Fiber pretreatment device and method

A pretreatment device and fiber technology, applied in fiber processing, textile material processing, spray/jet textile material processing, etc., can solve the problems of uniform humidification of fibers, high labor intensity, artificial intermittent, etc. The effect of humidification can not be continuous production, reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Fiber pretreatment device:

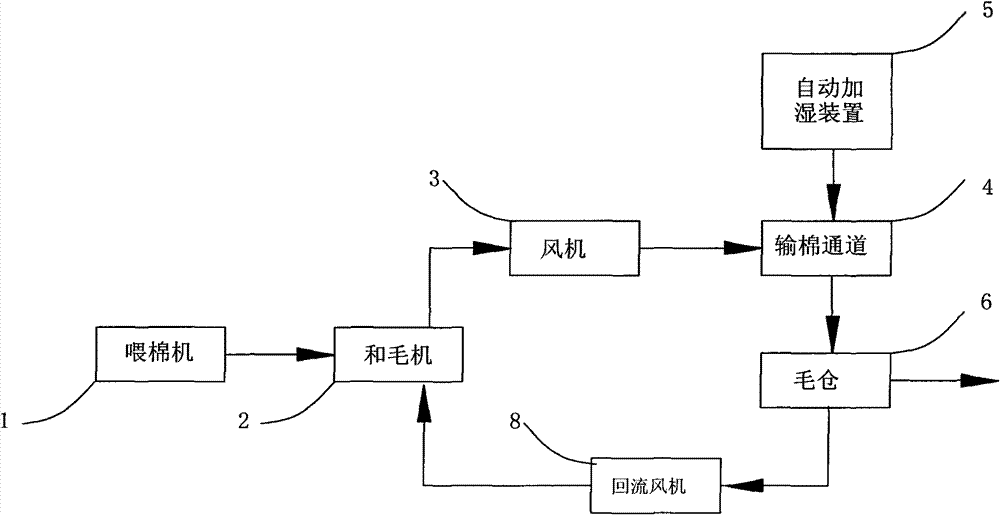

[0060] like figure 1 As shown, a fiber pretreatment device is composed of a cotton feeding machine 1, a knitting machine 2, a fan 3, a cotton transport channel 4, an automatic humidifying device 5 and a wool bin 6.

[0061] The cotton feeding machine 1 is connected with the cotton wool machine 2, and the wool machine 2 is connected with the fan 3. The fan 3 is connected to the top of the wool bin 6 through the cotton delivery pipeline 4, and the automatic humidifying device 5 is connected with the cotton delivery pipeline 4, and enters the top of the wool warehouse 6. .

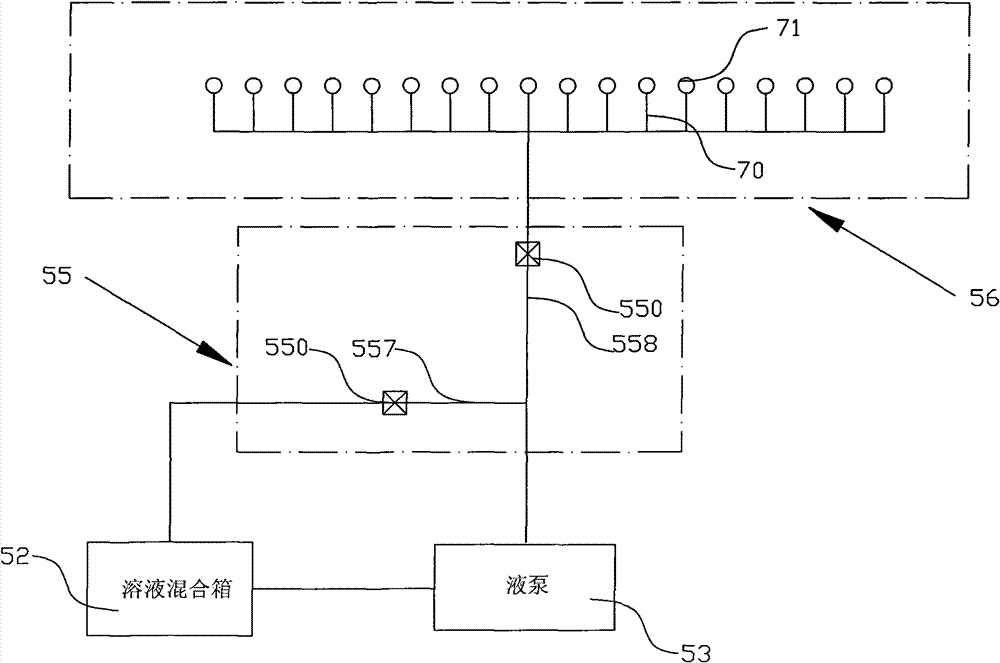

[0062] like figure 2 As shown, the automatic humidifying device 5 is composed of a filter 51, a solution mixing tank 52, a liquid pump 53, a control valve group 55 and a nozzle group 56. The filter 51, the solution mixing tank 52, the liquid pump 53 and the control valve group 55 pass through the pipeline Connection, the control valve group 55 is connected with the nozz...

Embodiment 2

[0096] Fiber pretreatment device:

[0097] like figure 1 As shown, a fiber pretreatment device is composed of a cotton feeding machine 1, a knitting machine 2, a fan 3, a cotton transport channel 4, an automatic humidifying device 5 and a wool bin 6.

[0098] Cotton feeding machine 1 is connected with woolen machine 2, and woolen machine 2 is connected with fan 3 again, and fan 3 is connected wool warehouse 6 tops through cotton conveying pipeline 4, and automatic humidifying device 5 and cotton conveying pipeline 4 enter wool warehouse 6 tops.

[0099] like figure 2 As shown, the automatic humidifying device 5 is composed of a filter 51, a solution mixing tank 52, a liquid pump 53, a control valve group 55 and a nozzle group 56. The filter 51, the solution mixing tank 52, the liquid pump 53 and the control valve group 55 pass through the pipeline Connection, the control valve group 55 is connected with the nozzle group 56 pipelines, and the control valve group 55 is connec...

Embodiment 3

[0112] Fiber pretreatment device:

[0113] like figure 1 As shown, a fiber pretreatment device is composed of a cotton feeding machine 1, a knitting machine 2, a fan 3, a cotton transport channel 4, an automatic humidifying device 5 and a wool bin 6.

[0114] Cotton feeding machine 1 is connected with woolen machine 2, and woolen machine 2 is connected with fan 3 again, and fan 3 is connected wool warehouse 6 tops through cotton conveying pipeline 4, and automatic humidifying device 5 and cotton conveying pipeline 4 enter wool warehouse 6 tops.

[0115] like figure 2 As shown, the automatic humidifying device 5 is composed of a filter 51, a solution mixing tank 52, a liquid pump 53, a control valve group 55 and a nozzle group 56. The filter 51, the solution mixing tank 52, the liquid pump 53 and the control valve group 55 pass through the pipeline Connection, the control valve group 55 is connected with the nozzle group 56 pipelines, and the control valve group 55 is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com