Intelligent aeration control device and method for sewage plant

A sewage treatment plant, aeration technology, applied in water aeration, electrical program control, chemical instruments and methods, etc., can solve the problems of inaccurate aeration, high labor intensity, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

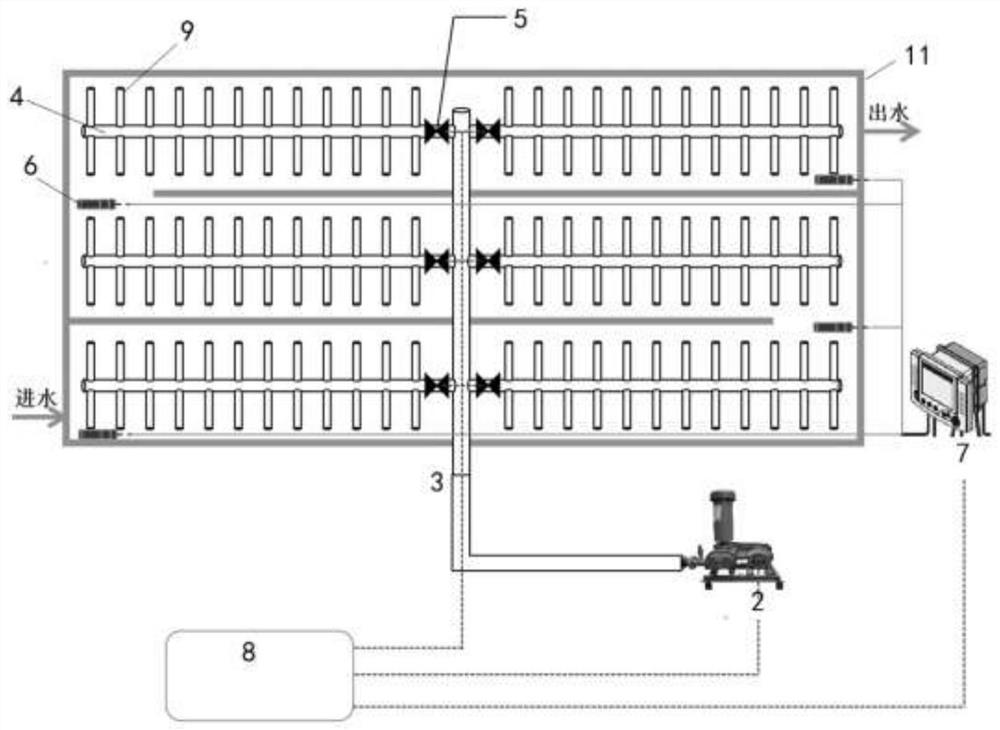

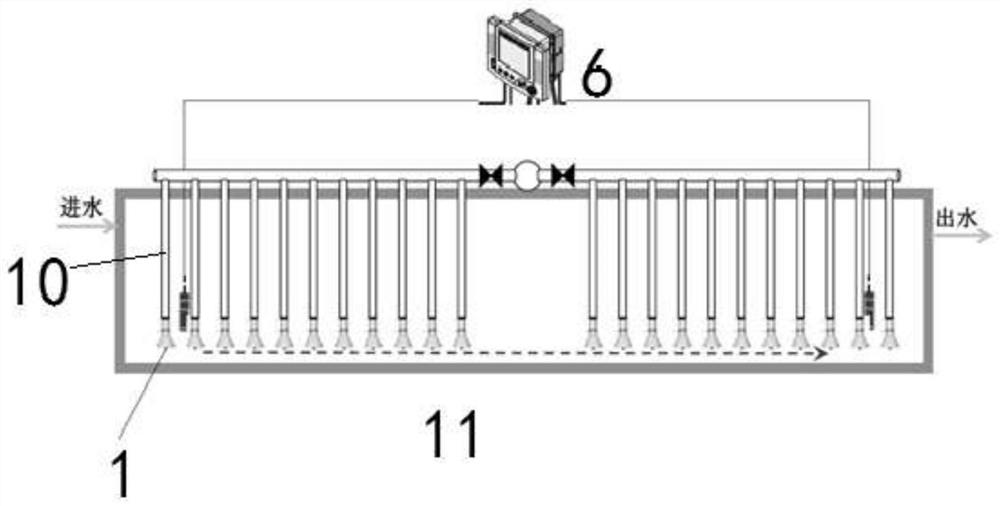

[0025] See the specific device figure 1 , a total of three grids and three paragraphs.

[0026] The design scale of a new construction project of a sewage treatment plant is 50,000m 3 / d. See Table 1 for the influent water quality and effluent requirements of the sewage treatment plant. Biochemical tank sludge is inoculated with activated sludge from the old plant (hydrolysis tank + SBR process).

[0027] Table 1 Influent Water Quality and Outlet Water Requirements of Sewage Treatment Plant

[0028]

[0029] Note: ① From December 1st to March 31st, the emission limits in brackets will be implemented

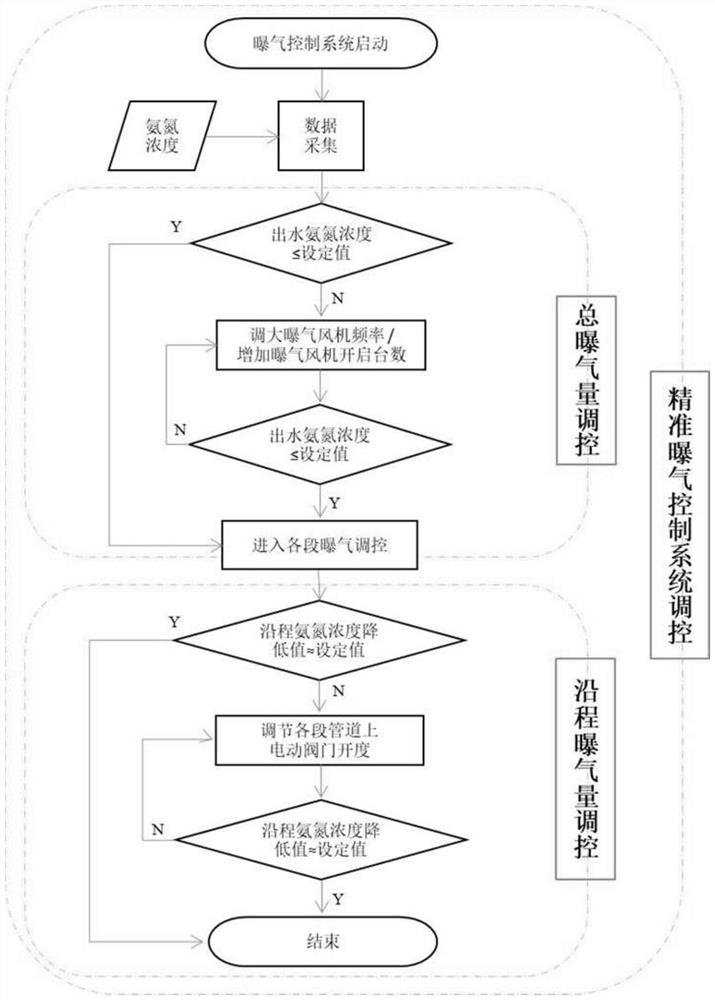

[0030] The sewage plant adopts "pretreatment + modification A 2 / O+MBR+Ozone Disinfection” process, the concentration of ammonia nitrogen along the aerobic tank is measured and the aeration rate is adjusted. The changes of ammonia nitrogen during the biological denitrification and nitrification stage are as follows Figure 4 As shown, the ammonia nitrogen concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com