Hydrophilic polyester fiber modified by cellulose nanocrystal and preparation method thereof

A polyester fiber and nanocrystal technology, which is applied in the preparation field of hydrophilic polyester fiber, can solve the problems of poor hydrophilicity of conventional polyester, and achieve the effects of improving hydrophilic effect, good hydrophilic performance and improving hydrophilic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The hydrophilic polyester chips modified by cellulose nanocrystals are carried out by in-situ polymerization, and the polymerization method is a batch polymerization process, and its formula is as follows:

[0036]

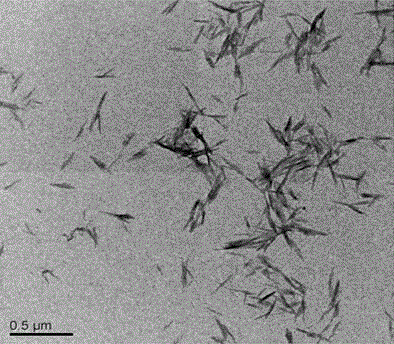

[0037] The cellulose nanocrystals are dispersed in water in the form of aqueous suspension, and the concentration in the suspension is 1 wt%. The length of nanocrystals is less than 500nm and the diameter is less than 50nm. The microscopic morphology of cellulose nanocrystals can be seen in figure 1 . According to the composition of raw materials in the polymerization reaction, a certain amount of terephthalic acid (PTA) and ethylene glycol with a molar ratio of 1:1.4 were weighed. The cellulose nanocrystal aqueous suspension is added to a weighed 80% ethylene glycol solvent, the moisture in the suspension is absorbed by molecular sieves, and then the ethylene glycol suspension containing the cellulose nanocrystal is prepared. The content of cellulose...

Embodiment 2

[0041] The hydrophilic polyester chips modified by cellulose nanocrystals are carried out by in-situ polymerization, and the polymerization method is a batch polymerization process, and its formula is as follows:

[0042]

[0043] The cellulose nanocrystals are dispersed in water in the form of aqueous suspension, and the concentration in the suspension is 1 wt%. The length of the nanocrystal is less than 500nm, the diameter is less than 50nm, and the form of the cellulose nanocrystal is the same as that of Example 1. According to the composition of raw materials in the polymerization reaction, a certain amount of terephthalic acid (PTA) and ethylene glycol with a molar ratio of 1:1.6 were weighed. The cellulose nanocrystal aqueous suspension is added into a weighed 80% ethylene glycol solvent, the moisture in the suspension is absorbed by molecular sieves, and then the ethylene glycol suspension containing the cellulose nanocrystal is prepared. The content of cellulose na...

Embodiment 3

[0047] The hydrophilic polyester chips modified by cellulose nanocrystals are carried out by in-situ polymerization, and the polymerization method is a batch polymerization process, and its formula is as follows:

[0048]

[0049] The cellulose nanocrystals are dispersed in water in the form of aqueous suspension, and the concentration in the suspension is 1 wt%. The length of the nanocrystal is less than 500nm, the diameter is less than 50nm, and the form of the cellulose nanocrystal is the same as that of Example 1. According to the composition of raw materials in the polymerization reaction, a certain amount of terephthalic acid (PTA) and ethylene glycol with a molar ratio of 1:1.8 were weighed. The cellulose nanocrystal aqueous suspension is added into a weighed 80% ethylene glycol solvent, the moisture in the suspension is absorbed by molecular sieves, and then the ethylene glycol suspension containing the cellulose nanocrystal is prepared. The content of cellulose na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com