Pretreatment process of deodorization cotton

A technology for pretreatment and deodorization, applied in the textile field, can solve the problems of poor bulkiness, poor cohesion between fibers, and insufficient mixing of deodorant cotton, and achieve the effects of improving cohesion and moisture regain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

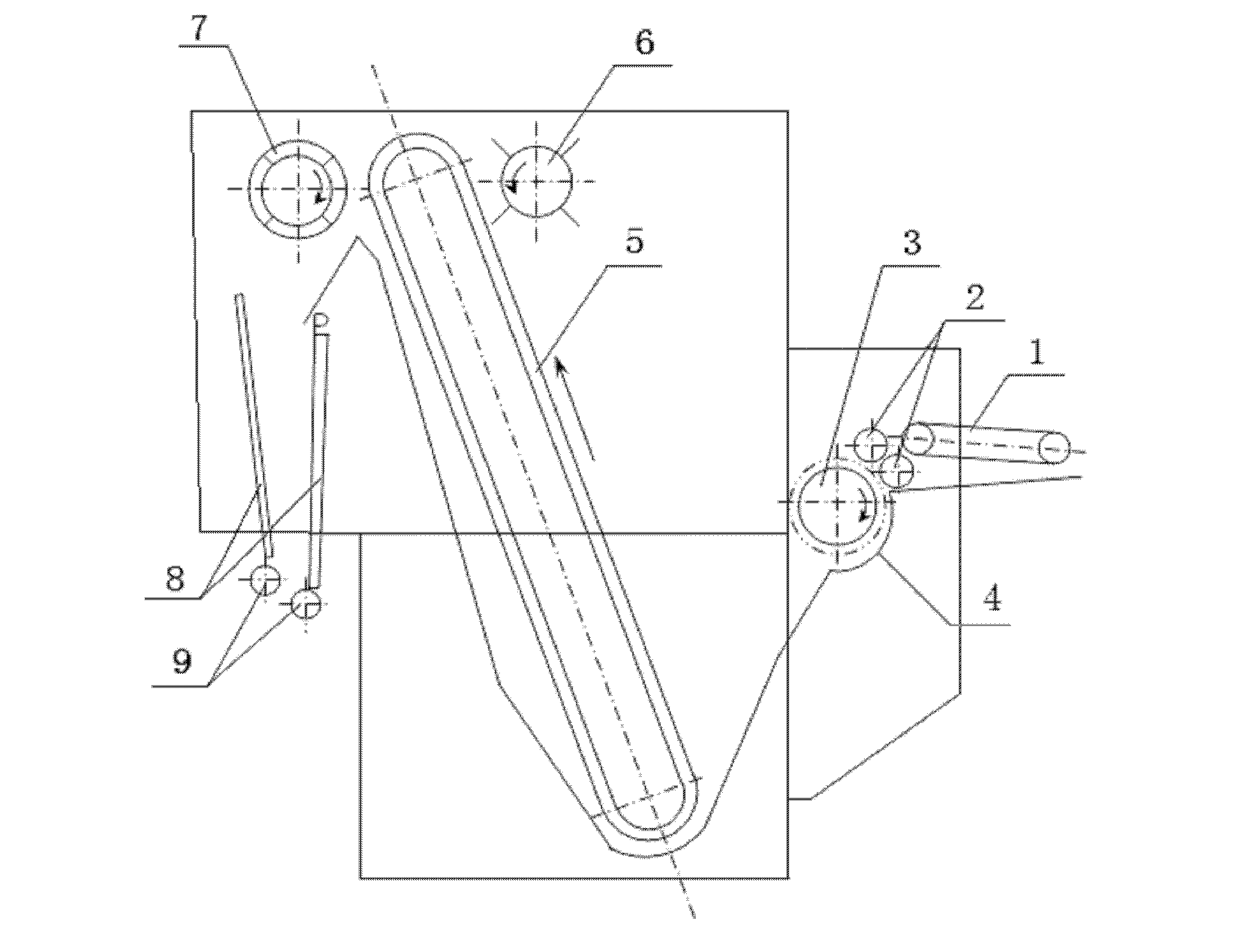

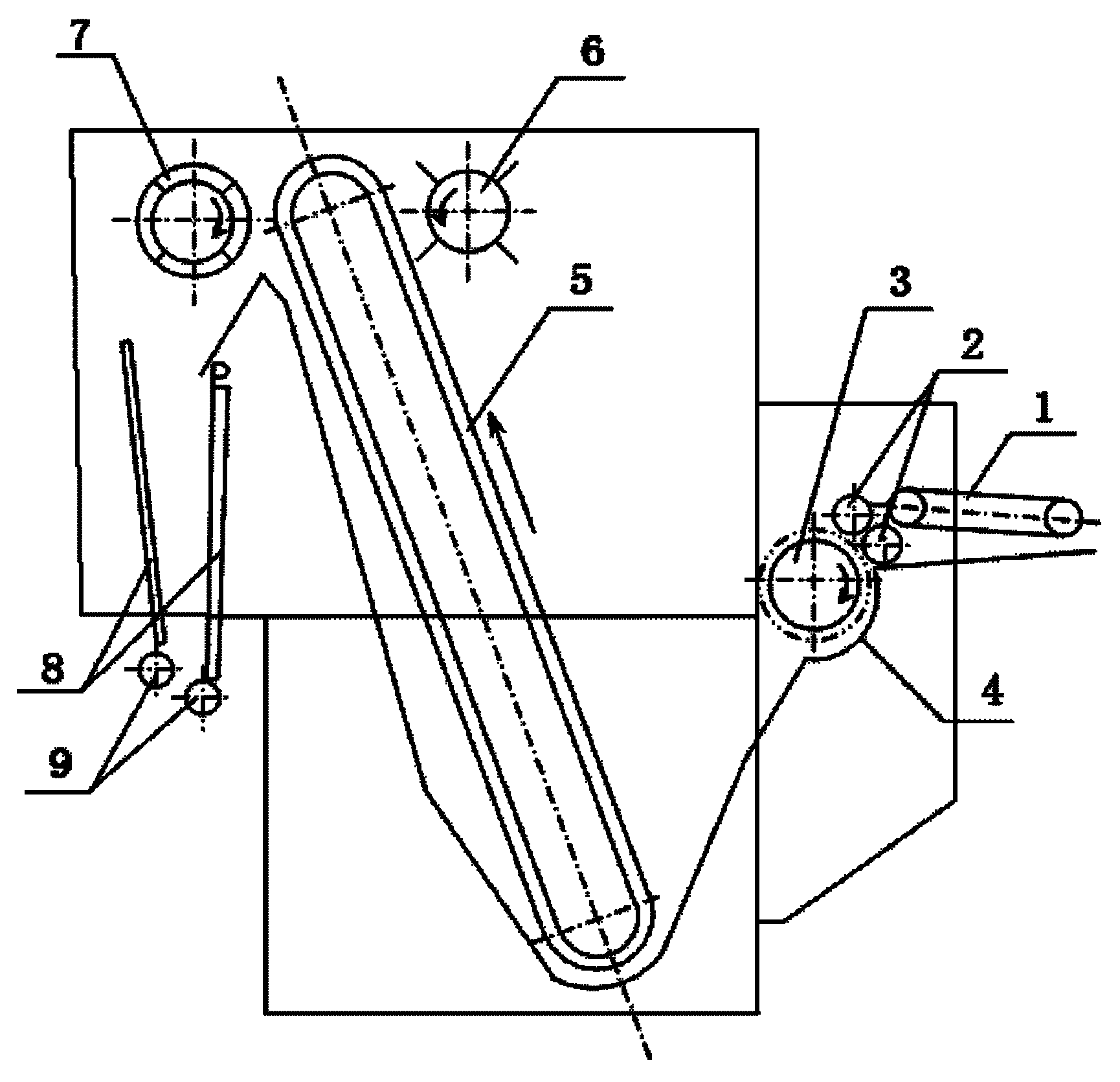

[0009] The present invention will be further described now in conjunction with accompanying drawing.

[0010] see figure 1 , the present invention is carried out sequentially according to the following process steps: 1. Send the deodorant cotton into the vibrating opener through the cotton feeding curtain 1, in order to make the deodorant cotton open properly, so as to avoid excessive opening of the deodorant cotton to produce short fibers If the neps and deodorant cotton are not loose enough to achieve the loosening effect, the feeding speed of the deodorant cotton must be controlled at about 500 g / m; 2. The deodorant quilt is held by a pair of feeding rollers 2, and The card beater 3 opens the deodorant cotton for the first time, and under the interaction between the card pin beater 3 and the carding plate 4, the fibers of the deodorant cotton become loose; 3. Deodorant after the first loosening Cotton is transported to the cotton equalizing roller 6 by the corner nail curt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com