Fast organic pollutant removing method based on vulcanized zero-valence-iron-activated hydrogen peroxide

A technology of organic pollutants and zero-valent iron, applied in water pollutants, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve reagent consumption and iron sludge production, reduce iron sludge generation, and use efficiency Low-level problems, to achieve the effect of improving electron transfer efficiency, reducing difficulty, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A. Preparation of zero-valent iron sulfide

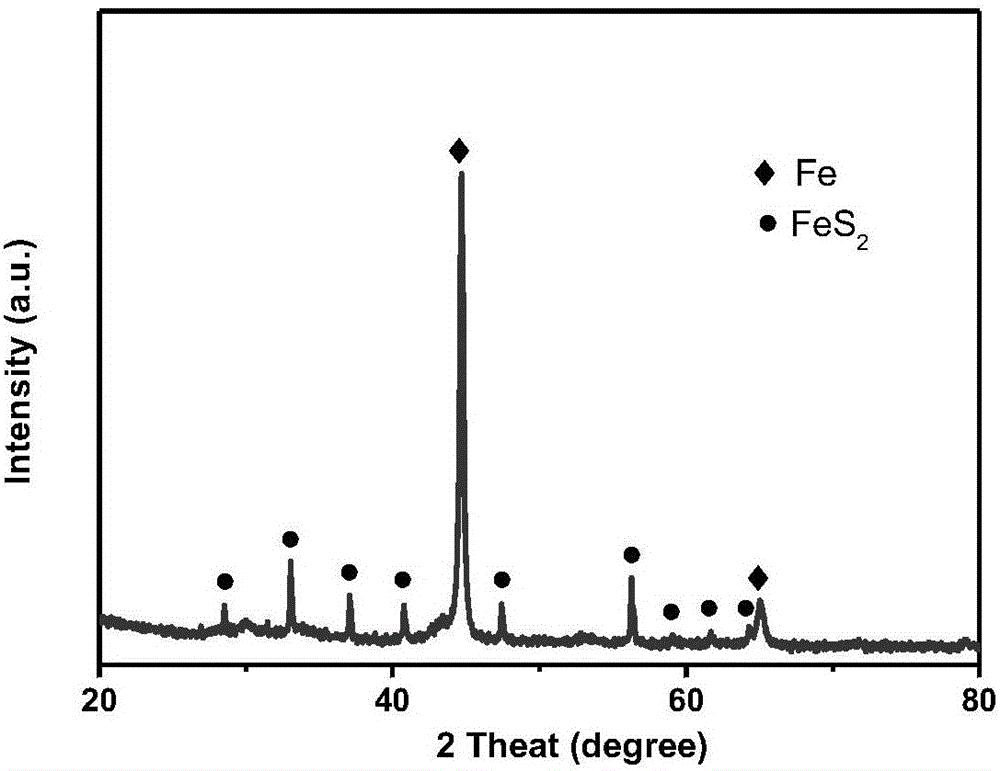

[0033]100g of reduced iron powder (20 mesh, purchased from Nanjing Best Metal Materials Co., Ltd.) and 10g of pyrite (100 mesh, purchased from Luoyang Weixiang Abrasives Co., Ltd.) were uniformly mixed, and a mortar grinder (FRITSCH, PULVERISETTE 2) Grinding for 24 hours at a speed of 80rpm, so that FeS in pyrite 2 Coated in Fe 0 On the surface, the obtained particle size is 200-5000 mesh zero-valent iron sulfide powder, which is characterized by XRD, see figure 1 , the results show that the sulfide zero-valent iron powder is FeS 2 / Fe 0 Complex crystal structure.

[0034] B. Removal of organic pollutants

[0035] The polluted medium to be treated is water polluted by phenol and p-chlorophenol, pH=6.7, COD=1320mg / L, and the concentration of phenol is 420mg / L and p-chlorophenol is 126mg / L measured by ultraviolet spectrophotometry, in 100L waste water Add 75g of zero-valent iron sulfide powder and 360mL of 30% hydrogen pe...

Embodiment 2

[0037] A. Preparation of zero-valent iron sulfide

[0038] Mix 300g of reduced iron powder (40 mesh, purchased from Nanjing Best Metal Material Co., Ltd.) with 50g of pyrite (200 mesh, purchased from Tongling Heer Mineral Products Co., Ltd.), and use a disc grinder (FRITSCH, PULVERISETTE 13) Grinding for 16 hours, the rotating speed is 440rpm, so that FeS in pyrite 2 Coated in Fe 0 On the surface, obtain zero-valent iron sulfide powder with a particle size of 400-8000 meshes to obtain FeS 2 / Fe 0 Composite crystal form of zero-valent iron sulfide powder.

[0039] B. Removal of organic pollutants

[0040] The polluted medium to be treated is dye-contaminated water, pH=8.2, COD=3450mg / L, the concentration of methyl orange is 1380mg / L, and the concentration of orange G is 560mg / L by ultraviolet spectrophotometry. Add 240g of sulfide to 100L of waste water Zero-valent iron powder and 960mL 30% hydrogen peroxide constitute a reaction system. After mixing and reacting at room t...

Embodiment 3

[0042] A. Preparation of zero-valent iron sulfide

[0043] Mix 60 g of reduced iron powder (60 mesh, purchased from Hangzhou Fangsheng Chemical Co., Ltd.) with 5 g of pyrite (325 mesh, purchased from Foshan Perete Mineral Raw Materials Co., Ltd.), and use a vibrating cup mill (FRITSCH, PULVERISETTE 9) Grinding for 12 hours, the rotating speed is 1200rpm, so that FeS in pyrite 2 Coated in Fe 0 On the surface, obtain zero-valent iron sulfide powder with a particle size of 800-12500 mesh, and obtain FeS 2 / Fe 0 Composite crystal form of zero-valent iron sulfide powder.

[0044] B. Removal of organic pollutants

[0045] The polluted medium to be treated is a water body polluted by nitrobenzene, pH=5.5, COD=680mg / L, and the concentration of nitrobenzene measured by high performance liquid chromatography is 270mg / L, and 30g of sulfide zerovalent iron powder and 150mL of 30% hydrogen peroxide constituted the reaction system. After mixing and reacting at room temperature for 12 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com