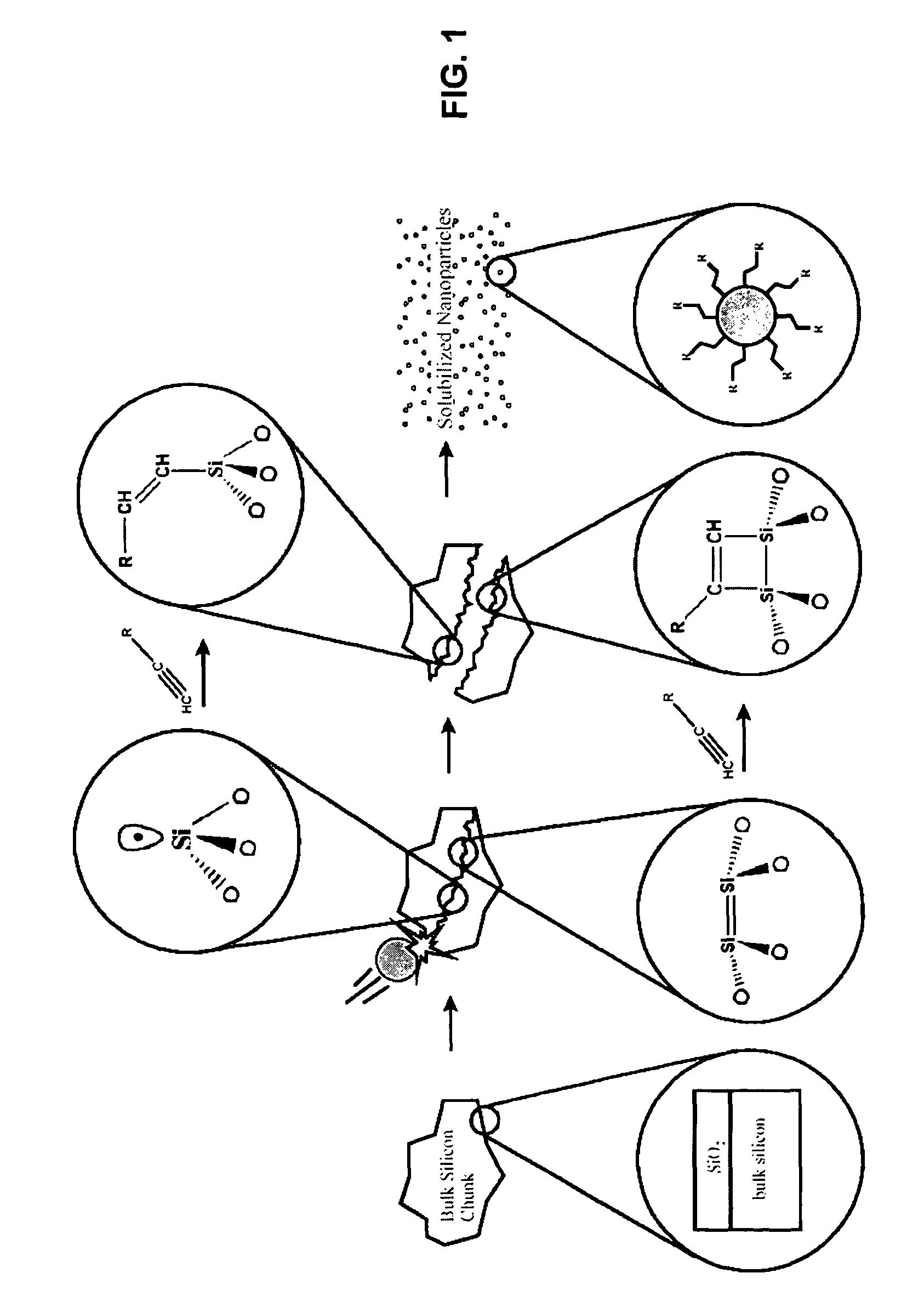

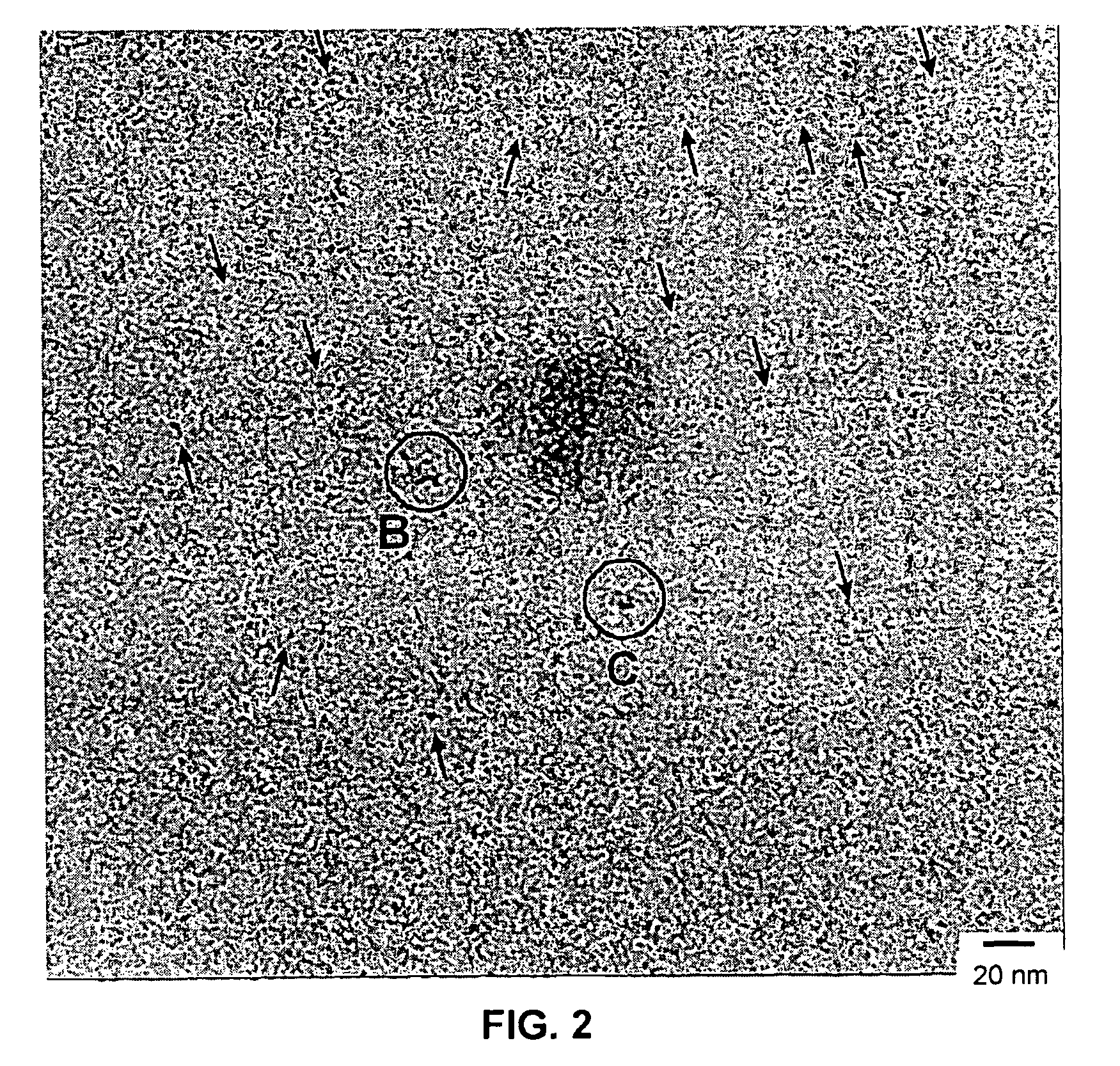

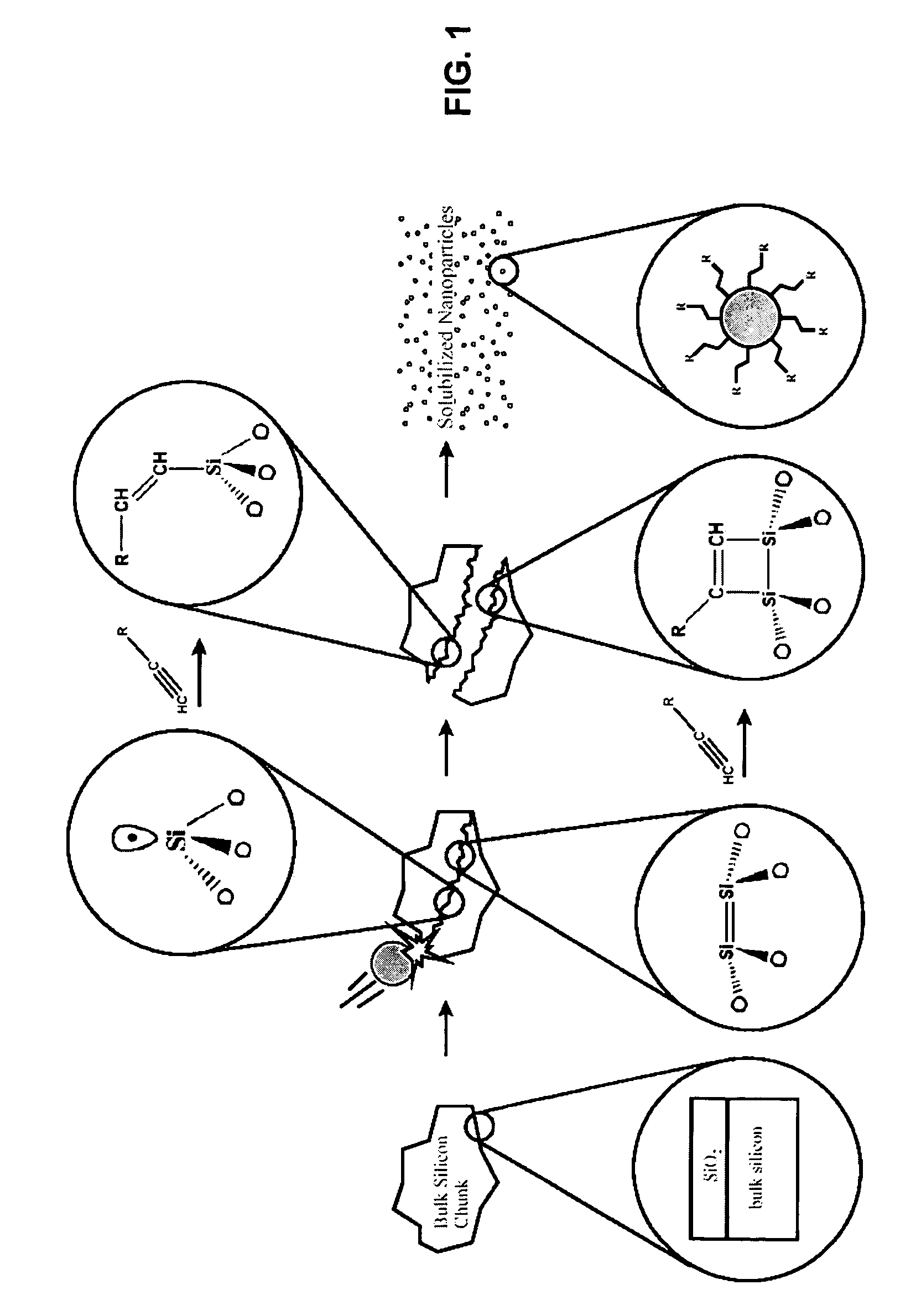

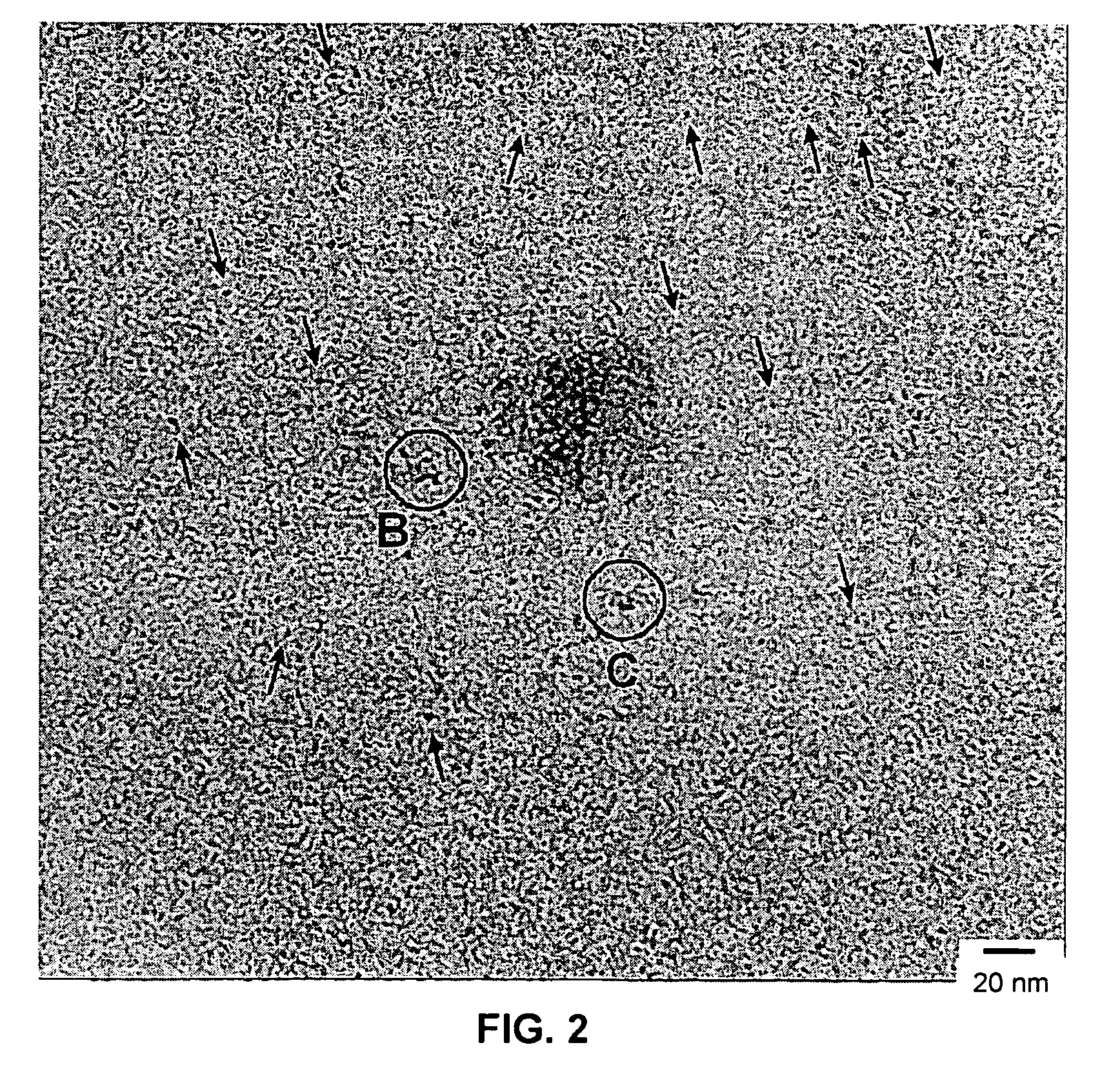

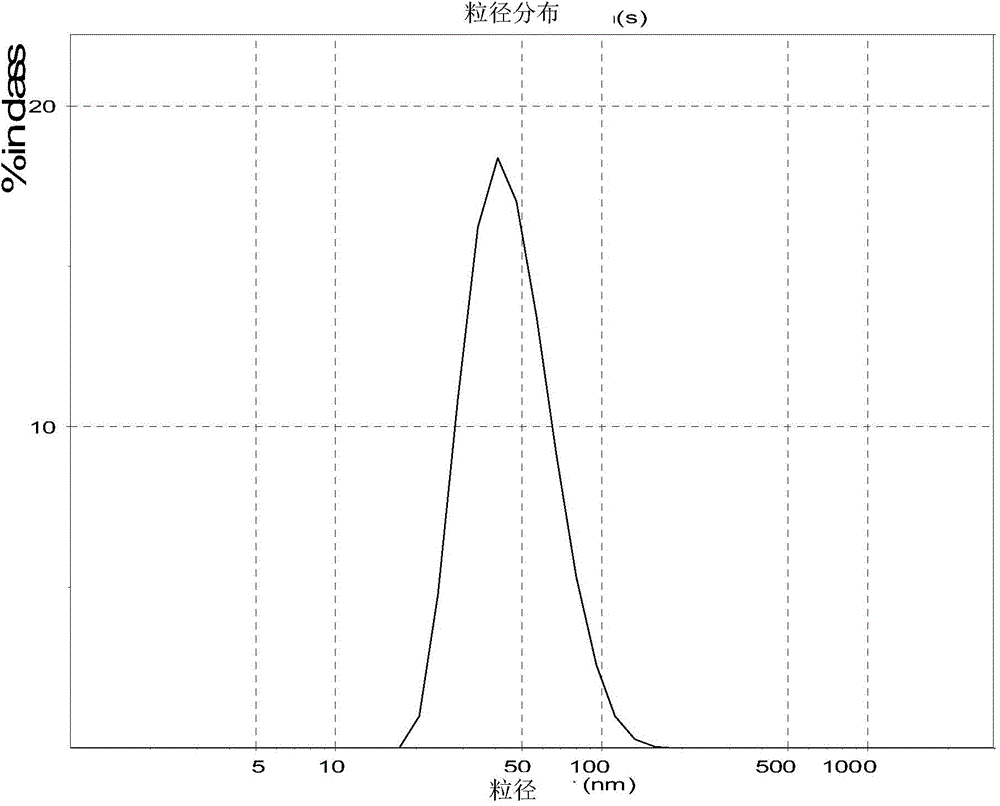

Method of forming stable functionalized nanoparticles

ActiveUS7883995B2Stable and functionalized nanoparticlesStable functionalized nanoparticlesMaterial nanotechnologySiliconHigh energyFunctionalized nanoparticles

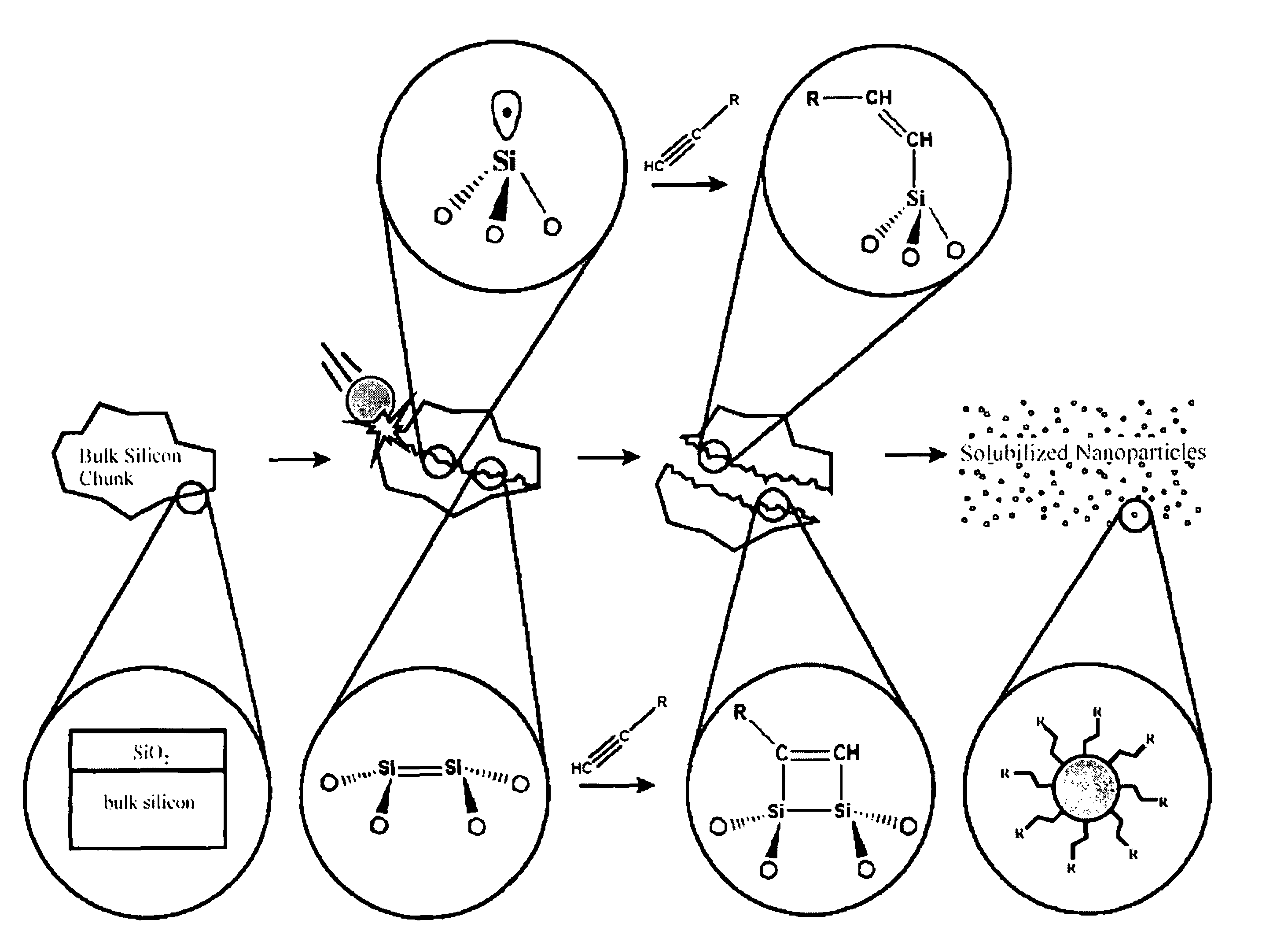

A novel top-down procedure for synthesis of stable passivated nanoparticles uses a one-step mechanochemical process to form and passivate the nanoparticles. High-energy ball milling (HEBM) can advantageously be used to mechanically reduce the size of material to nanoparticles. When the reduction of size occurs in a reactive medium, the passivation of the nanoparticles occurs as the nanoparticles are formed. This results in stable passivated silicon nanoparticles. This procedure can be used, for example in the synthesis of stable alkyl- or alkenyl-passivated silicon and germanium nanoparticles. The covalent bonds between the silicon or germanium and the carbon in the reactive medium create very stable nanoparticles.

Owner:THE ADMINISTRATORS OF THE TULANE EDUCATIONAL FUND

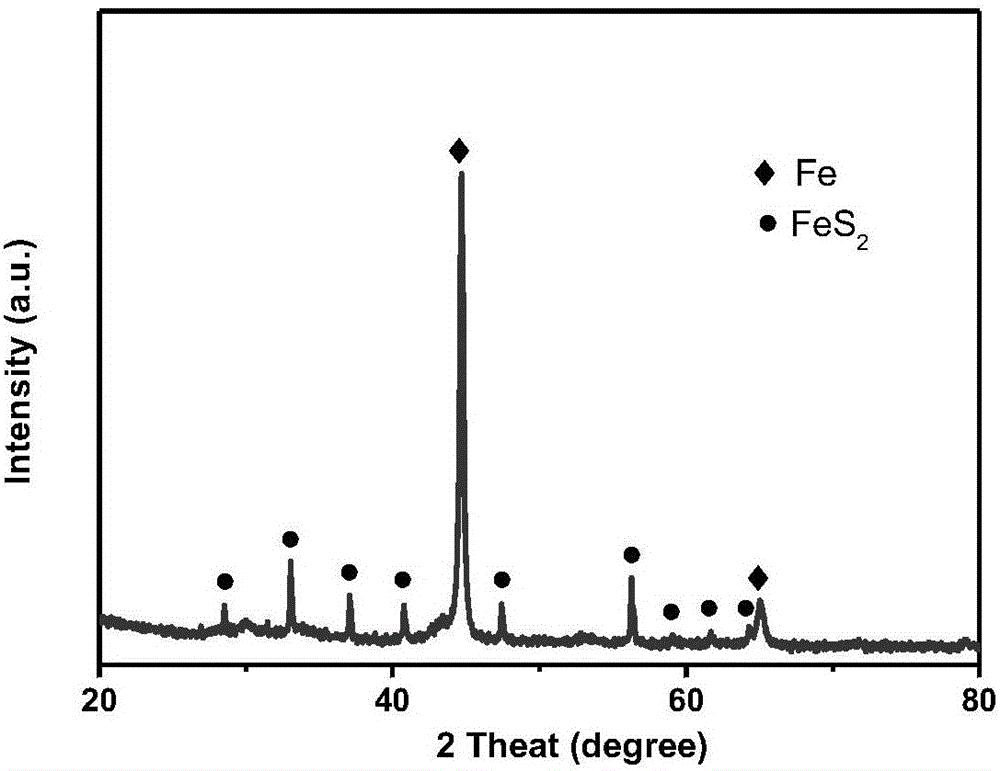

Fast organic pollutant removing method based on vulcanized zero-valence-iron-activated hydrogen peroxide

ActiveCN106396074AImprove utilization efficiencyReduce dosageWater treatment compoundsWater contaminantsMechanochemistryChemical process

The invention discloses a fast organic pollutant removing method based on vulcanized zero-valence-iron-activated hydrogen peroxide. The method has the advantages that the surface of Fe0 is coated with crystal type FeS2 with excellent conductivity through a mechanical chemical process so as to replace a possibly-formed passive film (iron oxide), the generation and regeneration of Fe2+ in a system are accelerated, a pH environment needed by a Fenton system is provided by using FeS2 and H2O2 and reaction of the FeS2 and H2O2 with Fe3+, and accordingly target pollutants can be removed efficiently and fast; the materials needed by the method are wide in source and cheap, and the method is high in pollutant degrading drive force, fast, and high in reagent utilization efficiency; the method is high in universality, applicable to the treatment of various industrial wastewater and other polluted water and most organic pollutants in soil and underground environments, evident in economic, environment and social benefits and worthy of large-scale popularization and has no strict requirements on the initial pH condition of a target medium.

Owner:ZHEJIANG UNIV OF TECH

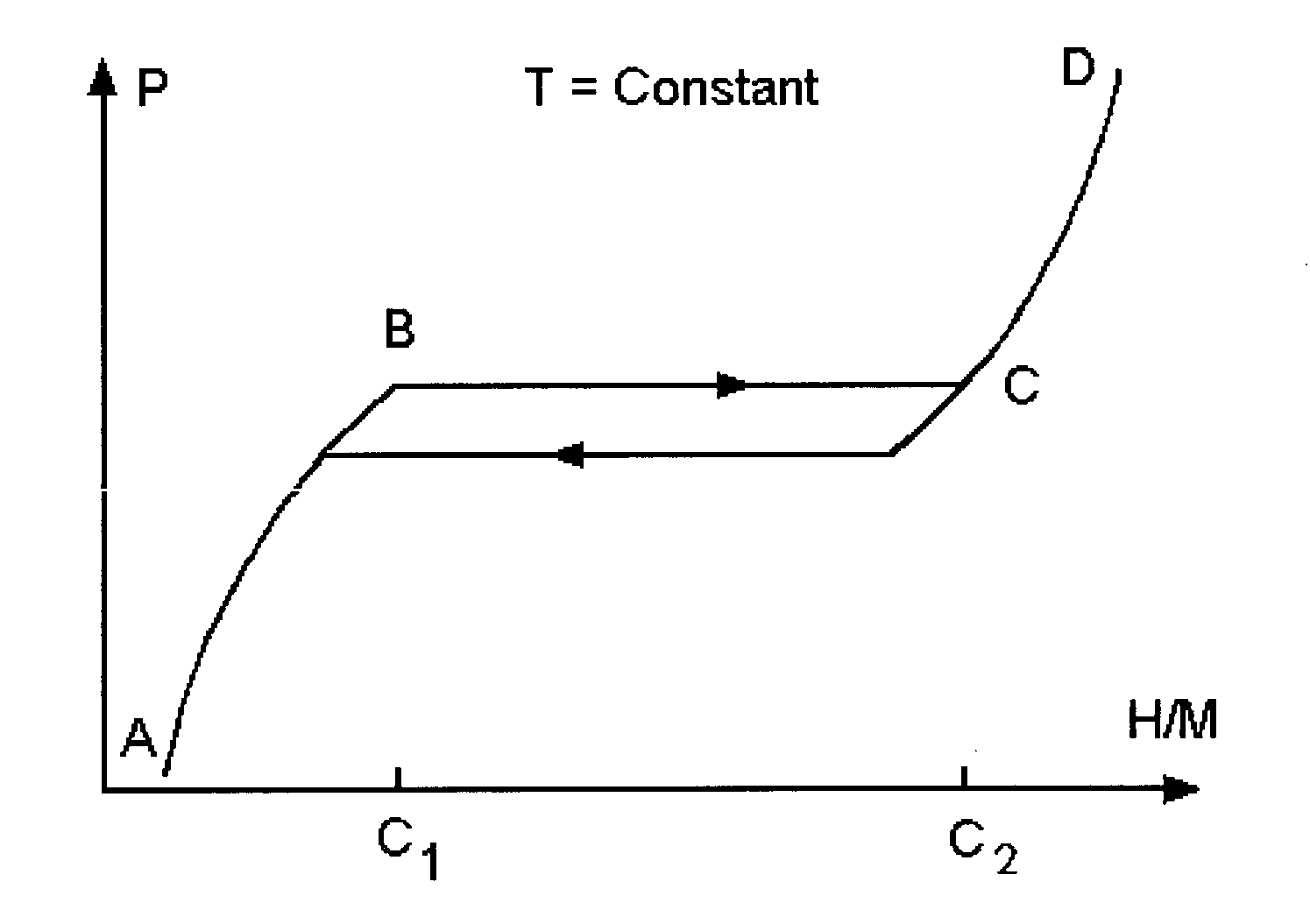

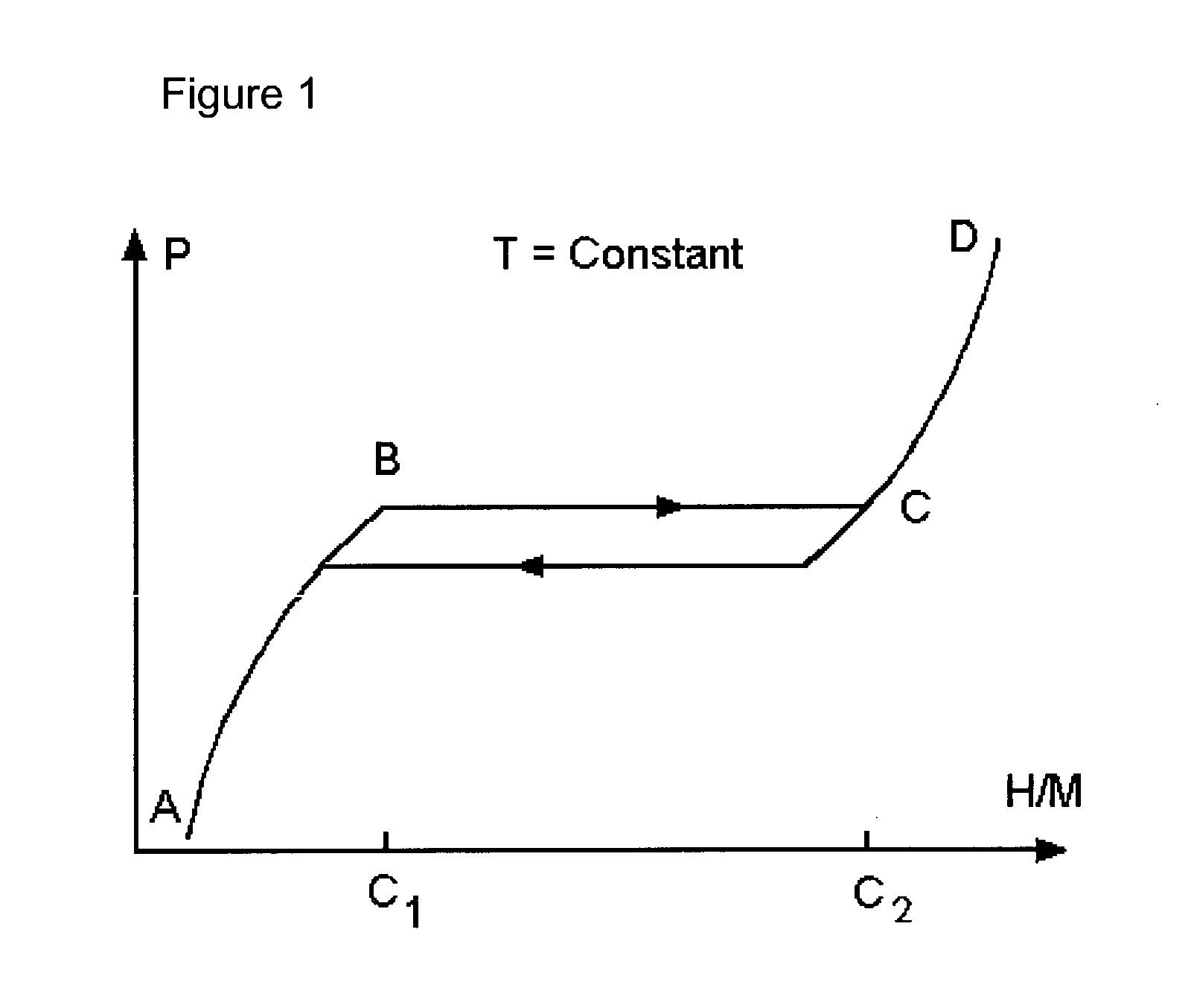

Nanoparticle mixtures for hydrogen storage, transportation, and distribution

InactiveUS20060101943A1Increase rangeImprove performanceNanotechReversible hydrogen uptakeNanoparticleHydrogen fuel cell

This invention uses nanoparticle mixtures to broaden the range of economic materials, improve performance across this broader range, and thereby lower costs of hydride and other storage systems. Nanoparticles can have dramatically different mechanical, chemical, electrical, thermodynamic, and / or other properties than their parent (precursor) materials. Because of this fundamental characteristic, nanophase materials can greatly improve the range of possibilities of materials selection, performance, cost, and practicality for hydride storage systems, advancing the early commerciality of such systems for hydrogen fuel cells or other applications. Among such hydrogen storage improvements are cheaper and better-performing metals, alloys, and / or compounds; lower weight; and reduced storage volumes.

Owner:SNOW DAVID G +1

Method of forming stable functionalized nanoparticles

ActiveUS20090047773A1Stable and functionalizedStable and functionalized nanoparticlesMaterial nanotechnologySiliconHigh energyNanometre

A novel top-down procedure for synthesis of stable passivated nanoparticles uses a one-step mechanochemical process to form and passivate the nanoparticles. High-energy ball milling (HEBM) can advantageously be used to mechanically reduce the size of material to nanoparticles. When the reduction of size occurs in a reactive medium, the passivation of the nanoparticles occurs as the nanoparticles are formed. This results in stable passivated silicon nanoparticles. This procedure can be used, for example in the synthesis of stable alkyl- or alkenyl-passivated silicon and germanium nanoparticles. The covalent bonds between the silicon or germanium and the carbon in the reactive medium create very stable nanoparticles.

Owner:TULANE EDUCATIONAL FUND

Method for preparing PVC leatheroid and PU synthetic leather with high efficiency release of negative ions

InactiveCN1654739AChange the defect of a single functionIncrease concentrationTextiles and paperSemiconductor materialsImpurity

The preparation process of artificial PVC leather and synthetic PU leather to release negative ion effectively includes the following steps: treating tourmaline mineral through sorting, water selecting, eliminating impurity, airflow grinding, acid or alkali treating; mechanical and chemical compounding tourmaline powder with RE salt or oxide and nanometer semiconductor material to obtain nanometer composite tourmaline material; adding the nanometer composite tourmaline material in 1.5-20 wt% into the material for artificial PVC leather and synthetic PU leather; and conventional artificial leather preparing process. The present invention added the negative ion releasing function to artificial PVC leather and synthetic PU leather, and negative ion with powerful oxidizing property is utilized to destroy bacteria's activity and to deodorize through reaction with various bad smell, such as ammonia, benzene, formaldehyde, etc.

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

Method for preparing detonation nanometer diamond dispersion

The invention discloses a method for preparing detonation nanometer diamond dispersion. The method comprises the following steps: preliminarily dispersing commercially available nanometer diamond in deionized water, and performing mechano-chemical deagglomeration and chemical modification; purifying the nanometer diamond subjected to deagglomeration to remove impurities, cleaning and grading, and preparing water-based dispersion; selectively adding a corresponding concentrating agent for concentration according to the polarity or non-polarity of a subsequent selected dispersing solvent, and removing the supernatant; adding a polar solvent into the prepared concentrate, or adding a surface group conversion agent and a non-polar solvent, removing an aqueous phase after the nanometer diamond is converted to enter the non-polar solvent, adding a dispersion stabilizer, a pH value regulator and the like, performing ultrasonic treatment or stirring and dispersing, and preparing the polar or non-polar medium detonation nanometer diamond dispersion which can be stably stored. The process is simple, the prepared product is high in purity, high in concentration and high in yield and can be prepared into paste and aerosol, drying is not needed in the process, and the dispersion can be stably dispersed in different liquid media.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

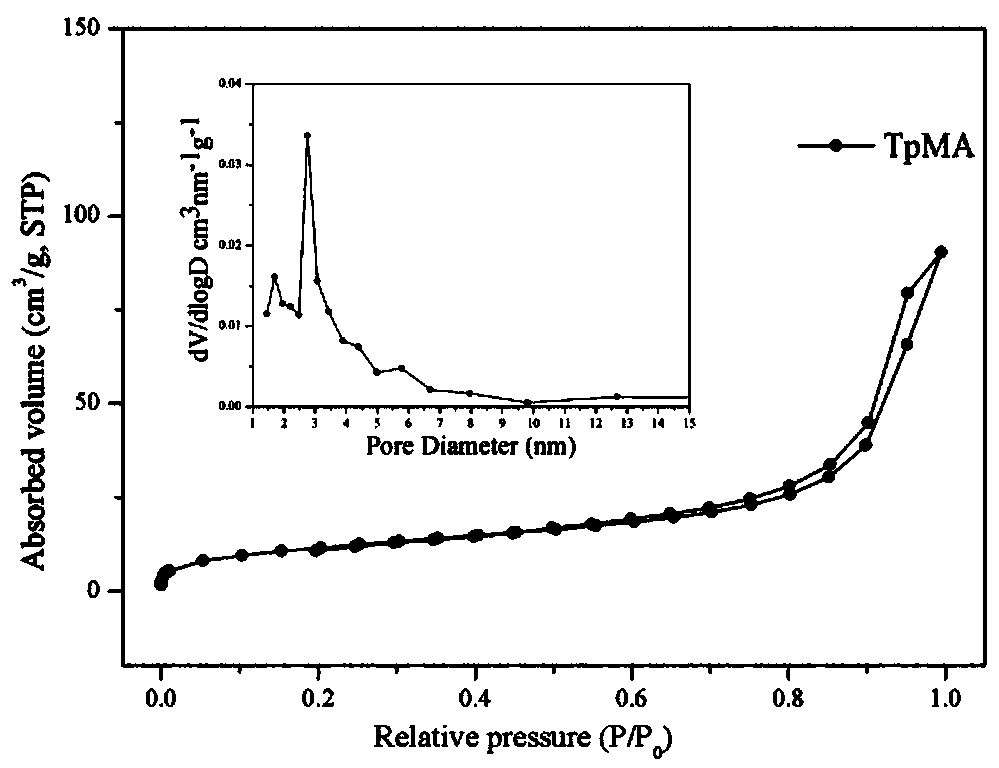

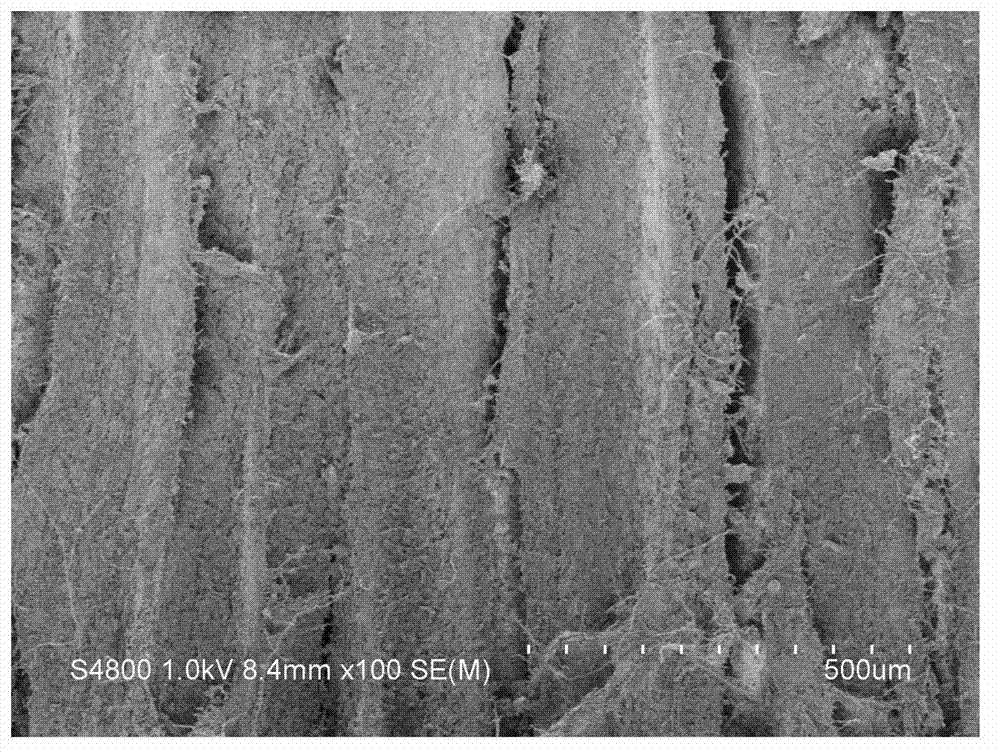

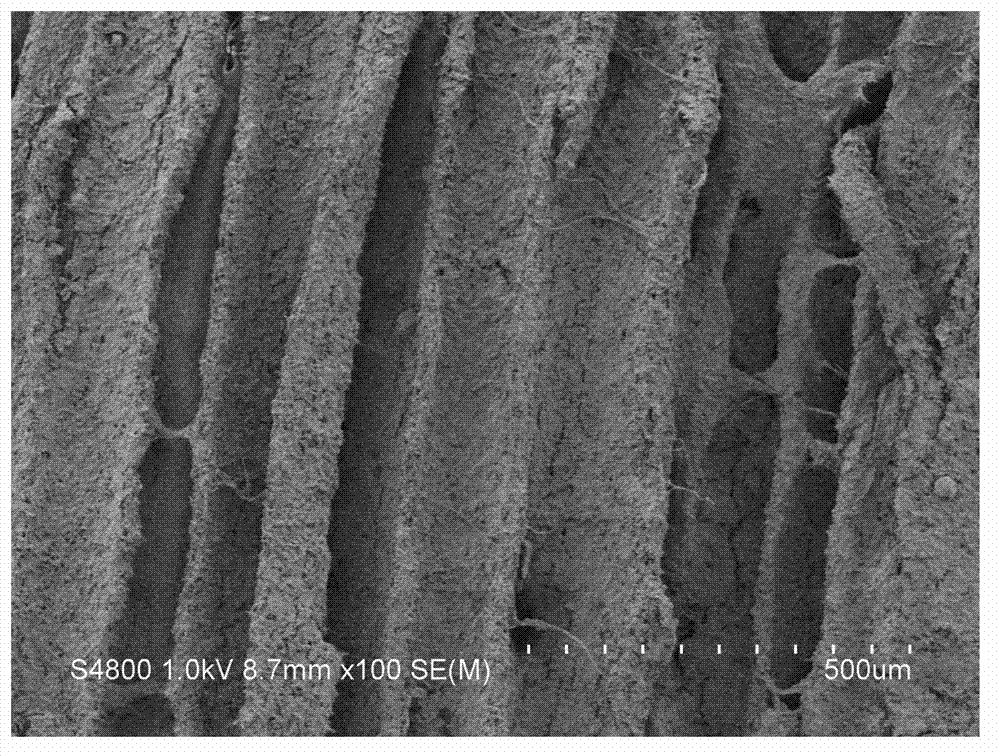

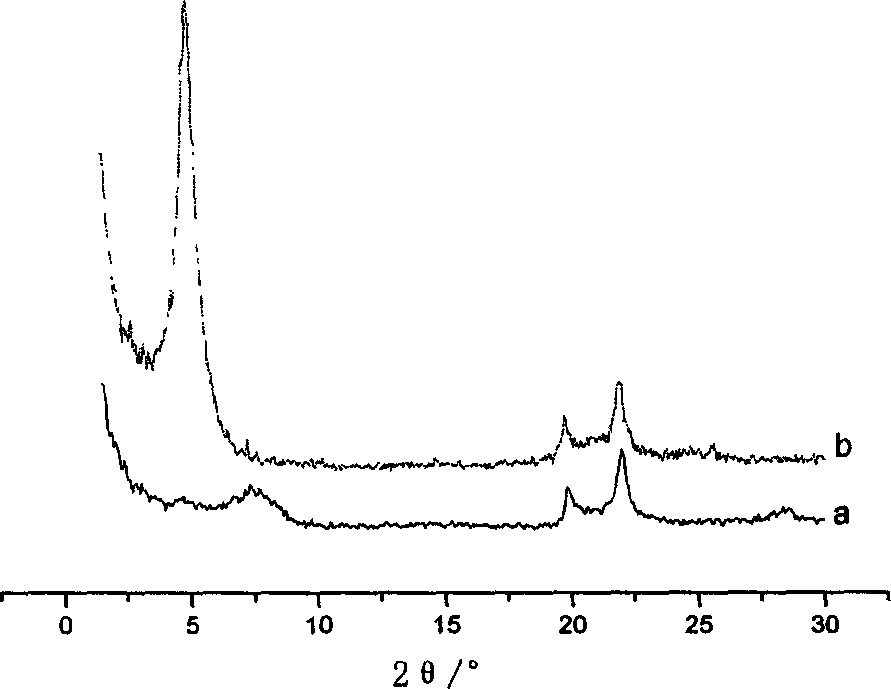

Mechanochemical preparation method for covalent organic framework material and application

ActiveCN109232588AEasy to prepareReduce build timeOrganic chemistryWater/sewage treatment by irradiationWastewaterRoom temperature

The invention provides a method for synthesizing an efficient photocatalytic covalent organic framework material by using a mechanochemical method. The method is characterized by comprising the following steps: using the mechanochemical method, using melamine and 2,4,6-triformyl resorcinol as raw materials, distributing according to a certain mole ratio, using a planetary ball-milling device, acquiring sticky slurry at a room temperature through wet-process ball-milling, after washing and drying the sticky slurry, to obtain the stable covalent organic framework material. The method is simple in process, only less solvent is used in a grinding reaction process, the environment is protected, and production cost is reduced. Reaction time is only 1 / 36 of that of a hydrothermal method, a reaction condition is mild, and the method can be applied for large-scale production. In addition, the prepared stripping sheet-like structure powder material is wide in visible light absorption range, highin separation efficiency of a photon-generated carrier, capable of rapidly decomposing toxic organic substances in water, has excellent performance of treating organic wastewater, can be repeatedly used, and has good industrial application prospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Immobilization of ionic liquids via mechnochemical intercalation in layered materials

InactiveUS20140005415A1Organic chemistryMolecular sieve catalystsPropylene carbonateCoupling reaction

A facile mechanochemical intercalation approach was adopted to immobilize ionic liquids into layered materials. The immobilized ionic liquids were found to be useful as catalysts for the coupling reaction of CO2 and propylene oxide to synthesize propylene carbonate. The immobilized ionic liquid exhibited similar reactivity as the free ionic liquid. Overall, the 10 mechanochemical approach proves to be effective in immobilizing ionic liquids in layered compounds and thus may expand the applications of ionic liquids and, meanwhile, improve catalyst separation and recycling.

Owner:TEXAS STATE UNIVERSITY

Low-cost environment-friendly injection-molding high heat-resistant high impact-resistant rigid polyvinyl chloride composite and preparation method thereof

The invention discloses a low-cost environment-friendly injection-molding high heat-resistant high impact-resistant rigid polyvinyl chloride composite and a preparation method thereof. The composite is prepared from the following raw materials in part by weight: 100 parts of medium-low polymerization degree polyvinyl chloride, 10 to 100 parts of high polymerization degree polyvinyl chloride, 4 to 100 parts of impact-resistant modifier, 5 to 50 parts of nano rigid particle, 1 to 5 parts of lanthanum tin compound stabilizer, 1 to 3 parts of acrylate processing aid, 1 to 10 parts of internal lubricant and 0.3 to 2 parts of external lubricant. The low-cost environment-friendly injection-molding high heat-resistant high impact-resistant rigid polyvinyl chloride composite is prepared by the steps of: performing mechanochemistry treatment on the polyvinyl chloride and the aid in a high-speed mixer through new technology; and pelleting by using a cone-shaped double-screw extruder. The compatibility between the polyvinyl chloride and the aid is improved through the new technology, the problem that the conventional nano particles easily agglomerate and have poor compatibility between a heat-resistant modifier and a substrate so as to reduce the mechanical property is solved, and the product has the advantages of high heat resistance, high toughness and good comprehensive mechanical property.

Owner:ZHEJIANG UNIV

Method for extracting functional ingredients from lucid ganoderma sporocarp

InactiveCN102824377AReduce extraction timeHigh crystallinityPlant ingredientsSteam pressureAdditive ingredient

The invention discloses a method for extracting functional ingredients from lucid ganoderma sporocarp. As a better implementation scheme, the method for extracting functional ingredients can comprises the following steps: lucid ganoderma sporocarp is firstly ground and then subjected to steam explosion treatment under the condition that the steam pressure is 0.6-2.4 Mpa for 60-210 seconds; after the steam explosion treatment, the lucid ganoderma sporocarp is extracted with water or an organic agent, filtered, concentrated and dried; and finally the active ingredients such as ganoderma lucidum polysaccharides and lucid ganoderma triterpenoid substances can be obtained. According to the method, a short-term steam explosion technology is adopted to pretreat the lucid ganoderma sporocarp, the thermal mechanochemistry action of steam explosion is utilized to break the cell wall of the lucid ganoderma sporocarp, the structure of the solid lucid ganoderma sporocarp is broken, so that the active ingredients of the lucid ganoderma sporocarp can be favorably dissolved out, the extraction time is shortened, the production cost is lowered, and the extraction rate of the functional ingredients is obviously improved compared with that of the conventional extraction method.

Owner:FUJIAN JIANSHEN BIOLOGICAL ENG +1

Method of fabricating ultra-fine cermet alloys with homogeneous solid grain structure

The present invention relates to a method of fabricating ultra-fine grain cermet alloys with a homogenous solid solution grain structure. More particularly, the invention relates to a method of fabricating an ultra-fine TiC-base cermet alloy with a homogenous solid solution structure which does not comprise a core-rim structure in the carbide grain.The object of the present invention is to provide a method of fabricating a TiC-base cermet alloy without the core-rim structure.The above objects of the present invention could be achieved by employing a conventional sintering process (vacuum sintering) of (Ti,TM)C carbide obtained from a mechano-chemical synthesis (high energy ball-milling) from milling the powders of Ti, TM, Ni and Co metals.

Owner:KOREA INST OF SCI & TECH

Process for preparing limellar stripping nano imvite

InactiveCN1792791ASuitable for mass productionSuitable for industrial productionSilicon compoundsPhysical chemistryMontmorillonite

A layer stripping method for preparing nano-montmorillonite includes such steps as organic intercalating to Na-based montmorillonite by mechano-chemical method for modifying it, water washing, drying, and mechanical stripping by grinding.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Forming method for nanometer beta' phase element and nanometer oxide composite reinforced Fe-based ODS alloy

InactiveCN103233182AExcellent high temperature mechanical propertiesImprove mechanical propertiesHigh energyOxide composite

The invention provides a forming method for nanometer beta' phase element and nanometer oxide composite reinforced Fe-based ODS alloy, and belongs to the field of metal dispersion reinforcement technology. A matrix element powder (Fe, Cr, Mo) and a beta' phase forming element powder (Ni, Al) and an oxide are formed into a component (Fe2O3, YH2 and Ti), and are pre-mixed uniformly, and then a high energy ball milling is carried out in Ar atmosphere with high purity, and a nanometer oxide dispersion phase is formed in situ by mechanical chemical reaction, thereby the nucleation energy barrier is reduced, and the oxide is nucleated uniformly. And then alloy powder after high energy ball milling is processed by SPS sintering or hot isostatic pressing densification. After solid solution and ageing heat treatment, the nanometer beta' phase element and the nanometer oxide composite reinforced Fe-based ODS alloy are obtained. According to the invention, two reinforced phases such as nanometer beta' phase and nanometer oxide are simultaneously introduced into the Fe-based ODS alloy, and the reinforced effects of the two nanometer precipitated phases are superposed, and the two precipitated phases has the advantages of very fine particle sizes, uniform distribution, high heat stability and substantial reinforcement effect, thereby further enlarging the usage temperature limit of the Fe-based ODS alloy.

Owner:UNIV OF SCI & TECH BEIJING

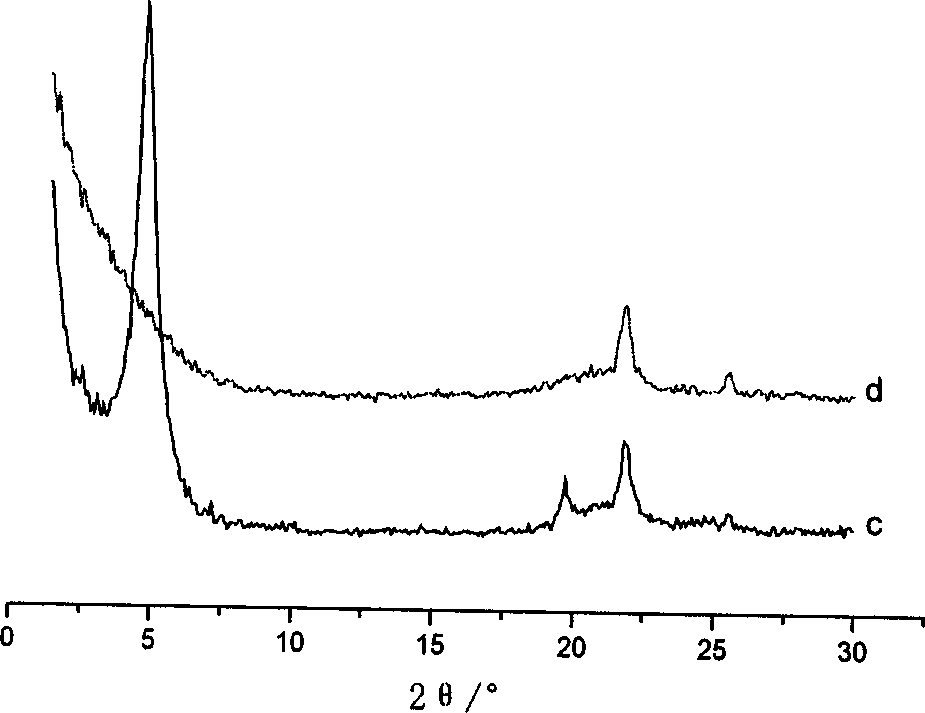

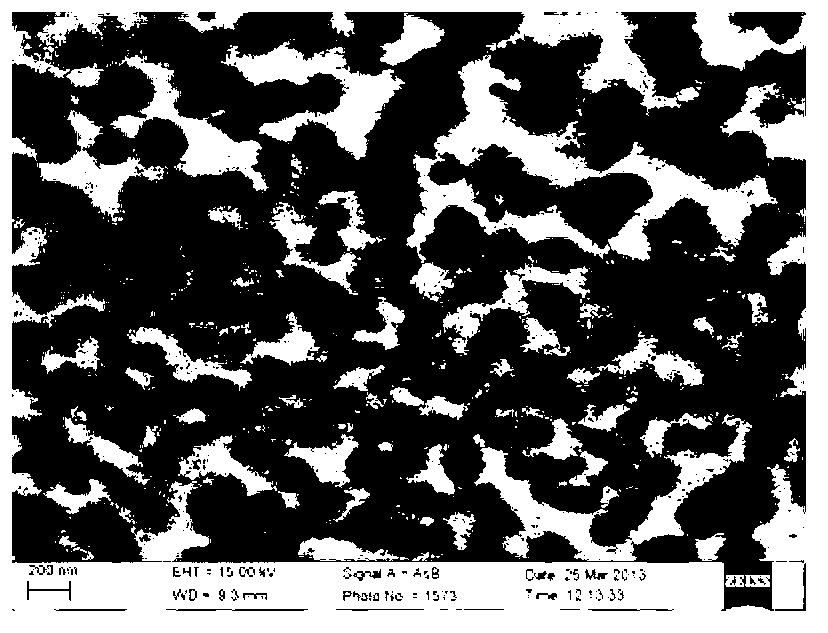

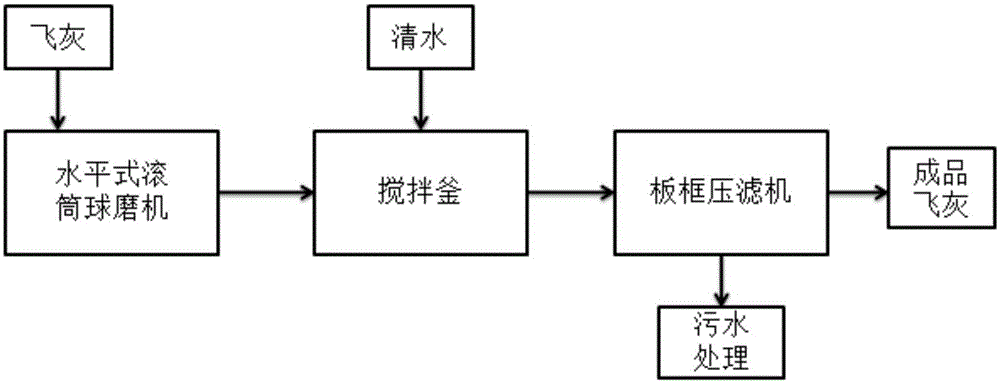

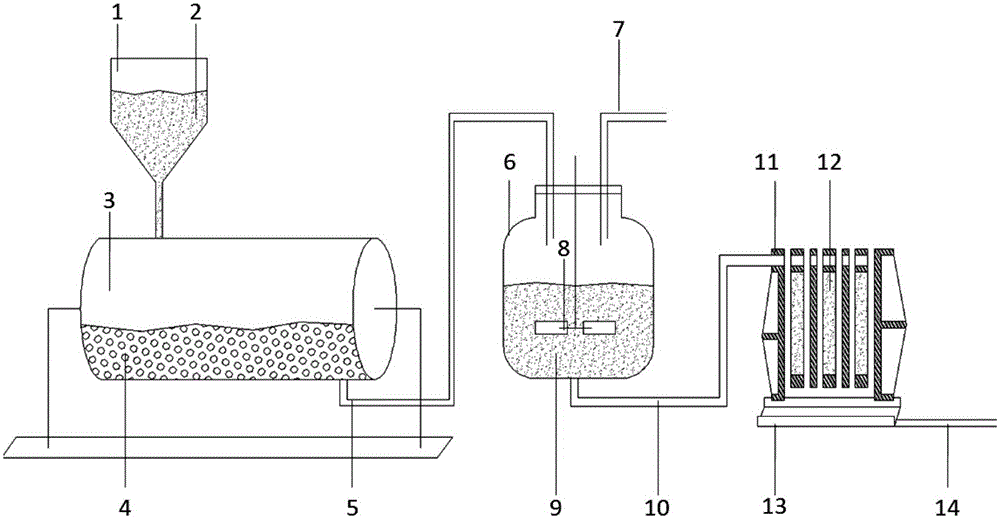

Method and system for treating fly ash in manner combining mechanochemistry and washing, with characteristics of high efficiency, low cost and zero harm

ActiveCN105013798AEfficient solidification of heavy metalsEfficiently achieve degradabilitySolid waste disposalElectronic waste recyclingEnvironmental resistanceResource utilization

The invention relates to the field of harmless fly ash treating, and provides a method and system for treating fly ash in a manner combining mechanochemistry and washing, with characteristics of high efficiency, low cost and zero harm. The system comprises a feed bin, a horizontal roller type ball mill, a stirring kettle and a plate-and-frame filter press, wherein the bottom of the feed bin is connected to a feed opening of the horizontal roller type ball mill; stainless steel milling balls are placed in a closed barrel body of the horizontal roller type ball mill; two ends of a discharge pipeline are connected to the bottom of the horizontal roller type ball mill and the upper part of the stirring kettle respectively; the upper part of the stirring kettle is connected with a water inlet pipeline, and the bottom of the stirring kettle is connected to the plate-and-frame filter press. According to the method and the system which are disclosed by the invention, the heavy metal solidification, the dioxin degradation and the chlorine removal of the fly ash can be realized at the same time in high efficiency, the treated fly ash is thoroughly harmless and has conditions of resource utilization, and the heavy metal solidification rate of the treated fly ash is more than 70%; an additive is not additionally added, so that the treating cost is low; the technological process is simple, the reaction conditions are mild, the treating process is environment friendly, and harmful by-products are not generated; the equipment investing cost and the operating cost are low, the treating effects are significant, and the technological process is simple to realize.

Owner:ZHEJIANG UNIV

Nanocarbon composite structure having ruthenium oxide trapped therein

InactiveCN1964917AImprove electrochemical activityIncrease capacityMaterial nanotechnologyCarbon compoundsMechanochemistryMaterials science

A novel nanocarbon composite structure having ruthenium oxide trapped therein, wherein using Ketjen black, through a mechanochemical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and the space of electrode material have been expanded so as to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having ruthenium oxide trapped therein exhibits high electrochemical activity, so that it is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

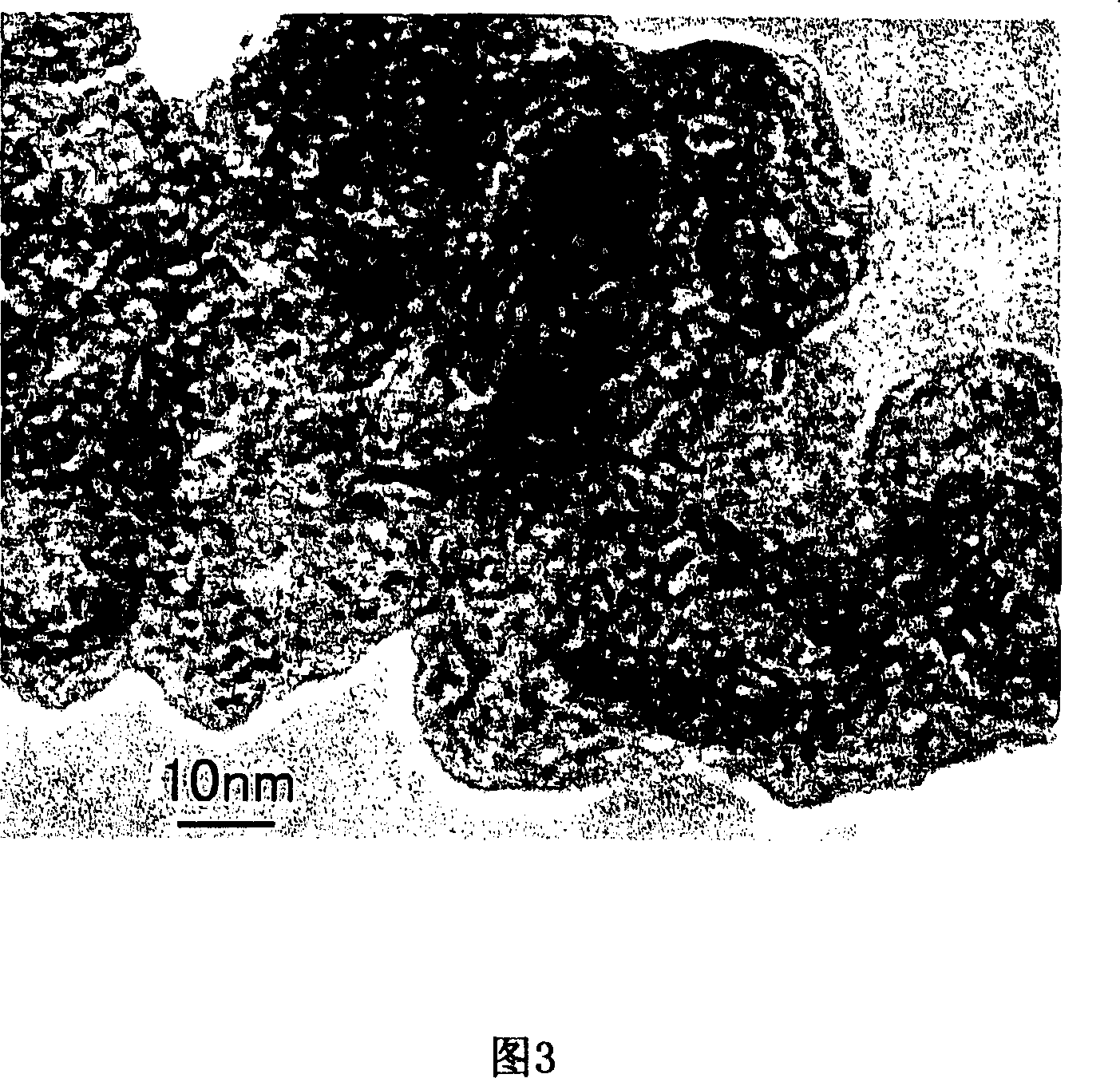

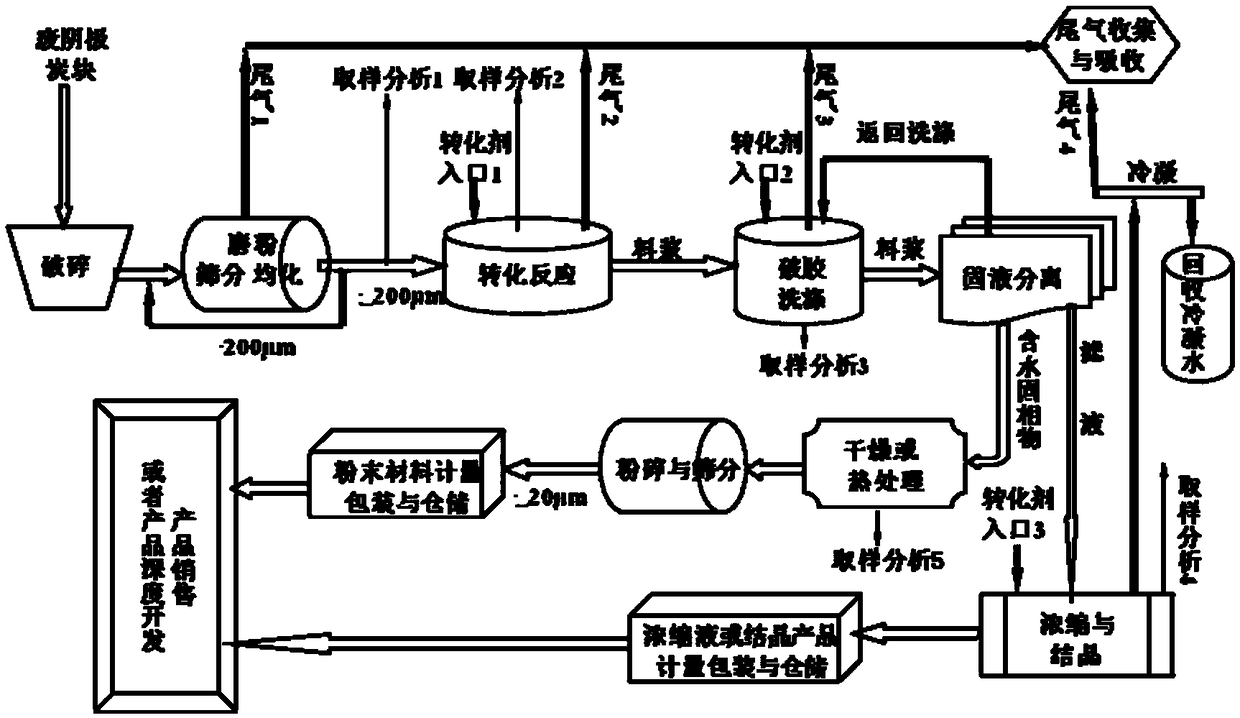

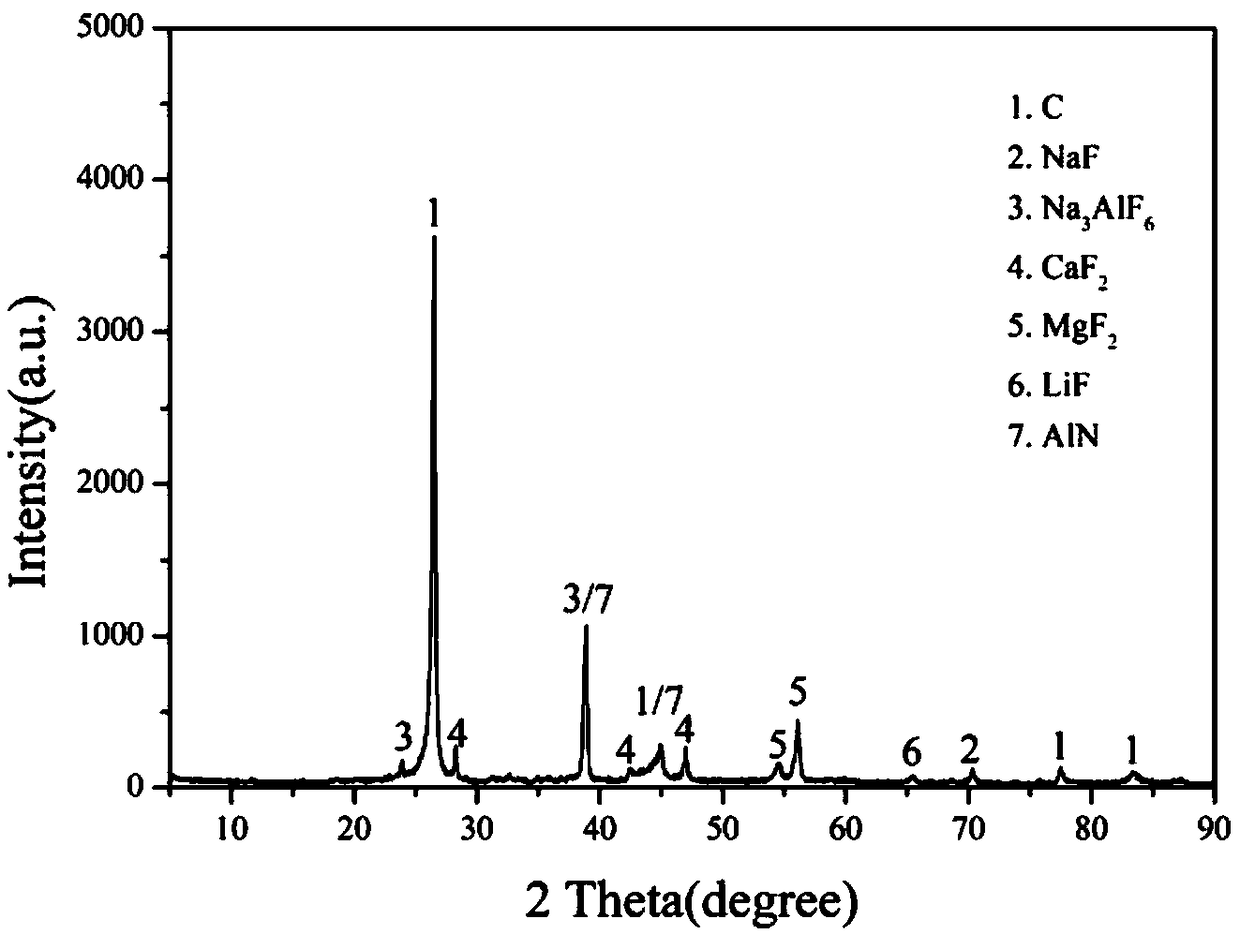

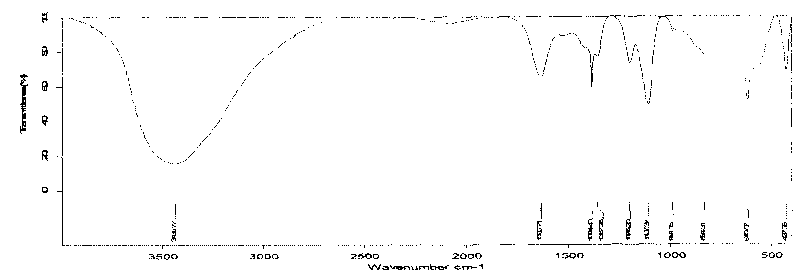

Method and system for converting sodium-containing and fluorine-containing compounds in waste cathode carbon block of aluminum electrolytic cell

ActiveCN109047285AEasy to controlEasy to industrializeMagnesium fluoridesTransportation and packagingPollutionHeat treated

The invention relates to a method and system for converting sodium-containing and fluorine-containing compounds in a waste cathode carbon block of an aluminum electrolytic cell. The conversion methodcomprises the step that a conversion agent is used for converting the sodium-containing compound in the waste cathode carbon block of the aluminum electrolytic cell into a fluorine-free soluble sodiumcompound, converting the fluorine-containing compound into an insoluble and harmless mineral fluorine compound and converting a cyanide-containing compound into harmless N2 or NH3 and CO2 in an oxidized manner through a mechanochemical conversion reaction in a conversion mill, and therefore the hazards of fluoride and cyanide in the waste cathode carbon block of the aluminum electrolytic cell arecompletely eliminated. The conversion system comprises a waste cathode carbon block crushing device, a milling device, the conversion mill, a stirred reactor and a solid-liquid separation device which are sequentially connected in series, and the solid-liquid separation device is then directly connected with a concentration or crystallization device and a drying or heat treatment device, and thedrying or heat treatment device is connected to the crushing device. By means of the method and system, the process is simple, mass production is easy, the production cost is low, pollution of three wastes is avoided, and the method and system are environmentally friendly.

Owner:XIANGTAN UNIV

Hydrotalcite preparation method

ActiveCN101746734ASimple processWide variety of sourcesOxide/hydroxide preparationIon exchangeFire retardant

The invention relates to a hydrotalcite preparation method. Hydrotalcite is prepared in one step by adopting mechano-chemical process, the method includes uniformly mixing trivalent metal compound, divalent metal compound, solid base and carbonate, ball milling by a ball miller for 1-5 minutes, washing, and drying to obtain the required hydrotalcite. The invention has simple technological flow, less equipment investment, available main raw materials and low cost. The hydrotalcite obtained by the method has wide application for example, the hydrotalcite may be used as catalyst, catalyst precursor, ion exchanger or absorbent, medicine carrier, fire retardant and PVC heat stabilizer.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

Method for preparing rod-shaped hydroxyapatite capable of controlling nano size

InactiveCN101507832AImprove mechanical propertiesGood biocompatibilityProsthesisApatiteBiocompatibility Testing

The invention relates to a method for preparing rod-shaped hydroxyapatite controllable in nanometer size by adopting a hydrothermal method. The method comprises the steps of preparing water-soluble chitosan quaternary ammonium salt from 2,3-epoxypropyltrimethylammonium chloride modified chitosan, taking the chitosan quaternary ammonium salt as a template and adopting the hydrothermal method to prepare nanometer rod-shaped hydroxyapatite. The method solves the defects that the prior precipitation method, hydrothermal method, mechanochemical method, sol-gel method and the like are difficult to control crystal textures in nanometer size scale, uncontrollable in morphology and poor in mechanical properties and biocompatibility. The method has the advantages of preparing crystal-type hydroxyapatite which is pure, controllable in morphology and size and uniform in size positioned in a nanometer range, improving the mechanical properties and biocompatibility of the hydroxyapatite and enabling the hydroxyapatite to be used for preparing inorganic toughening / reinforcing biodegradable osseous-tissue bracket material, along with simplicity, convenient operation and low manufacture cost.

Owner:YANGZHOU UNIV

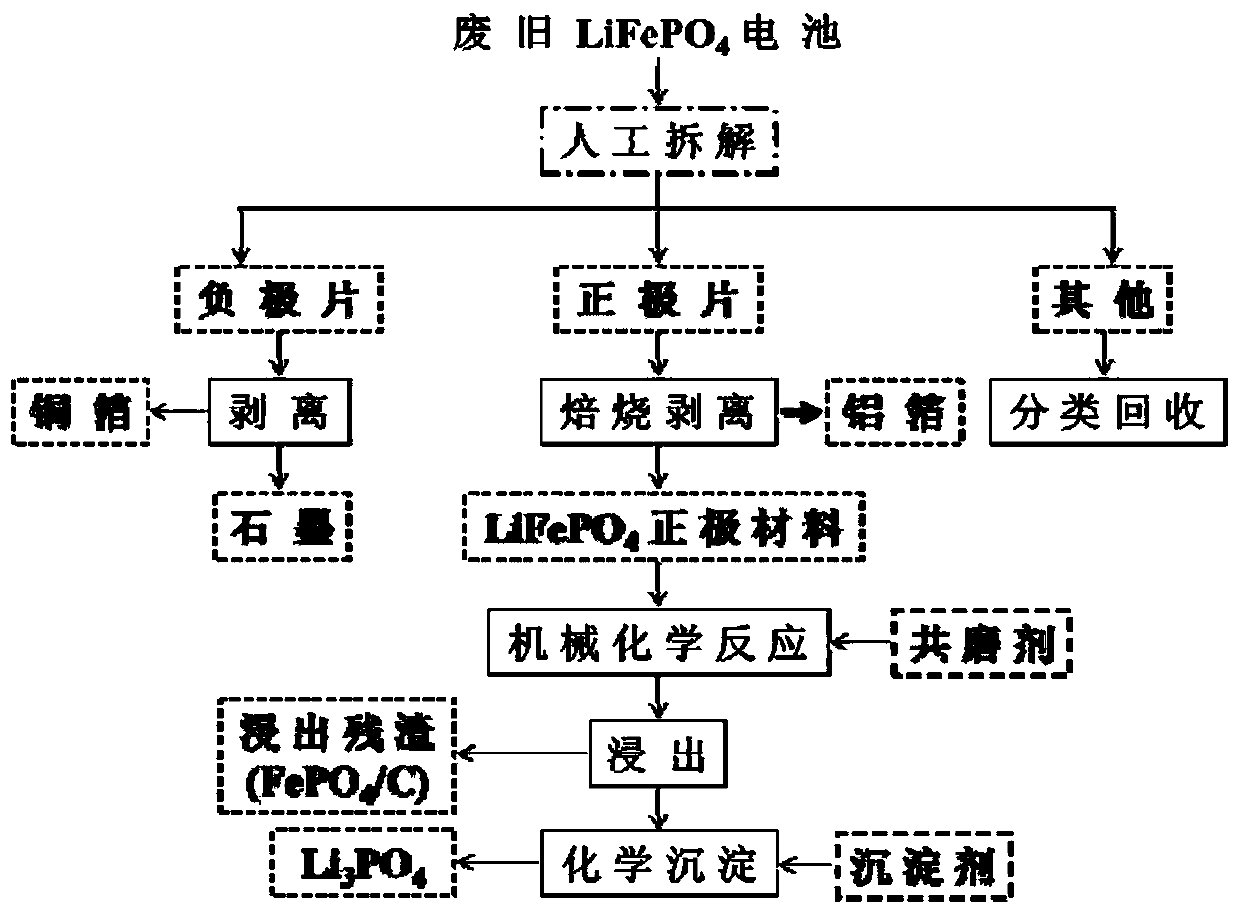

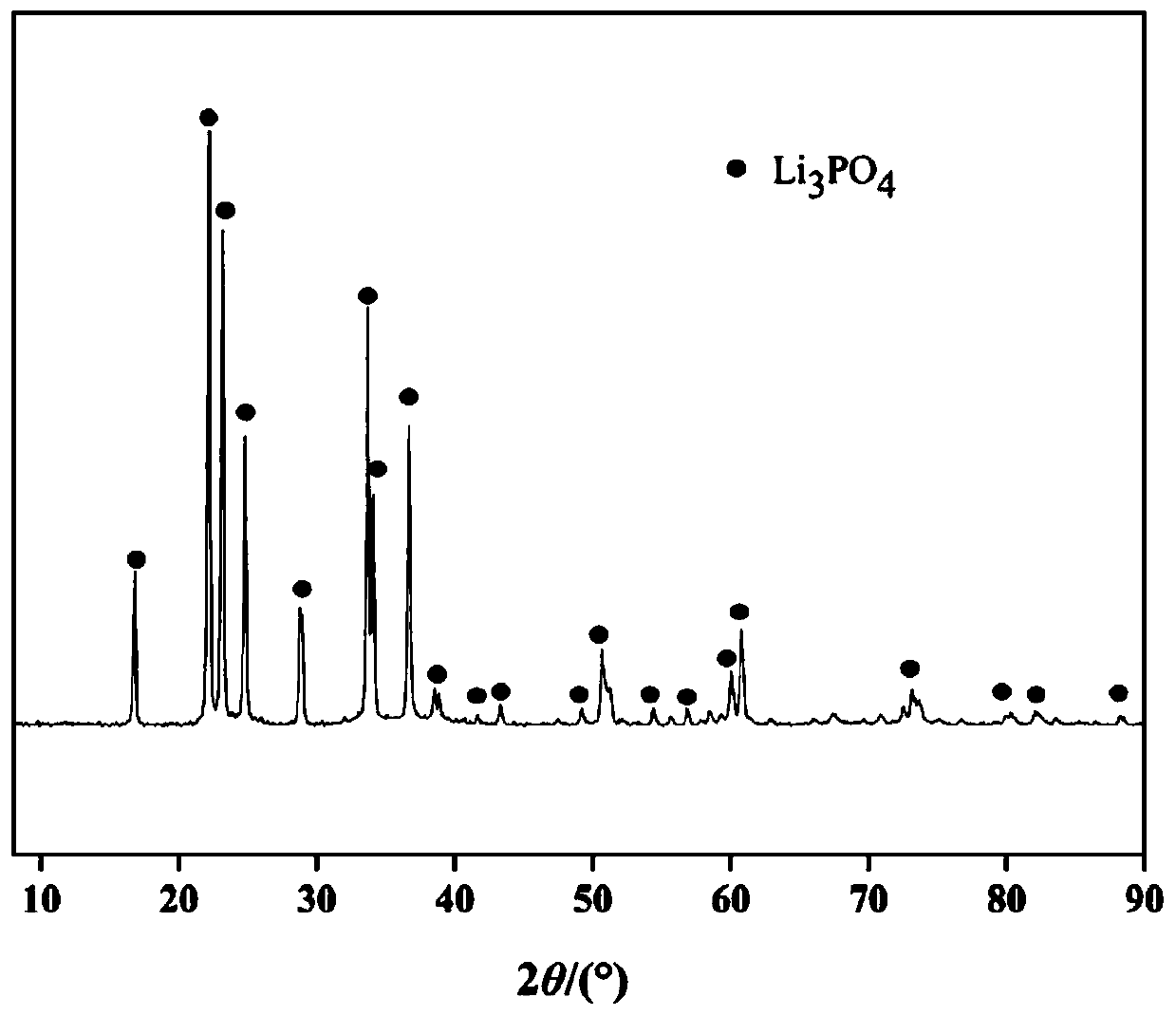

Process for selectively recovering lithium in waste lithium iron phosphate battery by means of mechanochemical activation method

InactiveCN110760682AAvoid lostNo pollutionWaste accumulators reclaimingProcess efficiency improvementLithium iron phosphateEnvironmental engineering

The invention provides a process for selectively recovering lithium in waste lithium iron phosphate battery by means of a mechanochemical activation method, and belongs to a new solid waste reclamation technology in the field of environmental protection and resource comprehensive utilization. According to the process, the core principle is to carry out mechanical activation in the first place, sothat an excellent activation effect can be achieved through adding an inter-grinding agent; and then a composite leaching agent is used for selectively leaching the lithium in a positive electrode material of an lithium iron phosphate battery into a solution, at the moment, lithium and iron are completely separated while iron and phosphorus, together with carbon powder, enter leaching residue in the form of iron phosphate precipitate, so that in-situ recovery of iron and phosphorus is achieved. The process has the characteristics of short flow, simple operation, low energy consumption, environmental friendliness, no secondary pollution and a wide application prospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Rare earth/tourmaline composite material, as well as preparation method and application thereof

InactiveCN103349961AImprove performanceIncrease profitOther chemical processesCombustible gas purificationRare-earth elementMulti pollutant

The invention relates to a rare earth / tourmaline composite material, as well as a preparation method and the application thereof, and aims to solve the difficult problem that quickly and efficiently removing various pollutants in water is difficult. The rare earth / tourmaline composite material is rare earth modified tourmaline obtained by adding tourmaline into a rare earth element solution with the concentration of 0.01-1.0 mol / L to be subjected to ultrasonic dispersion processing, and then performing stirring, solid-liquid separation as well as drying or calcining. The rare earth / tourmaline composite material provided by the invention has high mechanochemistry stability, has functions of composition, synergy and the like, can also reduce cost, improves the utilization ratio of the material, has the advantages of high adsorption speed, large capacity, wide applicable pH range, easiness in reutilization and the like, can improve operation efficiency and lower cost in the application of a water purification processing process, has a higher adsorption capacity, can realize sustainable use, and has high recycling rate and a good development prospect in the environmental field; the preparation process provided by the invention is simple; the modified tourmaline prepared according to the preparation process is good in dispersion.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Composite of metal oxide nanoparticles and carbon, method of production thereof, electrode and electrochemical element employing said composite

ActiveUS20130095384A1Promote crystallizationRapid heat treatmentMaterial nanotechnologyAlkali titanatesDispersityChemical reaction

A composite powder in which highly dispersed metal oxide nanoparticle precursors are supported on carbon is rapidly heated under nitrogen atmosphere, crystallization of metal oxide is allowed to progress, and highly dispersed metal oxide nanoparticles are supported by carbon. The metal oxide nanoparticle precursors and carbon nanoparticles supporting said precursors are prepared by a mechanochemical reaction that applies sheer stress and centrifugal force to a reactant in a rotating reactor. The rapid heating treatment in said nitrogen atmosphere is desirably heating to 400° C.-1000° C. By further crushing the heated composite, its aggregation is eliminated and the dispersity of metal oxide nanoparticles is made more uniform. Examples of a metal oxide that can be used are manganese oxide, lithium iron phosphate, and lithium titanate. Carbons that can be used are carbon nanofiber and Ketjen Black.

Owner:NIPPON CHIMI CON CORP

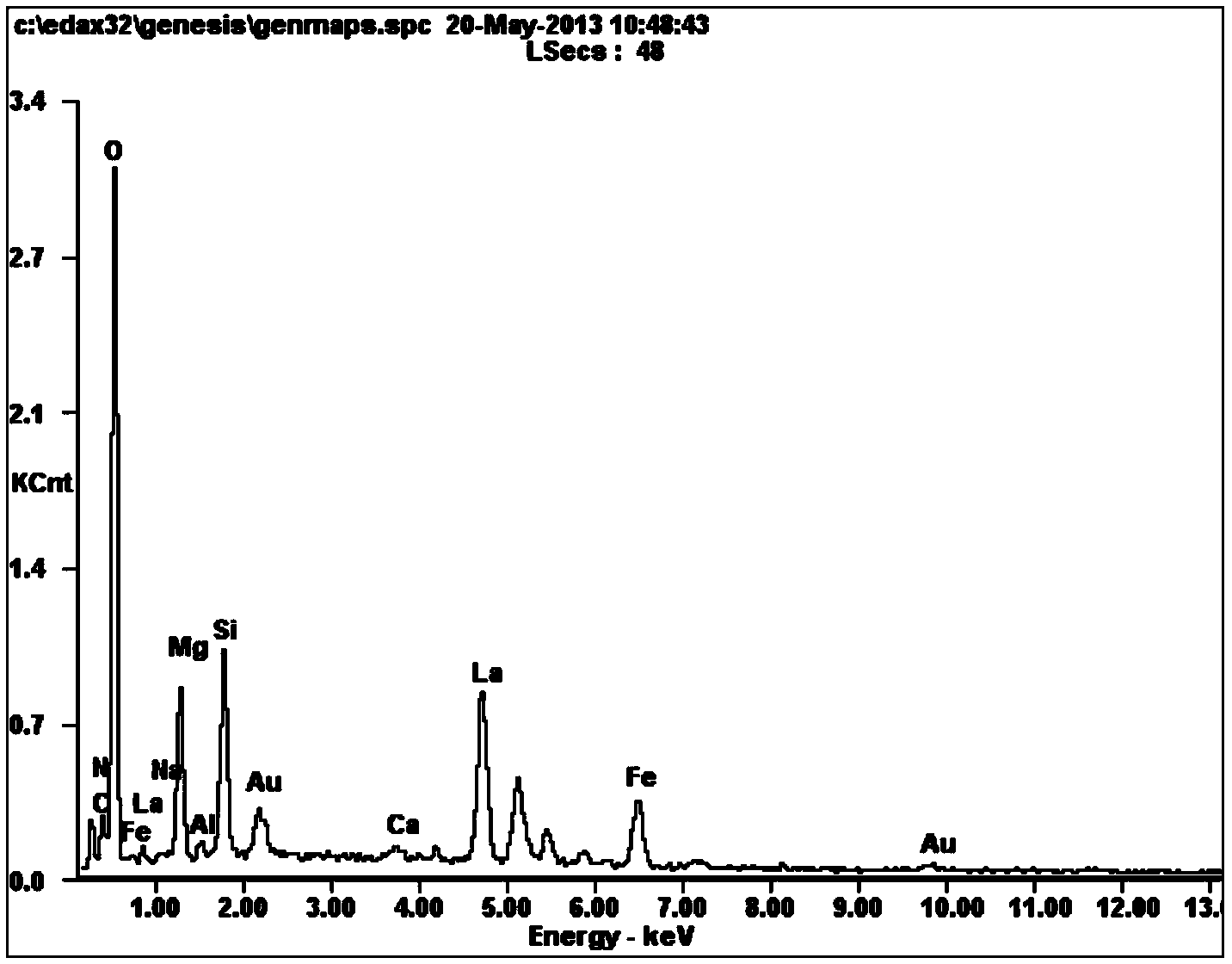

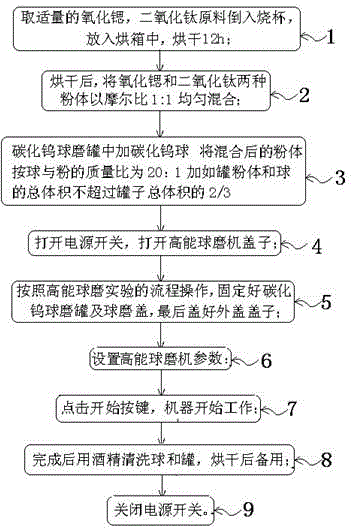

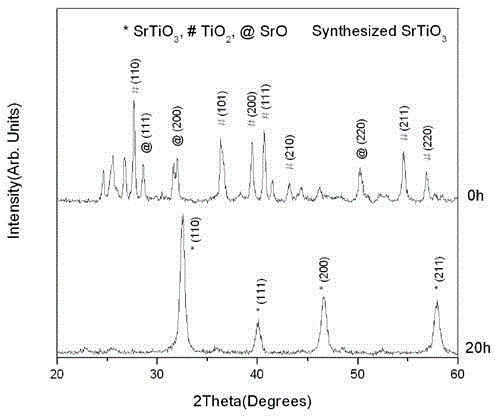

Technology for synthesizing SrTiO3 nano-powder through mechanochemical method

ActiveCN103601235AImprove uniformityImprove consistencyMaterial nanotechnologyTitanium compoundsPowder mixtureHigh energy

The invention relates to a technology for synthesizing SrTiO3 nano-powder through a mechanochemical method. The technology at least comprises the following steps: 1, taking a proper amount of each of strontium oxide and titanium dioxide raw materials, respectively dumping the raw materials into beakers, putting the beakers in an oven, and drying for 12h; 3, uniformly mixing the above two powders with a molar ratio of 1:1; 3, adding the above obtained powder mixture and tungsten carbide balls to a pot, wherein the total volume of the powder mixture and the tungsten carbide balls does not exceed 2 / 3 of the total volume of the pot, and a mass ratio of the powder mixture to the tungsten carbide balls is 20:1; 4, turning on a power switch, and uncovering the cover of a high-energy ball mill; 5, operating according to the flow of a high-energy ball milling experiment; 6, setting parameters comprising a rotating speed of 200rpm and a cycle period of 30min; 7, clicking a start button for the working starting of the ball mill; 8, uncovering the cover of the high-energy ball mill and the cover of the ball milling pot 24h later, sampling, cleaning the ball milling pot with alcohol, and drying for later use; and 7, turning off the power switch. The SrTiO3 nano-powder synthesized in the invention has the characteristics of low energy consumption, high purity, small particle size, high automation degree, good quality consistency and repetitiveness, less pollutant emission and the like.

Owner:XIDIAN UNIV

Recovery method for waste lithium ion battery anode materials based on mechano-chemical method

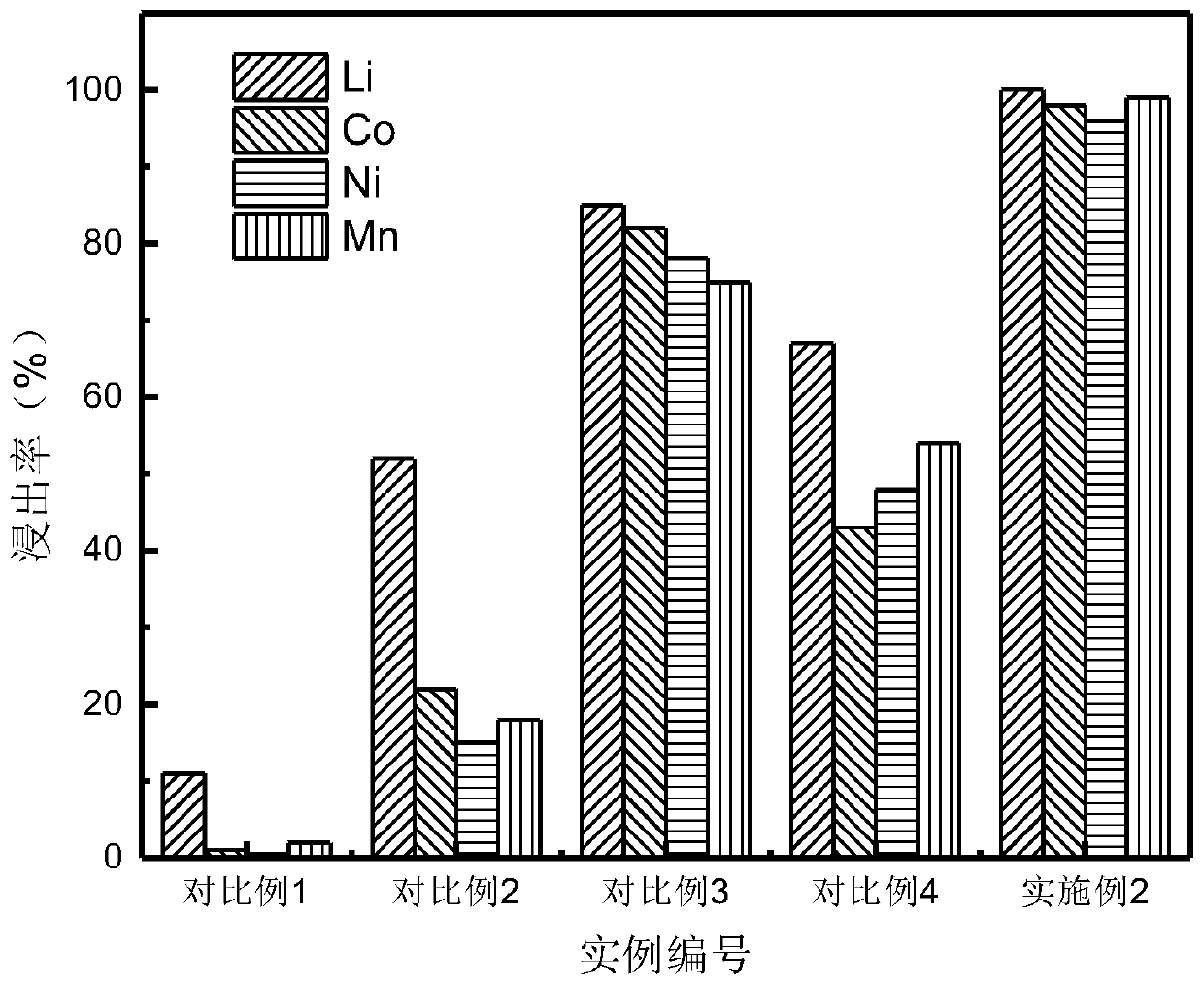

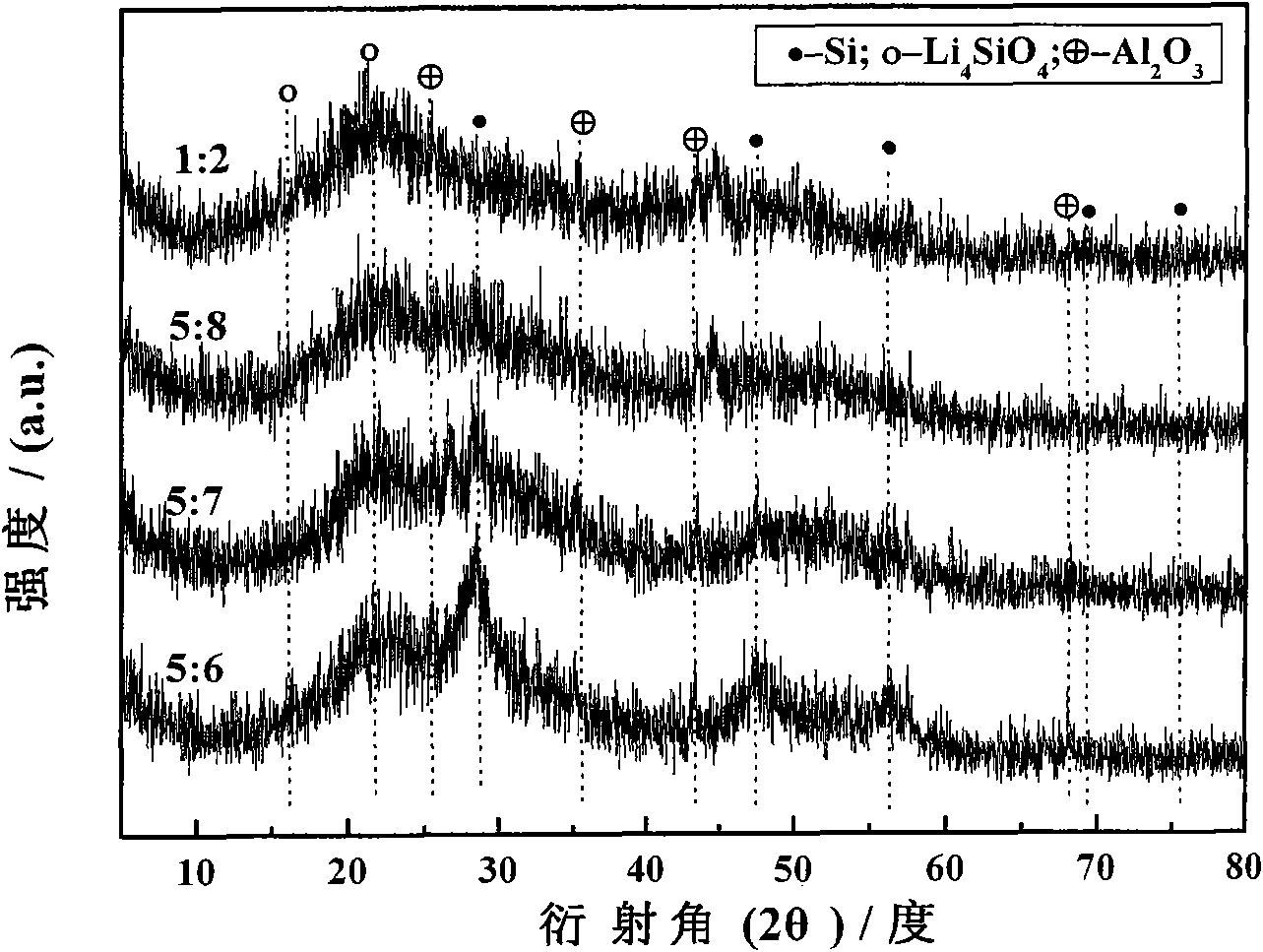

ActiveCN110791652AEfficient leachingHazard reductionWaste accumulators reclaimingProcess efficiency improvementMetallic lithiumChemical reaction

The invention discloses a recovery method for waste lithium ion battery anode materials based on a mechano-chemical method, and belongs to the field of waste lithium ion battery recycling. The waste lithium ion battery anode materials are ground into powder, the powder is sufficiently and evenly mixed with an activating agent and an organic reducing agent, the activating agent can generate activefree radicals, a mixture is obtained, the mixture is subjected to ball grinding, the waste lithium ion battery anode materials generate plastic deformation, lattice imperfection is generated in crystal particles, and the crystal particles generate crystal transfer or are not crystallized; and products obtained after ball grinding are added into deionized water, and valuable metal ions are leached.The method does not depend on high-concentration strong acid, strong base, strong oxidization reducing reagents, expensive organic acid and the like, the mechano-chemical reaction in a solid phase isadopted as a reaction body, and efficient leaching of valuable metal lithium, cobalt, nickel, manganese and the like in the waste lithium ion battery anode materials is achieved under the mild leaching environment.

Owner:HUAZHONG UNIV OF SCI & TECH

Mechanochemical reduction remediation method for hexavalent chromium polluted soil

ActiveCN107297386AImprove stabilityEfficient Green Restoration Treatment MethodContaminated soil reclamationSoil treatmentBall mill

The invention belongs to the technical field of heavy metal polluted soil treatment and in particular relates to a mechanochemical reduction remediation method for hexavalent chromium polluted soil. The method disclosed by the invention comprises the following steps: grinding naturally aired hexavalent chromium polluted soil in a mortar, sieving, carrying out a mechanochemical reaction on the sieved soil particles, reducing agents (such as ferrous sulfate, calcium polysulfides and the like) and zirconia in a ball mill tank according to a ratio, and transforming hexavalent chromium with high toxicity, easiness in migration and high bio-availability into trivalent chromium with low toxicity, easiness in precipitation and low bio-availability by virtue of mechanochemical reduction, thereby realizing harmless treatment of the hexavalent chromium polluted soil. The method disclosed by the invention has the characteristics of being high-efficiency, green and zero in secondary pollution and is a hexavalent chromium polluted soil remediation method with excellent application prospects.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY +1

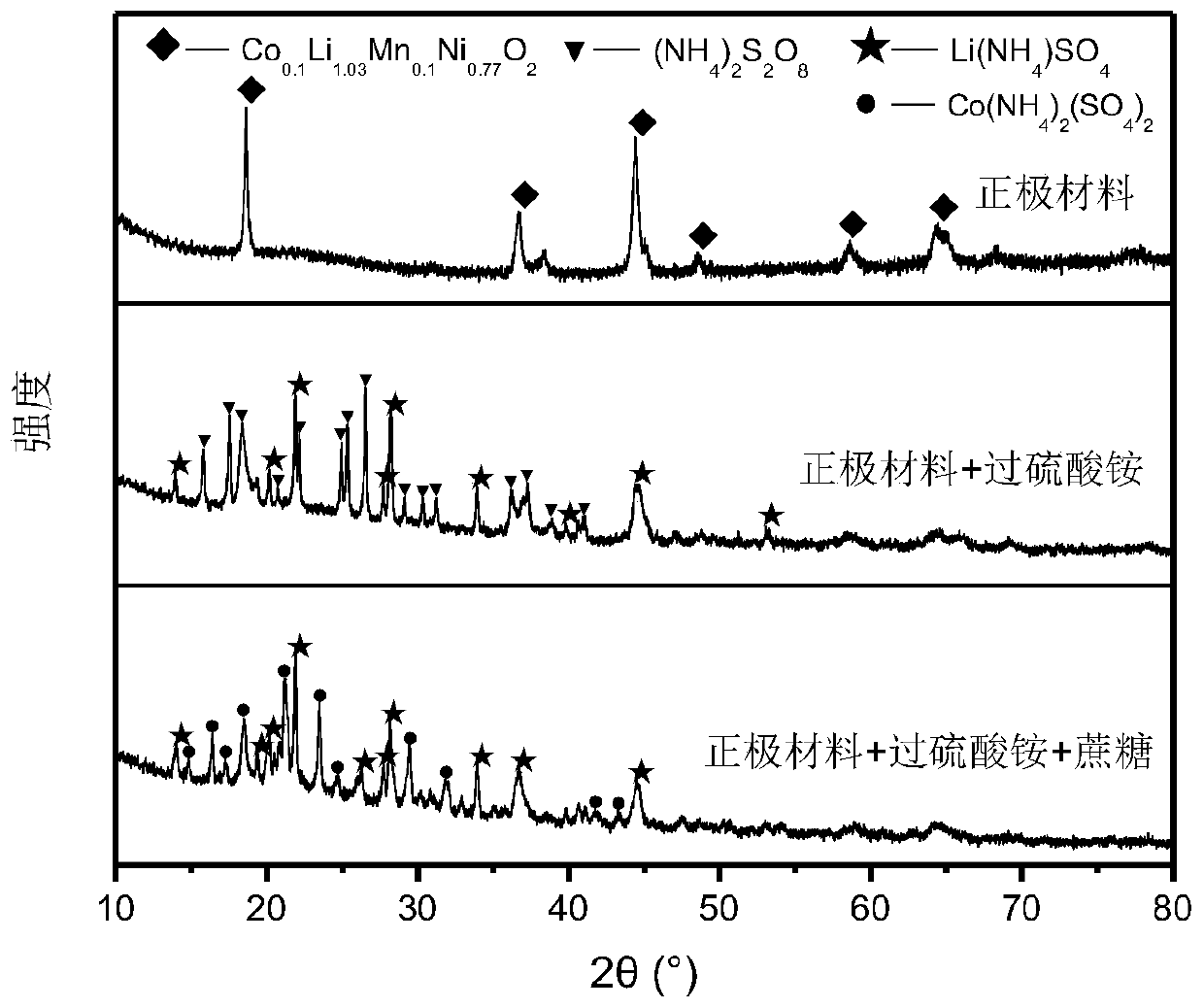

Mechanochemistry recycling method of waste lithium battery cathode material

ActiveCN105304971ANothing producedNo secondary pollutionWaste accumulators reclaimingLi-accumulatorsSolid reactionStrong acids

The invention discloses a method of treating a waste lithium battery by adopting a mechanochemistry method, selectively recycling metal lithium and meanwhile directionally preparing a cobalt-based magnetic functional material, belonging to a new technology of treating solid wastes in the field of environmental protection and comprehensive utilization of resources. The method particularly comprises five procedures of discharging, splitting, ball milling, lithium recycling and calcining. The method is characterized in that a dry ball milling mode is adopted, so that materials and an assistant generate a solid phase reaction and no waste liquid is produced; by controlling the reaction process, the metal lithium is selectively recycled, and a magnetic material is directionally synthetized from metal cobalt. The method is simple and convenient to operate, low in cost, high in recovery rate, and mild in reaction condition, the assistant is cheap and easy to get, a prepared cobalt ferrite is excellent in magnetism, strong acids and strong oxidizers are not used all the way, and the method is a green and environment-friendly waste lithium battery recycling method.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Non-fischer-tropsch process for gas-to-liquid conversion using mechanochemistry

InactiveUS20140275687A1Preparation by oxidation reactionsRefining by heating/coolingThermal energyHigh carbon

A novel production process is disclosed for the conversion of methane or natural gas, particularly shale gas, into a liquid fuel near the point of origin. The process is notably “non-Fischer-Tropsch” meaning that it does not require oxygen to be admitted into the reactor for supplying thermal energy by partial combustion, which is normally required to split methane. This freedom from high temperature operation and the other demands of an oxygenation process means that higher carbon efficiency is achievable This is made possible with mechanochemistry and “sonic catalysis” that employ kinetic energy to promote the breakdown of methane molecules, the reformation of the resulting carbon-hydrogen fragments, and the rejuvenation of the catalyst surface. A number of liquid fuels can be produced which are easily transported and fully marketable without further processing. Within the range of output products is a liquid solvent which can be used as a substitute “fracking” fluid, which is recoverable as recycled feedstock for further conversion—thus eliminating the problem of water treatment. The reactor can be made more compact, lighter, modular, skid-mounted and fully transportable to the well-head where the gas-to-liquid conversion process reduces the release of natural gas and enables the monetization of stranded or flared gas.

Owner:BEENE JONES +1

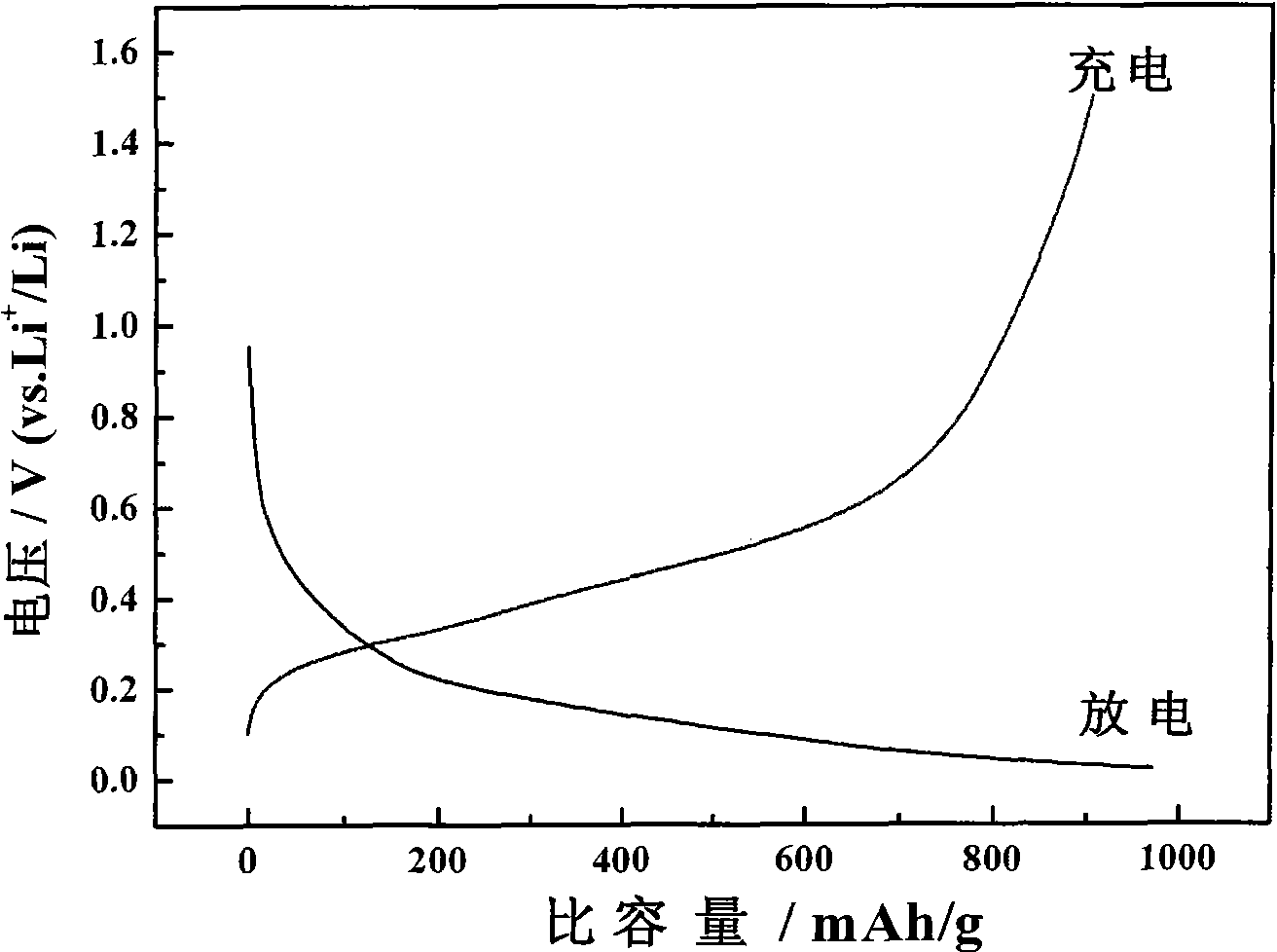

Composite cathode material for lithium ion battery and preparation method thereof

ActiveCN101789506ASimple preparation processEasy to operateElectrode manufacturing processesSource fieldSodium-ion battery

The invention relates to composite cathode material for a lithium ion battery and a preparation method thereof, belonging to the chemical power source field. The invention aims to solve the problems that the first lithium ion insertion process of oxide cathode material performs an irreversible reaction, the first coulombic efficiency is low, etc. The preparation method comprises the following steps: using precursor MO, reducing agent metal lithium and a defined amount of organic solvent to perform wet mechanochemical in situ reduction and obtain power, heating the obtained power under vacuum atmosphere to remove organic solvent, and obtaining the composite material. The method of the invention has simple process, low cost and wide application range; and the first efficiency of the prepared composite cathode material is more than 80%, the maximum is more than 95%, and the composite cathode material also has good electrochemical cycle stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

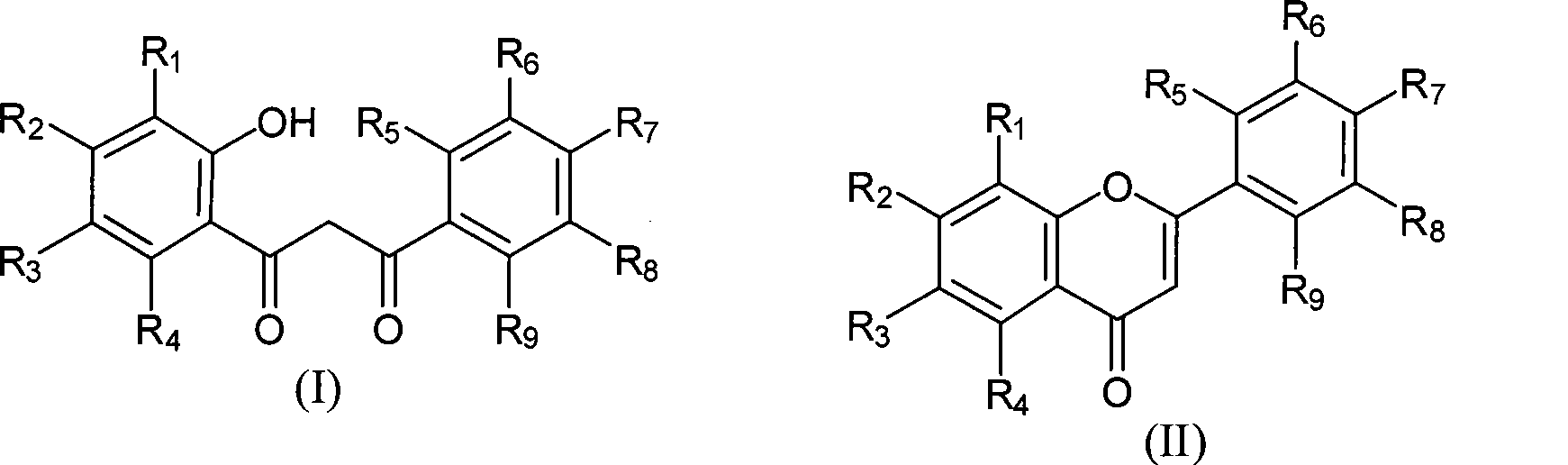

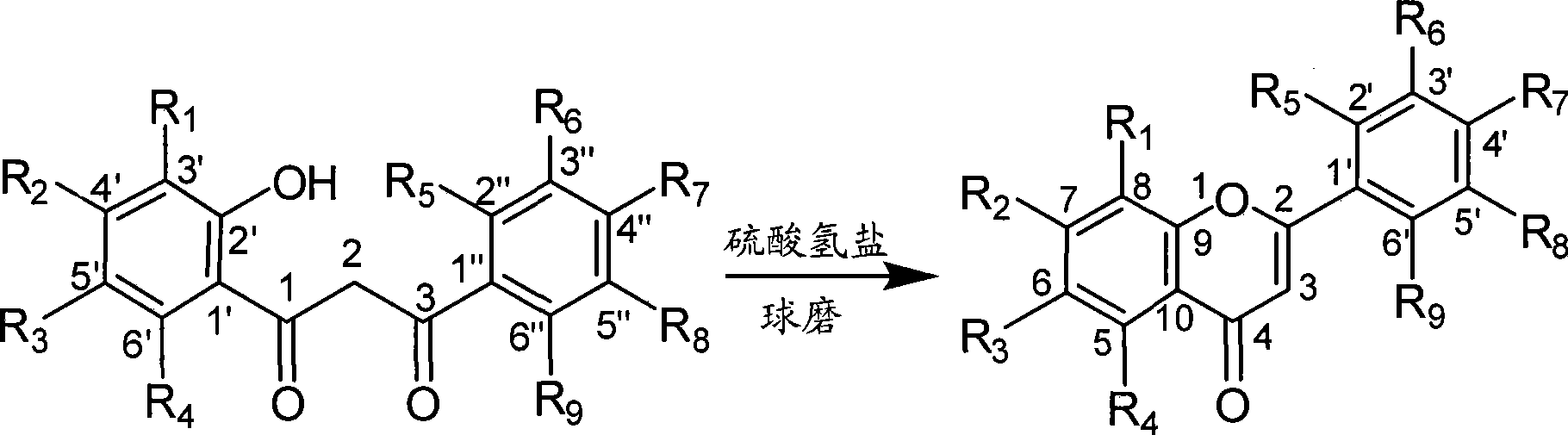

Mechanochemical preparation of flavonoid

The invention discloses a mechanochemical preparation method for flavone compounds with a structure shown in a formula (II), which comprises the following steps: 1-(2'-hydroxy phenyl)-3-aryl-1, 3-propanedione with a structure shown in a formula (I) is taken as a raw material, hydrosulfate is taken as a catalyst, and silica gel is taken as a grinding aid to perform a ball grinding reaction in a closed ball grinding tank; and after the reaction is finished, a reaction mixture is separated and purified to obtain the flavone compounds with the structure shown in the formula (II). The method has the advantages of short reaction time, generally higher reaction yield, safe and reliable production, low production cost, simple post-treatment, small pollution and so on, and is the preparation method for the flavone compounds with better popularization and application prospects.

Owner:ZHEJIANG UNIV OF TECH

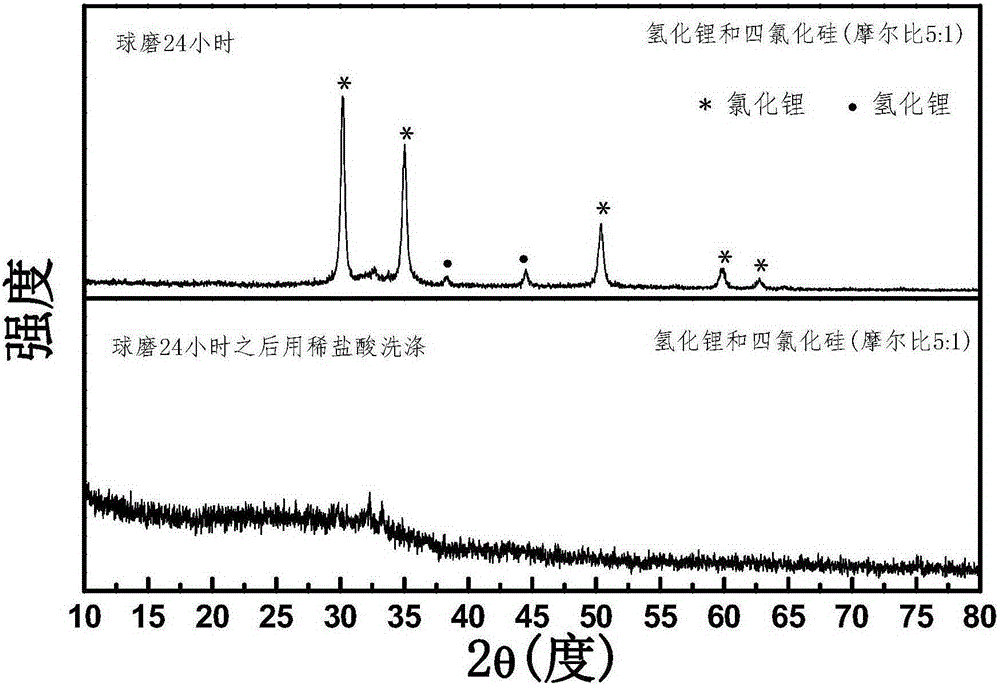

Method for preparing silica powder through mechanical chemical method

ActiveCN105271238AEasy to collect and useRational use of resourcesSilicon compoundsRoom temperatureSilicon

The invention discloses a method for preparing silica powder through a mechanical chemical method. The method includes the following steps that 1, silicon halide, metal hydride and grinding balls are added into a ball-milling tank in protecting atmosphere, and then the ball-milling tank is sealed, wherein the molar ratio of the silicon halide to the metal hydride is 1:2-1:6; 2, a ball-milling reaction is carried out on the silicon halide and the metal hydride under the conditions of the room temperature and the 100-rpm-to-500-rpm ball-milling rotating speed in the sealed ball-milling tank, and the ball-milling time is 1 h to 24 h; 3, after the ball-milling reaction is completed, hydrogen in the ball-milling tank is collected, and then powder in the ball-milling tank is taken out; 4, the powder is subjected to acid pickling and then washed till washing liquid is neutral; 5, the washed powder is dried and cooled, and the simple-substance silica powder is obtained. The method for preparing the silica powder has the advantages of being simple in technology, efficient and nontoxic, and facilitating industrialization implementing.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com