Air supply system and method for industrial furnace

A technology of air supply system and industrial furnace, which is applied in the direction of combustion method, air supply adjustment, lighting and heating equipment, etc., which can solve the problems of large investment and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

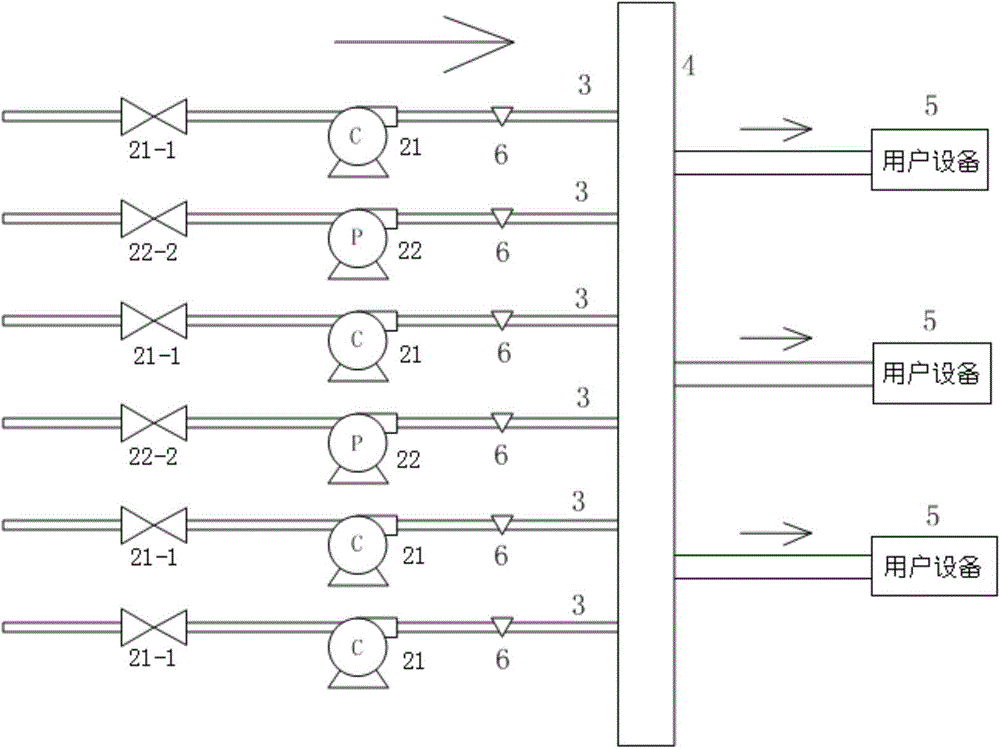

[0026] figure 1 It is a structural schematic diagram of the industrial furnace air supply system of the present invention.

[0027] Such as figure 1 As shown, the industrial furnace air supply system includes: constant speed fan 21, variable frequency fan 22, main pipe 4, branch pipe 3, user equipment 5, backstop baffle 6, air pressure sensor, controller and control panel. The user equipment is equipment such as a hot blast stove or a blast furnace that requires a fan to supply air.

[0028] The constant speed fan 21 has a constant speed fan damper 21-1, and the frequency conversion fan 22 has a frequency conversion fan damper 22-2.

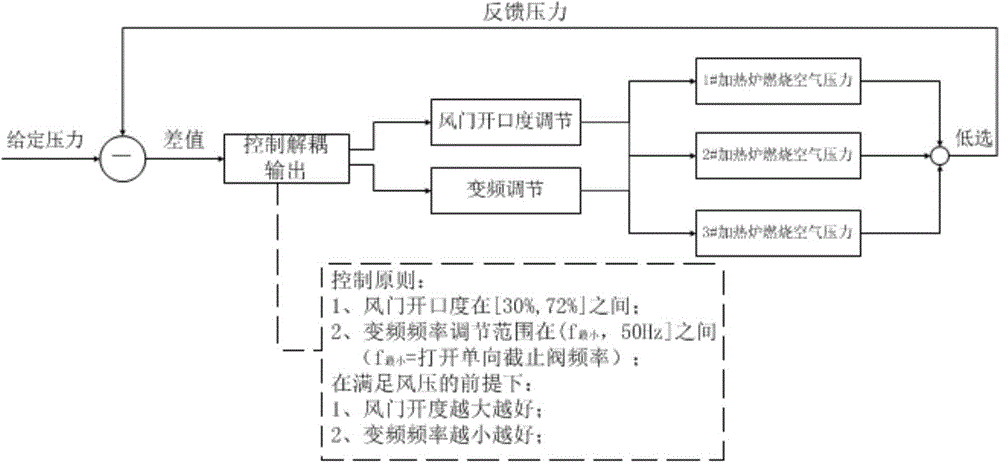

[0029] The wind pressure sensor tests the actual wind pressure in the main pipeline. The controller compares the actual wind pressure measured by the wind pressure sensor with the set constant value of wind pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com