Steady flow cooler

A cooler and steady flow technology, which is applied in the field of steady flow coolers, can solve the problems of not being able to dynamically push materials, not being able to achieve cooling air distribution, and not being able to achieve cooling effects, etc., to achieve high strength and rigidity, and improve cooling efficiency and cooling effect , Easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

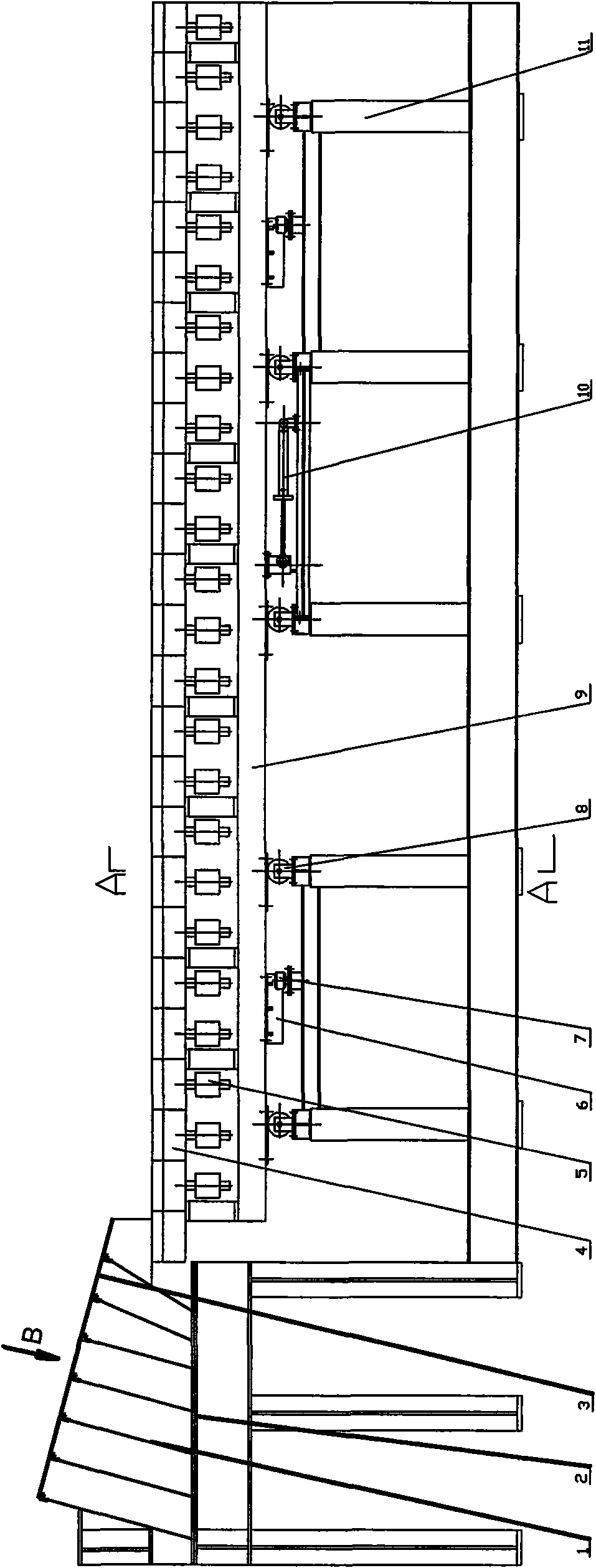

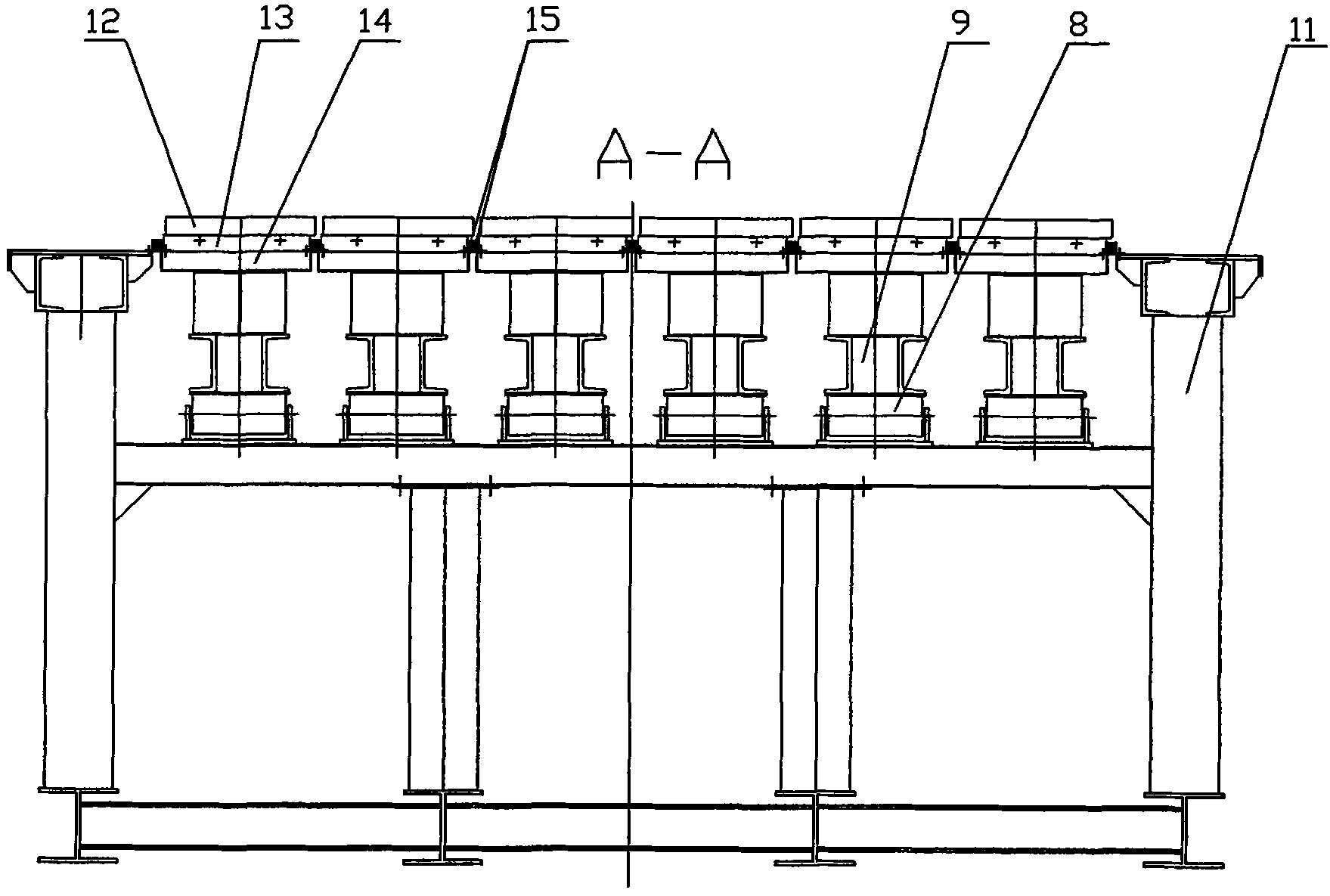

[0034] Below in conjunction with accompanying drawing, the utility model is described in detail:

[0035] 1. New hot end fixed grate bed:

[0036] 1. Innovatively designed box structure

[0037] Welded by steel plate as attached image 3 The hot end of the fixed grate bed air supply device 1 has a box-type structure, and the box is divided into several small squares by criss-cross partitions. A front grate plate 3 is installed on the upper part of each small square. The fixed grate bed 2 is inclined Installed downwards on the support, each front grate plate 1 forms an obliquely downward plane.

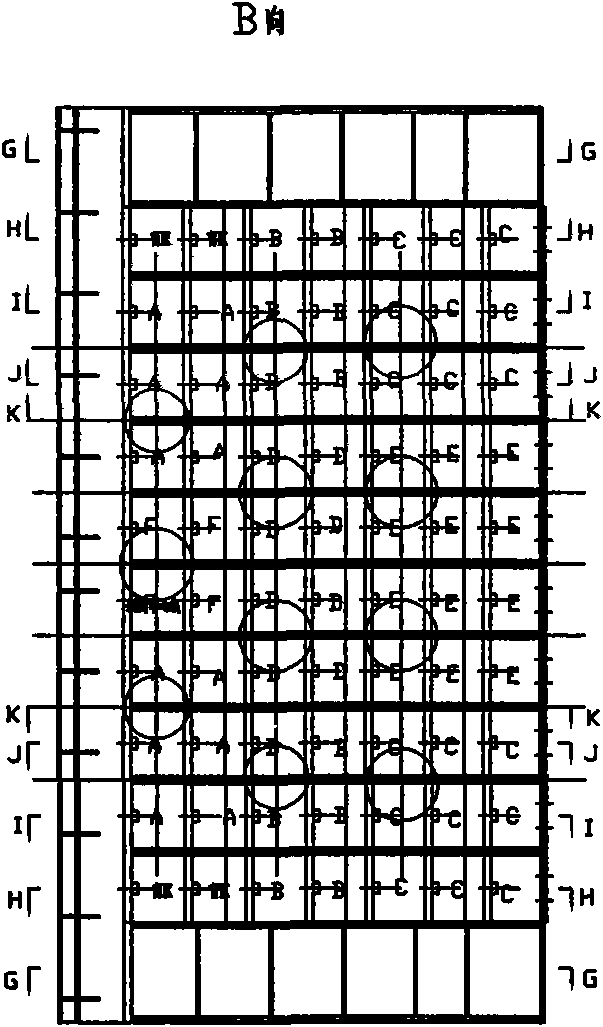

[0038] 2. Separate air supply for the fixed grate bed 2, and each partition divides the box into A, B, C, D, E, F areas and blind areas, and the air is supplied by different air ducts 16, which can be cooled according to the cooling of each area. Conditions, clinker layer thickness, etc. determine the air pressure and air volume of the air supply, realize more detailed control flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com