Powder type white emulsion and preparation method thereof

A white latex and powder technology, applied in adhesives, adhesive types, starch adhesives, etc., can solve the problems of formaldehyde residue, unstable storage, high production cost, low production cost, stable storage, and reduced packaging. The effect of shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

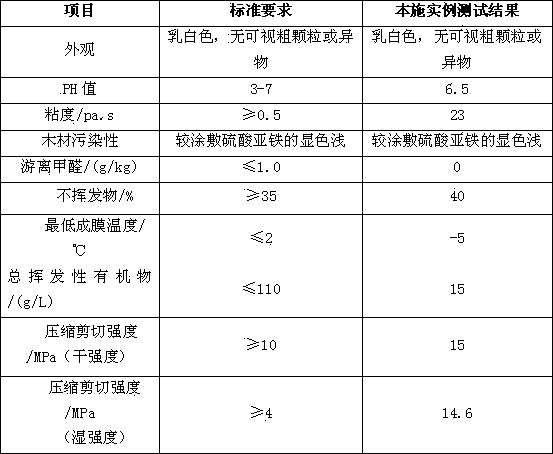

Embodiment 1

[0038] 1) Add 65 parts by weight of plantain taro raw starch with 75% linear structure, 15 parts by weight of polyurethane-acrylate rubber powder, and 0.5 parts by weight of medium-temperature α-amylase into the double-cone mixer. Stir and activate for 30 minutes at temperature and speed of 200 rpm;

[0039] 2) Add 2 parts by weight of sodium tripolyphosphate, 1 part by weight of citric acid, and 5 parts by weight of polyethylene oxide (molecular weight: 80,000) into step 1), and stir at a high speed of 500 rpm for 5 minutes to obtain pre-reaction materials;

[0040] 3) Send the pre-reactant obtained in step 2) into a high-speed rotary impact machine, use a water bath to control the temperature at 50-80°C, and perform a cross-linking reaction for 10 minutes at a rotary speed of 1200 rpm;

[0041] 4) Add 3 parts by weight of calcium sulfate and 0.5 parts by weight of polysilane-based defoamer to step 3), continue to react for 2 minutes and discharge to obtain powder-type white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com