Mechanochemical preparation of flavonoid

A technology of flavonoids and mechanochemistry, applied in the direction of organic chemistry, can solve problems in the research and exploration stage, and achieve the effects of shortening reaction time, low production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

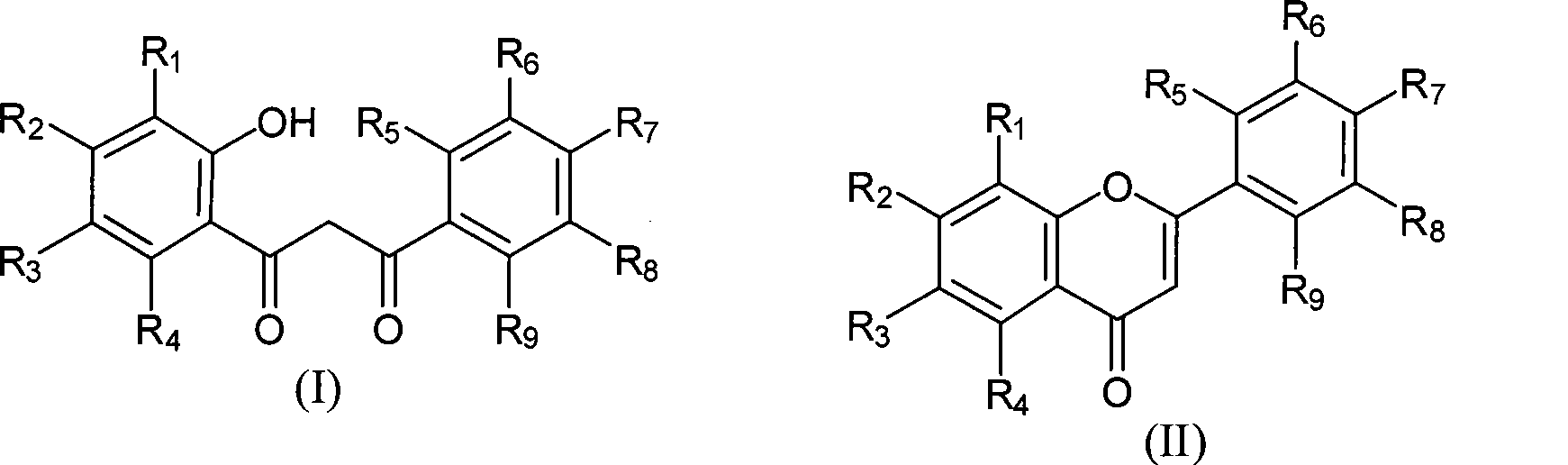

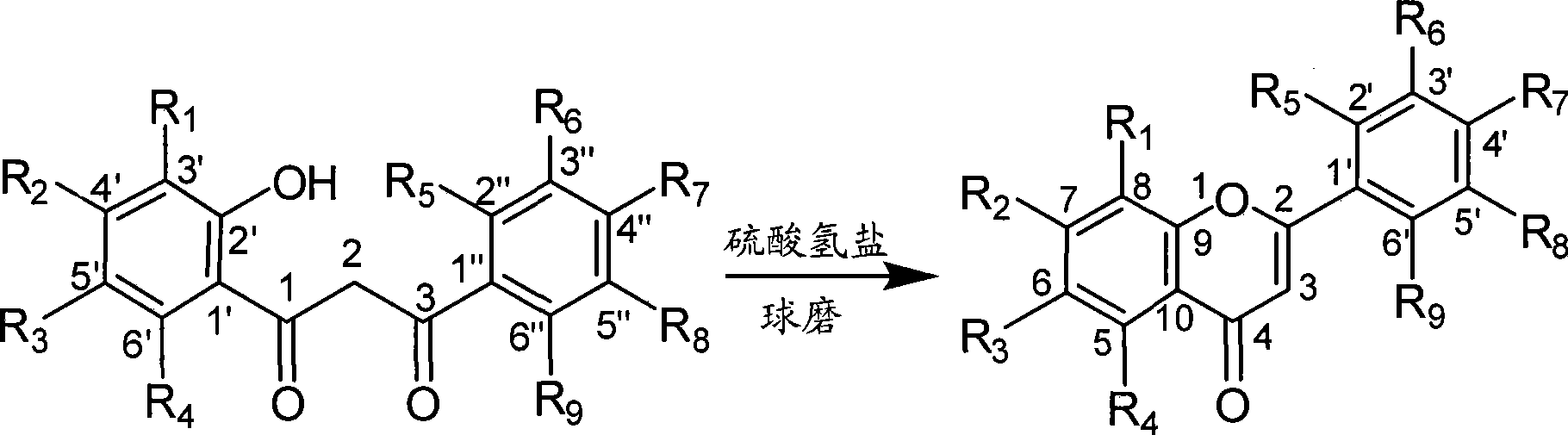

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of flavone

[0024] Add 1-(2′-hydroxyphenyl)-3-phenyl-1,3-propanedione (2.40 g, 10 mmol), potassium bisulfate (0.07 g, 0.5 mmol) and silica gel (12 g ), then add grinding balls, and tighten the jar lid. The ball mill jar was put into a ball mill and operated at a rotational speed of 1290 rpm to allow the mixture to react for 5 minutes, and TLC (sample was dissolved in DMF) was used to track the progress of the reaction. After the reaction, the reaction mixture was washed with hot absolute ethanol and filtered. The filtrate was boiled to evaporate part of the ethanol to saturation, cooled to room temperature, and the solid was precipitated and dried to obtain 2.02 g of flavones with a yield of 90%.

[0025] White solid, mp: 96-97°C. 1 H NMR (400MHz, CDCl3): δ=8.24(d, J=8.0Hz, 1H, ArH), 7.94(d, J=8.0Hz, 2H, ArH), 7.71(t, J=8.0Hz, 1H, ArH ), 7.53-7.60 (m, 4H, ArH), 7.43 (t, J=8.0Hz, 1H, ArH), 6.86 (s, 1H, CH). 13 C NMR (100MHz, CDCl 3 ): ...

Embodiment 2

[0026] Embodiment 2: the preparation of flavone

[0027] Add 1-(2'-hydroxyphenyl)-3-phenyl-1,3-propanedione (2.40g, 10mmol), potassium hydrogensulfate (0.14g, 1mmol) and silica gel (12g) into a 75mL ball mill jar , then add the grinding balls, and tighten the jar lid. The ball mill jar was put into a ball mill and operated at a rotational speed of 1290 rpm to allow the mixture to react for 5 minutes, and TLC (sample was dissolved in DMF) was used to track the progress of the reaction. The separation and purification steps are the same as in Example 1 to obtain 2.04 g of flavonoids with a yield of 91%, and the physical data are the same as in Example 1.

Embodiment 3

[0028] Embodiment 3: the preparation of flavone

[0029] Add 1-(2'-hydroxyphenyl)-3-phenyl-1,3-propanedione (2.40g, 10mmol), potassium hydrogensulfate (0.27g, 2mmol) and silica gel (24g) into a 75mL ball mill jar , then add the grinding balls, and tighten the jar lid. The ball mill jar was put into a ball mill and operated at a rotational speed of 1290 rpm to allow the mixture to react for 5 minutes, and TLC (sample was dissolved in DMF) was used to track the progress of the reaction. The separation and purification steps are the same as in Example 1 to obtain 2.09 g of flavonoids with a yield of 93%, and the physical property data are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com