Adjustable circular air blow cooling system

A cooling system and ring blowing technology, applied in textiles and papermaking, fiber treatment, artificial filament physical therapy, etc., can solve problems such as difficult cooling of thick filaments, wind speed calibration, difficult calibration, and inability to adjust the height of the ring blowing head. Achieve stable wind pressure and air volume, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

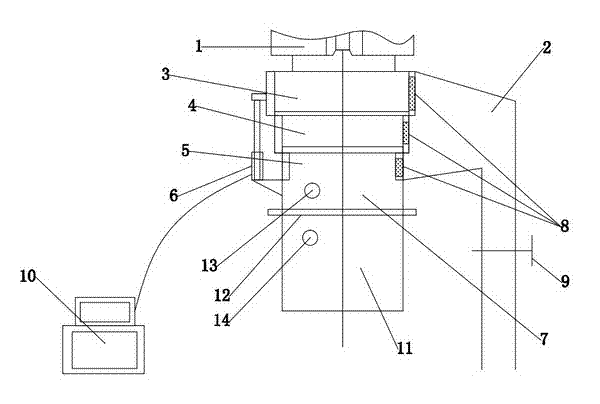

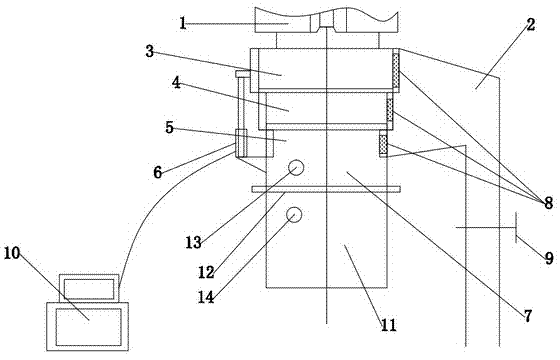

[0008] For an in-depth look at an adjustable ambient air cooling system, combining figure 1 described as follows:

[0009] Adjustable ring blowing cooling system, the spinning unit 1 is the ring blowing head, and then connected to the air silo 7, the side of the ring blowing head is the air inlet pipe 2, and the ring blowing head includes the upper ring blowing head 3, the middle ring blowing head 4, The lower ring blowing head 5, the lower ring blowing head 5 is fixed on the wind silo 7, the middle ring blowing head 4 slides on the lower ring blowing head 5, the upper ring blowing head 3 slides on the lower ring blowing head 5, and the upper ring blowing head 3. The middle ring blowing head 4, the lower ring blowing head 5 and the lower ring blowing head 5 are respectively installed with rectifying sleeves 8 on the side close to the air inlet pipe 2. The upper ring blowing head 3 is fixed on one end of the hydraulic rod 6, and the other end of the hydraulic rod 6 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com