Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Stable wind pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

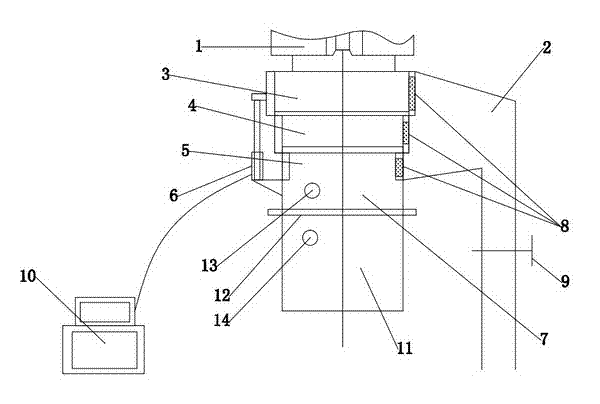

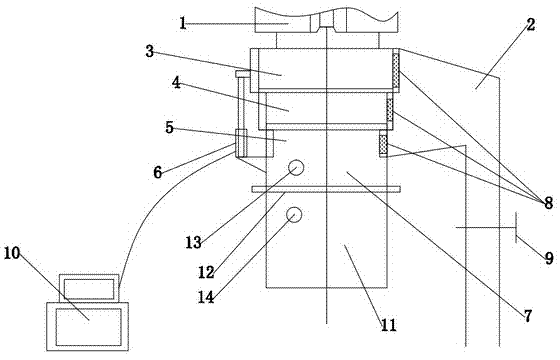

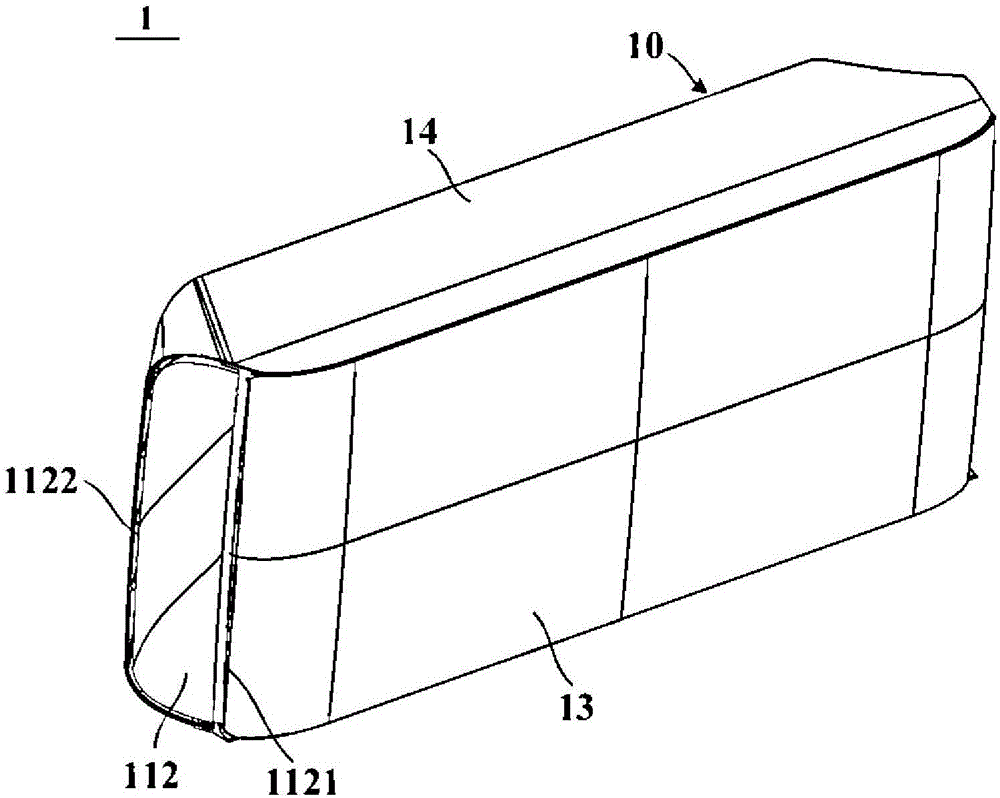

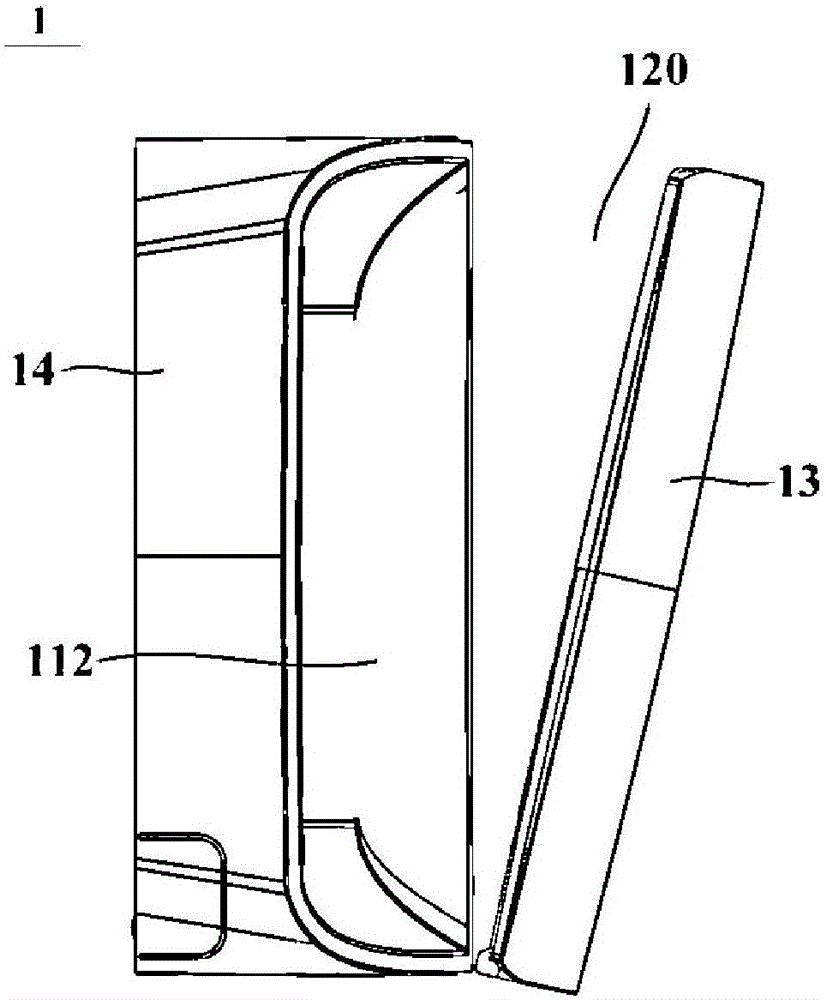

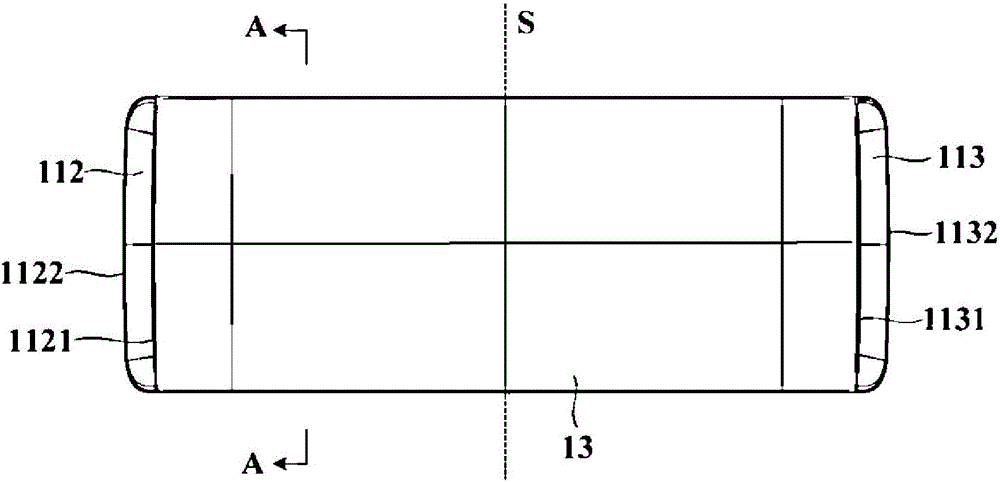

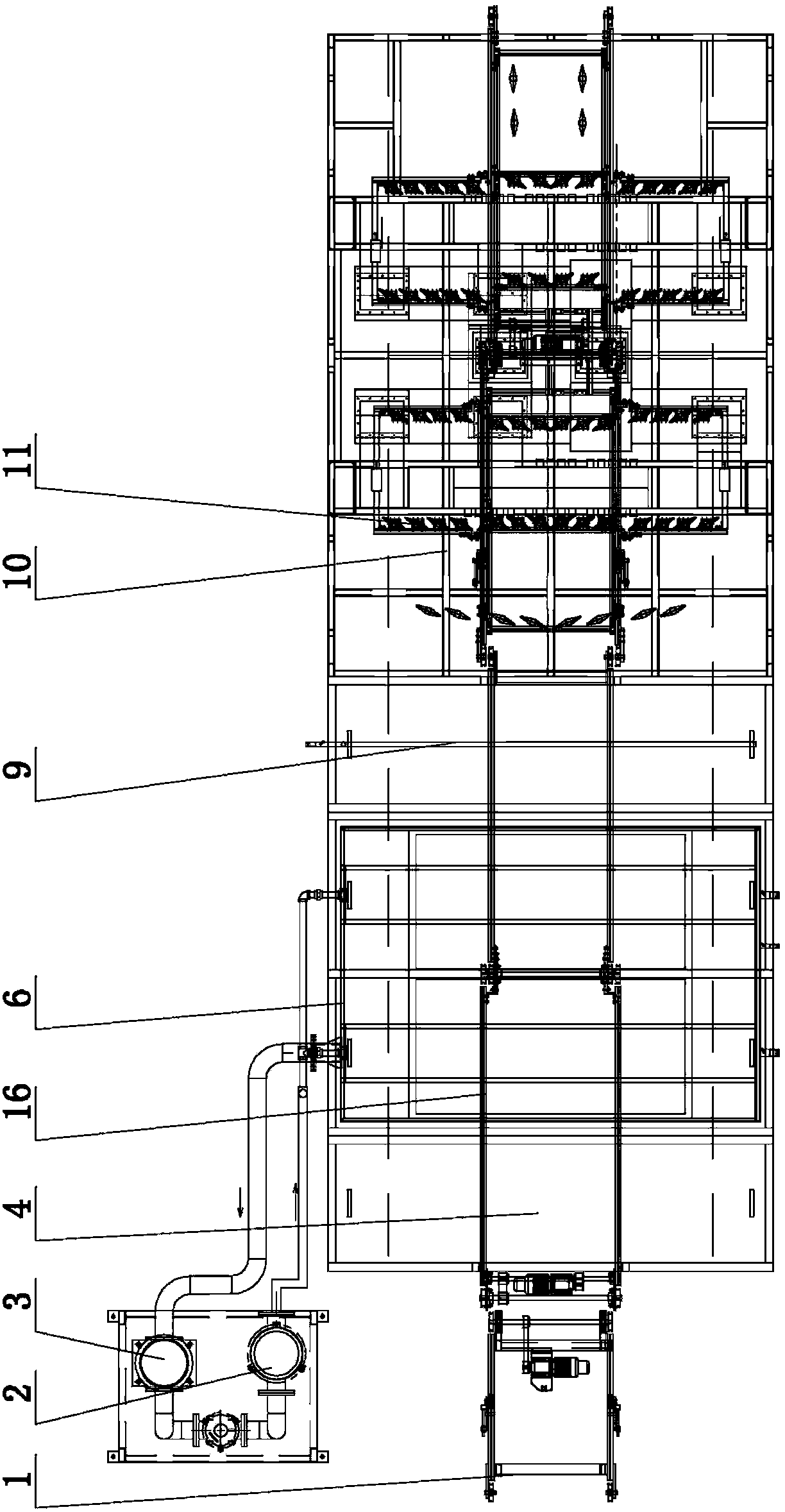

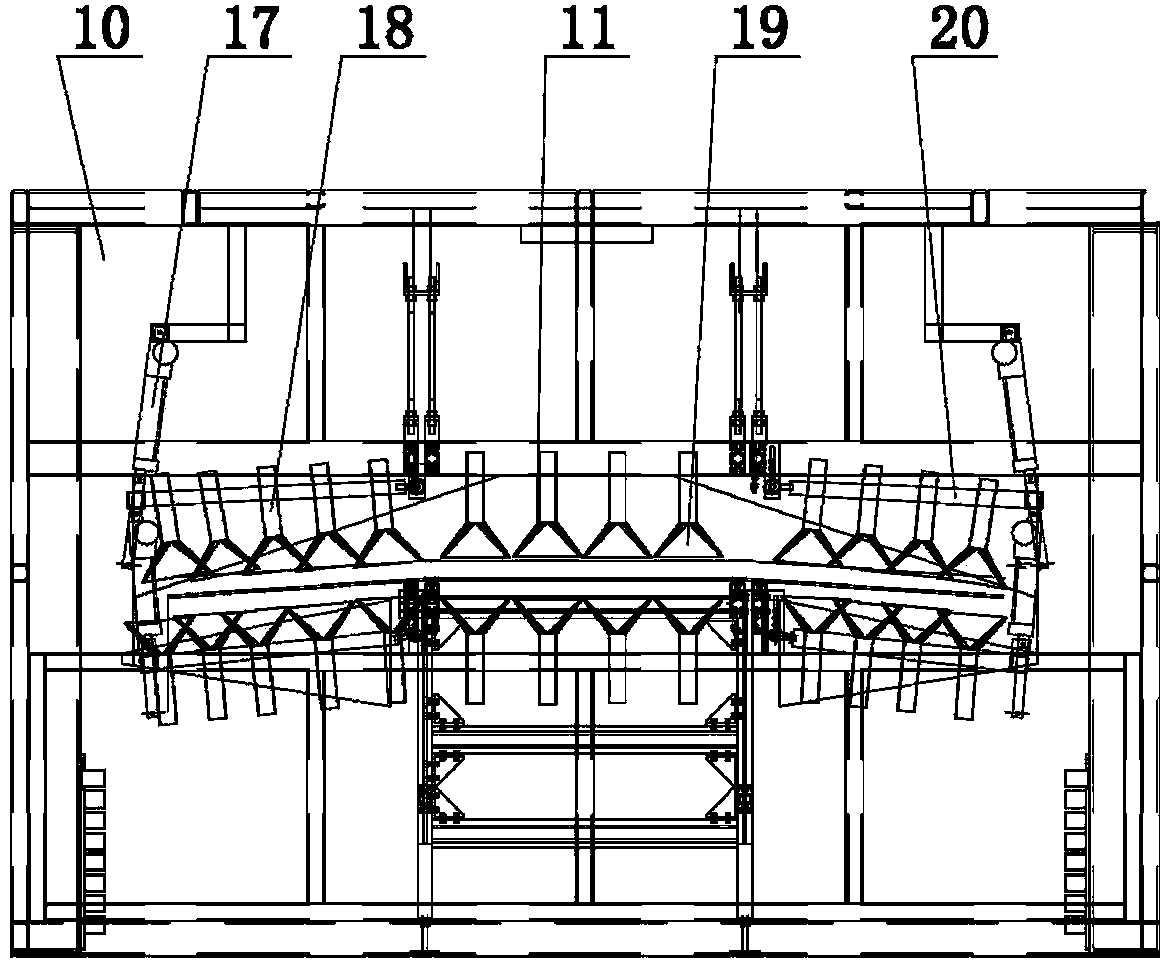

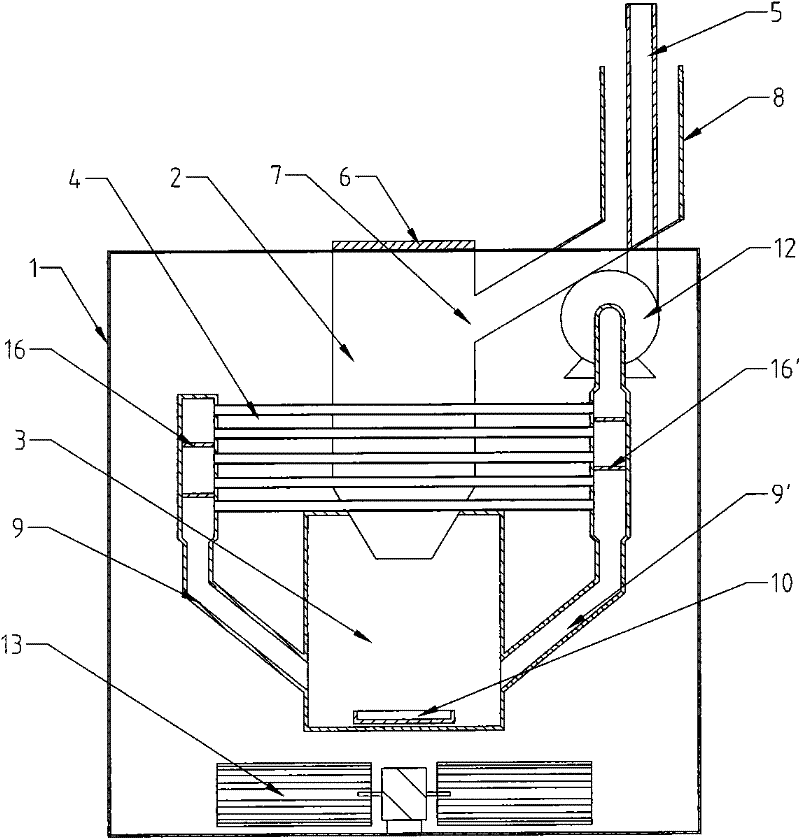

Adjustable circular air blow cooling system

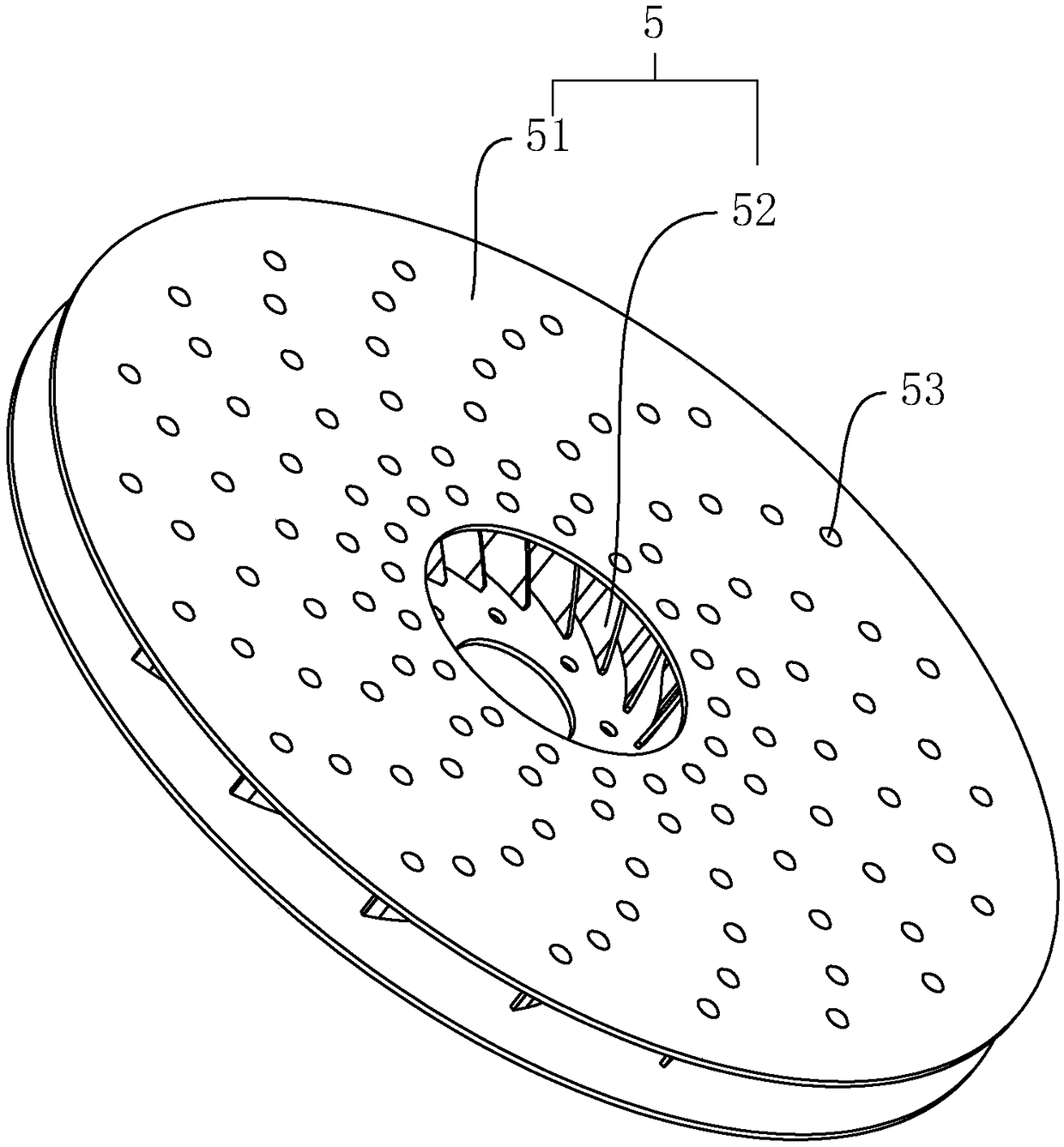

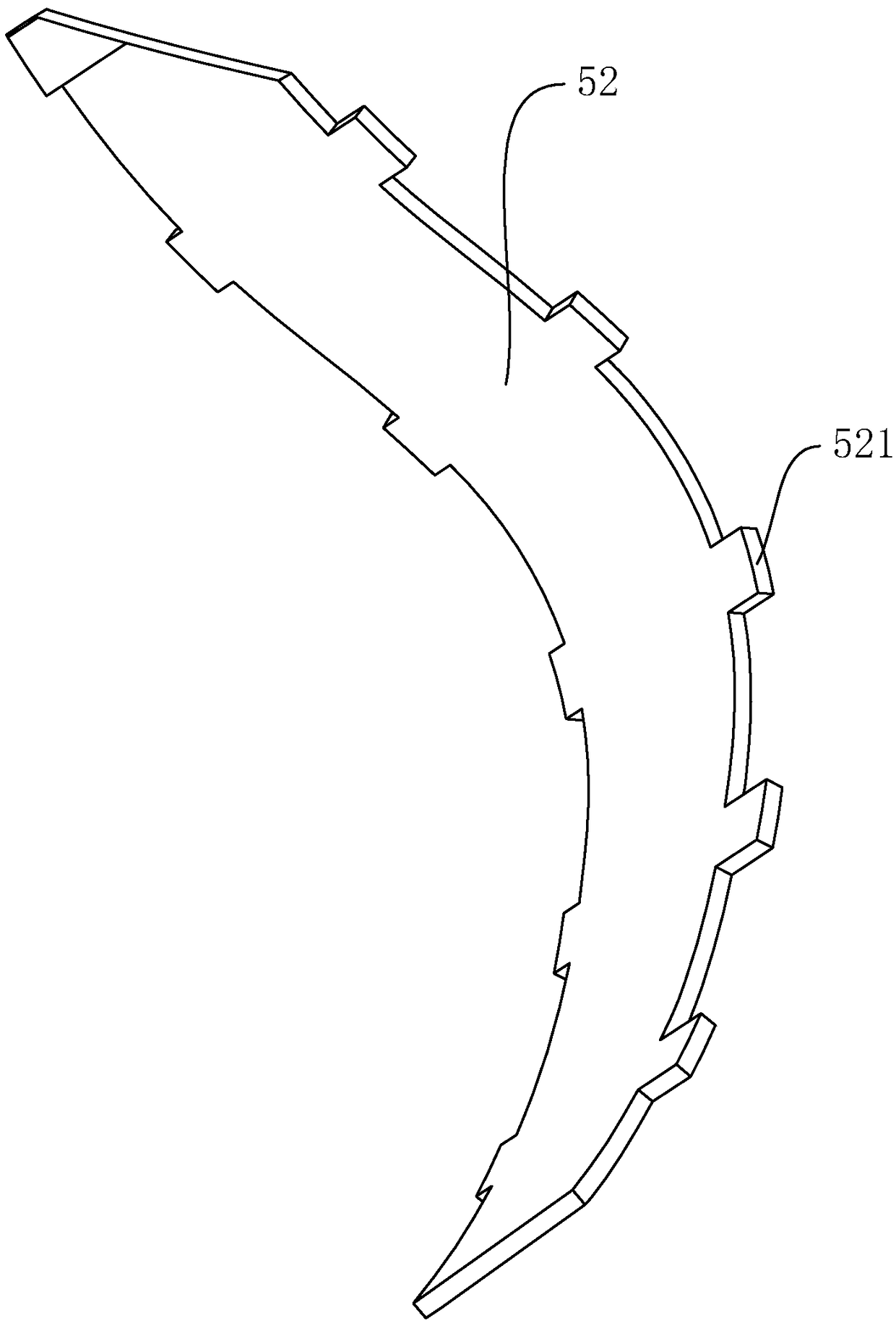

InactiveCN102199796BStable wind pressureStable air volumeArtificial filament physical treatmentFilament/thread formingFiberAutomatic control

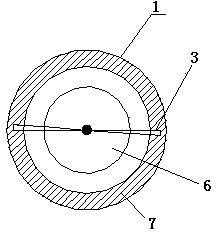

The invention discloses an adjustable circular air blow cooling system, which belongs to the field of fiber manufacturing equipment. High-precision pressure sensors are arranged in both the static pressure bin and air duct bin of a circular air blow device, an automatic control valve is arranged at the position of an air intake pipe, a whole production line is controlled by one computer, and thus, the automatic interlocked air pressure regulation can be realized; and the circular air blow device of which the circular blow head is adjustable is arranged, so that the air pressure and volume stability of the air duct bin are ensured all the time and the product quality is guaranteed to a maximum degree.

Owner:DALIAN SYNTHETIC FIBER RES & DESIGN INST

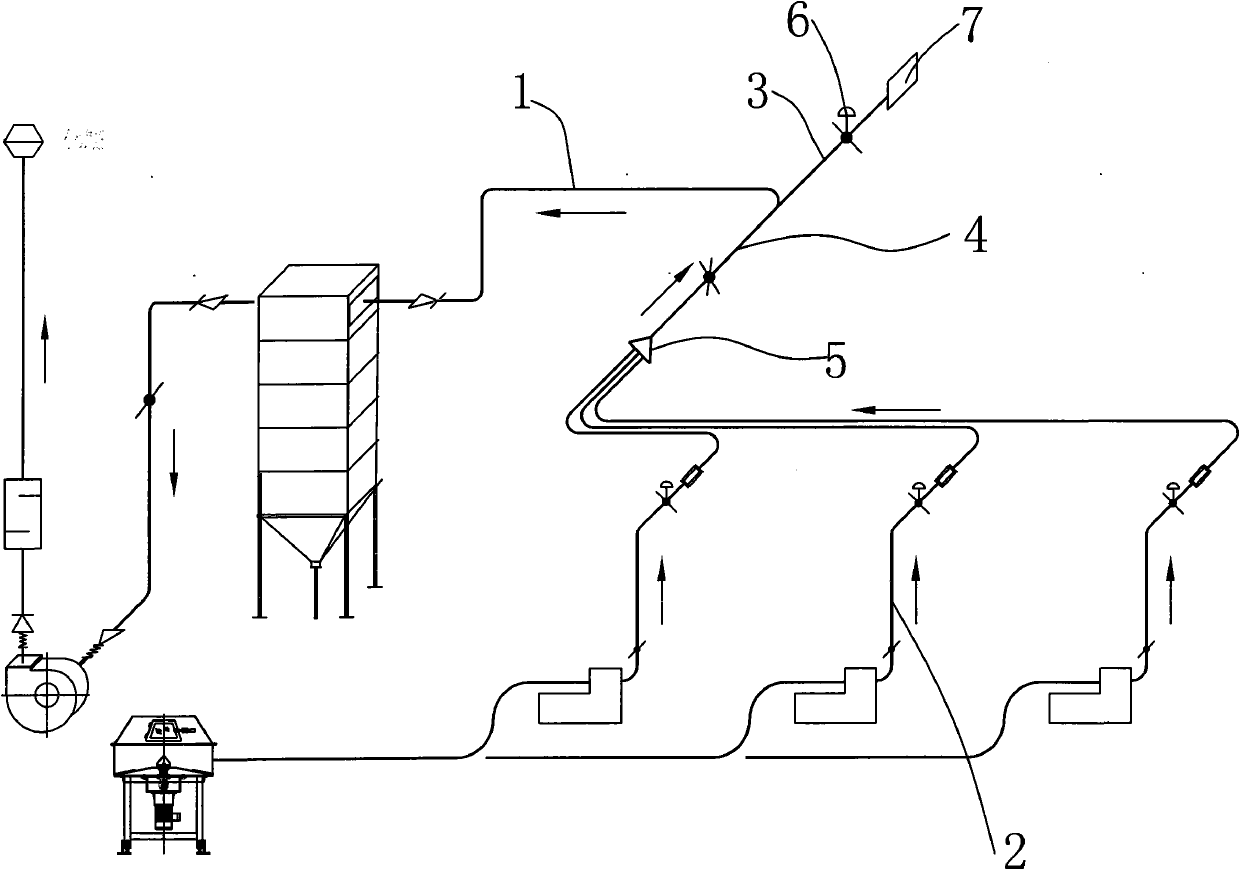

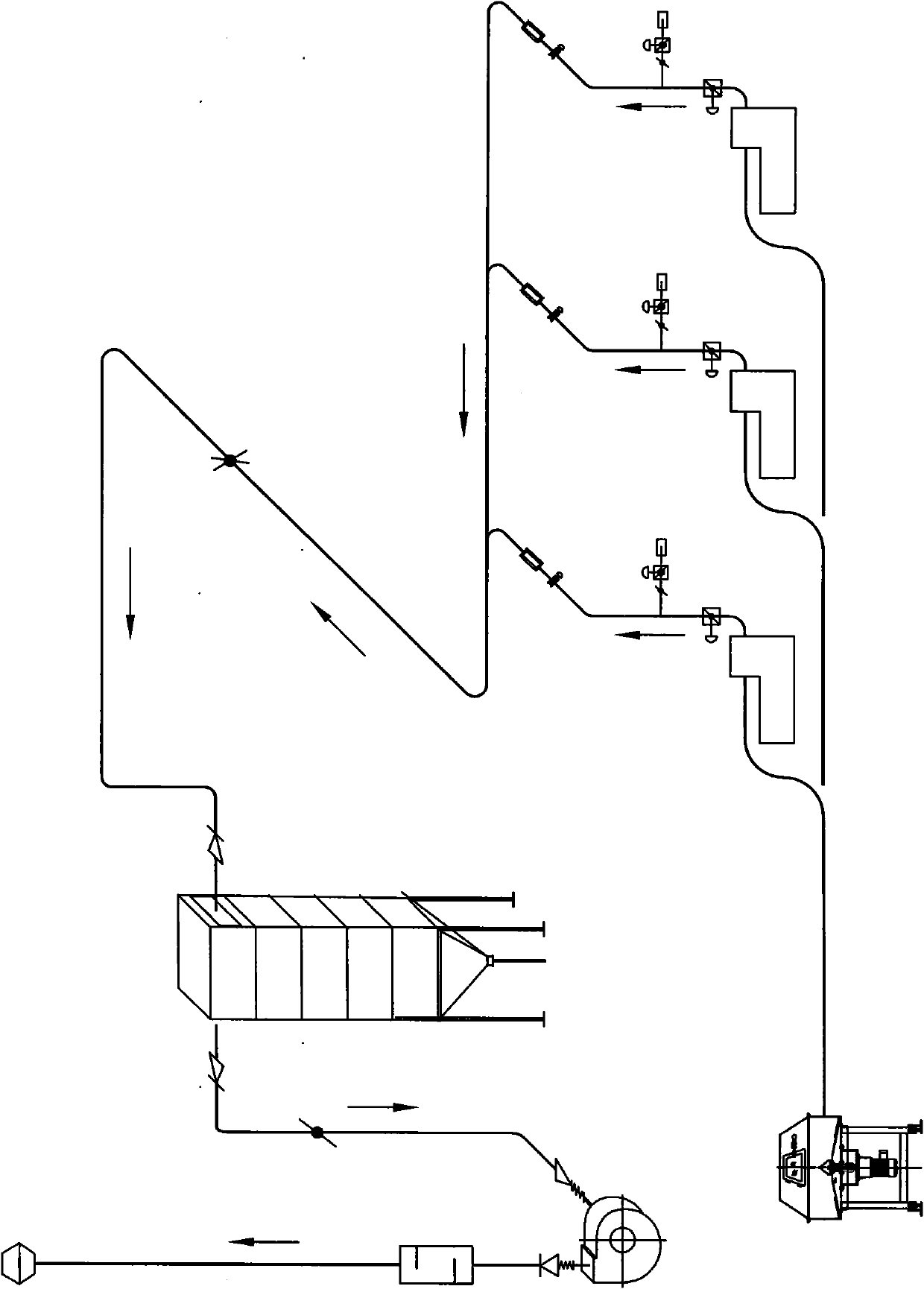

Wind power dedusting system for rolling process of cigarettes factory

InactiveCN101904559AStable designUnified designCigarette manufactureCleaning using gasesControl valvesWind power

The invention discloses a wind power dedusting system for a rolling process of a cigarettes factory. The wind power dedusting system comprises a deduster connecting pipe, a plurality of branch wind pipes and a plurality of pieces of rolling and packing equipment, wherein each piece of rolling and packing equipment is connected with a branch wind pipe; the wind power dedusting system also comprises a wind compensating pipe with a wind compensating silencer and a main wind pipe; the deduster connecting pipe and the wind compensating pipe are respectively communicated with the main wind pipe; the main wind pipe is respectively communicated with each branch wind pipe through a pipe collector; and the wind compensating pipe is provided with a control valve which is used for automatically switching on to compensate wind when a certain branch wind pipe is stopped. The wind power dedusting system can concentrate wind power for supply, and ensure stable wind quantity, wind pressure and wind speed; the pipeline design is more standardized and unified; and the effective operability and the yield of the rolling and packing equipment are improved, the production cost is reduced and the service environment of workers is improved.

Owner:长沙赛普尔自动化工程设备有限公司

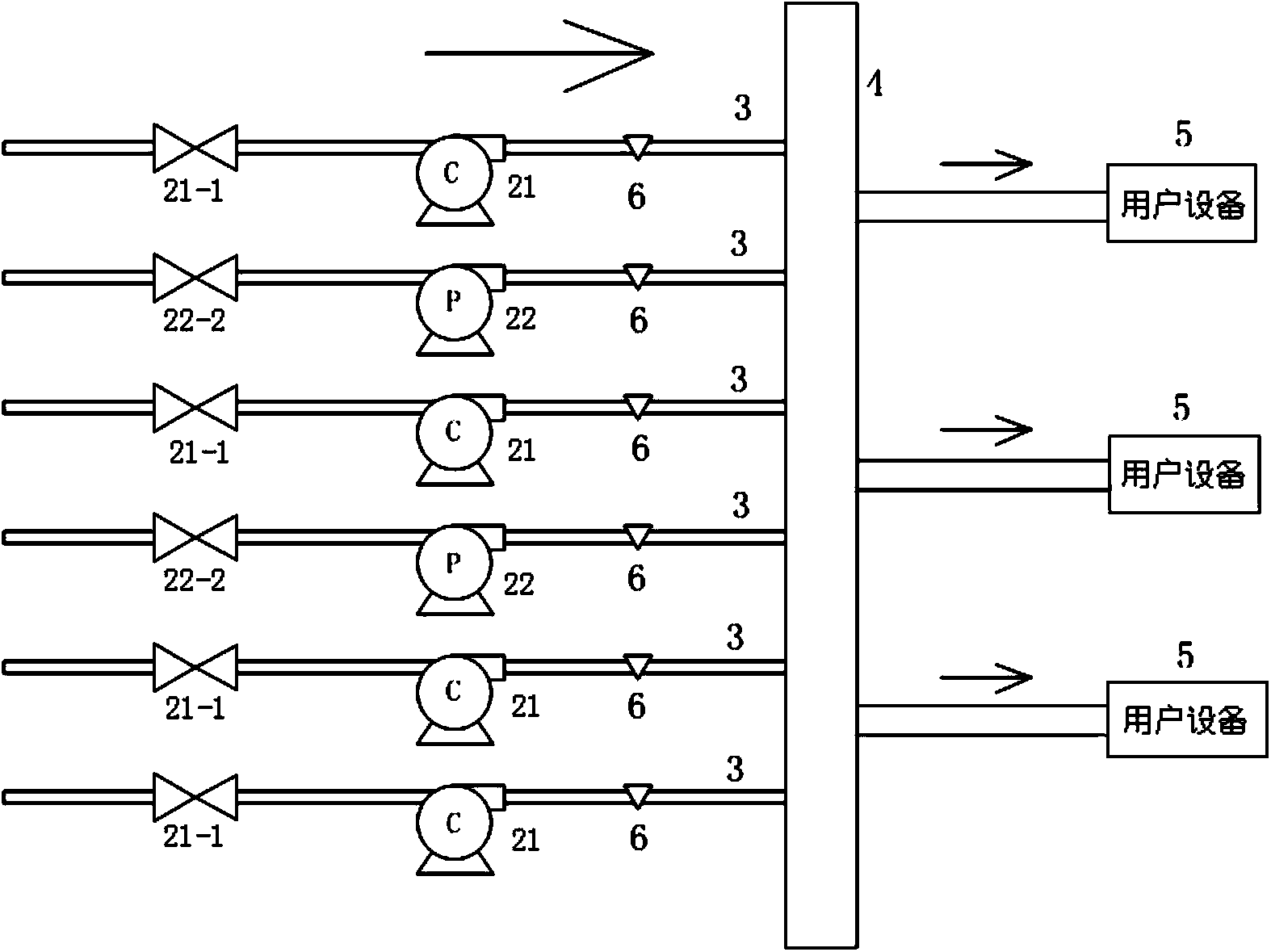

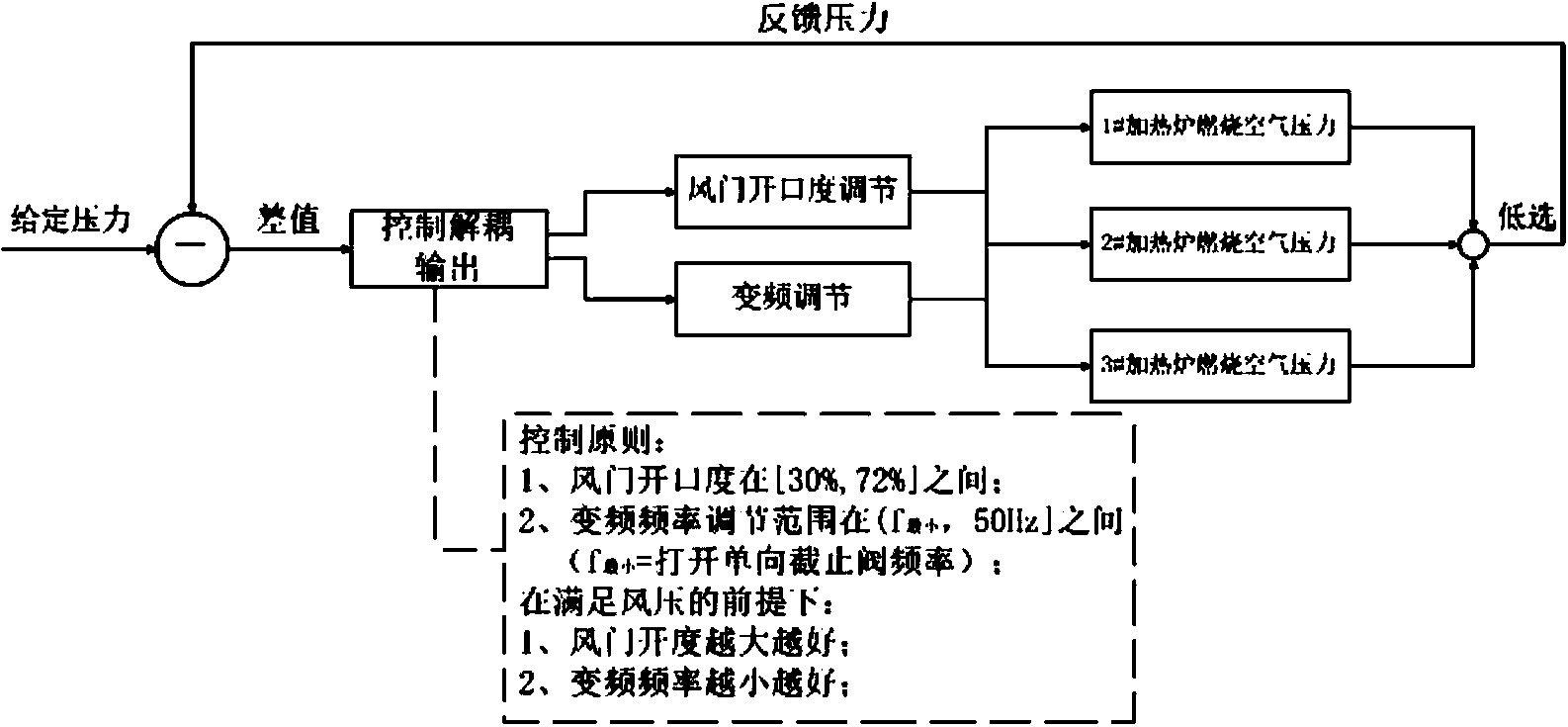

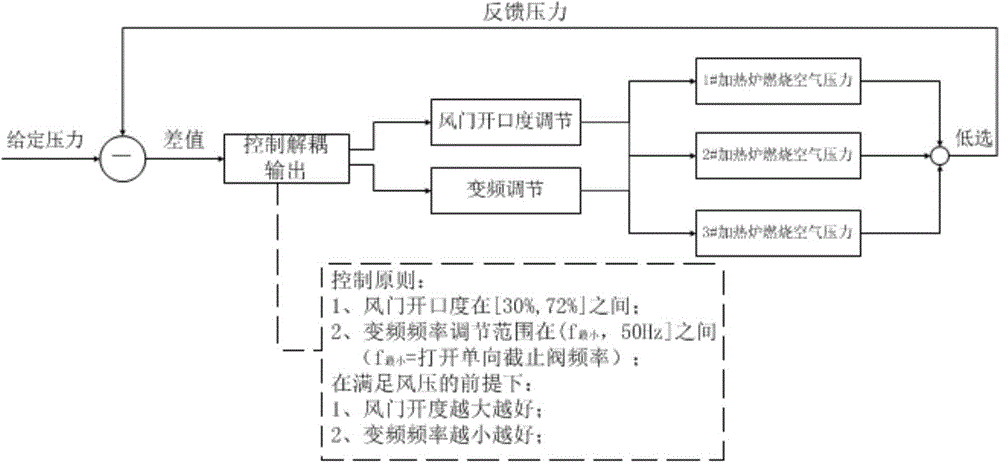

Air supply system and method of industrial furnace

ActiveCN104141964ALess investmentGood energy saving effectAir supply regulationFrequency conversionControl theory

The invention provides an air supply method of an industrial furnace. When air pressure is required to be increased, opening degrees of air doors of frequency conversion fans are increased; when the air pressure is required to be further increased, opening degrees of air doors of constant-speed fans are increased; when the air pressure is still required to be increased, working frequency of each frequency conversion fan is increased; when the air pressure is required to be decreased, the working frequency of each frequency conversion fan is decreased; when the air pressure is required to be further decreased, the opening degrees of the air doors of the frequency conversion fans are decreased; and when the air pressure is still required to be decreased, the opening degrees of the air doors of the constant-speed fans are decreased. The air supply method of the industrial furnace has the advantages as follows: for the fan units operating in an air door adjustment mode, only part of fans are subjected to frequency conversion renovation; and on the basis that the air pressure is stably adjusted through frequency conversion, the part of fans and other fans are controlled coordinately and combined to the overall fan unit network for stable operation.

Owner:上海金自天正信息技术有限公司

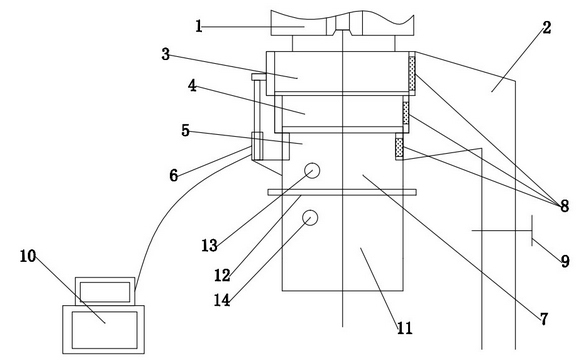

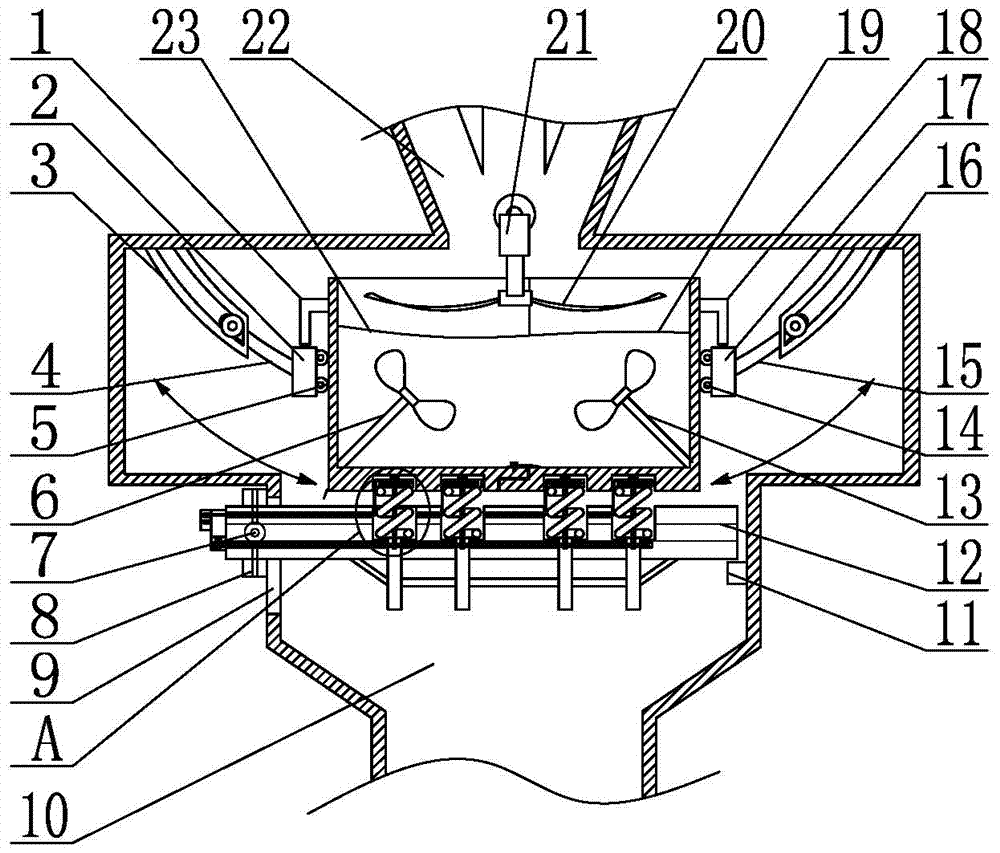

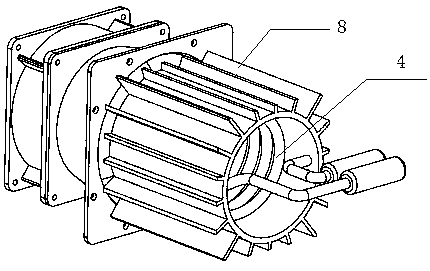

Adjustable circular air blow cooling system

InactiveCN102199796AStable wind pressureStable air volumeArtificial filament physical treatmentFilament/thread formingFiberAutomatic control

The invention discloses an adjustable circular air blow cooling system, which belongs to the field of fiber manufacturing equipment. High-precision pressure sensors are arranged in both the static pressure bin and air duct bin of a circular air blow device, an automatic control valve is arranged at the position of an air intake pipe, a whole production line is controlled by one computer, and thus, the automatic interlocked air pressure regulation can be realized; and the circular air blow device of which the circular blow head is adjustable is arranged, so that the air pressure and volume stability of the air duct bin are ensured all the time and the product quality is guaranteed to a maximum degree.

Owner:DALIAN SYNTHETIC FIBER RES & DESIGN INST

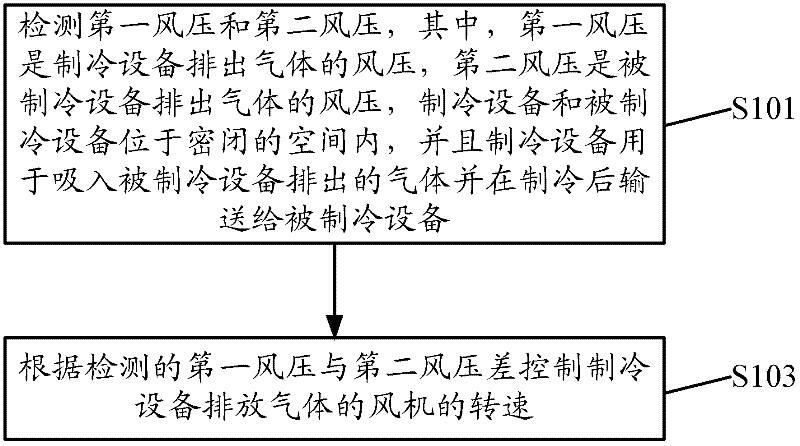

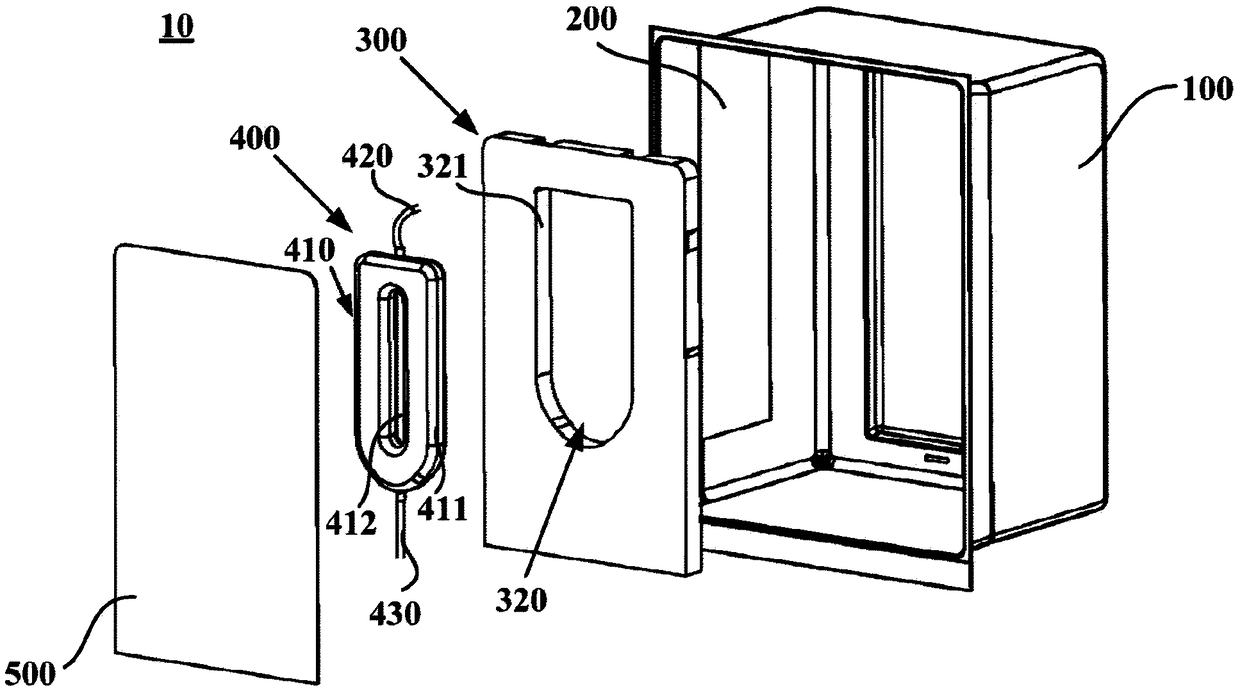

Method and device for controlling refrigerating device, and refrigerating system

ActiveCN102374614AStable wind pressureAvoid wastingSpace heating and ventilation safety systemsLighting and heating apparatusProduct gasAir blower

The invention discloses a method and device for controlling a refrigerating device, and a refrigerating system, wherein the method comprises the steps of: detecting a first wind pressure and a second wind pressure, wherein the first wind pressure is a wind pressure of a gas exhausted by the refrigerating device, the second wind pressure is a wind pressure of gas exhausted by a refrigerated device, the refrigerating device and the refrigerated device are positioned in a closed space, the refrigerating device is used for sucking the gas exhausted by the refrigerated device and conveying the refrigerated gas to the refrigerated device; and controlling the rotating speed of an air blower of exhausting the gas of the refrigerating device according to the detected difference of the first wind pressure and the second wind pressure. Through detecting and comparing the wind pressure of the gas exhausted by the refrigerating device and the wind pressure of the gas exhausted by the refrigerated device, and controlling the rotating speed of the air blower of the refrigerating device according to a comparison result, the rotating speed of the air blower of the refrigerating device is regulated and the actual refrigerating effect of the refrigerated device is not influenced. The stability of the wind pressure in the closed space can be ensured and the problem of resource waste is avoided.

Owner:DAWNING INFORMATION IND BEIJING +1

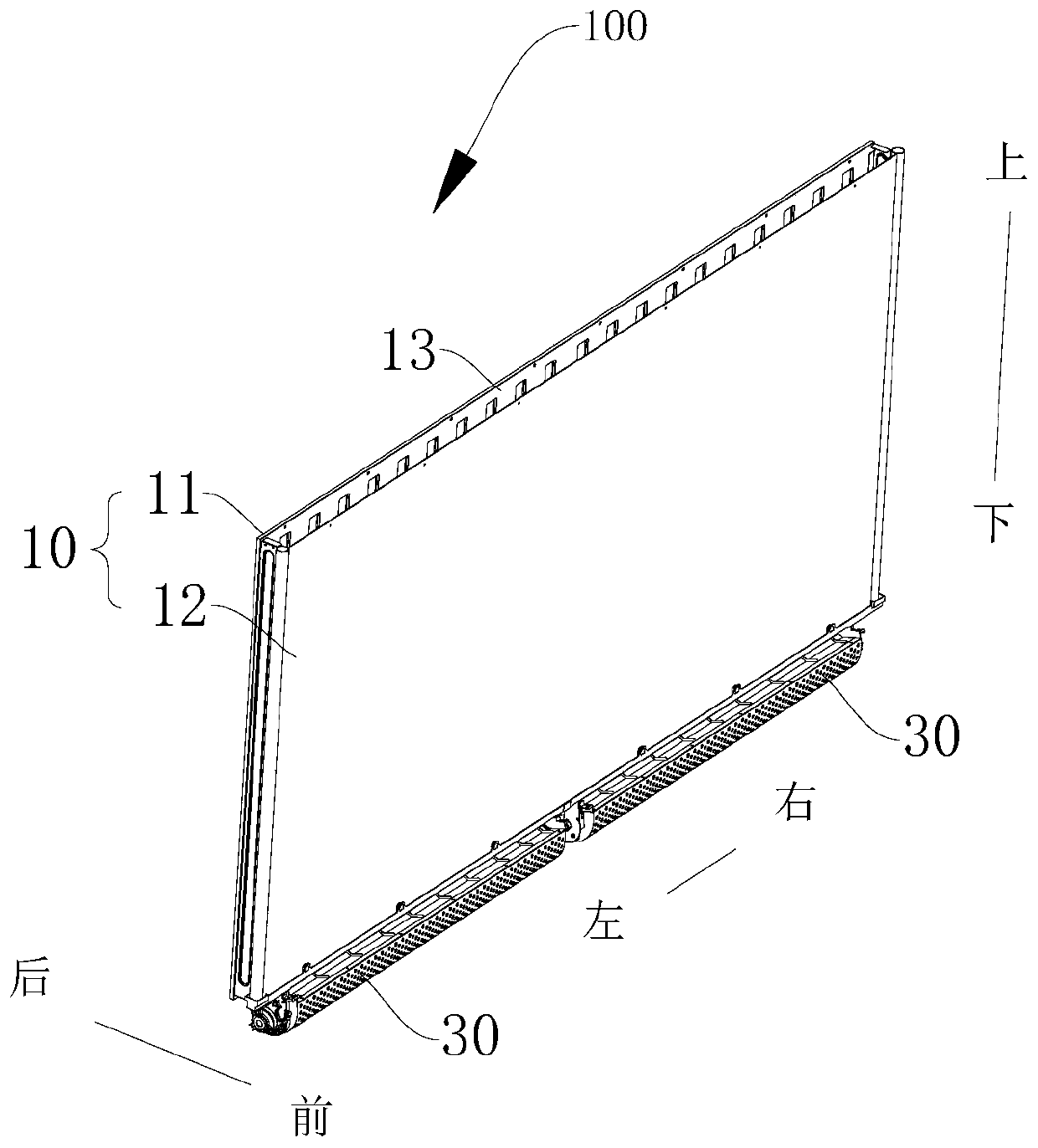

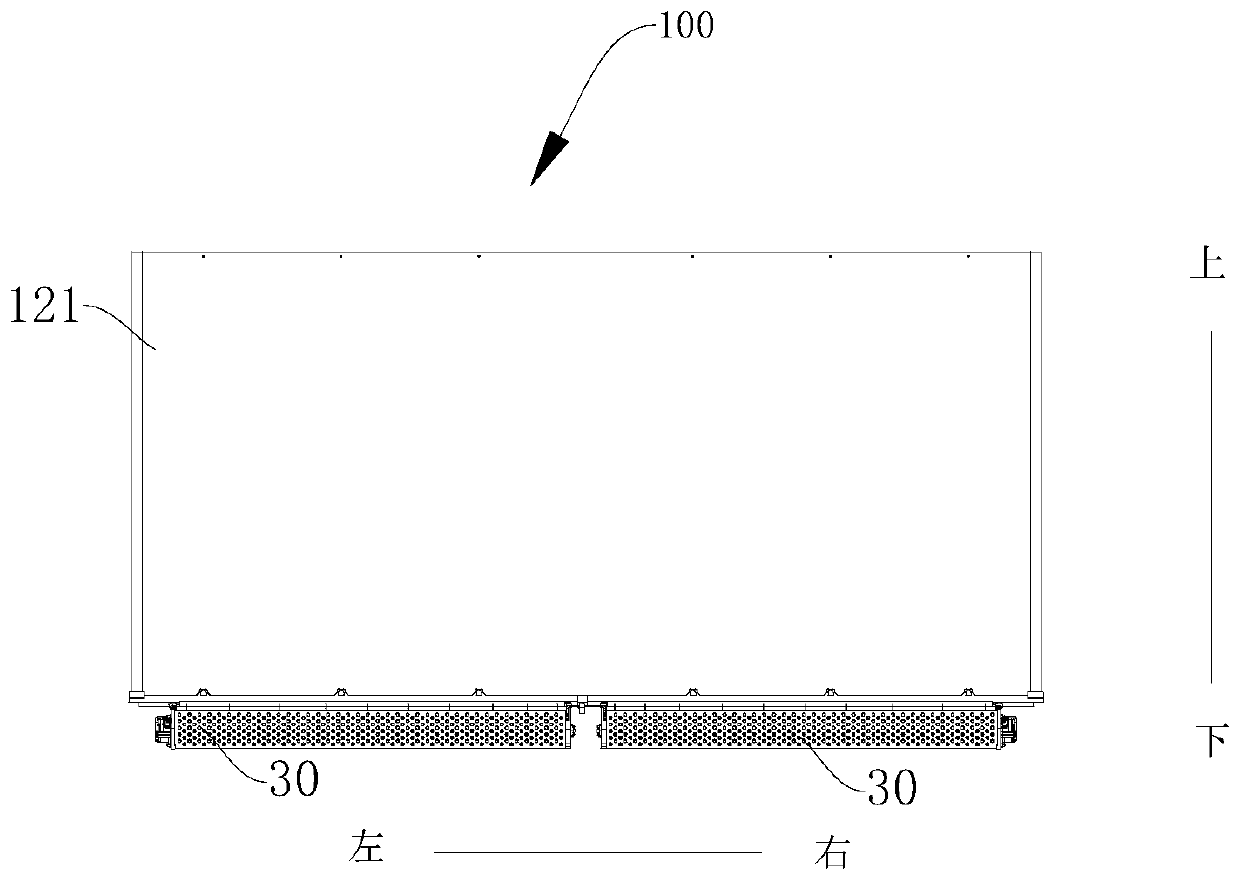

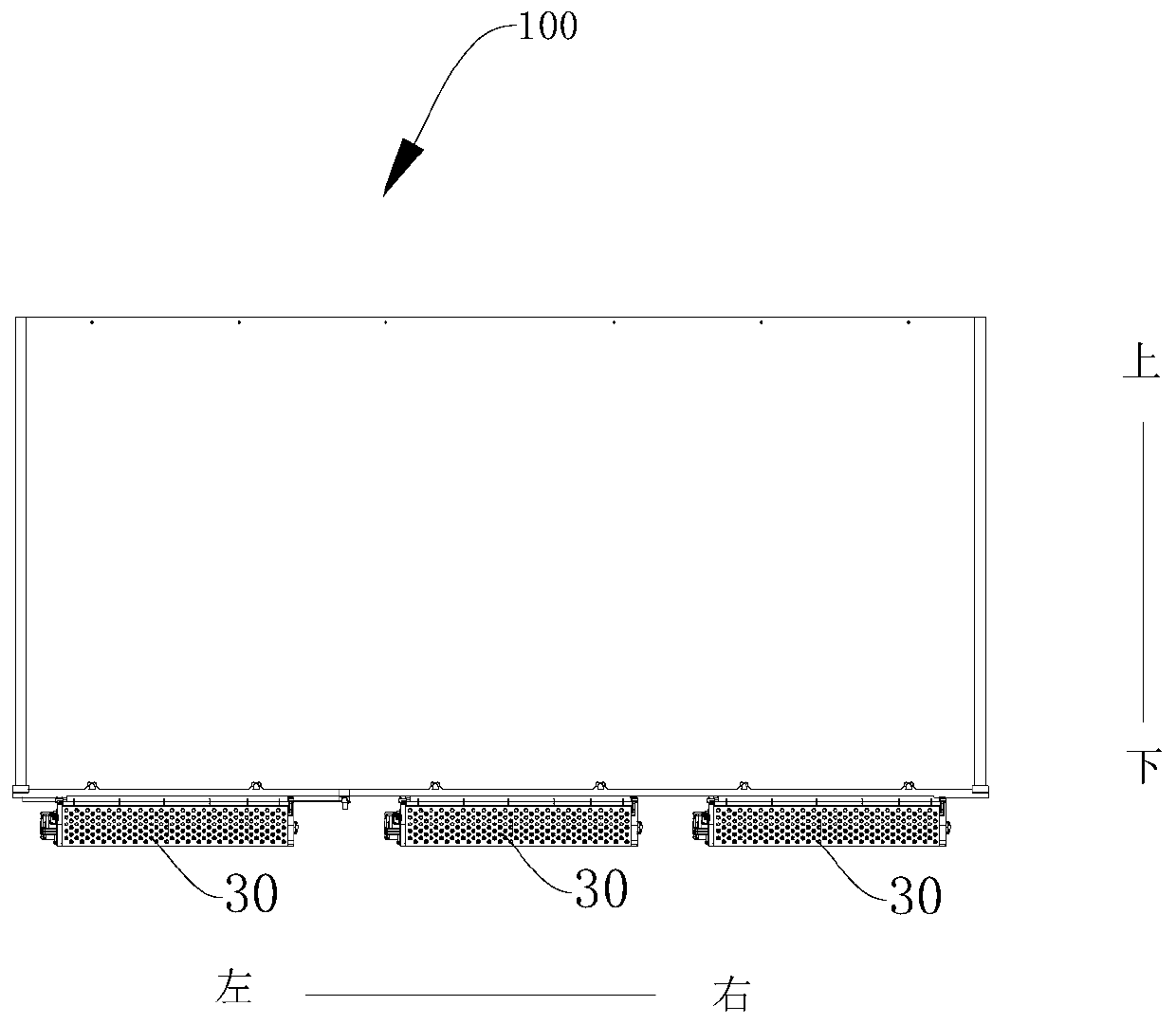

Air conditioner indoor unit

ActiveCN106705216AWeaken restrictions on installation locationBig angleDucting arrangementsElectrical apparatusElectric fieldEngineering

The invention relates to an air conditioner indoor unit which comprises a shell, a heat exchange device, a first centrifugal fan, a second centrifugal fan, a first axial flow fan set, a second axial flow fan set, a first ion air generation device and a second ion air generation device. The shell is provided with an air inlet, lower air outlet and two lateral air outlets, the heat exchange device is arranged in the shell and configured to exchange heat with air flowing through the shell, and the first centrifugal fan and the second centrifugal fan are arranged on the rear side of the heat exchange device and configured to promote the air after going through heat exchange by the heat exchange device to respectively flow towards the lower air outlet, the first lateral air outlet and the second lateral air outlet; the first axial flow fan set and the second axial flow fan set are arranged on flowing paths from the two centrifugal fans to the two lateral air outlets respectively and configured to promote air from the two centrifugal fans to respectively continue to flow towards the two lateral air outlets; the first ion air generation device and a second ion air generation device are respectively arranged on flowing paths from the two axial flow fan sets to the two lateral air outlets and configured to promote air from the two axial flow fan sets to respectively continue to flow towards the two lateral air outlets.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

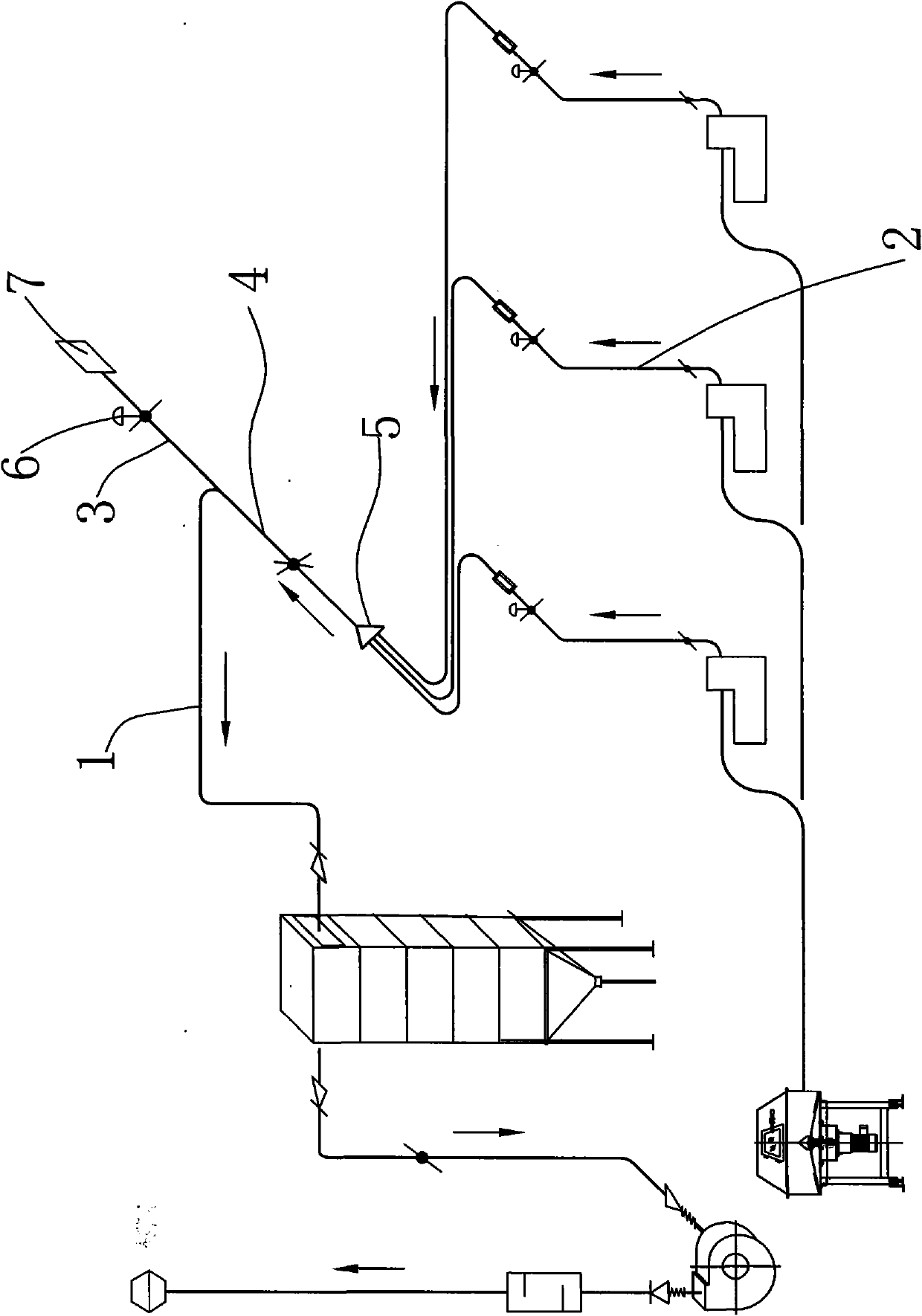

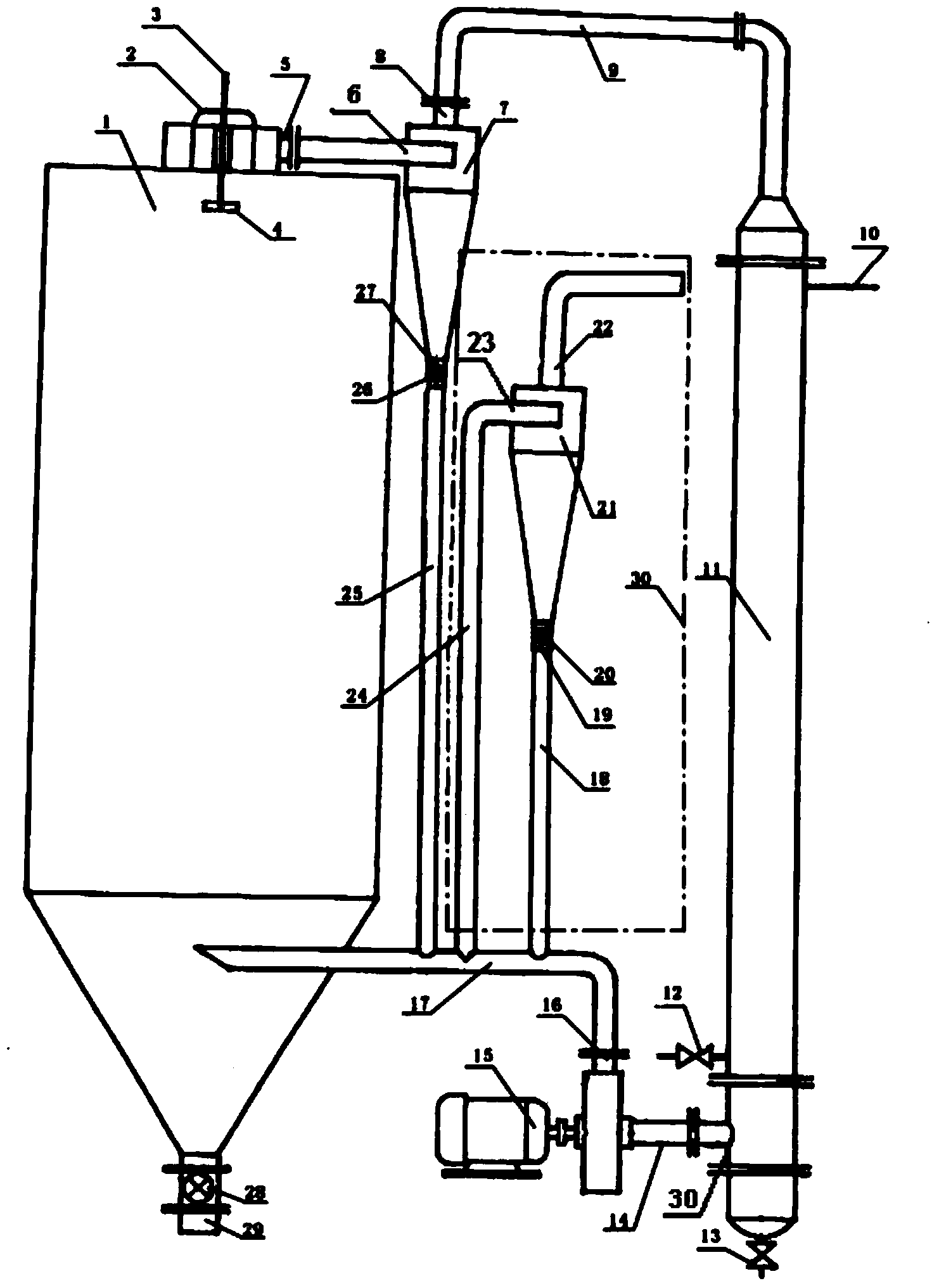

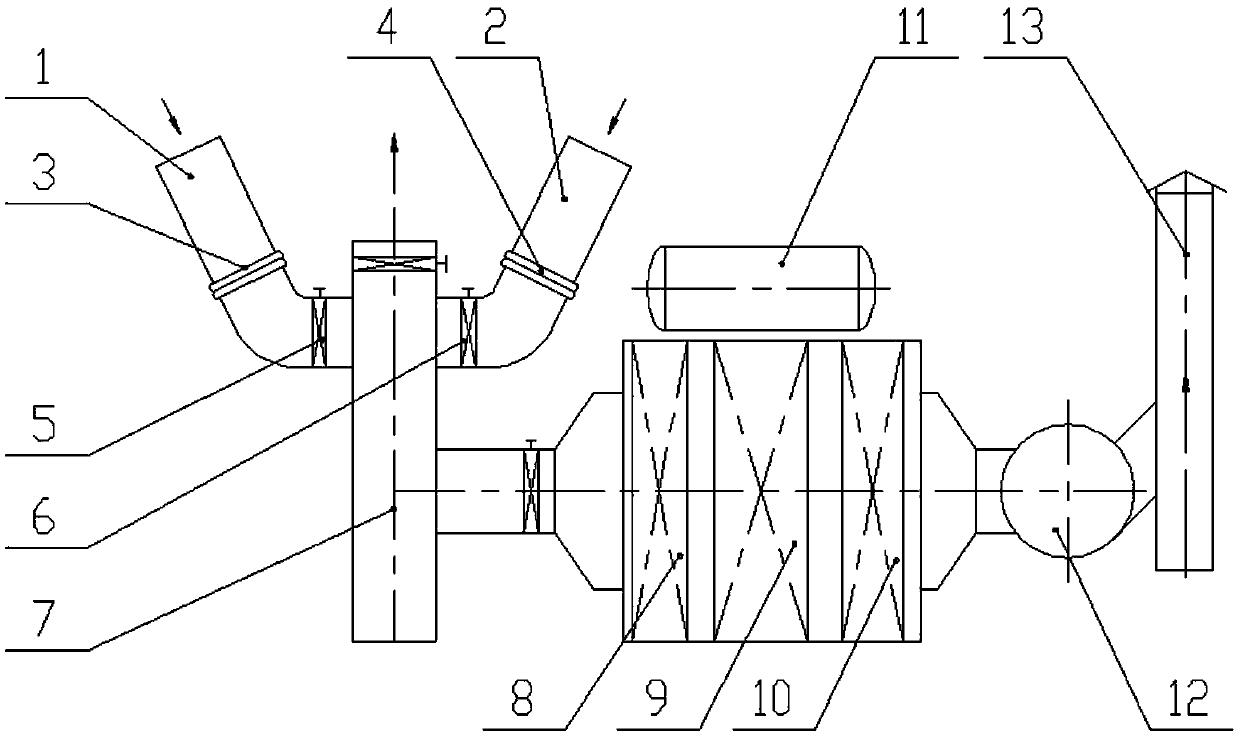

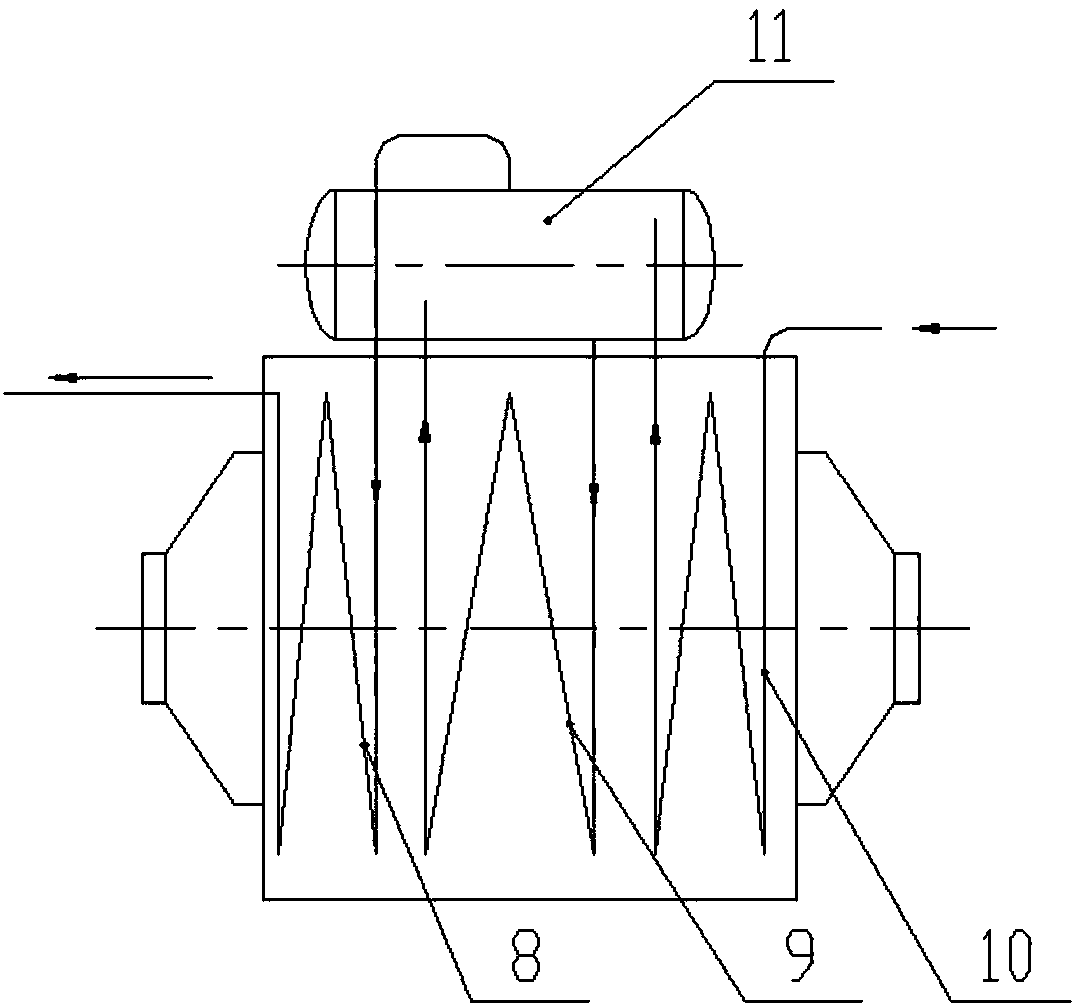

Spraying and powder making device

InactiveCN103464052AReduce material lossImprove cooling efficiencyGranulation by liquid drop formationSpray towerEngineering

Disclosed is a spraying and powder making device. The spraying and powder making device comprises a spraying tower, a first cyclone separator, a shell-and-tube heat exchanger, a high-pressure draught fan, a second cyclone separator and an air inlet pipe, wherein a first air outlet is formed in the upper end of the spraying tower; a first air inlet, a second air outlet and a first material return opening are formed in the first cyclone separator, and the first air inlet is connected with the first air outlet of the spraying tower; the upper end of the shell-and-tube heat exchanger is connected with the second air outlet of the first cyclone separator, and a discharge port is formed in the lower end of the shell-and-tube heat exchanger; an air absorbing opening and a blowing opening are formed in the high-pressure draught fan, and the air absorbing opening is in butt-joint connection with the discharge port of the shell-and-tube heat exchanger; a second air inlet and a second material return opening are formed in the second cyclone separator; a pipe opening at one end of the air inlet pipe stretches to the interior o a cavity in the lower portion of the spraying tower, the other end of the air inlet pipe is connected with the blowing opening of the high-pressure draught fan, and the second air inlet, the second material return opening and the first material return opening are respectively and fixedly connected with the surface of the pipe body of the air inlet pipe. The spraying and powder making device avoids product loss and pollution between environments, improves cooling efficiency and working efficiency and reduces manufacturing cost.

Owner:启仲化工(广西)有限公司

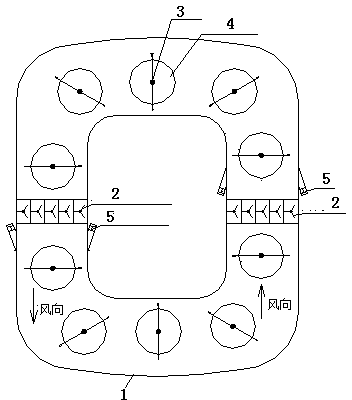

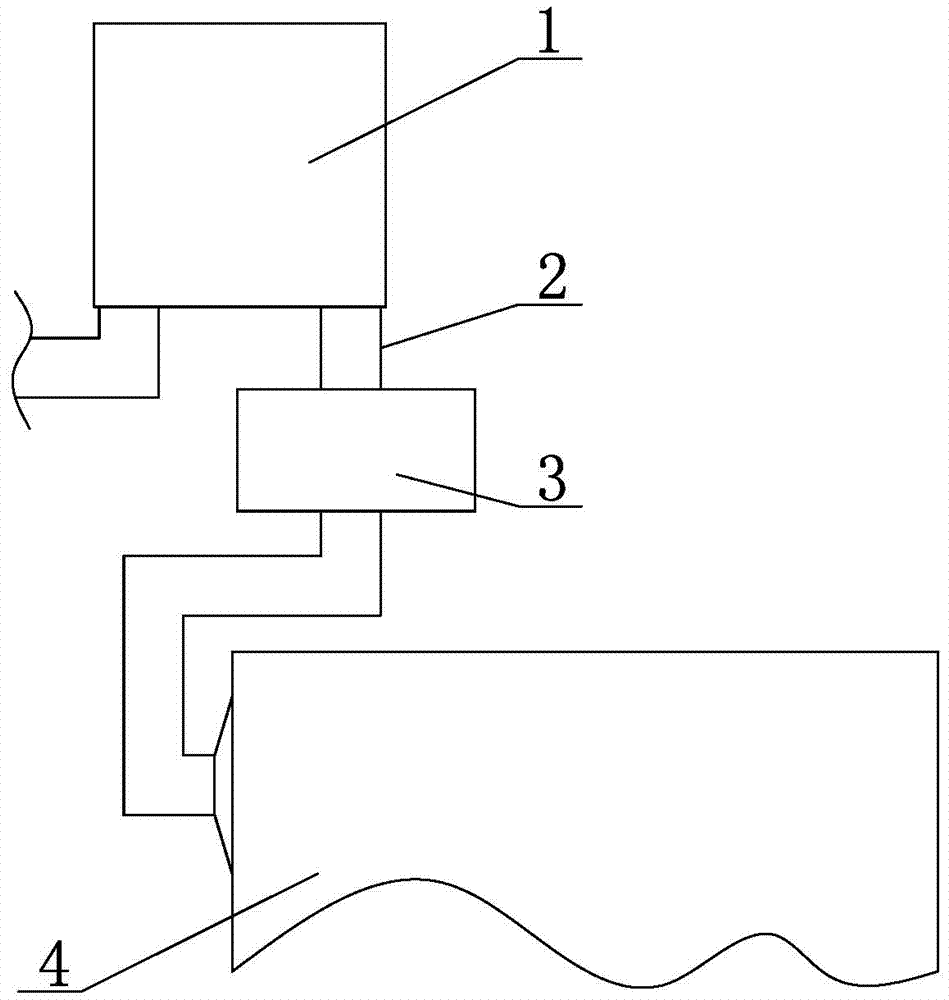

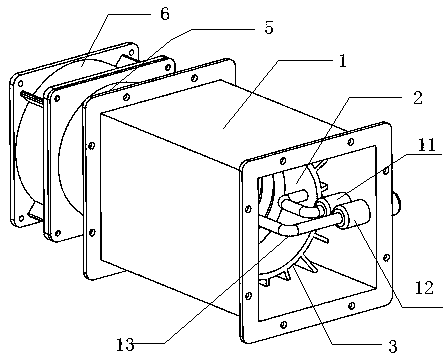

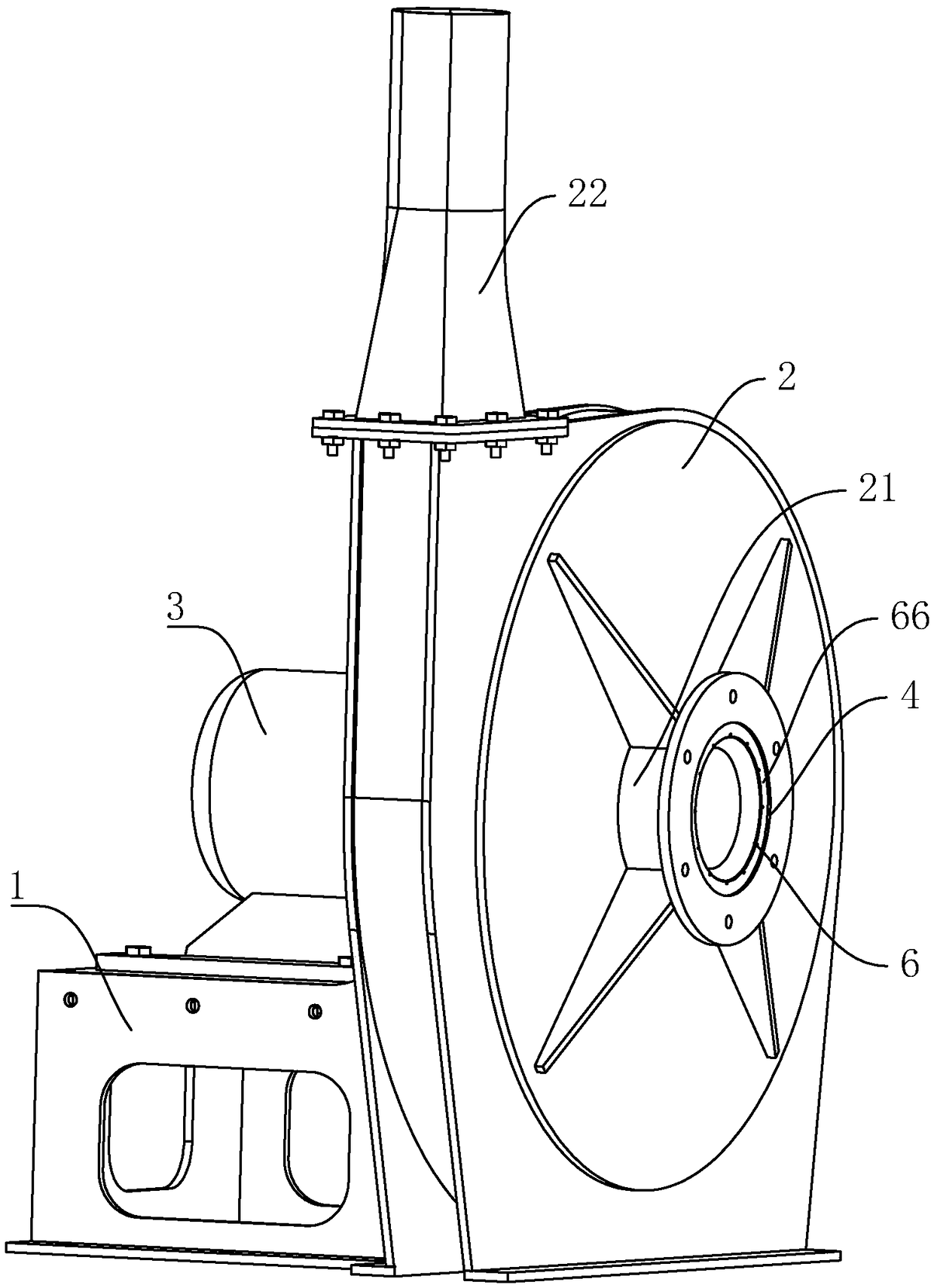

Closed loop type wind power generation system

InactiveCN104295447AA steady stream of outputImprove utilizationWind motor combinationsMachines/enginesClosed loopEngineering

A closed loop type wind power generation system is characterized by comprising an annular air barrel (1), at least one air blower array (2) and a plurality of wind driven generators (3). The air blower arrays (2) are arranged in the annular air barrel and are used for enabling air in the annular air barrel to achieve single-direction circulating flow and generate wind in the annular air cylinder; wherein the wind can drive blades of the wind driven generators to rotate. The pressure and speed of the wind are maintained to be within the set proportionality range under the action of the air blower arrays so as to ensure the power generation efficiency and stability of the wind driven generators (3). The wind driven generators (3) are arranged in the annular air barrel (1) and are driven by the blades to rotate to generate power. The closed loop type wind power generation system has the advantages of being capable of continuously generating power, and being clean and environmentally-friendly.

Owner:JIANGSU HONGXIN REVOLVING COMPENSATOR TECH

Method for removing dust of dust filtering of FA201B carding machine

The invention relates to a FA201B carding machine dust collection method. The FA201B carding machine safe stripper area triangular space, flat strips, and licker-in degassing four absorption points are connected to concourse tube by spring tube. Three or four FA201B carding machines are formed one set. Droppings and dust are continuously absorbed to filter equipment. The droppings under the machine are intermittently absorbed into fiber compactor by uphill line pipeline. The invention is upper machine continuous absorption and under machine intermittent absorption method. It can reduce energy consumption, simplify structure, and economize material cost.

Owner:NANTONG DOUBLE GREAT TEXTILE

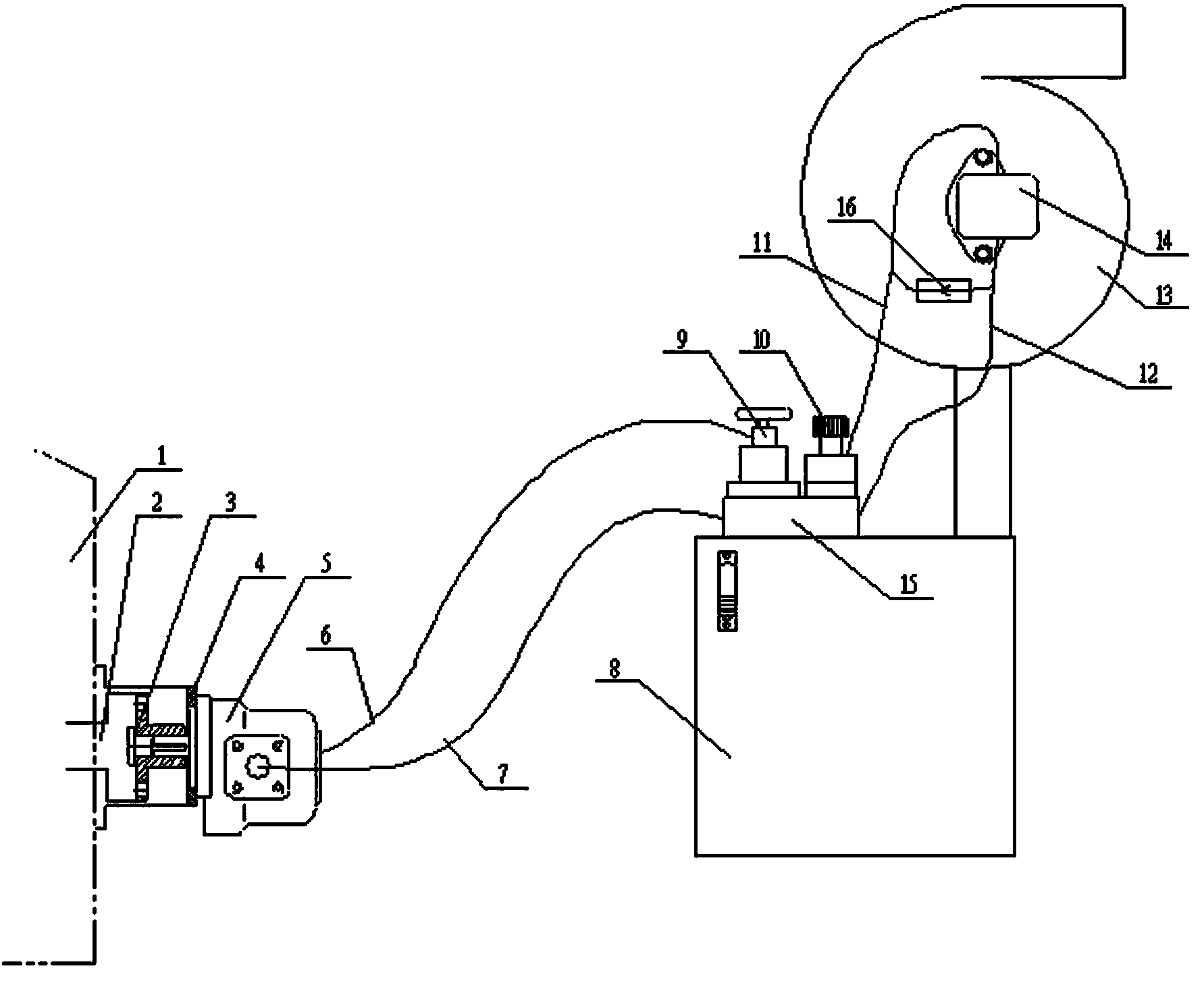

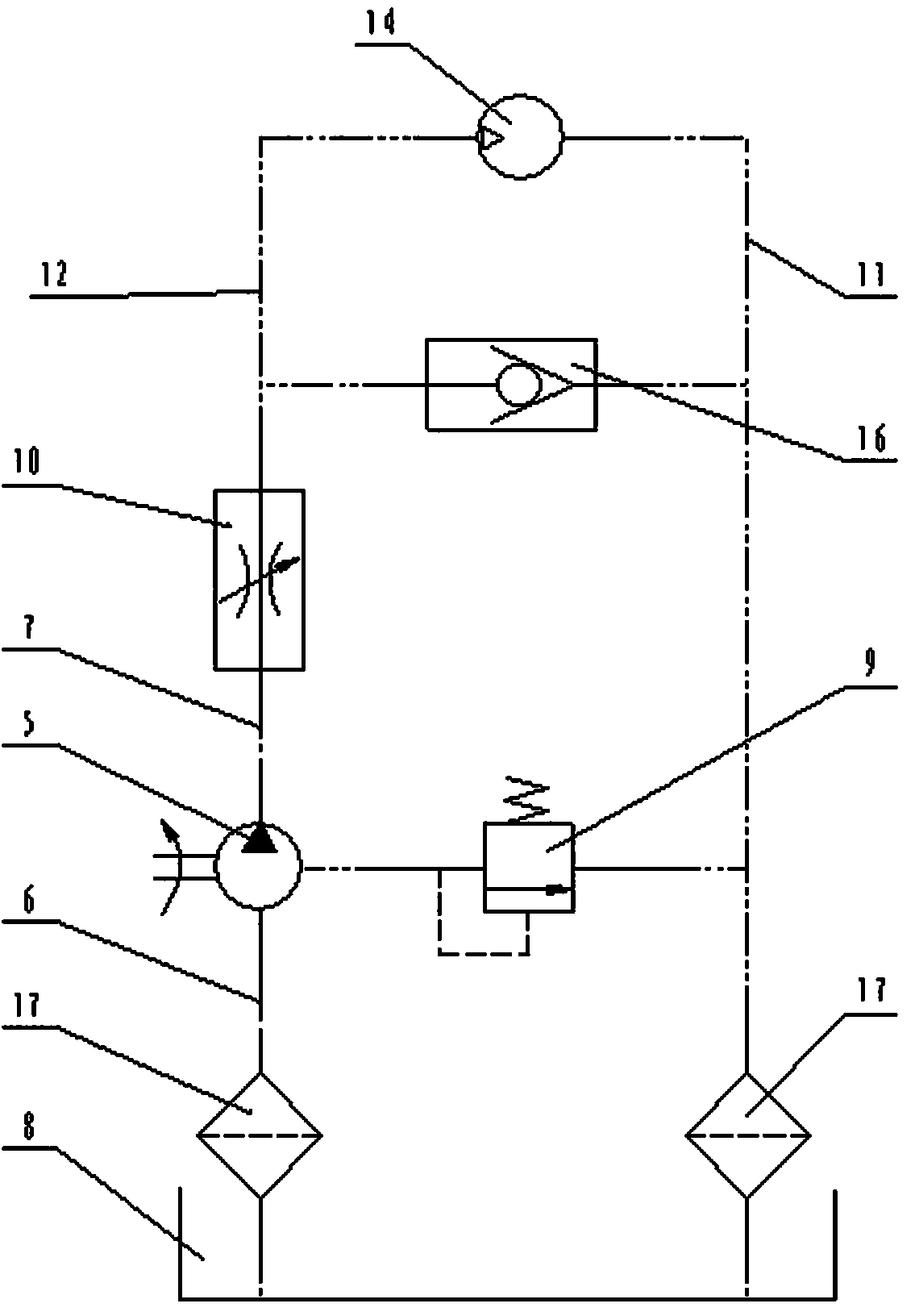

Hydraulic driving device for draught fan of pneumatic type seeding machine

InactiveCN104106331AStable speedFix stability issuesPump installationsSingle grain seedersHydraulic motorFuel tank

The invention provides a hydraulic driving device for a draught fan of a pneumatic type seeding machine, relating to the technical field of pneumatic type seeding machines. The hydraulic driving device is characterized in that a power output shaft of a tractor is connected with an oil pump and drives the oil pump to rotate, power oil supplied by the oil pump is conveyed to a hydraulic motor by an oil pump outlet pipe and a hydraulic motor inlet pipe, the hydraulic motor drives the draught fan for seeding to rotate, and is communicated with an oil tank by a hydraulic motor outlet pipe, a hydraulic control element is arranged in a hydraulic system, and the running speed of the draught fan for seeding is controlled by the hydraulic control element. The hydraulic driving device has the beneficial effects of being matched with the tractor conveniently, ensuring the stable rotation of the hydraulic motor for driving the draught fan for seeding without limitation of the size of an oil valve of the tractor to finally achieve ideal seeding, and overcoming the phenomena of unstable wind power, seedling shortage and seedlingless ridges caused by turning, stopping, machine tool lifting and the like of the existing domestic pneumatic type seeding; besides, the hydraulic driving device has the characteristics of simple and compact structure, small occupied area, convenience in adjustment and reliability in working.

Owner:HEBEI NONGHAHA MASCH GRP CO LTD

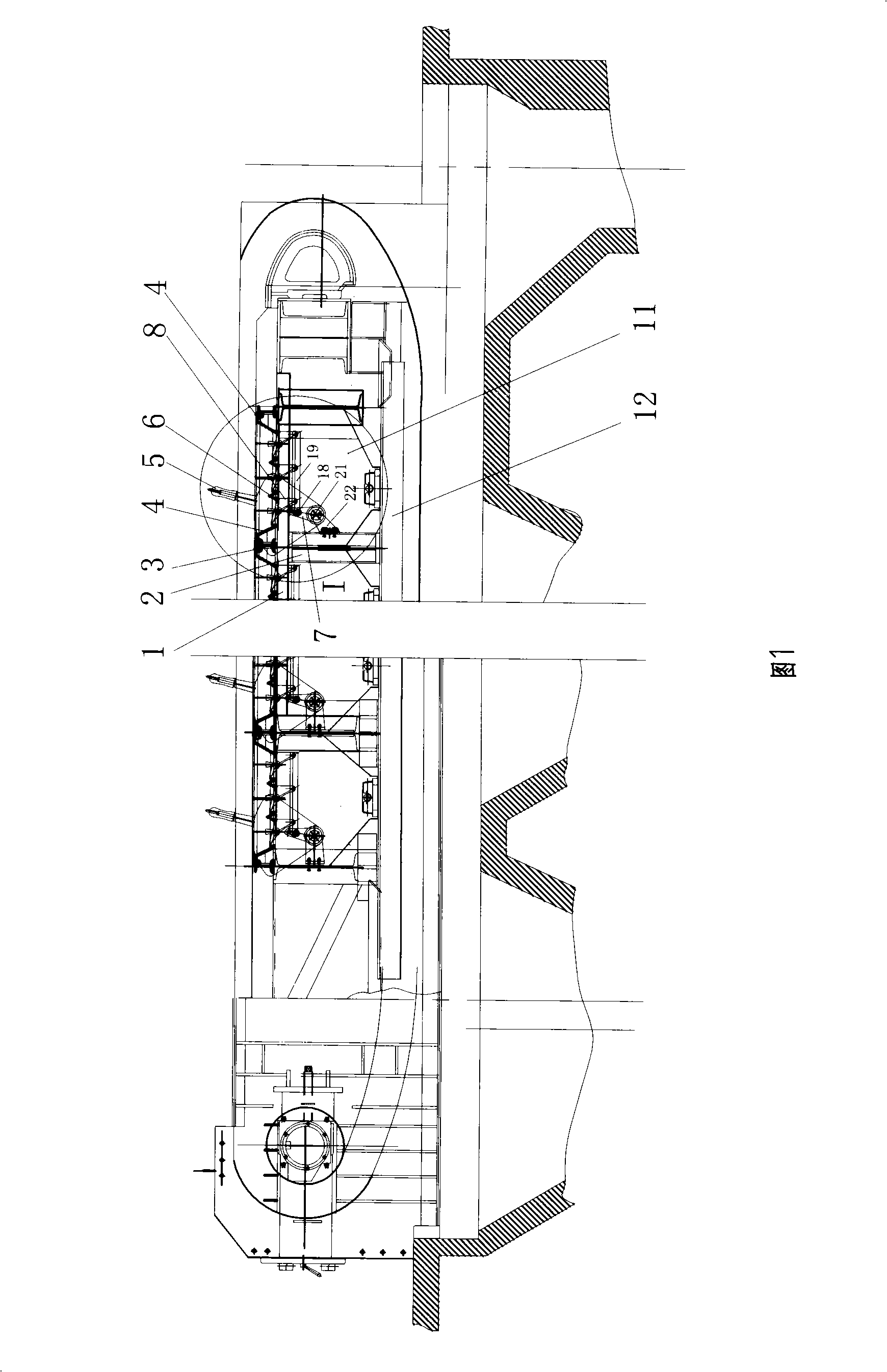

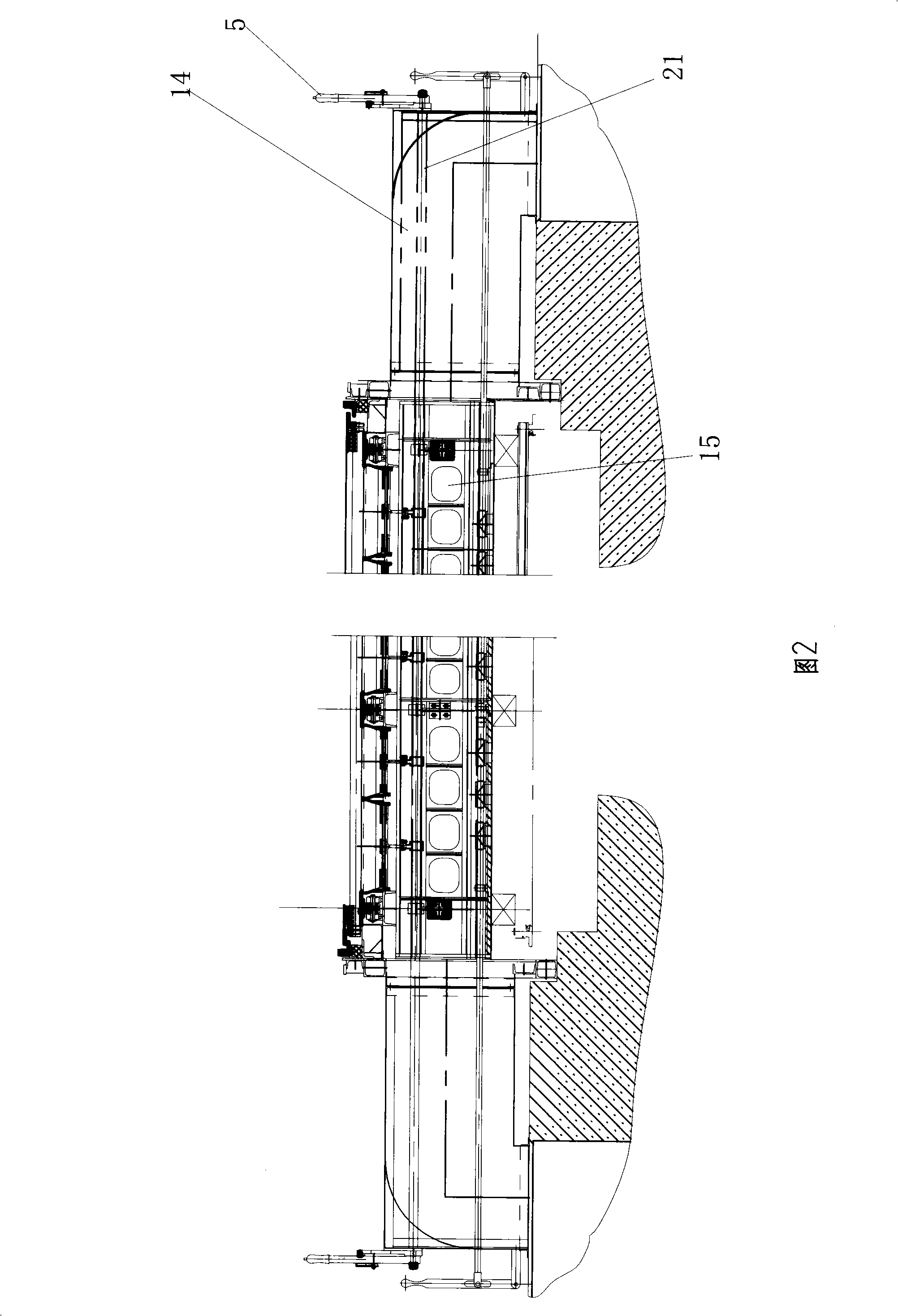

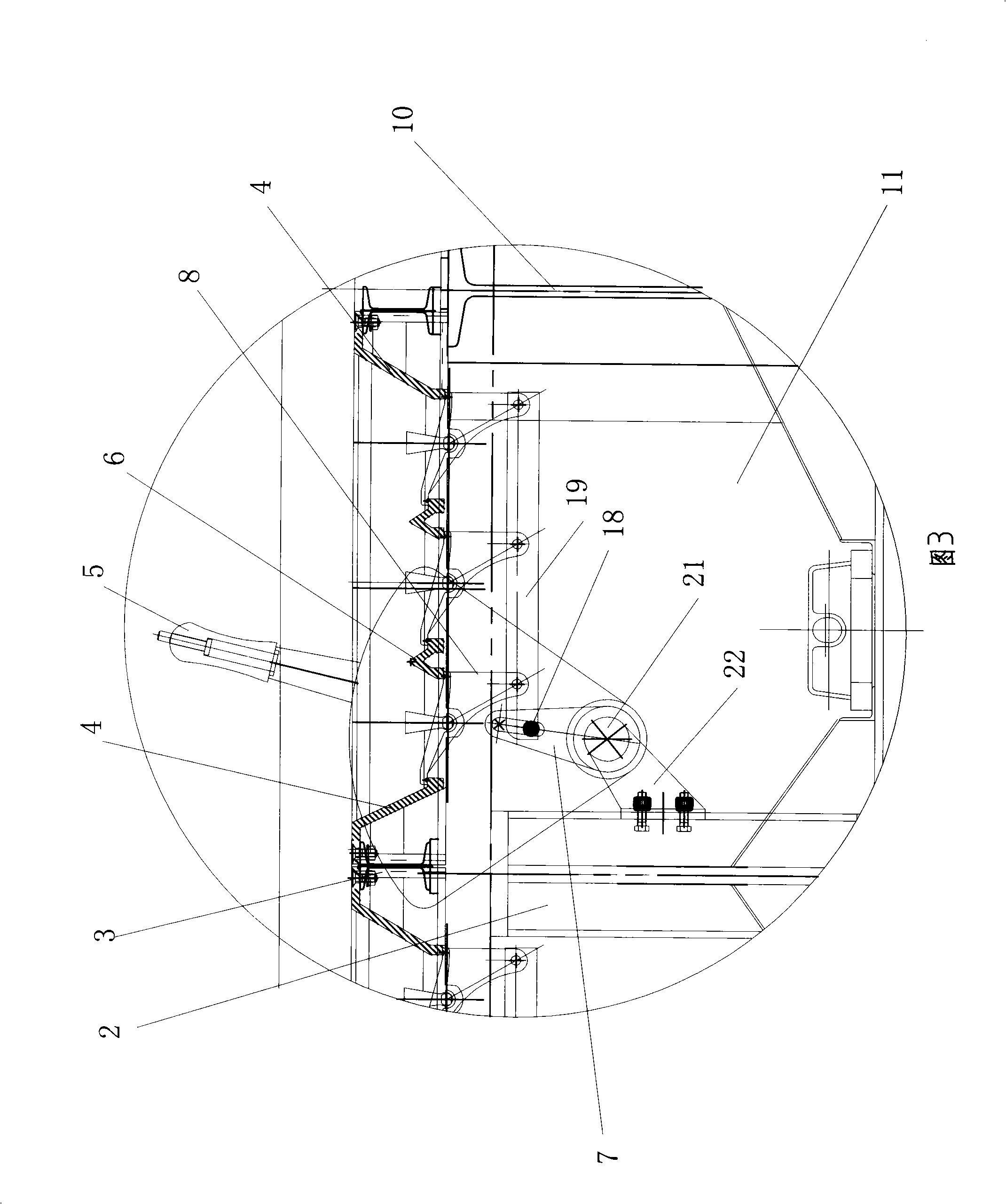

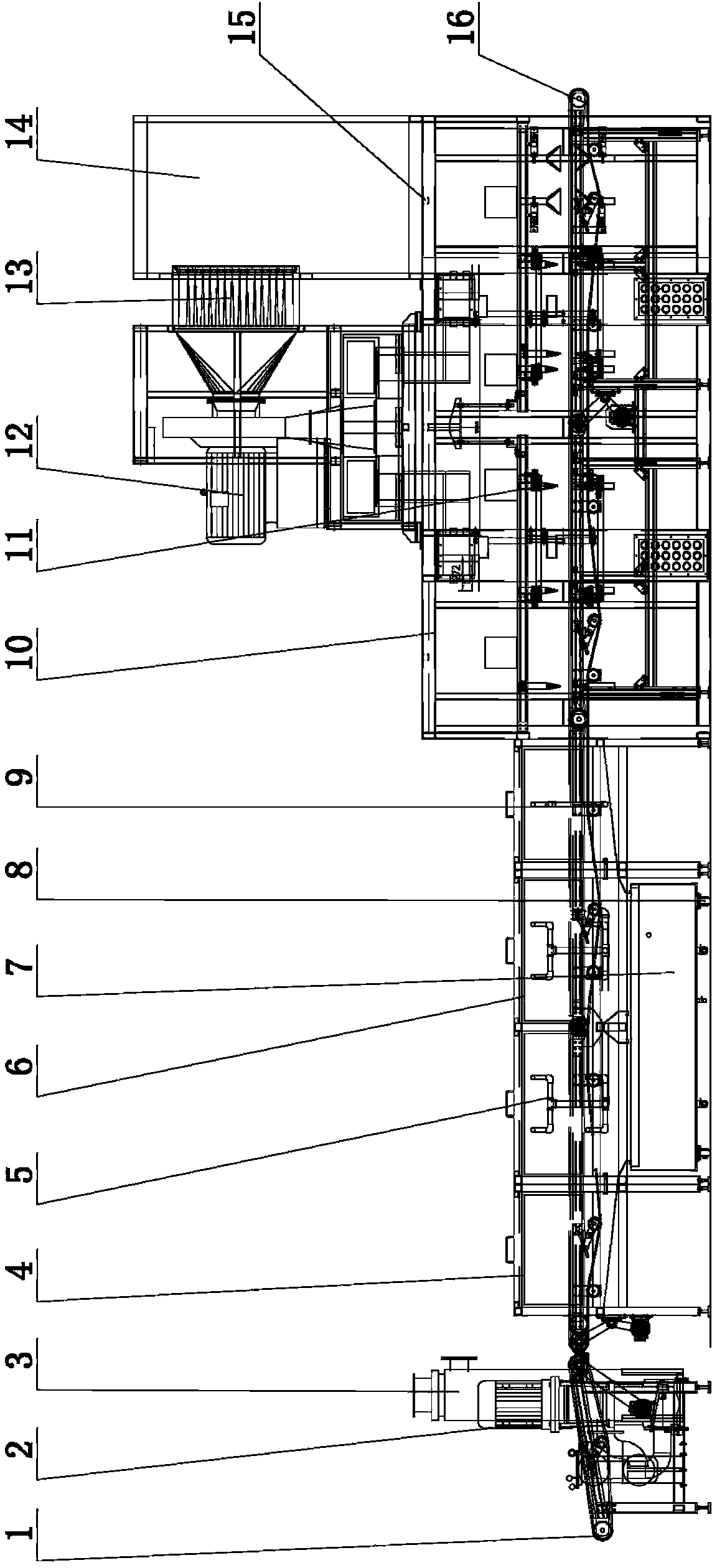

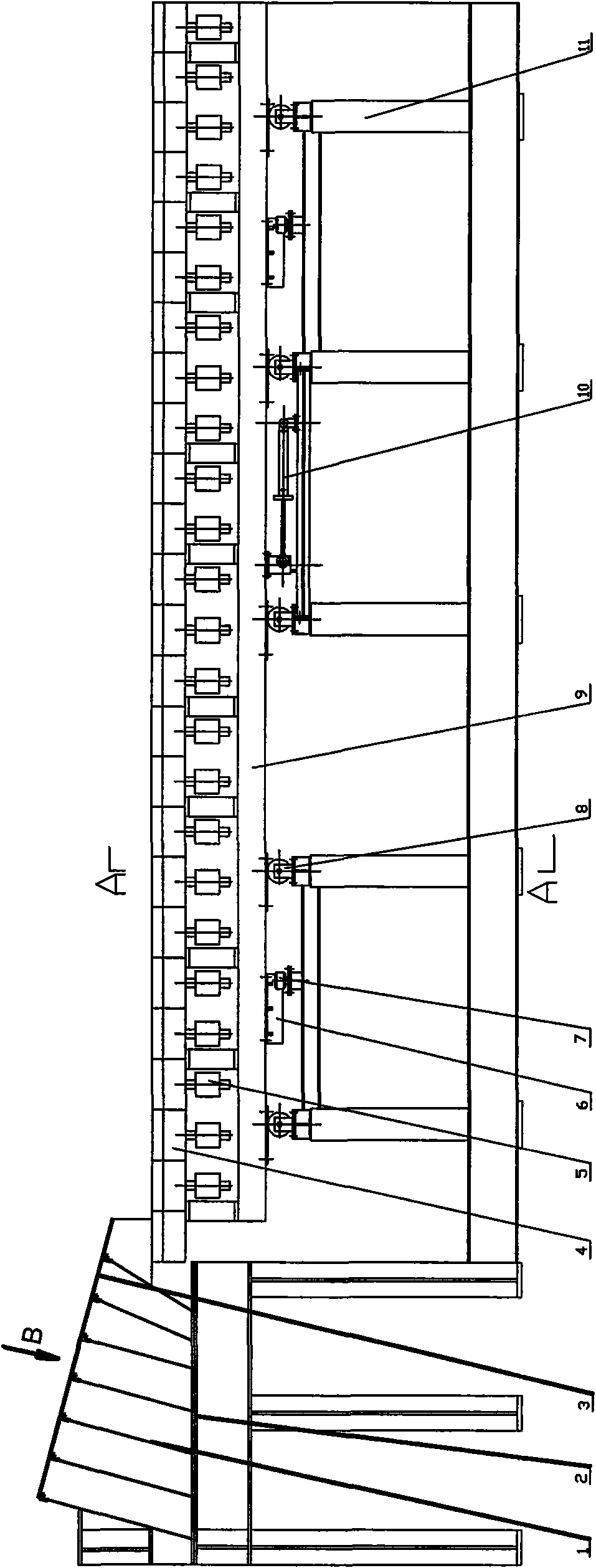

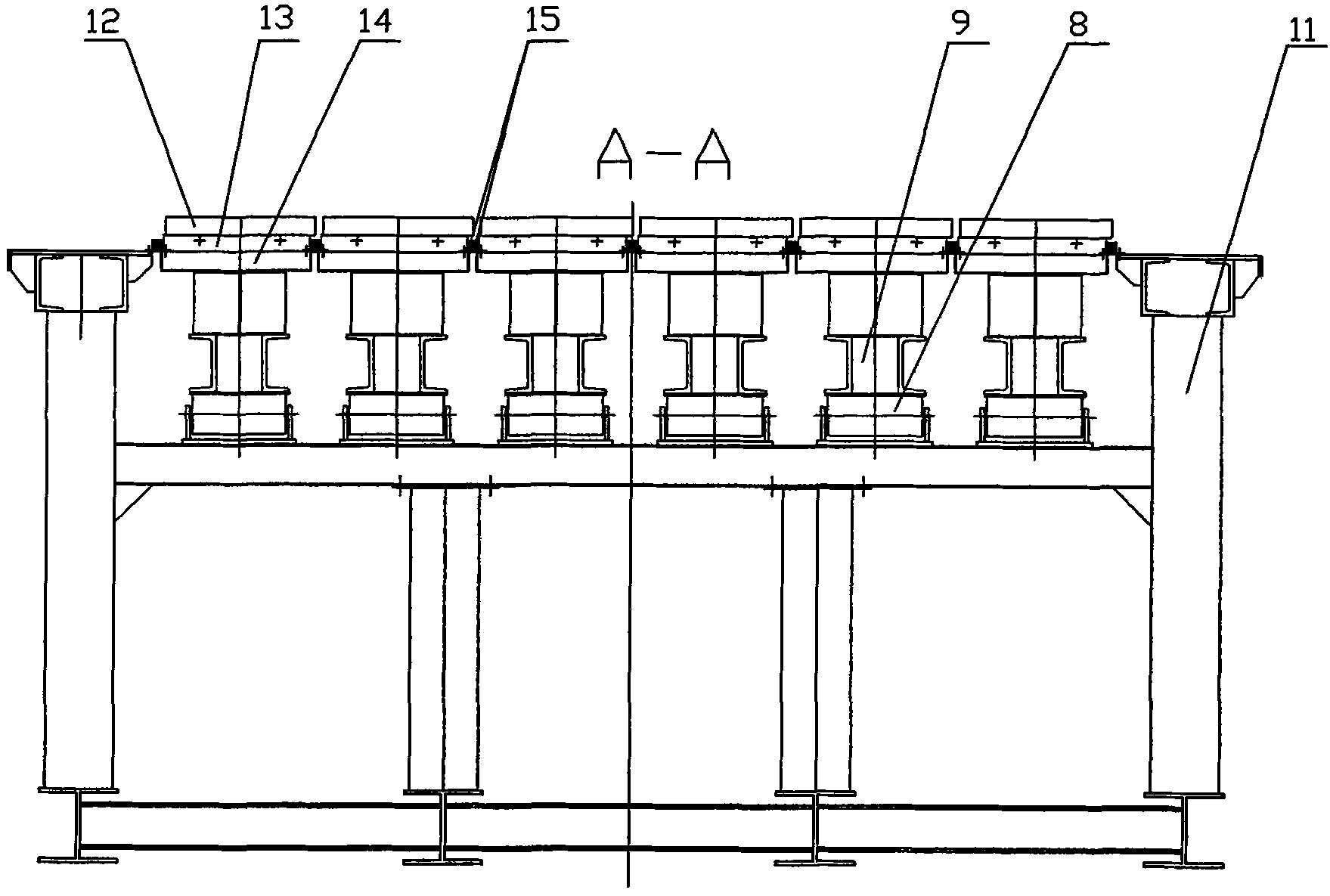

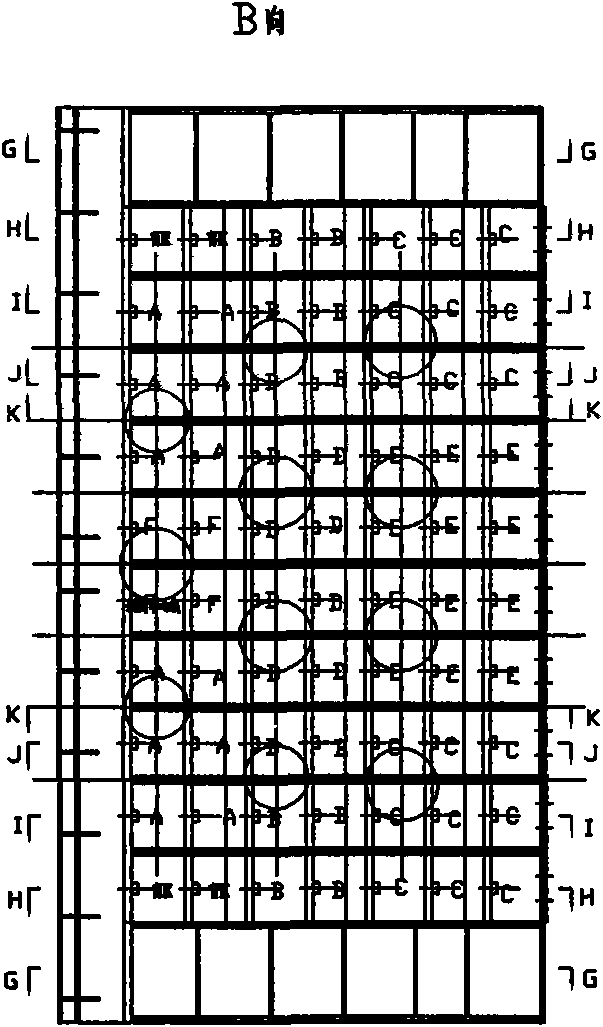

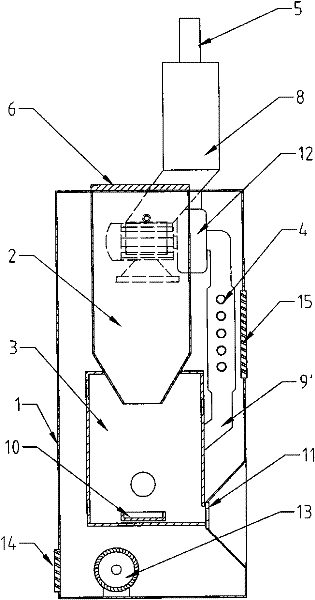

Large wind barn small air scoop crossbeam type chain-grate

InactiveCN101290122AImprove combustion qualityReduce wind speedTravelling grateEngineeringWind speed

The invention discloses an endless grate, in particular to a big wind bin and small wind catcher crossbeam-type endless grate. The endless grate comprises a frame consisting of a middle beam (2), an upper lead rail (1) and a lower lead rail (12); a furnace chain connected with a drive device is arranged on the frame; the endless grate is characterized in that: the lower part of the furnace chain on the upper part is provided with a wind bin (11) communicated with the furnace chain; a wind chest (14) communicated with the wind bins (14) is arranged on the whole side of the grate; the wind chest (14) is connected with a wind supply device. The endless grate changes the mode that each wind chamber respectively supplies wind in the prior art, thereby greatly reducing wind speed, stabilizing wind pressure, ensuring the even wind supply to the furnace chain, improving the burning quality of fuel and saving energy.

Owner:瓦房店市永宁机械厂

Curve cleaning machine

InactiveCN103357632AReduce usageReduce labor intensityDrying gas arrangementsFlexible article cleaningSmall footprintEngineering

The invention provides a curve cleaning machine and relates to cleaning equipment aiming at automobile front and rear windshields, side window glass and curve glass of solar photothermal products. The invention provides the curve cleaning machine which is small in occupied size, is convenient to overhaul, is good in air drying effect and is small in noise. The curve cleaning machine provided by the invention comprises a water washing section and an air drying section. Conveying devices are respectively arranged in the water washing section and the air drying section; the water washing section is provided with at least two sets of high-pressure sprinkler pipes above and below the conveying devices; and a water tank is arranged below the water washing section corresponding to the high-pressure sprinkler pipes. The curve cleaning machine is characterized in that the water tank is connected with the at least two sets of high-pressure sprinkler pipes by a circulating water pump and a heater.

Owner:辽宁北方机械股份有限公司

Waste heat recovery overall device for external exhaust of glass annealing furnace

InactiveCN109751875AStable temperatureStable wind pressureIncreasing energy efficiencySteam superheatersAir volumeSuperheater

A waste heat recovery overall device for external exhaust of a glass annealing furnace comprises an inlet flue branch pipe, an inlet flue main pipe, a damper regulating valve, a waste heat recovery overall device body, an outlet flue, an induced draft fan, a chimney and the like, wherein the waste heat recovery overall device body comprises a steam superheater, an evaporator, and an economizer. Atpresent, the cooling air of the glass annealing kiln is discharged to the outside due to the small air volume and dispersed air volume, and consequently energy waste is caused; and the waste heat recovery overall device for external exhaust of the glass annealing furnace is used for collecting the external exhaust heat recovery, and utilizes the heat source to the maximum extent to generate superheated steam.

Owner:株洲大源节能环保科技有限公司

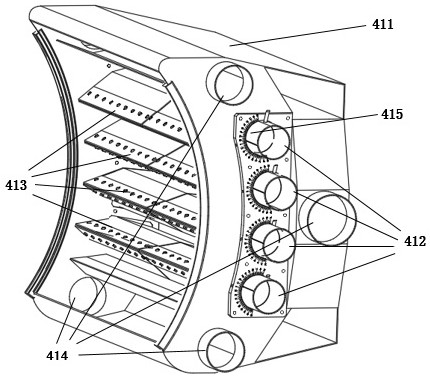

Steady flow cooler

ActiveCN101957145AStrongHigh rigidityHandling discharged materialClinker productionCooling efficiencyControl unit

The invention discloses a steady flow cooler, which relates to the steady flow cooler for cooling and conveying high-temperature cement clinker and the like. The steady flow cooler comprises a bracket, a fixed grate bed and a movable grate bed which are engaged on the bracket, wherein the fixed grate bed and the movable grate bed are provided with an air supply device respectively; a drive device and a guide device are arranged below the movable grate bed; the fixed grate bed has a box-type structure and is partitioned into a plurality of units by partition boards, a front grate plate arranged obliquely downwards is arranged above each unit, a plurality of adjacent front grate plates form an area, an independent air supply device is arranged below each area, and the air pressure and the air quantity of the each air supply device are controlled by a control unit; and the movable grate bed comprises a plurality of movable longitudinal beams arranged on the bracket and driven to run by the drive device and the guide device, a plurality of independent rear grate plates are arranged on each movable longitudinal beam, and an air supply device with adjustable air pressure and air quantity is arranged below the rear grate plates respectively. The steady flow cooler greatly improves the cooling efficiency and the cooling quality of the cement clinker.

Owner:江苏鹤林智能机械有限公司

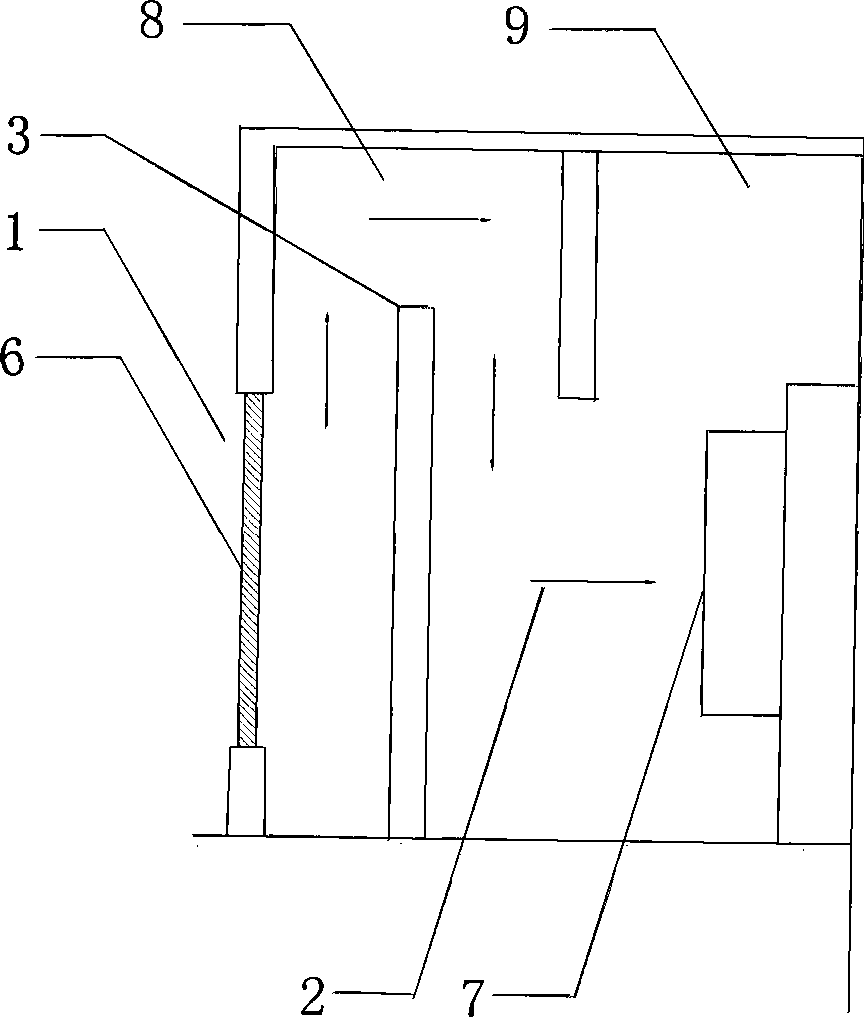

Improved labyrinth type air intake chamber structure

ActiveCN101367607AImprove filtering effectGuaranteed uptimeGlass tempering apparatusAerospace engineering

The invention provides an improved labyrinth type air intake chamber structure which can guarantee a relative stable wind pressure in a fan house as well as effectively prevent dust and impurities in air from entering equipment through fan inlet during air draft. The air intake chamber structure comprises an air inlet and an air outlet; wherein, the air inlet is provided with a filter screen; the air inlet is opposite to the air outlet; and the air outlet is opposite to an air suction port of a fan in the fan house. The air intake chamber structure is characterized in that an air stopping wall is arranged between the air inlet and the air outlet.

Owner:无锡海达光能股份有限公司

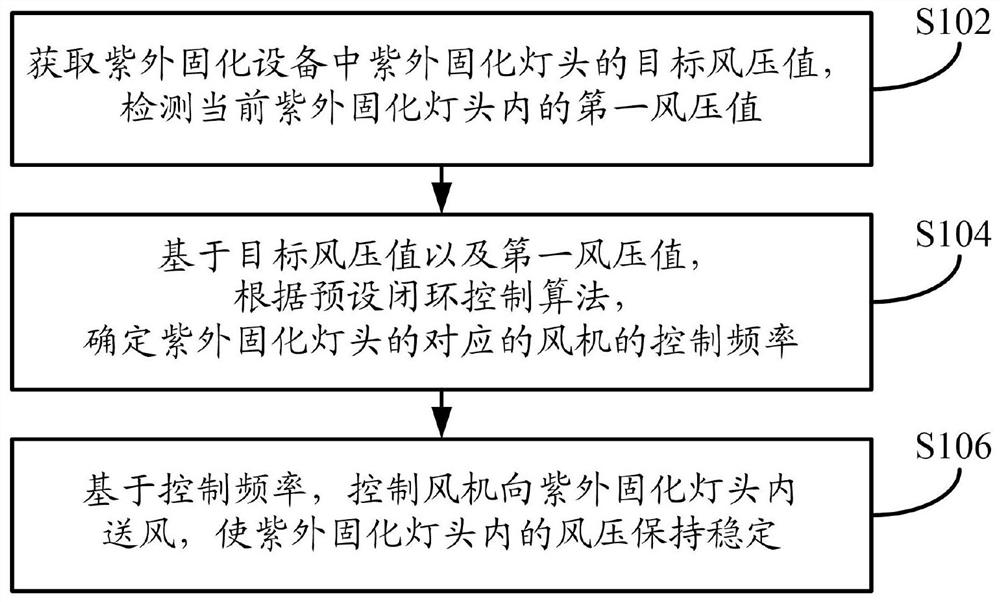

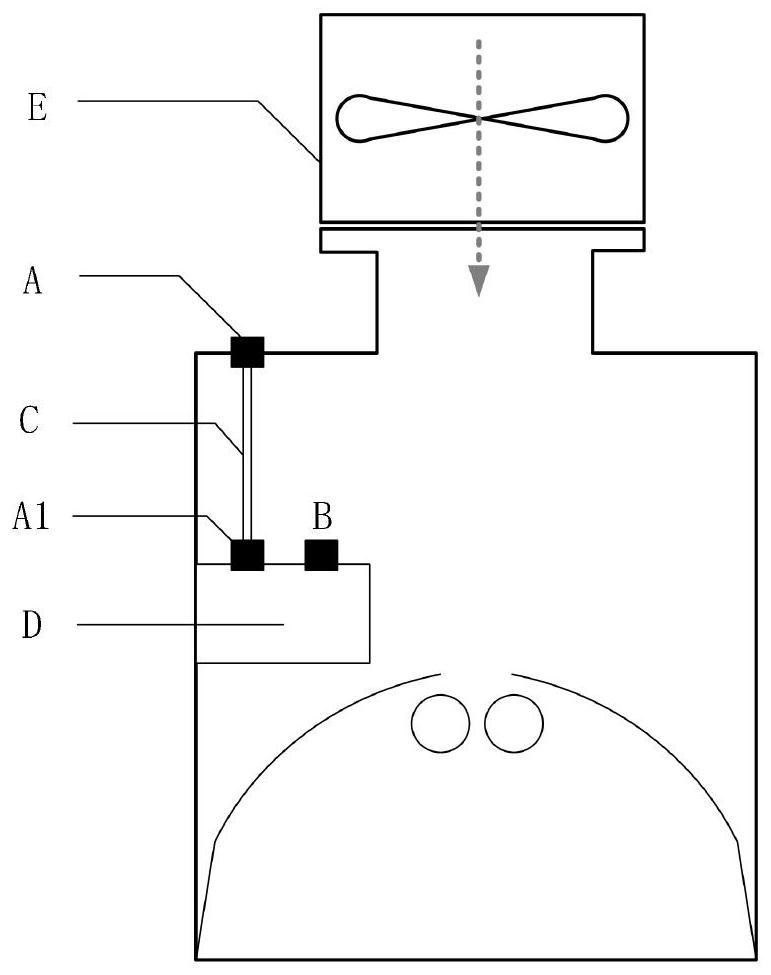

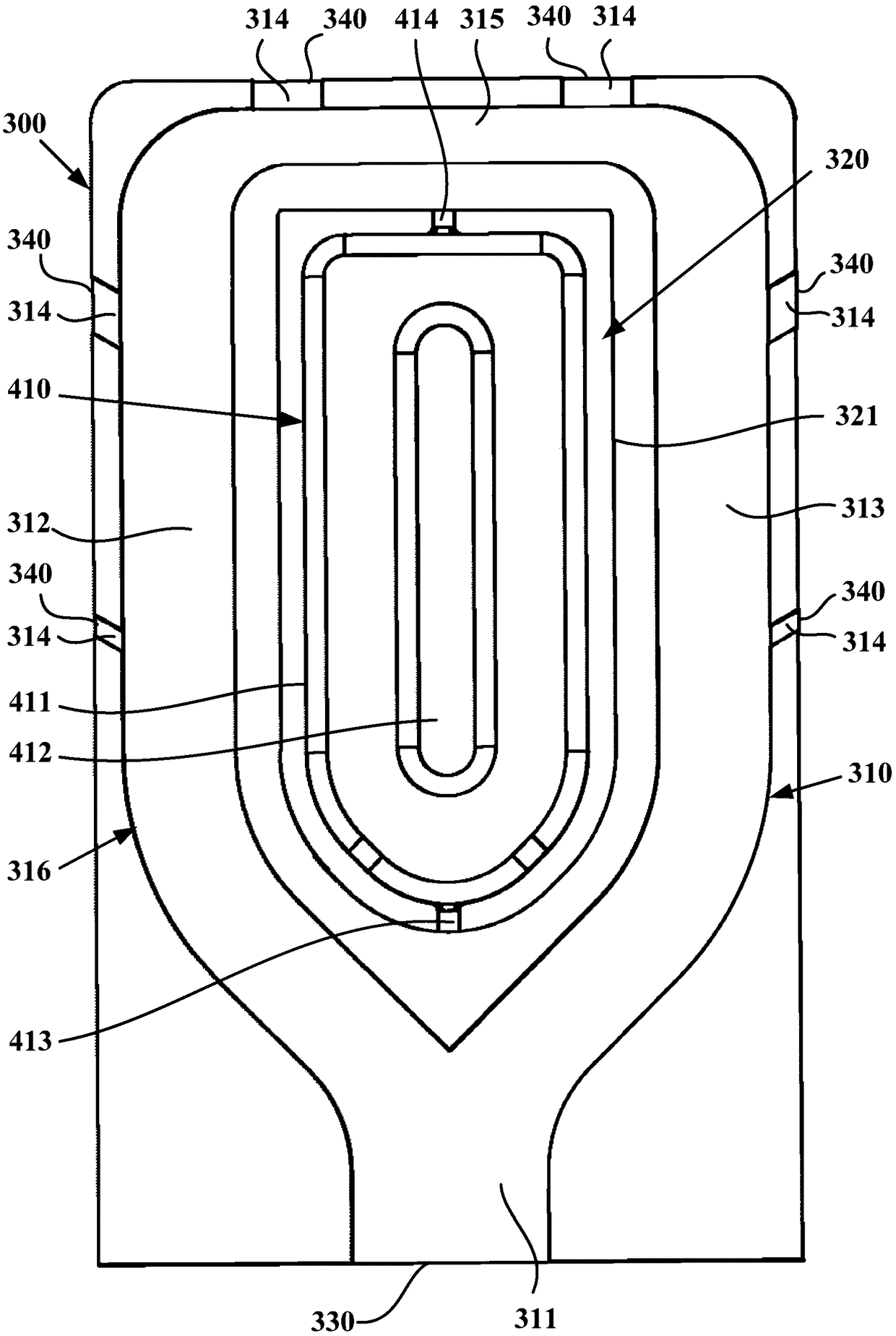

Fan control method in ultraviolet curing equipment and ultraviolet curing equipment

PendingCN111701822AImprove cooling effectStable wind pressurePretreated surfacesPump controlUltravioletEngineering

The embodiment of the invention discloses a fan control method in ultraviolet curing equipment and the ultraviolet curing equipment. The fan control method comprises the steps that a target wind pressure value of an ultraviolet curing lamp holder in the ultraviolet curing equipment is obtained, a first wind pressure value in the ultraviolet curing lamp holder at present is detected; based on the target wind pressure value and the first wind pressure value, the control frequency of a fan corresponding to the ultraviolet curing lamp holder is determined according to a preset closed-loop controlalgorithm; and based on the control frequency, the fan is controlled to supply air into the ultraviolet curing lamp holder. By means of the fan control method in the ultraviolet curing equipment, theair pressure in the ultraviolet curing lamp holder can be kept stable.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Control device for air outlet direction of air conditioner indoor unit and air conditioner

ActiveCN111578487ASufficient air supply distanceImprove uniformityMechanical apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a control device for an air outlet direction of an air conditioner indoor unit and an air conditioner. The air conditioner indoor unit comprises a case and a heat exchanger, wherein the case comprises a rear shell and a front panel, the front panel comprises a radiation panel, and the front panel is connected to the front side of the rear shell to form an air duct with an air return opening and an air supply opening; and the heat exchanger is arranged in the air duct and connected to the rear shell. The control device comprises a plurality of fans and an air direction control module, wherein the air direction control module controls the rotating speed of each fan to control the air outlet direction of the air duct. According to the control device for the air outletdirection of the air conditioner indoor unit of the embodiment, the rotating speed of the fans is controlled through the air direction control module to obtain different air outlet directions, air pressure loss is small, it is guaranteed that the air conditioner indoor unit has the enough air supply distance, the uniformity of the indoor temperature is improved, and the air outlet direction can bestably controlled for a long period, so that different air outlet requirements of users are met.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

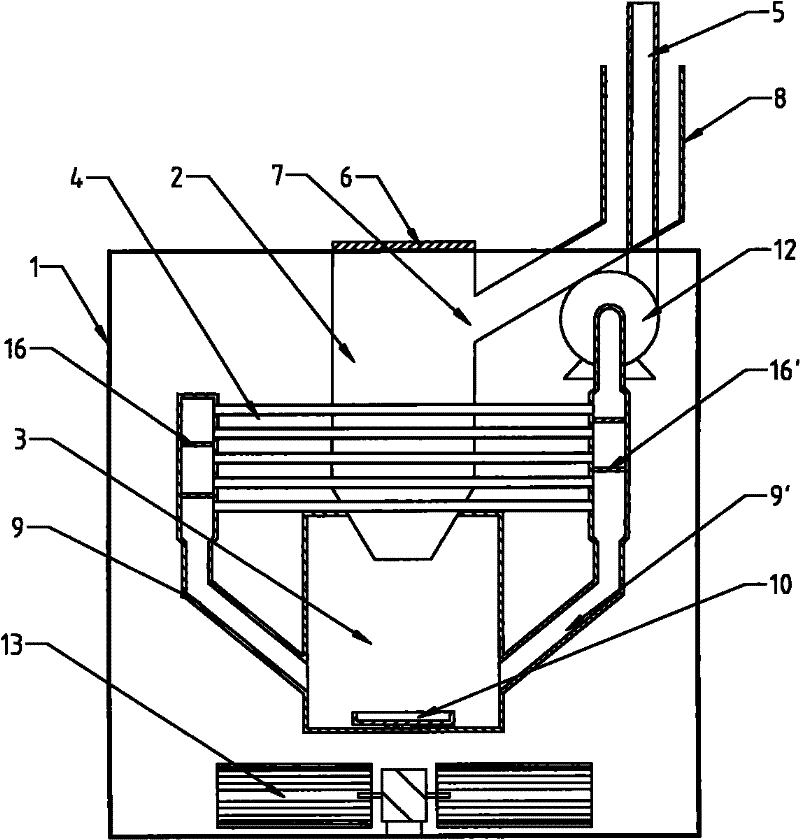

Air supply system and method for industrial furnace

ActiveCN104141964BLess investmentGood energy saving effectAir supply regulationFrequency conversionIndustrial engineering

The invention provides an air supply method of an industrial furnace. When air pressure is required to be increased, opening degrees of air doors of frequency conversion fans are increased; when the air pressure is required to be further increased, opening degrees of air doors of constant-speed fans are increased; when the air pressure is still required to be increased, working frequency of each frequency conversion fan is increased; when the air pressure is required to be decreased, the working frequency of each frequency conversion fan is decreased; when the air pressure is required to be further decreased, the opening degrees of the air doors of the frequency conversion fans are decreased; and when the air pressure is still required to be decreased, the opening degrees of the air doors of the constant-speed fans are decreased. The air supply method of the industrial furnace has the advantages as follows: for the fan units operating in an air door adjustment mode, only part of fans are subjected to frequency conversion renovation; and on the basis that the air pressure is stably adjusted through frequency conversion, the part of fans and other fans are controlled coordinately and combined to the overall fan unit network for stable operation.

Owner:上海金自天正信息技术有限公司

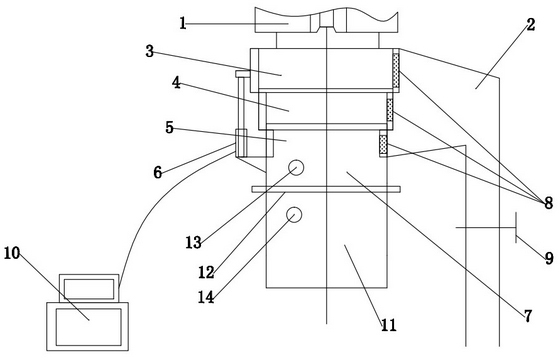

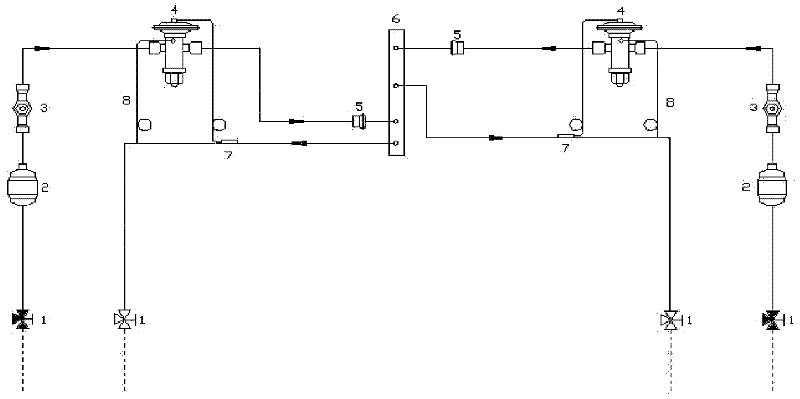

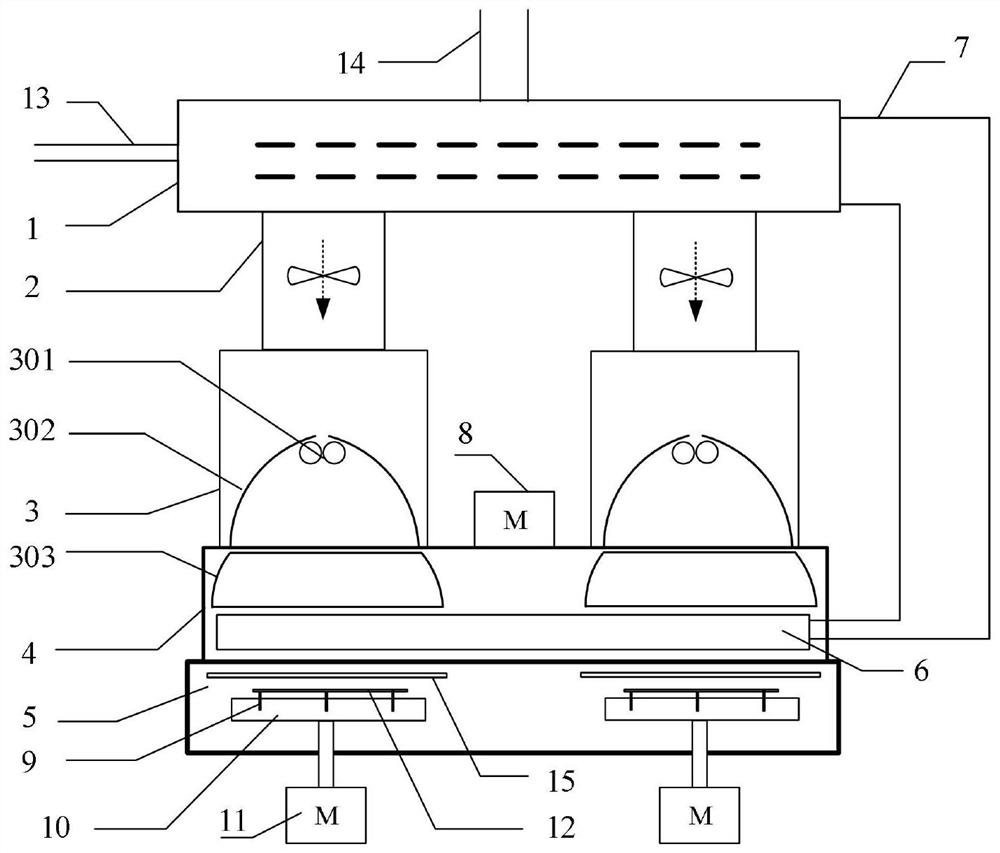

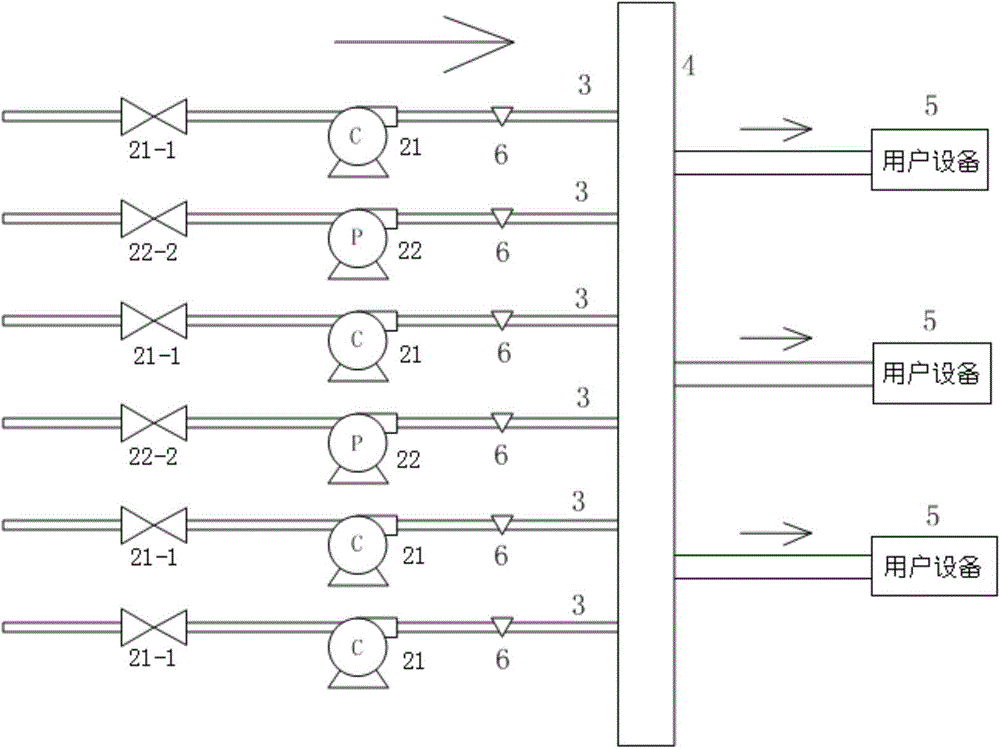

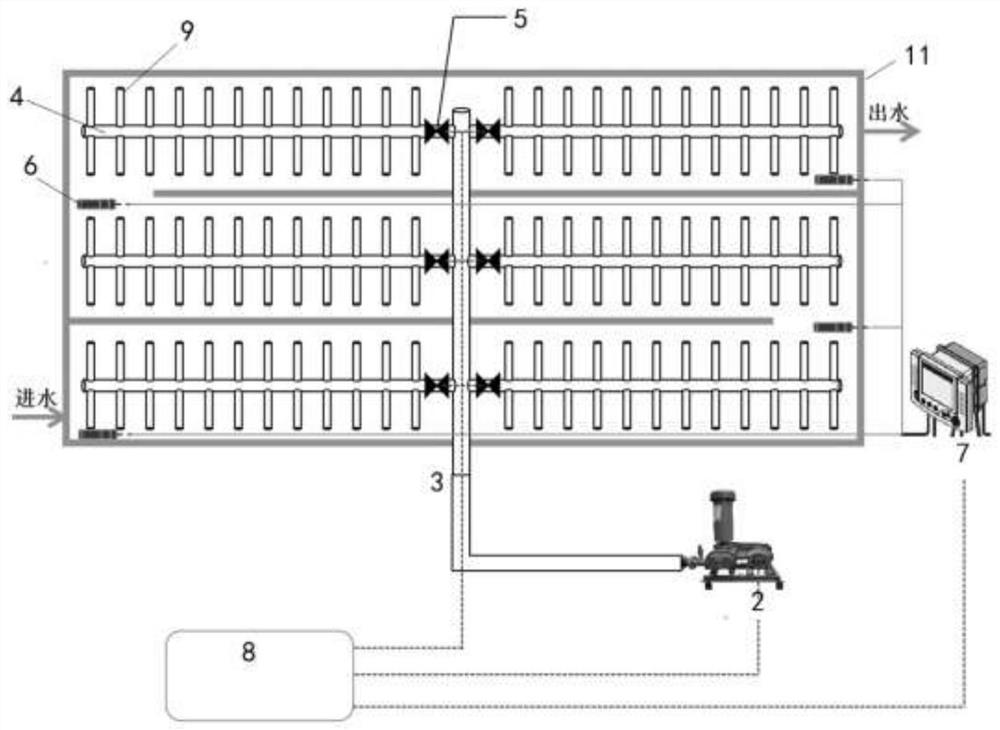

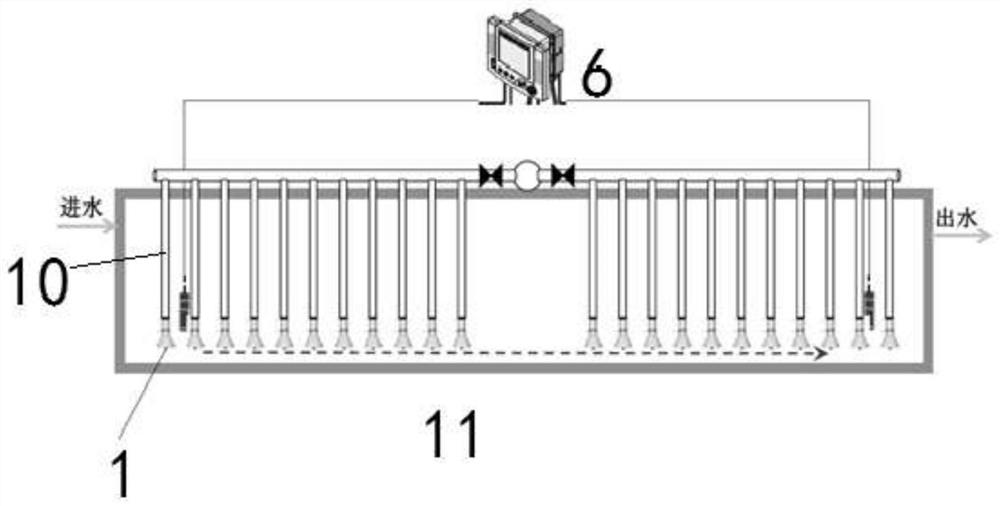

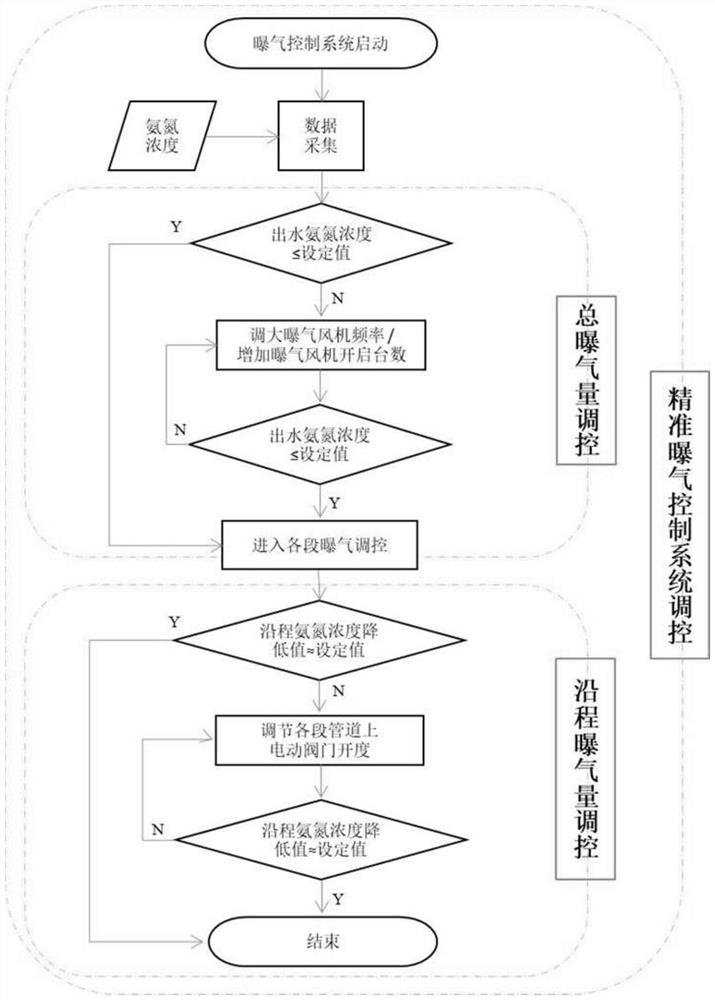

Intelligent aeration control device and method for sewage plant

PendingCN112811623AOxygen utilization remains constantStable wind pressureWater aerationSustainable biological treatmentAmmoniacal nitrogenAeration system

The invention discloses an intelligent aeration control device and method for a sewage plant, and belongs to the technical field of water treatment control. The device includes three units, wherein the first unit is an aeration system which comprises a spiral-flow aerator (1), a variable-frequency aeration fan (2), an aeration main pipeline (3), an aeration branch pipeline (4), an aeration pipeline branch (9), an aeration connecting pipeline (10) and an electric adjusting valve (5); the second unit is an ammonia nitrogen measuring system that comprises an ammonia nitrogen probe (6) and an ammonia nitrogen measuring instrument (7); and the third unit is a control system that comprises an ammonia nitrogen data acquisition system, an analysis system and a regulation and control system, and the ammonia nitrogen data acquisition system, the analysis system and the regulation and control system are integrated together to form a control device (8). On the premise that theoretical calculation of the aeration rate is oriented, ammonia nitrogen required by the emission standard serves as a water outlet end ammonia nitrogen control point, and the aeration rate is regulated and controlled through the on-way ammonia nitrogen concentration in the aerobic tank, so that the nitrification process is optimized, and intelligent aeration control over the aerobic tank is achieved.

Owner:北京安国水道自控工程技术有限公司

Preparation process of high-purity corundum

ActiveCN107244684AEconomical and practicalNo pollution in the processTransportation and packagingAluminates/aluminium-oxide/aluminium-hydroxide purificationPrillElectric arc furnace

The invention relates to a preparation process of high-purity corundum and belongs to the fields of a production process and a production device of corundum. The preparation process of the high-purity corundum is characterized by comprising the following steps: adding alumina monohydrate micropowder into a mixed solution of hydrochloric acid and water; adding manganese oxide into an obtained suspension liquid to obtain wet gel; drying the wet gel under the condition of 100 to 180 DEG C for 12 to 24 hours to obtain dry gel, crushing the dry gel and screening out granules of 50 to 70 meshes; mixing the obtained dry gel granules and a composite functional aid in a mixing machine, putting into an electric arc furnace, heating and calcining to obtain gamma-aluminum oxide; and calcining the obtained gamma-aluminum oxide in the electric arc furnace at 1500 to 1550 DEG C to obtain a high-purity corundum product. A high-purity high-quality corundum product is produced through reasonable process design; the mixing machine can accurately control a mixing link in production of the corundum to realize an uninterrupted weighing process; and waste gas generated by the electric arc furnace in production of the corundum is effectively treated, and environmental pollution generated by the waste gas is avoided.

Owner:山东泰尔福新材料科技有限公司

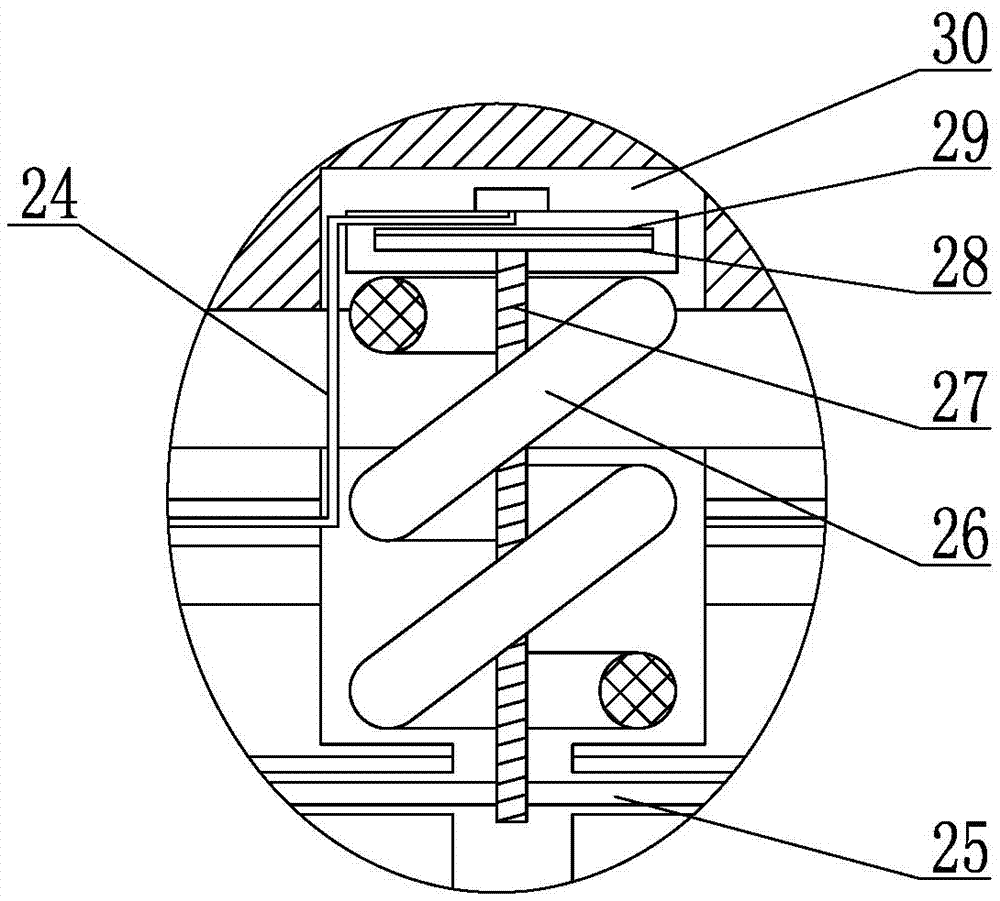

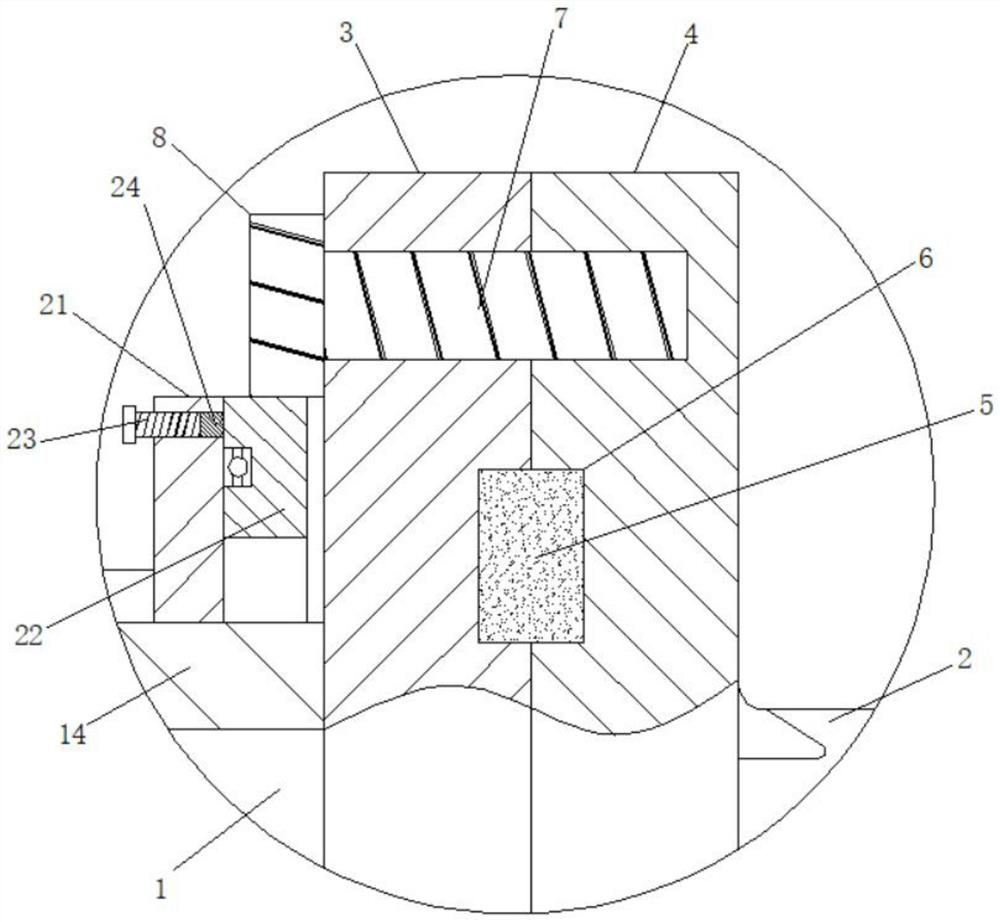

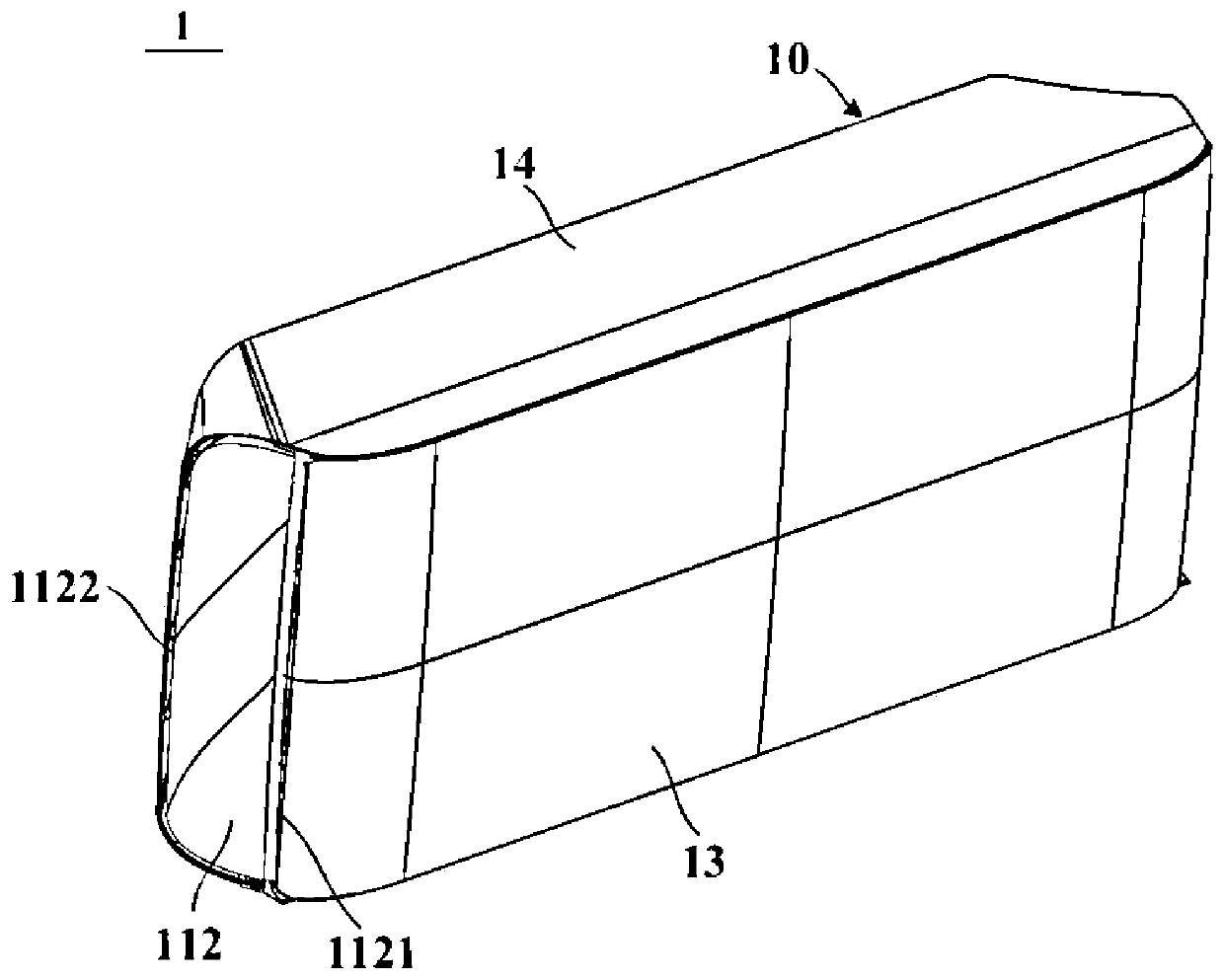

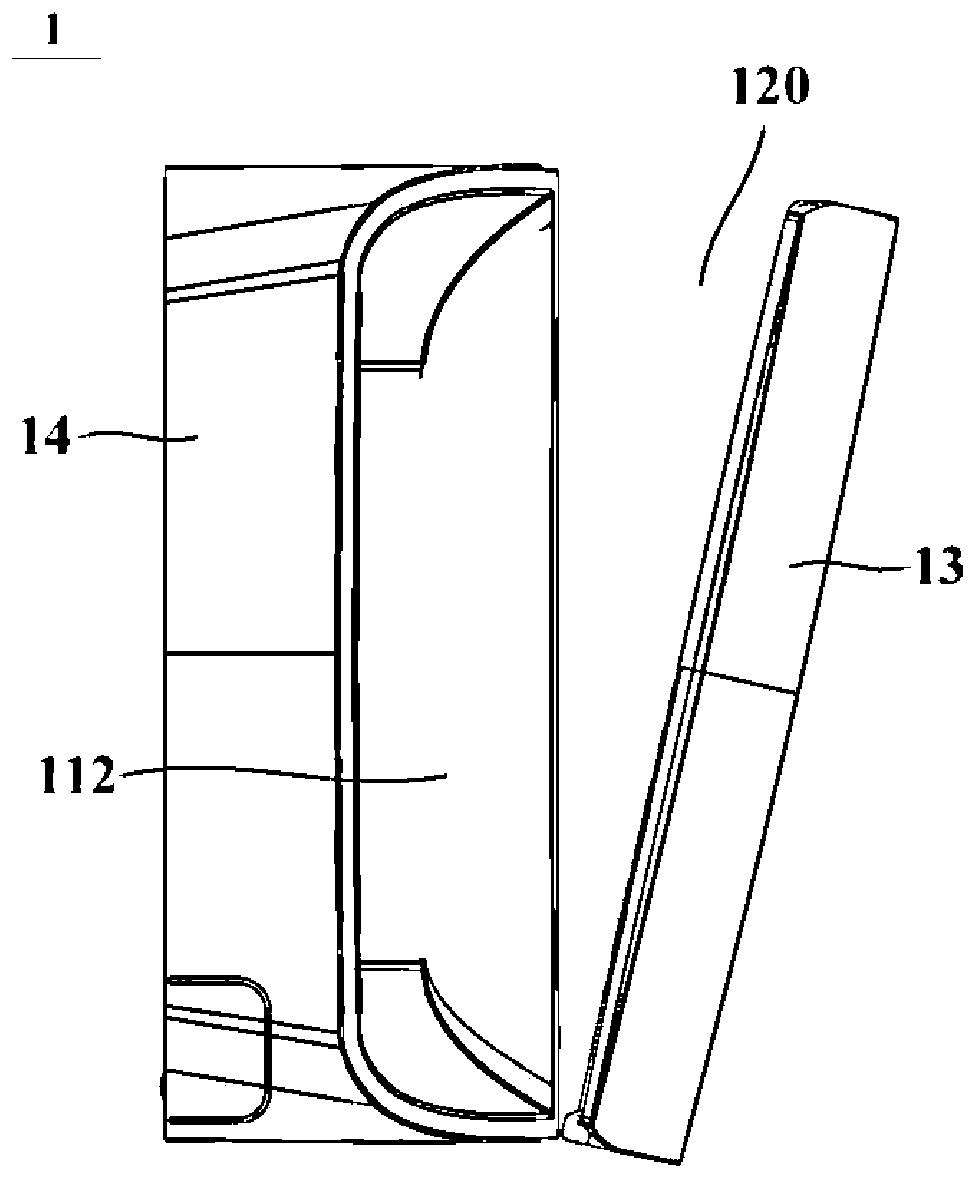

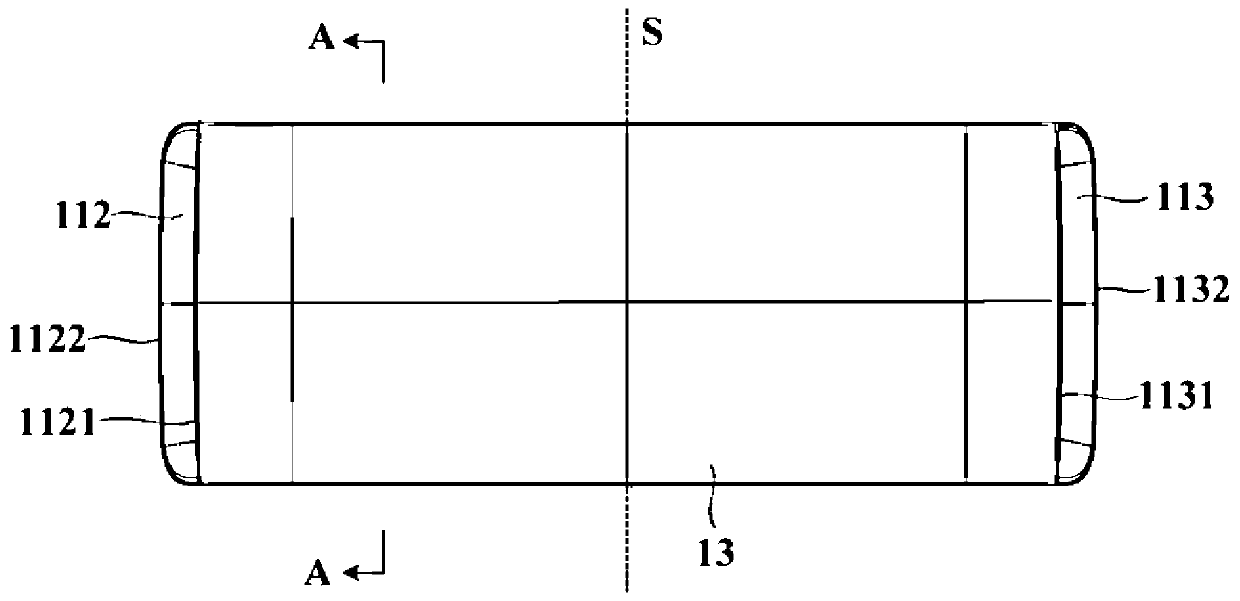

A sealing device with self-cleaning function for brushless fan casing

ActiveCN112228370BStable air volumeStable wind pressurePump componentsPump installationsBlade plateGear wheel

The invention relates to the field of brushless fan, in particular to a sealing device with self-cleaning function for the casing of a brushless fan, including a casing, an end cover, fan blades and a net cover, and the opposite ends of the casing and the end cover are respectively fixed with protruding Ring 1 and outer convex ring 2, outer convex ring 1 and outer convex ring 2 are fixedly connected by a plurality of bolts 1, the end of bolt 1 close to outer convex ring 1 is fixedly connected to gear 1, and a ring plate is sleeved on the shell, and the ring plate A plurality of leaf plates are fixed on the peripheral wall, and a plurality of brush strips are fixed on the side of the ring plate close to the net cover. The ring plate is provided with a centrifugal push-pull mechanism. It can be meshed with multiple gears at the same time. The casing of this brushless fan uses a sealing device with self-cleaning function to realize automatic cleaning of the grille, maintain stable air delivery pressure and high air delivery efficiency of the brushless fan, reduce energy consumption, and ensure that the casing and end cover are The tightness between them prevents external moisture and dust from entering the inside of the shell.

Owner:湖南伟力汽车零部件有限公司

air conditioner indoor unit

ActiveCN106705216BIncrease the air supply angleExpand the range of air supplyDucting arrangementsElectrical apparatusThermodynamicsEngineering

The invention relates to an air conditioner indoor unit which comprises a shell, a heat exchange device, a first centrifugal fan, a second centrifugal fan, a first axial flow fan set, a second axial flow fan set, a first ion air generation device and a second ion air generation device. The shell is provided with an air inlet, lower air outlet and two lateral air outlets, the heat exchange device is arranged in the shell and configured to exchange heat with air flowing through the shell, and the first centrifugal fan and the second centrifugal fan are arranged on the rear side of the heat exchange device and configured to promote the air after going through heat exchange by the heat exchange device to respectively flow towards the lower air outlet, the first lateral air outlet and the second lateral air outlet; the first axial flow fan set and the second axial flow fan set are arranged on flowing paths from the two centrifugal fans to the two lateral air outlets respectively and configured to promote air from the two centrifugal fans to respectively continue to flow towards the two lateral air outlets; the first ion air generation device and a second ion air generation device are respectively arranged on flowing paths from the two axial flow fan sets to the two lateral air outlets and configured to promote air from the two axial flow fan sets to respectively continue to flow towards the two lateral air outlets.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

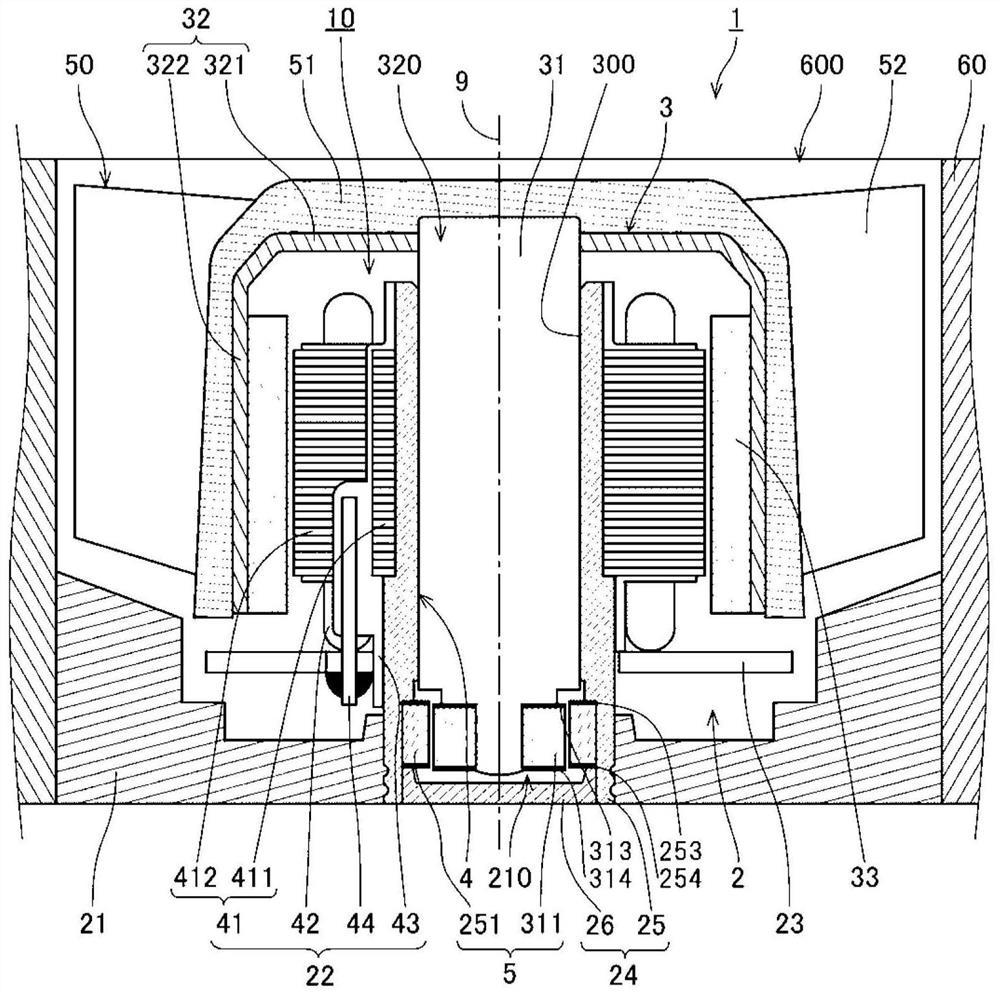

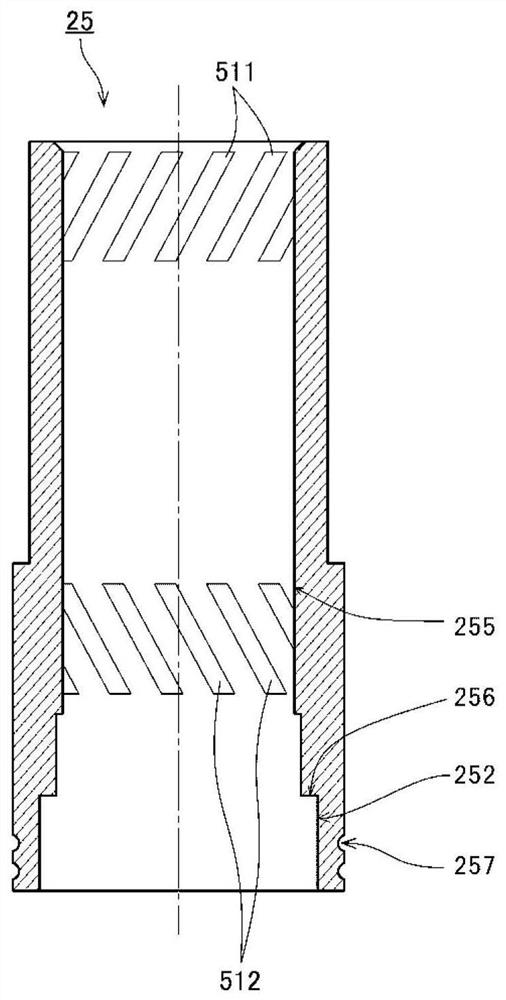

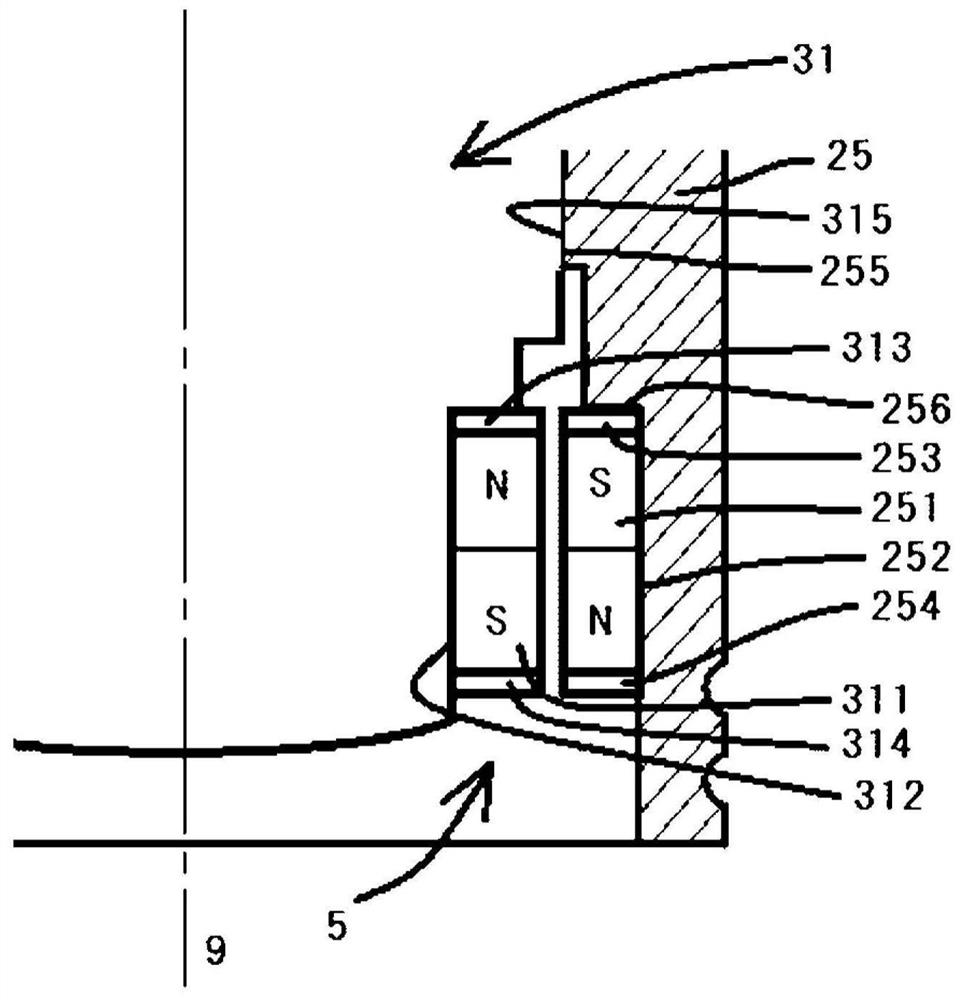

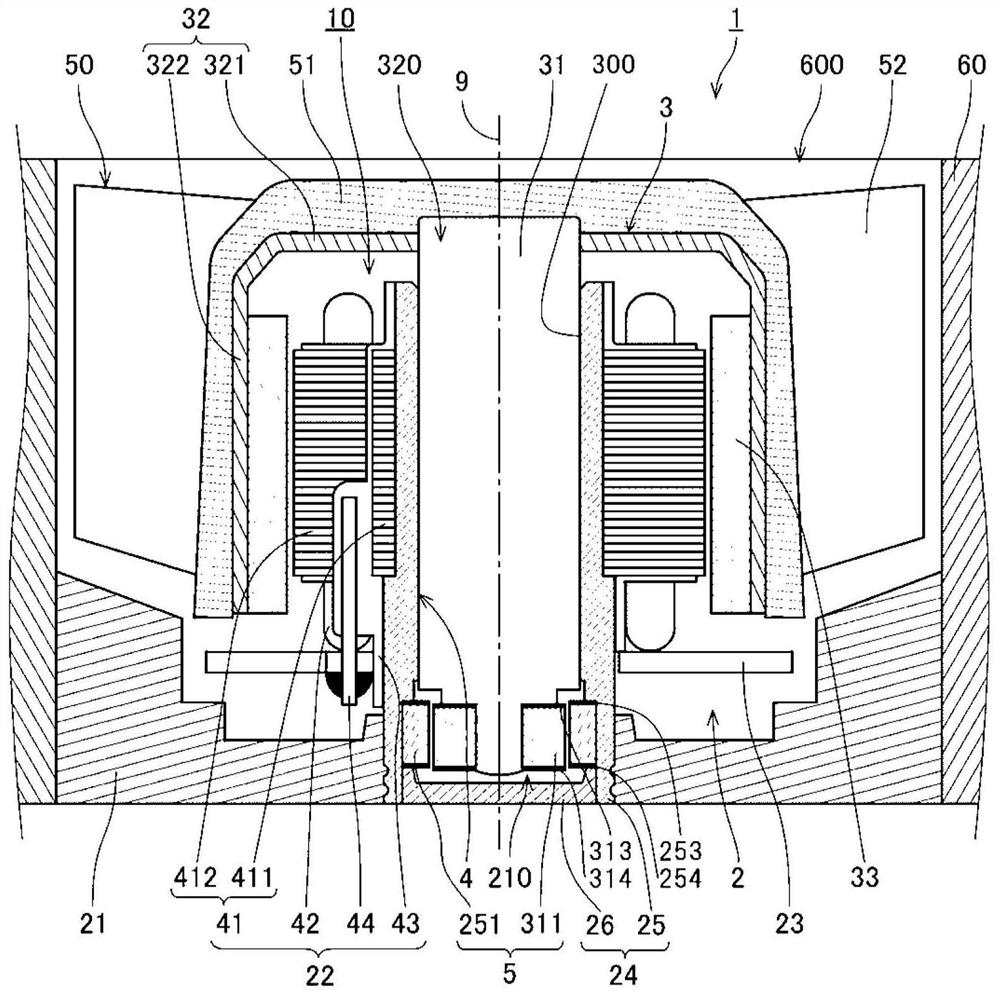

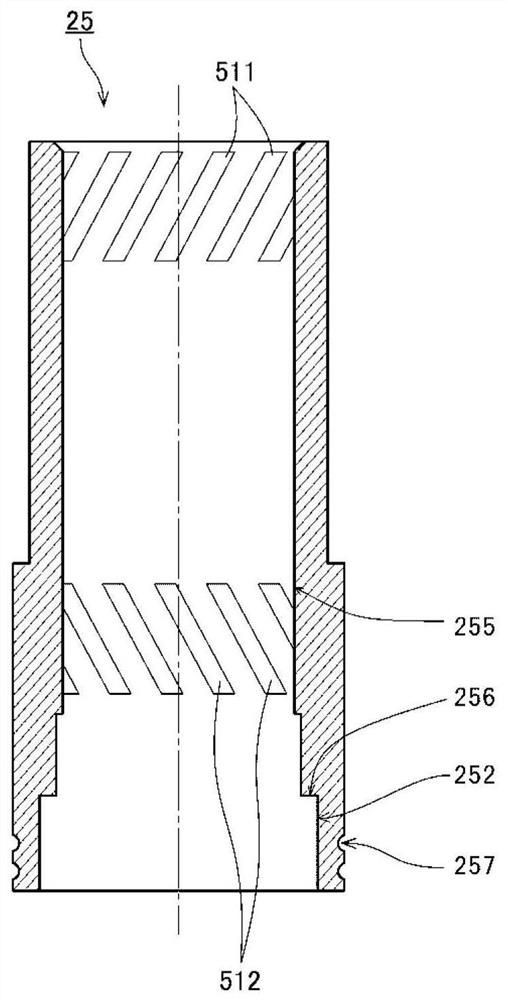

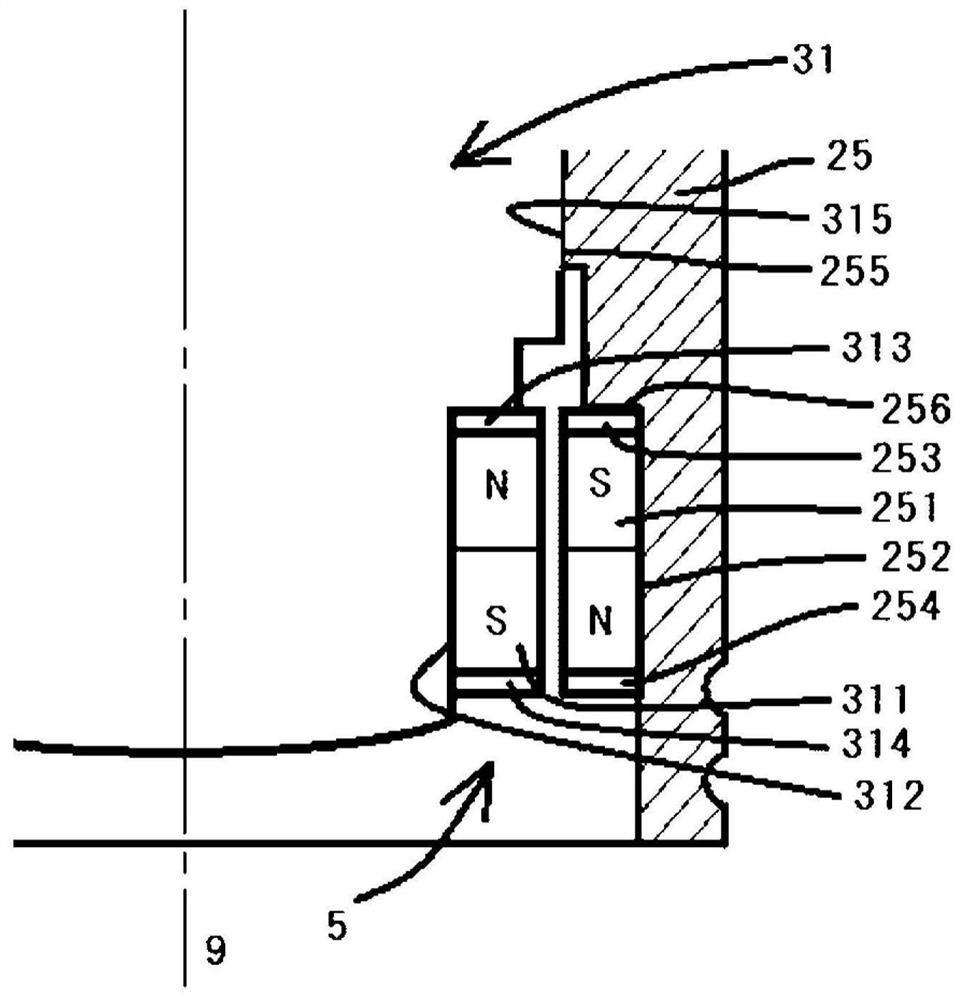

Gas dynamic pressure bearing, motor and fan motor

Provided are a gas dynamic pressure bearing, a motor, and a fan motor, the gas dynamic pressure bearing having: a shaft that is rotatable about a central axis and has a shaft dynamic pressure part; and a sleeve having a sleeve dynamic pressure part opposed to the shaft dynamic pressure part with a gap therebetween in the radial direction, in which one side of the gas dynamic pressure bearing in the axial direction has an axial bearing part that can be positioned in the axial direction by means of a rotation-side magnet supported by the shaft and a fixed-side magnet supported by the sleeve. Therotation-side magnet has a cylindrical shape extending in the axial direction and has different magnetic poles in the axial direction. The fixed-side magnet has a cylindrical shape extending in the axial direction, faces the rotation-side magnet with a gap therebetween in the radial direction, and has a magnetic pole different from the magnetic pole of the rotation-side magnet in the radial direction. The two axial end parts of the fixed side magnet are provided with fixed side auxiliary components of a strong magnetic body.

Owner:NIDEC CORP

A cooling device for high temperature gas

ActiveCN105135910BSmall footprintIncrease profitStationary tubular conduit assembliesConvex structureInterior space

Owner:安徽蓝盾光电子股份有限公司

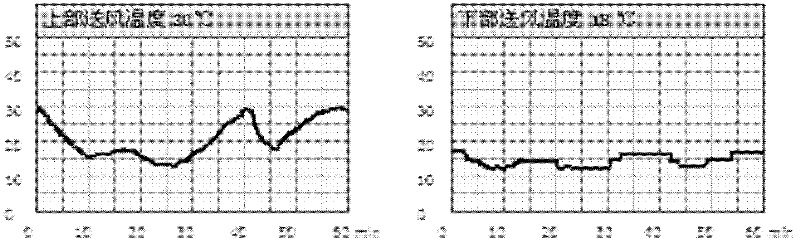

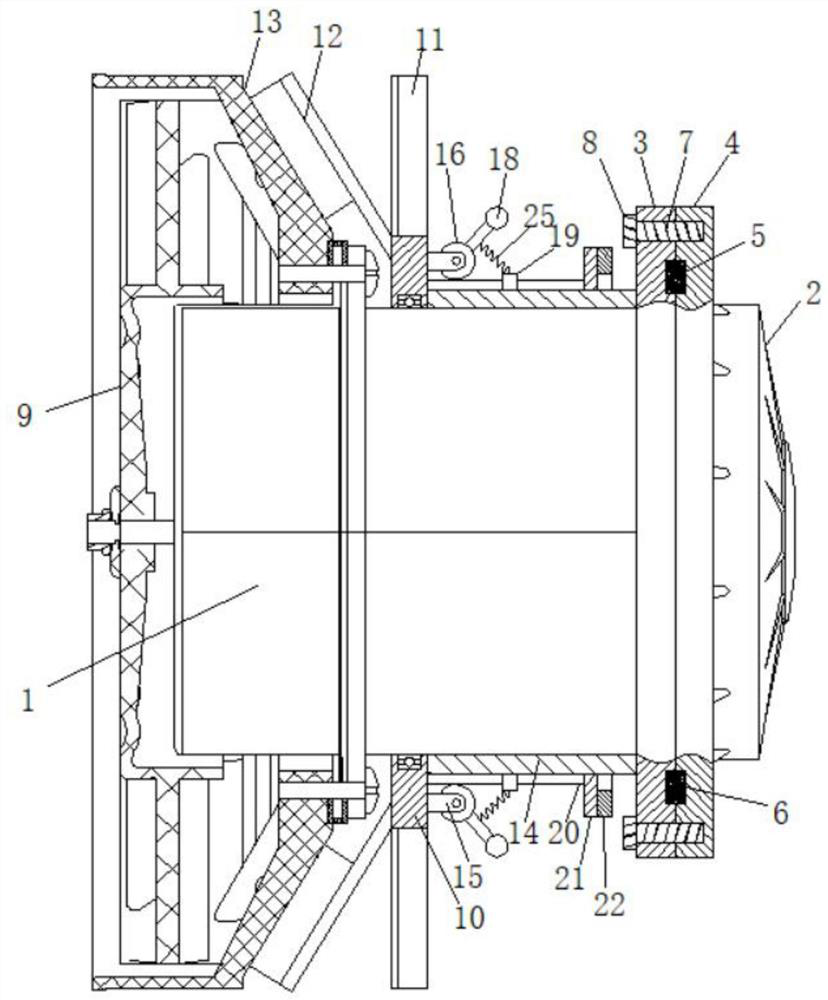

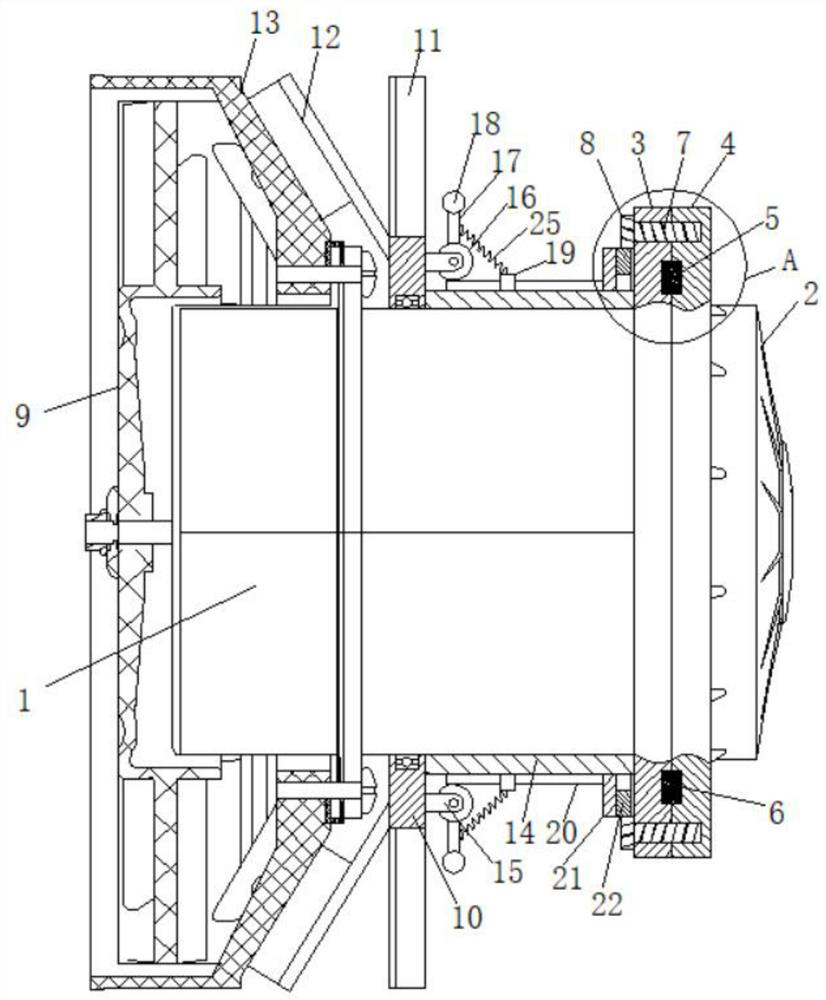

A frequency conversion flue-cured tobacco heat pump dual power barn

ActiveCN109330010BStable wind pressureStable air volumeTobacco preparationAutomatic controlThermodynamics

The invention discloses a frequency conversion flue-cured tobacco heat pump dual-power barn, which comprises a flue-cured tobacco room, a heating room, a heat pump unit, and a biomass fuel furnace. The return air outlet, the heating room is provided with a diversion wall facing the return air outlet, the heat pump evaporator of the heat pump unit is installed directly opposite the vent, the heat exchange device is installed above the heat pump evaporator, and the diversion fan is installed above the heat exchange device. The heat pump condenser of the heat pump unit is arranged at the air inlet, a biomass fuel furnace and a control device are arranged in the heating room, and a monitoring system connected to the control device is arranged in the flue-cured tobacco room. The present invention realizes automatic control through a control device, can precisely control temperature changes, and has high heat utilization efficiency. Compared with other curing methods, the curing cost is low and energy-saving, and the loss of tobacco leaf curing modulation is reduced, and the yellowing of tobacco leaves is coordinated with color fixing. Drying is matched with aroma, and the goal of roasting tobacco leaves to be yellow, dry and fragrant is achieved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

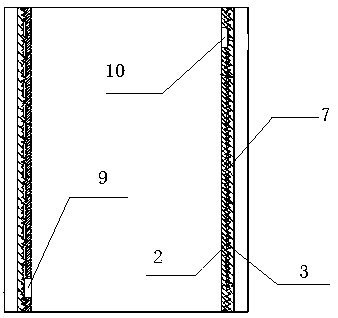

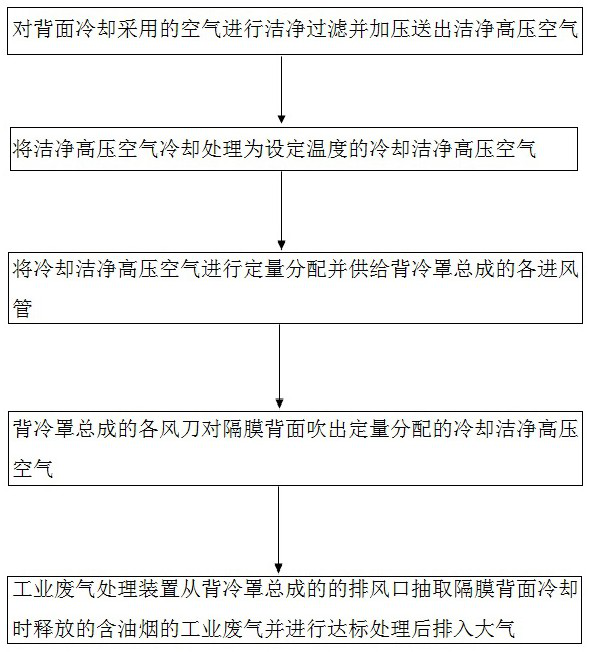

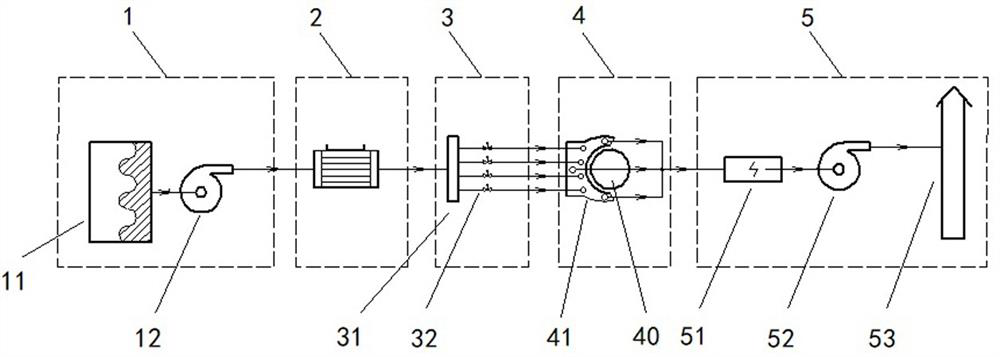

Wet-method lithium battery diaphragm back cooling process

PendingCN114464956ATo achieve the purpose of forced coolingImprove cooling efficiencyCell component detailsHigh diaphragmInternal resistance

The invention discloses a wet-process lithium battery diaphragm back cooling process. The process comprises the following steps: A, cleaning and filtering air adopted for back cooling, and pressurizing to send out clean high-pressure air; b, the clean high-pressure air is cooled into cooled clean high-pressure air at the set temperature; c, quantitatively distributing the cooled clean high-pressure air and supplying the cooled clean high-pressure air to each air inlet pipe of the back cooling cover assembly; d, each air knife of the back cooling cover assembly blows out quantitatively distributed cooling clean high-pressure air to the back surface of the diaphragm; and E, the industrial waste gas treatment device extracts the industrial waste gas containing oil smoke released when the back face of the diaphragm is cooled from an exhaust outlet of the back cooling cover assembly, and the industrial waste gas is discharged into the atmosphere after standard treatment. According to the process, the cooling efficiency of the back of the diaphragm can be improved, and industrial waste gas can be discharged up to the standard, so that the stripping strength of the back of the diaphragm is effectively improved; by improving the microstructure of the non-roller-attached surface of the diaphragm, the air permeability of the diaphragm is reduced, the internal resistance of the diaphragm is improved, and the rate performance of the battery is favorably improved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

refrigerator

ActiveCN106225387BImprove cooling efficiencyIncrease water outputLighting and heating apparatusCooling fluid circulationCold airEngineering

Owner:HAIER SMART HOME CO LTD

Blower for conveying powder raw materials and manufacturing method thereof

The invention relates to blowers, and aims to provide a blower for conveying powder raw materials and a manufacturing method thereof. According to the technical scheme, the blower is characterized bycomprising a machine frame, a blower box and a driving motor, wherein the blower box is detachably connected to one side of the machine frame, the driving motor is detachably connected to the machineframe, an output shaft of the driving motor extends into the blower box and is connected with a blower impeller, the blower impeller is located in the blower box, an air inlet is formed in one surface, away from the machine frame, of the blower box, an air outlet is formed in the top of the blower box, the blower impeller comprises impeller covers and blades, two impeller covers are oppositely arranged, the blades are located between the two impeller covers, the two surfaces, facing the impeller covers, of each blade are both and fixedly connected with riveting pieces, riveting holes are formed in the impeller covers, and the riveting pieces penetrate through the riveting holes and are bent and pressed on the impeller covers. The blower for conveying the powder raw materials has the advantages of reducing the loss of raw materials and improving the utilization rate of the raw materials.

Owner:江苏佳风风机科技有限公司

Aerodynamic bearings, motors and fan motors

A gas dynamic pressure bearing, a motor, and a fan motor are provided. The gas dynamic pressure bearing has: a shaft that can rotate around a central axis and has a shaft dynamic pressure part; Sleeve dynamic pressure parts with gaps facing each other, wherein one axial side of the gas dynamic pressure bearing has an axial bearing part, and the axial bearing part can use the magnet on the rotating side supported by the shaft and the magnet on the fixed side supported by the sleeve. positioned in the axial direction. The rotating side magnet has a cylindrical shape extending in the axial direction and has different magnetic poles in the axial direction. The fixed-side magnet has a cylindrical shape extending in the axial direction, faces the rotating-side magnet with a gap in the radial direction, and has a magnetic pole different from that of the rotating-side magnet in the radial direction. The fixed-side magnet has fixed-side auxiliary parts of a ferromagnetic material at both ends in the axial direction.

Owner:NIDEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com