Surface treatment method of tantalum spinneret

A surface treatment and spinneret technology, applied in the field of surface treatment of tantalum spinnerets, can solve problems such as affecting the spinnability of spinnerets and plugging holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] refer to figure 2 , to illustrate the surface treatment method for wet spinning of the present invention. The steps of embodiment 1 are as follows:

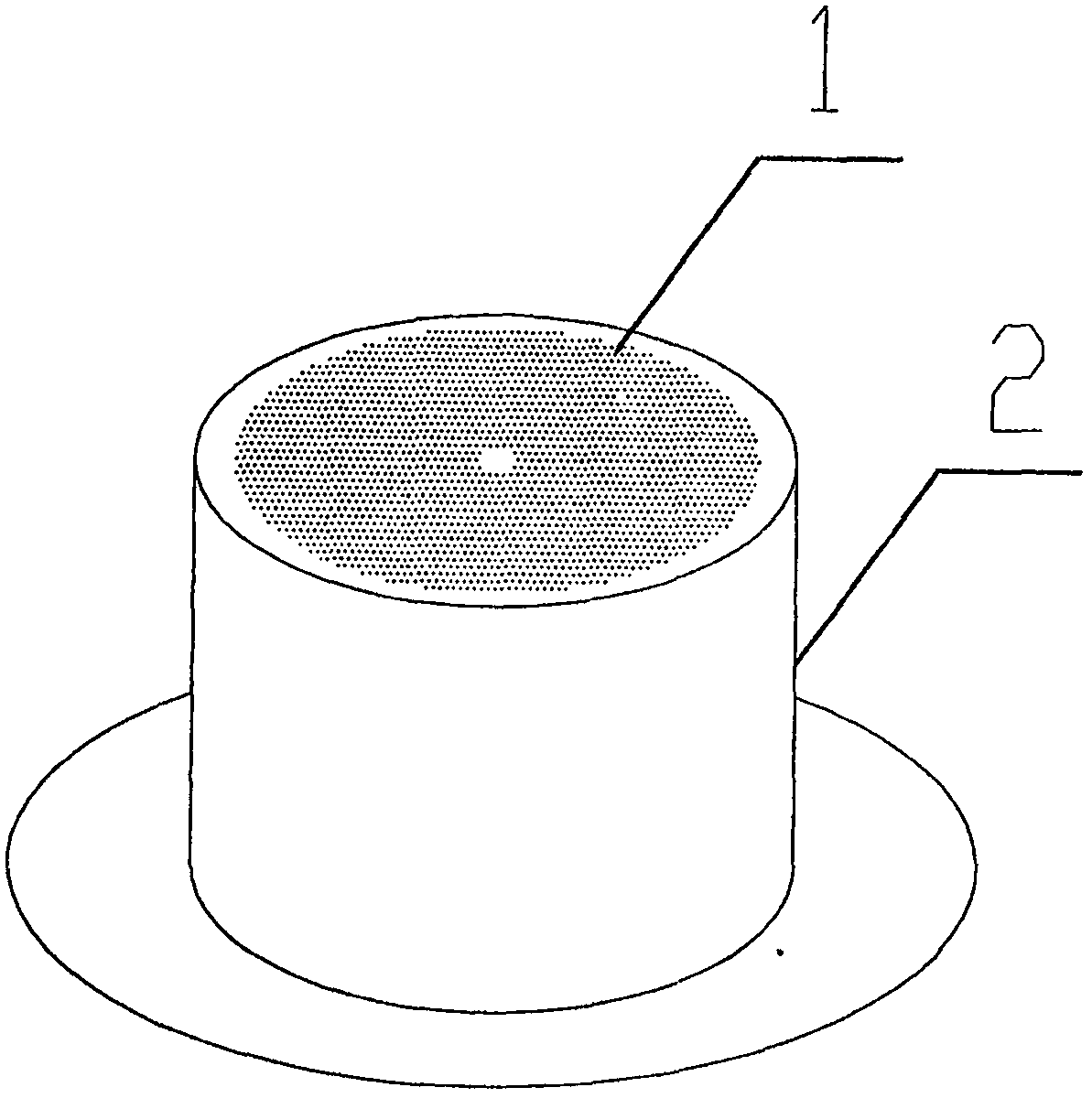

[0081] Step 1. Process and manufacture the metal tantalum plate into 45 tantalum spinnerets with the prior art. Each tantalum spinneret as figure 1 shown. The tantalum spinneret includes a body 2, the outer diameter of the spinneret outlet surface 1 is 16mm, the number of micropores 12 is 2600, and the inner diameter of the micropores is 0.052±0.001mm.

[0082] Step 2. At room temperature 25°C, use 0.01% H 3 po 4 , add 150 volts of anode voltage and constant voltage for 1 hour and then clean it to form a layer of amorphous Ta on the surface of the tantalum spinneret. 2 o 5 Membrane 3, as in Figure 4 .

[0083] Step 3, using step (c), polishing and removing the amorphous Ta on the silk surface 1 2 o 5 film3.

[0084] Step 4, coating: add 10 volts of anode voltage to the molten lithium nitrate solution at 488°...

Embodiment 2

[0092] refer to figure 2 , to illustrate the surface treatment method of the spinneret used for wet spinning according to the present invention. The steps of embodiment 2 are as follows:

[0093] Step 1, process and manufacture metal tantalum plate into 27 tantalum spinnerets with prior art, wherein each such as figure 1 shown. The tantalum spinneret includes a body 2, the outer diameter of the spinneret outlet surface 1 is 16mm, the number of micropores is 1400, and the inner diameter of the micropores is 0.083±0.001mm.

[0094] Step 2. At room temperature 25°C, use 0.01% H 3 po 4 , add 150 volts anode voltage constant voltage for 1 hour and then clean. A layer of amorphous Ta is formed on the surface of the tantalum spinneret 2 o 5 film3.

[0095] Step 3, using step (c), polishing to remove the Ta on the silk outlet surface 1 2 o 5 film3.

[0096] Step 4, coating: add 10 volts of anode voltage to the molten lithium nitrate solution at 488°C, and react at constan...

Embodiment 3

[0101] refer to figure 2 , the present invention is used for wet spinning surface treatment method, and the step of embodiment 3 is as follows:

[0102] Step 1, process and manufacture metal tantalum plate into 1 tantalum spinneret with prior art, such as figure 1 As shown, the tantalum spinneret includes a body 2, the outer diameter of the spinneret outlet surface 1 is 22mm, the number of micropores is 330 holes, and the inner diameter of the micropores is 0.082±0.001mm.

[0103] Step 2. Nitriding the tantalum spinneret prepared in step (a) according to the method of step (b) of the inventor's patent 02106915.8 to obtain a spinneret with a hardness of HV385.

[0104] Step 3, adopt ethylene glycol: 0.01% H 3 po 4=2:1 solution, the solution temperature is 90°C and the anode voltage is constant at 60 volts for 1.5 hours and then cleaned. A layer of amorphous Ta is formed on all surfaces of the spinneret 2 o 5 film3.

[0105] Step 4, using step (c) to polish and remove T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com